Abstract

This work aims to design a sustainable two-echelon supply chain not only based on the widely used cost perspective, but also based on the efficient use and preservation of limited resources. For this purpose, a branch and efficiency (B&E) algorithm is developed, which includes an optimization model and an evaluation model. The proposed tri-objective optimization model simultaneously minimizes the total cost of the supply chain, maximizes the sustainability score, and minimizes inequity among customers. The solutions obtained from the optimization model are then evaluated by extended data envelopment analysis (EDEA) models based on common criteria (i.e., cost and service) and traffic congestion criterion. To take into account real-world conditions, parameters related to labor and demand are assumed under uncertainty. Since the presented models consist of more than one objective function, fuzzy goal programming (FGP) method is utilized to tread the multi-objectiveness. The obtained results from tackling a case study problem demonstrate that considering sustainability issues can positively affect both the economic and social aspects of the problem. Furthermore, the developed B&E algorithm is able to reduce costs in each iteration; this is what supply chain managers are interested in. On the other hand, this algorithm can provide more services to applicants compared to one of the competing algorithms.

Similar content being viewed by others

Introduction

Strategic supply chain planning determines the infrastructure and physical structure of a supply chain through network design. The reason for using supply chain network design is to integrate and coordinate the operations of corporations which have grown over time (Govindan et al. 2017). Since strategic decisions require investment and affect the long-term performance of a supply chain, the uncertainty of environments must be regarded in supply chain network design. The uncertainty of environments can result from the planners’ expectations and decision-makers’ lack of information about the probability distributions of the random parameters where, the effect of uncertainty on supply chain design is considered by fuzzy mathematical programming and robust optimization, respectively. Since turbulent and dynamic environments lead to inherent uncertainty in the supply chain structure, it is essential to design the supply chain network in such a way that the customer demand is met and the performance of the supply chain is assured (Hosseini et al. 2019). The multiple-sourcing strategy through improving the service level, and lateral transshipments through the horizontal interaction between supply chain members, leads to supply chain resilience, and accordingly, decreasing the costs and increasing the customer service level (Wei et al. 2018).

To satisfy the social and economic demand and prevent environmental degradation, the supply chain planning should be sustainable. It should be noted that the transportation system, logistics, and COVID-19 pandemic affect the sustainable pillars including the economy, society, and environment which is explained as follows:

-

I.

The vehicles transporting goods from origin to destination play a significant role in sustainability. Therefore, measuring the efficiency of vehicles concerning sustainability is important in supply chain planning (Kumar et al. 2019). In general, the vehicles that transport the goods in the supply chain have low acceleration, inferior braking, large tuning radius, and heavy weight which lead to an impact on the pavement lifetime and their maintenance, traffic capacity, and safety. The engines of such vehicles are a major source of pollution emissions that jeopardize the environmental aspect related to sustainability. It is worth noting that the sustainability of the transport system is one of the important factors in sustainable development, so that the Council of the European Union (2001) introduces the control of harmful emissions as a requirement for the sustainability of transport systems. Therefore, not paying attention to emissions in transportation systems in the supply chain, in addition to the negative impact on people’s perception, may accuse the supply chain of violating the law and condemn it to heavy fines. In this regard, neglecting the pillars of sustainability, including the environmental pillar, can lead to more pollution and threaten urban viability (del Mar Martínez-Bravo et al. 2019). In addition, due to the large load of these vehicles, they not only have a higher risk of accidents, but also are potentially involved in more severe accidents. From an economic point of view, it may be affordable to use the full capacity of the transportation system, but other aspects would be at stake. Therefore, it is necessary to pay attention to the types of vehicles because it affects traffic operations, transportation planning in the supply chain, and stability (Wang and Zeng 2018). However, very few studies in supply chain planning have addressed traffic congestion criteria (Jouzdani et al. 2013; Bai et al. 2011; Gao and Cao 2020).

-

II.

Considering the reverse logistics in supply chain planning, not only the natural resources and the environment are preserved, but also the firms’ competitive advantages increase. Thus, the firms both comply with environmental protection legislation and profit from the product recovery because of their competitive advantage (Zarbakhshnia et al. 2020). In addition, the environmental concerns of supply chain managers have made reverse logistics a key component in supply chain design (Özkır and Başlıgıl 2012).

-

III.

The COVID-19 pandemic has disrupted both human lives and the economy and impacted the labor which is the most essential factor in the functionality of supply chains. Due to COVID-19 restrictions, on the one hand, illness, death, social distance, fear of worker illness, and travel restrictions have caused a reduction in labor availability, and on the other hand, the demand for electronic commerce has grown. As a result, providing services of transportation and goods delivery is disrupted during the COVID-19 pandemic. For this purpose, it is necessary to address labor availability for product flow in supply chain planning (Nagurney 2021a, b).In this way, more attention is paid to society in sustainability.

The rest of the paper is organized as follows. The “Literature review” section reviews the most relevant studies concerning the application of DEA models. In the “Problem statement and mathematical modeling” section, the efficiency of vehicles is measured by an extended DEA model. Considering the efficiency scores, a tri-objective optimization model is developed for supply chain network design. The developed B&E algorithm is used to run this model. For this purpose, a leader–follower model and a bi-objective model are developed. In the “Uncertainty modeling” section, the parameters related to labor and demand are taken into account uncertain. To deal with this uncertainty and obtain a deterministic counterpart, fuzzy chance-constraint programming and robust optimization are employed. In the “Solution approach” section, the developed models are treated by goal programming (GP) and fuzzy goal programming (FGP). In the “Case study” section, a sensitivity analysis is performed on some of the important parameters which are introduced as contributions to the supply chain network design. Then, through a case study, the proposed models are validated. Finally, in the “Conclusion and outlook” section, the conclusions are provided.

Literature review

Data envelopment analysis (DEA) is a widely used technique for performance evaluation in supply chain management and supply chain planning.Furthermore, the DEA technique has many applications in the field of sustainability (Hermoso-Orzaez et al. 2020; Jiang et al. 2021; Ebrahimi et al. 2021; Omrani et al. 2018; Kalantary et al. 2018; Aydin & Tirkolaee 2022). By mathematical programming, DEA measures the relative efficiency of peer decision-making units (DMUs) for producing the maximum output or using the minimum input where each DMU has some inputs and outputs. In this way, comparing each DMU with other DMUs, both the progress of DMUs is controlled and the potentials of DMUs are introduced into business processes (Lima-junior and Carpinetti 2017; Soheilirad et al. 2017). It should be noted that the conventional DEA model faces two challenges. The first one is the structure of DMUs where the conventional DEA model considers the system to be a black-box to measure the overall efficiency of DMUs, while the efficiency of each DMU may be affected by a structure consisting of different scenarios and each scenario may have some priorities compared to other ones. For this purpose, Du et al. (2015) developed the leader–follower DEA model to deal with the priorities as a hierarchical structure through a non-cooperative game. The second challenge is related to solving the conventional DEA model. It should be noted that solving these models is iterative, and the efficiency of each DMU should be calculated compared to other DMUs in each iteration. In this regard, a simultaneous DEA model was proposed by Klimberg and Ratick (2008) which can calculate the efficiency of all DMUs in one iteration.

The research efforts focused on the DEA for supply chain network design are reviewed as follows. In some of these researches, using the exogenous data, the DEA model is run first and then, the supply chain network is designed according to the results of the DEA model. Amirteimoori (2011) proposed two DEA models for efficient transportation planning, which calculates the efficiency of links between warehouses and destinations. The final efficiency of each link was derived from the average efficiency of the two proposed models, where the first model assumes destinations as DMUs and the second model assumes warehouses as DMUs. Finally, by optimization model, the number of units shipped between warehouses and destinations was determined to minimize the sum of inefficiency links. Babazadeh et al. (2015) offered a two-phase model for the strategic design of a biodiesel supply chain network. In the first phase, the DEA model evaluated the cultivation areas based on social and climatic criteria, and then, in the second phase, the areas with the desirable efficiency score were regarded as candidate locations. The proposed mathematical model minimized the costs related to the locations. Omrani et al. (2017) suggested a multi-objective optimization model, to design an efficient supply chain network, that minimizes the costs and maximizes the efficiency of warehouses and plants. The supply chain structure included suppliers, factories, warehouses, and customers. The scenario-based robust optimization was used to address uncertain conditions. Lozano and Adenso-Diaz (2017) developed a bi-objective three-stage supply chain model that minimizes the cost and product losses. The product flow optimization model presented was solved by minimization of the maximum weighted deviation of different objective function values with respect to the corresponding optimal value. Kumar et al. (2019) proposed a two-phase optimization model for sustainable transportation planning. In the first phase, since there were different types of vehicles, the efficiency of each vehicle type is measured based on sustainability pillars. The results of the first phase were considered an objective function in the second phase and, along with other objective functions related to the costs and customers’ relationships, developed a tri-objective optimization model for transportation planning.

Some other research studies have focused on endogenous data. In these research studies, the DEA model is run using the results of the supply chain network optimization model. In this regard, Grigoroudis et al. (2014) offered a recursive DEA (RDEA) algorithm to design the supply chain network such that, in the first iteration, the supply chain network optimization model is solved, and then, the efficient solutions are evaluated using DEA model. In the second iteration, using the results of the previous iteration, the supply chain network optimization model was solved, and the efficient solutions of this iteration were determined by the DEA model. Petridis et al. (2016) suggested a branch and efficiency (B&E) algorithm for designing a two-stage supply chain. Their algorithm was a development of the algorithm proposed by Grigoroudis et al. (2014). In this algorithm, the inputs and outputs were provided based on the initial solutions. Then, the candidate warehouses were evaluated using the DEA model. In this way, the efficient solutions were included in the optimization model by efficiency cuts constraints. Pariazar and Sir (2018) developed a multi-objective stochastic programming model for supply chain design where supply availability and quality were affected by disruptions. Genetic algorithm (GA)-based search technique was used to tackle the complexity of the problem. After obtaining the supply chain configurations from the suggested GA, they were evaluated by the DEA model to calculate their fitness value. The inputs and outputs of the DEA model were also derived from the objective functions of the proposed model. As the main disadvantage of their approach, GA was not able to take into account other components of the optimization model as inputs and outputs, because it could only evaluate the final supply chain configurations. Therefore, the efficiency scores did not directly affect the constraints of the optimization model, and its impact was limited to fitness value. Moheb-alizadeh et al. (2021) suggested a nonlinear optimization model under stochastic conditions to design a closed-loop supply chain network. The objective functions of this model were related to profit, emission rate, social responsibility, and efficiency. The DEA model was also used to measure the efficiency score. Guo et al. (2022) integrated the supply chain design with the DEA model so that the performance of the solutions of the supply chain design optimization model was evaluated in order to select the optimal solutions that are efficient. They took into consideration environmental, social, and economic criteria to obtain the efficiency of the solutions. Finally, due to the multi-layer nature of supply chains, some studies have utilized the DEA model to measure the supply chain efficiency. For example, Tavana et al. (2013) developed a network DEA model to evaluate a three-stage supply chain, focusing on a semiconductor industry case study. Izadikhah and Farzipoor (2018) evaluated the supply chain performance, which includes two echelons called supplier and producer, from an economic, social, and environmental point of view. The structure of the evaluation model was based on a network DEA model with stochastic data. The application of this model was validated by evaluating 27 pasta supply chains.

Considering the requirement of location-allocation decisions to high investment, it is necessary to generate an efficient scheme design for the logistics network. Therefore, Hong and Mwakalonge (2020) proposed a multi-objective programming model to design a biofuel logistics network and then evaluated various schemes through the DEA model based on changing the importance weights of each objective function. Fathi and Saen (2018) offered a DEA network model to assess the performance of two-stage supply chains where the connections among supply chain echelons are bidirectional. Kalantary and Saen (2018) developed a network DEA model to assess the sustainability of multi-period supply chains. The application of this model was analyzed through a real case study in dairy industries. Álvarez-rodríguez et al. (2019) developed a network DEA model to evaluate a two-stage supply chain with three time periods. Tavana et al. (2016) broke down a two-stage supply chain into two sub-chains entitled supplier-manufacturer and manufacturer-distributor and then measured the efficiency of the sub-chains and the whole supply chain by a network DEA model.

Table 1 reviews and compares the research studies which employed DEA models in supply chain network design under a variety of criteria.

The research gaps are investigated based on a detailed comparison between the research works presented in Table 1. In this regard, the contributions of this study and why they are used in the real world in order to cover the existing research gaps are listed as follows:

-

i.

An optimization model with three objective functions is proposed to simultaneously take into account the objective functions of minimizing the costs, maximizing the profits through the product recovery process, maximizing the efficiency of vehicle types, and minimizing the inequity in unmet demand.

-

ii.

In the proposed supply chain network, the direct shipment between plants and customers and the lateral transshipment among warehouses are addressed simultaneously in order to improve the service level. In the real world, applying lateral transshipment and direct shipment strategies can impact supply chain efficiency by reducing supply chain-related costs and increasing service levels (Rabbani et al. 2020).

-

iii.

Reverse logistics is considered through the product recovery by plants, where, both the disposal fraction and performance factors are effective in the recovery of products. In this way, the supply chain becomes environmentally friendly by considering the reverse flow. It should be noted that public awareness and government legislation are pushing real-world supply chains to deal with reverse logistics (Govindan et al. 2015).

-

iv.

It should be noted that only a few researchers have focused on supply chain network design through endogenous data, and, on the other hand, the conventional DEA models are commonly used for efficient design. Therefore, in addition to focusing on supply chain network design through endogenous data, two variants of DEA models are developed. The application of DEA in supply chains is very widely used in the real world because the efficiency of supply chains can be improved by planning based on the results obtained from this type of data-driven method (Krmac and Djordjević 2019).

-

v.

Despite the significant role of traffic congestion on sustainability and transportation systems, this criterion has not been addressed in the literature. Here, the effect of traffic congestion on supply chain design is regarded. In fact, supply chain planners are strongly recommended to consider traffic congestion because traffic congestion affects not only the environmental aspect but also the economic aspect of the supply chain. In addition, traffic congestion regulates the load of the transportation system in supply chains (Jouzdani and Govindan 2021).

-

vi.

There are different types of vehicles that transport goods among echelons. For this reason, such vehicles differ in both their characteristics and their efficiency scores. The efficiency score of vehicle types is measured by an extended DEA model. Our extended model evaluates vehicle types in terms of sustainability. In this way, through the application of our model for supply chain design, the concern of supply chain managers regarding pollution, which entails both legal fines and ruining people’s perception, is addressed through the environmental pillar. Moreover, it is worth noting that sustainability in the real world affects many business activities and the performance of components related to supply chains (Govindan et al. 2020).

-

vii.

The impact of the COVID-19 pandemic on supply chain network design is taken into account by planning the labor. In the conditions of a pandemic, which is one of the epidemic events in the real world, productivity and access to labor as one of the essential resources in the supply chain are jeopardized. Hence, considering labor issues makes supply chains more realistic in terms of application (Nagurney 2021c).

-

viii.

Uncertain conditions are tackled in both the modeling and solution approach.

It is worth noting that our research compared to very recent high-quality research in the field of efficient design of supply chain, such as Guo et al. (2022); Moheb-alizadeh et al. (2021), has capabilities such as considering traffic congestion, direct and lateral transportation, human resources and uncertainty conditions for it, solution method under uncertainty, types of vehicles, and the development of new performance evaluation models to assessment optimal solutions. A graphical representation of the proposed methodology of the study is depicted in Fig. 1.

Problem statement and mathematical modeling

This work aims to propose an algorithm based on DEA to design two-stage supply chain networks with respect to sustainability, resilience, reverse logistics, and the COVID-19 pandemic in such a way that the costs are minimized and at the same time the efficiency scores are maximized. In the following, the main criteria of the study are explained. To deploy the vehicles at different stages in the supply chain, the efficiency score of the vehicle types is measured based on the pillars of sustainability. The resilience is enhanced in the supply chain by taking into account lateral transshipment between the echelon members, and direct shipment between suppliers and customers. The reverse logistics investigates the shipment of returned products from customers to suppliers and then inserts the recovered products in the forward supply chain network. The COVID-19 pandemic in the supply chain is observed based on the relationship between labor and product flow, where there is a concern about labor shortages. Therefore, a B&E algorithm is developed for designing a two-stage supply chain network which includes three echelons entitled plants, warehouses, and customers, by considering the sustainability, resilience, reverse logistics, and COVID-19 pandemic. The proposed algorithm integrates the multi-objective optimization model with the extended DEA model to reduce the total cost and also filter the higher efficient solutions, iteratively. The graphical representation of the suggested two-echelon supply chain network is depicted in Fig. 2.

Considering the fact that transportation affects not only the economy and society but also the environment, sustainable development is influenced by efficient transportation. Increasing the efficiency of the vehicles reduces environmentally destructive effects and increases the balance in economic and social pillars of sustainability. Therefore, transportation planning in the supply chain necessitates the efficiency evaluation of vehicle types through criteria related to economy, society, and environment. Accordingly, a DEA model is extended to evaluate the performance of vehicle types. The notation of the parameters and decision variables related to the model are given in Table 2.

The extended DEA model (EDEAM) maximizes the minimum efficiency and minimizes the maximum efficiency so that the distance between the minimum efficiency and the maximum efficiency is minimized. If the value of this distance is zero, the efficiency of the vehicle would be stable. The stable solution is due to the presence of a saddle point where, at this point, the minimax criterion and maximin criterion coincide (Hillier and Lieberman 2001). The mathematical formulation of this model is given as follows:

subject to

Objective function (1) consists of three terms. The minimum efficiency related to economic, social, and environmental dimensions is maximized in the first term. The minimum efficiency of each vehicle is maximized and the maximum efficiency of each vehicle is minimized, in the second term. If the max–min efficiency is equal to the min–max efficiency, the efficiency is stable. In the third term, the deviation between the minimum and maximum efficiency is minimized. Constraints (2)-(4) determine the minimum efficiency related to economic, environmental, and social dimensions, Constraints (5)–(7) specify the minimum efficiency related to economic, environmental, and social dimensions for each vehicle, Constraints (8)–(10) characterize the maximum efficiency related to economic, environmental, and social dimensions for each vehicle; the deviation between the minimum and maximum efficiency for each vehicle is measured in Constraint (11). Since the absolute term leads to the nonlinearity of this constraint, it is linearized as \(-{\widetilde{e}}_{\lambda }\le {e}_{\lambda }^{max}-{e}_{\lambda }^{min}\le {\widetilde{e}}_{\lambda }\). In Constraints (12)–(14), inputs related to economic, environmental, and social dimensions are arbitrarily set to one. Constraints (15)–(17) measure the inefficiency level related to economic, environmental, and social dimensions. In Constraints (18)–(20), the upper bound of the efficiency of each DMU is set to one. Constraints (21)–(23) measure the efficiency level related to economic, environmental, and social dimensions, and Constraints (24) and (25) indicate the positive decision variables and non-negative decision variables, respectively.

The proposed EDEAM is a general model and as a result, it can measure the efficiency of vehicle types based on various inputs and outputs. Kumar et al. (2019) introduced some inputs and outputs by which the efficiency of vehicle types can be evaluated in terms of sustainability. These inputs and outputs are represented in Fig. 3. In this figure, the network structure of EDEAM is presented which consists of three divisions, representing three pillars of sustainability. On the other hand, each division has independent inputs and outputs, compared to other divisions. The efficiency score of the vehicle types in terms of sustainability is derived from the efficiency scores of all divisions. In other words, by integrating three divisions, the efficiency score of the vehicles is measured.

After calculating the efficiency of the vehicle types with respect to sustainability, a multi-objective optimization model for supply chain network design is introduced. The results of the efficiency measurement are regarded as inputs of the optimization model. The proposed optimization model has three objective functions whose mathematical formulation is given by Formulas (26)–(63). This tri-objective optimization model aims to minimize the total cost, maximize the total profit, and minimize the inequity. In the following, the reasons for applying these objectives are explained. Cost minimization is one of the most widely used objectives of mathematical models. The production, establishment, labor, shipment, transportation, and shortages are among the cost-related factors in the model that should be minimized. To increase the service level and protect the supply chain structure against disruptions, the supply chain should be designed with respect to resilience. In the proposed supply chain structure, direct shipment from the first echelon to the third echelon is considered to increase the number of sources that serve the customer. Besides, the lateral transshipment among the members of the second echelon is taken into account to improve the service level and prevent disruptions to inventory. Therefore, considering direct shipment and lateral transshipment has led to a resilient supply chain design. The COVID-19 pandemic, on the other hand, disrupts the most essential supply chain functions which depend on labor. The issues such as illness, death, risk mitigation through travel restrictions, and social distancing lead to the labor shortages. For this reason, in the proposed supply chain structure, the labor availability is planned for each stage. The efficiency of vehicles as a criterion for selecting a transportation system plays an important role in obtaining a sustainable transportation system. Therefore, in the optimization model, the profit obtained from the use of sustainable vehicles is maximized. In addition, the profit obtained from producing the products through the recovery process is maximized. The companies have to collect and recover the used products due to the environmental legislation. Thus, the companies not only produce environmentally friendly products and save the consumption of resources, but also gain a competitive advantage. In this regard, the benefits resulting from reverse logistics in the proposed supply chain structure are regarded as well. Finally, the concept of inequity in satisfying the customer demand is considered which can minimize the gap between the customer’s unmet demands.

In this model, Objective Function (26) minimizes production costs, variable and fixed transportation costs related to stage 1 and stage 2, establishment cost, direct shipment cost, lateral transshipment cost, maximum shortage cost related to demand satisfaction, available labor cost in stage 1, available labor cost in stage 2, labor cost available between echelon 1 and 3, and maximum shortage cost related to available labor. Objective function (27) maximizes the profit from using sustainable vehicles in the supply chain and the profit from production through the recovery process. It is worth mentioning that through this objective function, not only the economic aspect of the transportation system in the supply chain is addressed, but also the aspects related to the environment and society, which are very effective in dealing with pollution and improving livability. In addition, this objective function takes into account the reverse flow, which makes the supply chain environmentally friendly due to the conservation of natural resources. Objective function (28) minimizes inequity in satisfying customer demand. Constraint (29) expresses the balance between the produced quantity, through the raw material and the recovery process, and the quantity that the customer receives through shipment and direct shipment. Constraints (30)–(31) indicate the upper and lower bound related to production. Constraint (32) presents the balance between the quantities of products received through shipment and lateral transshipment to each warehouse and the quantities of products sent to customers through shipment and lateral transshipment from each warehous. Constraint (33) states the balance among all products that leave the warehouses under lateral transshipment and all products which enter the warehouses under lateral transshipment. In Constraint (34), the quantities sent from warehouse \({j}^{^{\prime}}\) to warehouse \(j\) through lateral transshipment are equal to those received by warehouse j from warehouse \({j}^{^{\prime}}\) through lateral transshipment. Constraints (35)–(36) specify the maximum capacity related to lateral transshipment and direct shipment. In Constraints (37)–(38), if and only if there exists a connection between two echelons, the products will be transported at each stage, according to the capacity of that connection. Constraints (39)–(40) guarantee the establishment of a warehouse that is connected to stage 1, stage 2, and other warehouses. In Constraint (41), the minimum warehouse capacity for products transported from echelon 1 to echelon 2 is a coefficient of the quantity of products received by the warehouse plus the initial inventory of the warehouse. This coefficient is determined based on packaging, warehousing, and quality control activities. If the warehouse is established, Constraint (42) shows the maximum warehouse capacity for products transported from echelon 1 to echelon 2. Constraint (43) specifies the maximum percentage of unmet demand of customer \(k\). Constraint (44) characterizes the maximum percentage of unmet demand. Constraints (45)–(46) measure the inequity related to the customer demand satisfaction. Constraint (47) indicates the upper bound which is related to the lack of customer service. In Constraint (48), the number of recovered products belonging to each plant is determined based on the disposal fraction and performance of each plant, as well as the rate of return of all products sent to the customers. In Constraints (49)–(51), the total load transported by each vehicle type, in stages 1 and 2 and between the echelons 1 and 3, should not exceed the capacity of the vehicles’ types. In Constraints (52)–(54), according to the linear production function in economics, the product flow is related to available labor in stages 1 and 2 and echelons 1 and 3. Constraints (55)–(57) indicate the upper bound on the available labor, in each link \((i, j)\), \((j, k)\), and \((i, k)\). Constraints (58)–(60) determine the deviation between the upper bound of the availability of labor on each link and available labor on each link. Finally, Constraints (61), (62), and (63) represent the non-negative continuous decision variables, binary decision variables, and unrestricted in sign decision variables, respectively.

The following assumptions are incorporated into the proposed model:

-

i.

In the supply chain network, only a single product is produced, maintained, and transported.

-

ii.

Shortage is allowed. It is not necessary to satisfy all the customers’ demands.

-

iii.

Warehouse capacity is limited.

-

iv.

Customer is supplied by multiple sources.

-

v.

Used products are collected and recovered in plants and sent to distributors. There is no difference between the used and new products in the mathematical model.

-

vi.

Only a percentage of the used products can be recovered.

-

vii.

Labor belonging to the echelons of each stage can handle all types of vehicles.

-

viii.

For shipments among the echelons in addition to the number of transported units, attention is paid to vehicle types and labor where the transportation flow is forward.

The proposed B&E algorithm is developed for the acceptance of efficient and feasible solutions. The multi-objective optimization model presented in Formulas (26)–(63) is considered as the master problem (MP) in the B&E algorithm. When MP is solved, based on the resulting inputs and outputs, the efficiency score of each warehouse is calculated by the DEA model. The inputs and outputs are displayed in Fig. 4.

All the criteria, other than the traffic congestion criterion, are derived directly from solving the MP. In this work, the traffic congestion is examined by two scenarios. The scenarios are defined according to Davidson’s function and the BPR function. The traffic congestion functions are formulated in accordance with Khisty and Lall (2002) and are given in Eqs. (64)–(65):

On the other hand, a bi-objective model and a leader–follower model are developed in order to evaluate the DMUs. In the bi-objective model, the minimum efficiency level of each DMU is maximized with respect to all scenarios, and the efficiency level of each DMU is maximized in each scenario. The bi-objective model is formulated as follows:

Objective function (66) maximizes the minimum efficiency level of DMUs, Objective Function (67) maximizes the efficiency level of DMUs in each scenario, Constraint (68) expresses a minimum efficiency score per DMU, Constraint (69) indicates the inefficiency level in each DMU, in Constraint (70), the weighted sum of inputs is arbitrarily set equal to one, Constraint (71) presents the efficiency level of each DMU based on the weighted sum of outputs, in Constraint (72), the upper bound of the efficiency score of each DMU is set equal to one, Constraint (73) forestalls weights from being zero, and Constraint (74) displays non-negative continuous decision variables.

Each of the functions related to traffic congestion is taken into account as a scenario where, in the bi-objective model, no priority is given to the scenarios. Here, the abovementioned leader–follower model is developed to deal with the priorities of the scenarios in evaluating the DMUs. In this regard, each scenario is considered a player so that each player’s decision affects the subsequent players’ feasible choices set. Thus, the leader model shown by Formulas (75)–(81) measures the efficient scores of DMUs by considering the leader scenario.

Objective function (75) maximizes the efficiency level of DMUs in the leader scenario. Constraint (76) determines the efficiency level of each DMU in the leader scenario. In Constraint (77), the weighted sum of the inputs related to the leader is arbitrarily set equal to one. Constraint (78) presents the efficiency level of each DMU in the leader scenario based on the weighted sum of outputs. In Constraint (79), the upper bound of the performance score of each DMU is set equal to one in the leader scenario, Constraint (80) forestalls weights from being zero, and Constraint (81) displays non-negative continuous decision variables.

In addition, the follower model shown by Formulas (82)–(89) measures the efficiency of DMUs by considering the follower scenario such that the leader’s efficiency level is preserved.

Objective function (82) maximizes the efficiency level of DMUs in the follower scenario, Constraint (83) fixes the optimal solution related to the leader scenario, Constraint (84) specifies the efficiency level of each DMU in the follower scenario, in Constraint (85), the weighted sum of the inputs related to the follower is arbitrarily set equal to one, Constraint (86) presents the efficiency level of each DMU in the follower scenario based on the weighted sum of outputs, in Constraint (87), the upper bound of the efficiency score of each DMU is set equal to one in the follower scenario, Constraint (88) forestalls weights from being zero, and Constraint (89) displays non-negative continuous decision variables.

Finally, the overall efficiency of DMUs is measured by the leader–follower model shown by Formulas (90)–(98), where the efficiency level of the leader and the efficiency level of the follower are preserved.

Objective Function (90) maximizes the efficiency level of DMUs by considering the leader–follower approach, Objective Function (91) minimizes the deviation between the objective function related to the leader and the leader scenario’s optimal solution, Objective Function (92) minimizes the deviation between the objective function related to the follower and the follower scenario’s optimal solution, Constraint (93) determines the efficiency level of each DMU in the leader–follower approach, in Constraint (94), the weighted sum of the inputs related to the leader–follower approach is arbitrarily set equal to one, Constraint (95) indicates the efficiency level of each DMU is related to the leader–follower approach based on the weighted sum of the outputs, in Constraint (96), the upper bound of the efficiency score of each DMU is set equal to one in the leader–follower approach, Constraint (97) forestalls weights from being zero, and Constraint (98) displays non-negative continuous decision variables. It is worth mentioning that \({\omega }_{j{s}^{^{\prime}}} and\) \({\omega }_{js''}\) show the efficiencies of the DMUs. Where the efficiencies of all DMUs are set equal to one, it is more strict to reach the goal. Therefore, managers who take into account the efficiency of DMUs necessary for their decisions can apply a strict view.

Aggregating the results obtained from the bi-objective and leader–follower models by geometric mean, the efficiency of the solutions is obtained. Then, according to the decision-maker, the most efficient solutions are added to the MP by constraints entitled efficiency cuts. Therefore, the MP model would be updated, and the feasible and efficient solutions are filtered by re-solving the updated MP. This iterative procedure stops when the values of the solutions do not change or the number of solutions required by the decision-maker is generated. In this regard, the flowchart of the proposed B&E algorithm is depicted in Fig. 5.

In the proposed B&E algorithm, MP is solved at iteration zero, according to the vehicle’s efficiency scores. If the number of DMUs exceeds the predetermined threshold, then the inputs and outputs are provided. Here, it is assumed that each warehouse is a DMU. Therefore, the warehouses are evaluated based on the inputs and outputs obtained from MP, and the efficiency of each warehouse is measured by bi-objective and leader–follower models. In the first iteration, based on the results obtained from the aggregation of bi-objective and leader–follower models, MP is reformulated by efficiency cut constraints to filter out the solution with the highest efficiency for selection. In this regard, Eq. (99) is added to the MP to filter the solutions with an efficiency greater than or equal to the acceptable threshold. Accordingly, the 6th term of Eq. (26) is transformed to Eq. (100) and, Eqs. (39)–(42) are transformed to Eqs. (101)–(104), after reformulation.

If the updated MP improves the objective functions at each iteration, the next iteration starts; otherwise, the optimal solution is found. If the efficiency cut constraints lead to the infeasibility of MP, then the acceptable threshold for the solutions should be wider to provide the number of solutions that is sufficient for solving the MP. Otherwise, the solution of the previous iteration can be reported as the optimal solution.

In the following, the relationships between the solution space of MP and the solution space of subsequent iterations are explained by a proposition and then, the relationships among the solutions of subsequent iterations are explained by two corollaries.

Proposition

If \({S}^{f,0}\) represents the space of the solutions related to Formulas (26)–(63), and \({S}^{f,t}\) is the solution spaces for subsequent iterations, then \({f}^{c,0}\ge {f}^{c,1}\ge \dots \ge {f}^{c,T}\), where \({f}^{c,t} (t=0, 1,\dots ,T)\) is the objective function related to the costs, at each iteration.

Proof

Due to the addition of efficiency cuts at each iteration to the proposed model in Formulas (26)–(63), the number of DMUs selected for subsequent iterations reduces. Thus, in each iteration, both the binary and continuous decision variables for non-efficient solutions are zero. In other words, since the binary and continuous decision variables in each iteration are a subset of the binary and continuous decision variables in the previous iteration, the feasibility set reduces in subsequent iterations, compared to the previous iterations. Therefore, the overall cost is minimized through iterative efficiency cuts.

Corollary 1

The average of the overall costs of \(\left(t+1\right)\) th and \(\left(t+2\right)\) th iterations are not greater than the overall cost of \(t\) th iteration.

Proof

According to the Proposition, the feasibility set reduces in subsequent iterations compared to the previous iterations. On the other hand, the optimal solutions of the next iterations are the feasible solutions of the previous iterations. Therefore, considering \({f}^{c,t}\ge {f}^{c,t+1}\) and \({f}^{c,t}\ge {f}^{c,t+2}\), it can be concluded that \({f}^{c,t}\ge\).

Corollary 2

The average of the overall costs of iterations \(\left(t + 1\right)\) to \(T\), is not greater than the overall cost of iteration \(t\).

Proof

According to Proposition and Corollary 1, it can be concluded that \({f}^{c,t}\ge \frac{{f}^{c,t+1}+{f}^{c,t+2}+\dots +{f}^{c,T}}{T}.\)

Uncertainty modeling

Since the conditions in the real world are not deterministic, the planning should be performed such that the uncertainty is treated. Furthermore, since managers expect that decisions related to supply chain design in complex and uncertain real business environments will still perform well, in our article, two important parameters that have a significant effect on satisfying demand and supply chain performance, that is demand and labor, are considered under uncertain conditions (Peidro et al. 2009; Govindan et al. 2017).

Treating the uncertainty of demand: fuzzy chance-constraint programming

In Constraint (43), demand is assumed to be a deterministic parameter while this assumption is not really applicable because the demand amount for each customer is organized and determined before the optimal design of the supply chain network. Therefore, in some conditions, the amount of demand may change. Due to the real-world uncertainty conditions, it is inappropriate to assume a deterministic amount of demand for supply chain network design. Fuzzy chance-constraint programming is a powerful approach to solving optimization problems under uncertain conditions. To measure a fuzzy event, the concept of possibility is presented. Although the possibility is used for expressing the fuzzy behavior of phenomena, it is not self-dual; therefore, the concept of credibility is developed. In the concept of credibility, a confidence level is used to hold a fuzzy constraint (Bai 2016; Liu 2009). In this regard, Constraint (43) is transformed into Constraint (105) to consider the concept of credibility for customer demand.

Theorem 1

Let the demand of each customer be a triangular fuzzy random variable, which is shown by Constraint (106):

-

(a)

If \(0<{\alpha }^{D}<0.5\) then, Constraint (107) is equivalent to Constraint (105).

$$\begin{array}{cc}{g}_{k}^{^{\prime}}+\sum \limits_{j}\sum \limits_{\uplambda }{q}_{jk\uplambda }^{2\to 3}+\sum \limits_{i}\sum \limits_{\uplambda }{q}_{ik\uplambda }^{1\to 3}\ge 2{d}_{k}^{2}{\alpha }^{D}-{d}_{k}^{1}(2{\alpha }^{D}-1)& \forall k\end{array}$$(107) -

(b)

If \(0.5\le {\alpha }^{D}\le 1\) then, Constraint (108) is equivalent to Constraint (105).

$$\begin{array}{cc}{g}_{k}^{^{\prime}}+\sum \limits_{j}\sum \limits_{\uplambda }{q}_{jk\uplambda }^{2\to 3}+\sum \limits_{i}\sum \limits_{\uplambda }{q}_{ik\uplambda }^{1\to 3}\ge {d}_{k}^{3}\left(2{\alpha }^{D}-1\right)-{d}_{k}^{2}(2{\alpha }^{D}-2)& \forall k\end{array}$$(108)

Proof

Since assertion (b) can be proved similar to assertion (a), assertion (a) is only proved.

The possibility distribution associated with \({\widetilde{\upxi }}_{k}^{u}\) which is represented by Eq. (109):

If \(0<{\alpha }^{D}<0.5\), then we have:

Therefore, Constraint (111) is equivalent to Constraint (105):

If Eq. (112) is denoted for \({N}^{c}\in \left(0\right.,\left.1\right]\), then Eq. (113) is defined as follows:

Given \({Pos}^{{\widetilde{\xi }}_{k}^{u}}\left(x\right)\), \({\left({\widetilde{\xi }}_{k}^{u}\right)}_{\mathrm{inf}}\left(2{\alpha }^{D}\right)\) is the solution of Eq. (114):

By solving Eq. (114), Eq. (115) is obtained as follows:

Thus, \(Cr\{{g}_{k}^{^{\prime}}+\sum_{j}\sum_{\uplambda }{q}_{jk\uplambda }^{2\to 3}+\sum_{i}\sum_{\uplambda }{q}_{ik\uplambda }^{1\to 3}\ge {d}_{k}^{R}\}\ge {\alpha }^{D}\) is equivalent to Eq. (116):

Accordingly, assertion (a) is proved.

Treating the uncertainty of labor-related parameters: robust optimization

Nowadays, the COVID-19 pandemic resulted in labor shortages in the supply chain. Generally, the consequences of illness, death, travel restrictions, risk mitigations, and social distancing are the causes of labor shortages that lead to disruption in the supply chain. The COVID-19 pandemic, despite the growth of electronic commerce, had a devastating effect on freight service provision and transportation, due to labor shortages (Nagurney 2021a, b). Accordingly, the effect of labor availability on supply chain planning should be investigated. Considering the fact that labor availability is an essential factor in the supply chain functions during the COVID-19 pandemic and, at the same time, the COVID-19 pandemic threatens the human lives, conservatism solutions should be applied in supply chain planning. Soyster (1973) proposed a conservatism of robust solutions for linear programming, where the technological coefficients are uncertain.

In this study, the productivity factors related to the availability of labor in shipments among the echelons are assumed to be uncertain parameters. Therefore, the uncertain counterpart of Constraints (52)–(54) is provided by Constraints (117)–(119).

Then, in accordance with Soyster (1973), the deterministic counterpart of Constraints (117)–(119) is provided by Constraints (120)–(125):

Solution approach

The models proposed in this study have more than one objective function; hence, it is necessary to convert them into single-objective models for solving.

For this purpose, this section employs GP and FGP as solution approaches for the proposed multi-objective optimization models.

Goal programming

GP is one of the multi-objective programming techniques which converts a multi-objective model into a single-objective model. In GP, the decision-maker determines an aspiration level for each objective function. The objective function of GP is the minimization of deviations from the aspiration levels (Charnes and Cooper 1977). In this work, GP is used to solve the bi-objective optimization model presented in Eqs. (66)–(74). In this regard, Eq. (127) is the objective function of GP, and Eqs. (66)–(67) are replaced with Formulas (128)–(129):

Theorem 2

Assuming \({f}^{D1*}\) and \({f}_{s}^{D2*}\) as globally optimal solutions of Eqs. (66) and (67), respectively, the solution produced by the model including Formulas (127)–(130) and Formulas (68)–(74) is a Pareto efficient solution for the model built up by Formulas (66)–(74).

Proof

Let \({\beth }^{*}\) be the optimal solution obtained from solving Formulas (127)–(130) and (68)–(74) where \({\beth }^{*}\) denotes the optimal decision variables. If \({\beth }^{*}\) is not an efficient solution for the model built up by Formulas (66)–(74), there exists another feasible solution, \({\beth }^{**}\), that the values of the objective functions obtained from \({\beth }^{**}\) have fewer deviations from the aspiration levels, compared to the values of the objective functions obtained from \({\beth }^{*}\). On the other hand, the parameters \({w}^{D1}\) and \({w}^{D2}\) are all positive. Therefore, the weighted sum of the deviations related to the objective functions obtained from \({\beth }^{**}\) is less than the weighted sum of the deviations related to the objective functions obtained from \({\beth }^{*}\), which is in contradiction to the optimality of \({\beth }^{*}\).

Theorem 3

The sum of efficiency scores calculated under uncertain conditions are less than or equal to the sum of efficiency scores under deterministic conditions.

Proof

When the conditions are deterministic, only one of two scenarios is regarded to calculate the total efficiency score while, under uncertainty, more than one scenario is taken into account for this purpose. For uncertain conditions, the size of the feasible region can be reduced by adding each scenario. In other words, in measuring the efficiency, a model that considers all the scenarios is more stringent than a model dealing with only one scenario. Therefore, the total efficiency score under deterministic conditions is not less than the total efficiency score calculated under uncertain conditions.

Corollary 3

If DMUs are efficient after calculating the sum of the efficiency scores under uncertain conditions, then DMUs are efficient under deterministic conditions.

Proof

Based on Theorem 3, it is revealed that when the DMU is efficient under uncertain conditions, the lower bound of the efficiency score calculated under deterministic conditions is equal to one. On the other hand, the upper bound of each DMU is equal to one. Hence, DMUs are efficient under deterministic conditions.

Since Formulas (90)–(98) represent a multi-objective optimization model to measure the efficiency score of warehouses, they can be converted into a single-objective optimization model by GP. For this purpose, Eqs. (90)–(92) are replaced by Eqs. (132)–(134). The objective function of the GP, which includes the deviations related to Eqs. (90)–(92), is shown by Eq. (131):

Theorem 4

Assuming \({f}^{{LF}^{D*}}\), \({f}^{{L}^{D}*}\), and \({f}^{{F}^{D}*}\) as globally optimal solutions for Eq. (90), the leader model and the follower model, respectively, then the solution for the model built up by Formulas (131)–(135) and Formulas (93)–(98) is a Pareto efficient solution for Formulas (90)–(98).

Proof

Let \({\Delta }^{*}\) be the optimal solution obtained from solving the model generated by Formulas (131)–(135) and Formulas (93)–(98), where \({\Delta }^{*}\) denotes the optimal decision variables. If \({\Delta }^{*}\) is not an efficient solution for Formulas (90)–(98), then there is another feasible solution, \({\Delta }^{**}\), so that the values of the objective functions obtained from \({\Delta }^{**}\) have fewer deviations from the aspiration levels, compared to the ones obtained from \({\Delta }^{*}\). On the other hand, the parameters \({w}^{LF}\), \({w}^{L}\), and \({w}^{F}\) are all positive. Therefore, the weighted sum of the deviations related to the objective functions obtained from \({\Delta }^{**}\) is less than the weighted sum of the deviations related to the objective functions obtained from \({\Delta }^{*}\), which is in contradiction with the optimality of \({\Delta }^{*}\).

Theorem 5

The sum of the efficiency scores calculated by Formulas (90)–(98) is less than or equal to the sum of the efficiency scores where the leader and follower divisions are regarded as a whole unit.

Proof

When there exists a whole unit to calculate the total efficiency score, Eqs. (91)–(92) should be deleted. Deleting these equations does not reduce the size of the feasible region of Formulas (90)–(98). In other words, in measuring the efficiency, the model that is considered to be a whole unit is less stringent than the model dealing with the leader and follower as independent divisions. Therefore, the total efficiency score calculated when the leader and follower divisions are taken into account as a whole unit is not less than the total efficiency score calculated by Formulas (90)–(98).

Corollary 4

If DMUs are efficient after calculating the sum of efficiency scores obtained by Formulas (90)–(98), then DMUs are efficient where the divisions are regarded as a whole unit.

Proof

Based on Theorem 5, it is revealed that for an efficient DMU, the lower bound of the efficiency score obtained from the model that considers the divisions as a whole unit is equal to one. On the other hand, the upper bound of each DMU is equal to one. Therefore, DMUs are efficient, where divisions are regarded as a whole unit.

Fuzzy goal programming

Determining the precise amount of aspiration level by decision-maker can be challenging. The FGP approach can be used to account for the ambiguity in aspiration levels (Zimmermann 1978). In this regard, Formulas (26)–(63) are solved by FGP. Fuzzy goals for Eqs. (26)–(28) are determined in Eqs. (136)–(138) (Tiwari et al. 1987). In Formulas (136)–(138), approximately less than or equal to is denoted by \(\lesssim\). The membership functions assigned to fuzzy goals are presented in Eqs. (139)–(141):

By investigating the objective functions in the proposed model, the ideal and nadir solutions are calculated. To obtain the ideal solution for each objective function, it is sufficient to solve each objective function by considering Constraints (29)–(63). The nadir solution of each objective function is the worst value that each objective function achieves in the ideal solutions of other objective functions. Formulas (142)–(144) are the fuzzy counterparts of Formulas (26)–(63).

subject to.

Theorem 6

The solution of the model generated by Formulas (142)–(144) is a Pareto efficient solution for the model built up by Formulas (26)–(63).

Proof

Let \({\aleph }^{*}\) be the optimal solution obtained from solving the model generated by Formulas (142)–(144) where \({\aleph }^{*}\) denotes the optimal decision variables. If \({\aleph }^{*}\) is not an efficient solution for the model produced by Formulas (26)–(63), then there is another feasible solution, \({\aleph }^{**}\), such that the values of the objective functions obtained from \({\aleph }^{**}\) are better than the values of the objective functions obtained from \({\aleph }^{*}\). In other words, the membership functions belonging to \({\aleph }^{**}\) are greater than or equal to the membership functions belonging to \({\aleph }^{*}\), and at least one of the membership functions that belongs to \({\aleph }^{**}\) is greater than its corresponding membership function which belongs to \({\aleph }^{*}\). Since the parameters denoting the weights are all positive, the weighted sum of the membership functions of \({\aleph }^{**}\) is greater than the weighted sum of the membership functions of \({\aleph }^{*}\), which is in contradiction to the optimality of \({\aleph }^{*}\).

Case study

In this section, the application of the proposed models is indicated by a case study. It is assumed that there are 5 plants, 20 possible warehouses, and 5 demand zones in the proposed supply chain network. In addition, it is assumed that the goods are shipped in the supply chain network by 5 vehicle types. In this case study, the supply chain network and vehicle types data are extracted from Petridis et al. (2016) and Kumar et al. (2019), respectively. In this section, the effects of the contributions of this work included to the supply chain model proposed by Petridis et al. (2016) are analyzed, and then, the proposed B&E algorithm is implemented on the case study.

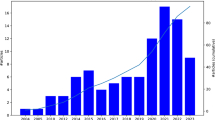

At first, the sensitivity of the parameters added to the supply chain network model is analyzed where the results are represented in Fig. 6. Figure 6a illustrates the relationship between sustainability and the objective function related to the costs. In this regard, increasing the government subsidies on using efficient vehicles leads to a reduction in total cost. Therefore, by considering sustainability, not only the economic aspect of the transportation system in the supply chain is addressed, but also an environmentally friendly supply chain is designed. Figure 6b shows the relationship between the costs of each unit of labor related to the stages and the objective function related to the costs. In this case, increasing the labor costs leads to an increase in total cost. Therefore, the key parameters related to sustainability and the impact of the COVID-19 pandemic led to decreasing and increasing the objective function of costs, respectively. Figure 6c and d illustrate the resilience effect on the objective function of costs where, based on these figures, an increase in the cost of direct shipment and lateral transshipment increases the total cost. Therefore, increasing the resilience costs leads to an increase in total cost. Figure 6e displays the effect of reverse logistics on the customer service level. Based on this figure, increasing the production benefits through the recovery process reduces the unsatisfied demand of all five customers. This means that not only does the supply chain meet environmental requirements, but it can meet more demands by saving resources. Finally, Fig. 6f demonstrates the relationship between the confidence level and customer service level. Again, increasing the confidence level leads to an increase in the number of demands which should be satisfied. For this reason, rising the confidence level, where there is a capacity constraint, leads to an increase in unsatisfied demand. Therefore, increasing the production amount through recovery as well as increasing the confidence level rises and reduces the customer service level, respectively.

Now, the proposed B&E algorithm is implemented to the case study introduced by Petridis et al. (2016). In this regard, some parameters are taken into account based on the ones presented by Petridis et al. (2016) and Kumar et al. (2019) while the other parameters are set according to Table 3.

The optimal solution for the model proposed by Petridis et al. (2016) demonstrated that 12 warehouses are selected to be established. On the other hand, to reduce the number of selected warehouses, when the B&E algorithm is implemented for the next iteration, 8 warehouses are selected to be established, which makes their problem infeasible. Therefore, the average of the two solutions calculated by Petridis et al. (2016), is considered the maximum number of warehouses required in the model proposed in this study. In other words, when the number of warehouses is less than 10, the proposed B&E algorithm is terminated. In iteration 0, the MP is solved and then, the inputs and outputs are provided for the bi-objective and leader–follower models. The results obtained from iterations 0 and 1 are reported in Table 4.

After evaluating the solutions of MP, the solutions of the bi-objective and leader–follower models are aggregated by geometric mean. The results of warehouse evaluation are reported in Table 5.

As shown in Table 5, the number of efficient warehouses drops below 10. Therefore, the algorithm would be terminated at iteration 1. The MP is resolved with respect to efficient warehouses and the results are reported in Table 4. As proved in the proposition, the objective function of costs is reduced at iteration 1 compared to iteration 0. On the other hand, the membership functions of iteration 1 have been improved compared to the membership functions of iteration 0. Based on the results, both the proposed B&E algorithm and the models proposed for evaluating the warehouses perform better than the algorithm and models proposed by Petridis et al. (2016). Based on the results in Table 5, the proposed models for warehouse evaluation led to the selection of 9 efficient warehouses for supply chain network design, while the model developed by Petridis et al. (2016) selects 12 efficient warehouses. Therefore, the proposed models have more discrimination power in measuring the efficiency of DMUs. On the other hand, not only the number of warehouses selected by the developed models is less than the ones selected by Petridis et al. (2016), but also the proposed B&E algorithm can improve the customer service level. As shown in Fig. 7, the B&E algorithm reduces the unmet demand for all 5 customers, compared to Petridis et al. (2016). Therefore, despite reducing the number of selected warehouses, the service level was improved as well.

Comparison of the developed B&E algorithm and Petridis et al. (2016)

Conclusion and outlook

To enhance the business image and receive government subsidies, the companies are required to design their supply chain network efficiently in such a way that the economic criteria and sustainability pillars are addressed. In this regard, the EDEA model and the developed B&E algorithm were integrated where the efficiency score of the vehicle types which transport the goods between the echelons of the supply chain was measured by the EDEA model, based on pillars of sustainability. The results obtained from the EDEA model were incorporated into a tri-objective optimization model developed to supply chain network design. The proposed optimization model considered not only the production, shortages, and transportation as common components of supply chain network design, but also other components including the reverse logistics, resilience, and the effect of the COVID-19 pandemic, the inequity in unsatisfied demand of customers, and the efficiency of vehicles in terms of sustainability. The resilience was investigated to increase the service level and better inventory management through direct shipment among the echelons and lateral transshipment among the members of an echelon. The reverse logistics system was taken into account based on the process of recovering the products in the supply chain network. In addition, considering the fact that the COVID-19 pandemic affects the most essential functions of the supply chain, called labor, the relationships between the product flow and labor were established in the optimization model. The results of the optimization model were filtered through the developed B&E algorithm so that the efficient solutions were only selected in each iteration, and hence, the optimization model was updated by efficiency cuts in each iteration. The efficiency of each solution was assessed by two models including the bi-objective model and the leader–follower model where both models are extensions of the DEA model. The inputs and outputs of the models were related to the service level, cost, and traffic congestion. The reason to deal with traffic congestion was the vehicles transporting goods between the echelons are generally slow and heavyweight. These characteristics not only led to the traffic congestion but also threaten all the pillars of sustainability. Despite the importance of the traffic congestion criterion, the research literature has not focused on this context. Therefore, two criteria related to traffic congestion were regarded in the efficient design of the supply chain network. On the other hand, considering the role of uncertainty in the real-world, parameters related to the demand and labor were assumed to be uncertain and were treated using fuzzy chance-constrained programming and robust optimization, respectively. Furthermore, GP and FGP methods were utilized to treat multi-objectiveness of the models. Finally, the application of the proposed models in this work was validated through a case study. The results demonstrated that the proposed models not only reduce the costs but also perform better than the competing models, both in improving the service level and increasing the discrimination power in measuring the performance.

This research provided a wide range of research opportunities for future studies. In this regard, the following recommendations are given to extend the current study:

-

i.

Applying other techniques to handle and analyze uncertainty such as stochastic optimal control (Savku and Weber 2018; Pervin et al. 2018; Tirkolaee et al. 2022c), possibilistic programming (Tirkolaee et al. 2022b), and regression models (Özmen et al. 2017, 2018), which can be compared to the proposed method,

-

ii.

Expanding the supply chain network by including more levels such as suppliers and retailers and with respect the target industry (Paksoy et al. 2013; Tirkolaee et al. 2021a),

-

iii.

Addressing the application of Industry 4.0 and digital technologies to deal with traffic congestion (Jahani et al. 2021; Tirkolaee et al. 2021b),

-

iv.

Developing heuristic and meta-heuristic algorithms to tackle to complexity of the problem in large scales (Goli et al. 2020; Tirkolaee et al. 2022a; Babaei et al. 2022), which can be also compared to the developed B&E algorithm.

Data availability

Not applicable.

References

Álvarez-rodríguez, C., & Martín-gamboa, M., Iribarren, D. (2019). Sustainability-oriented efficiency of retail supply chains: a combination of life cycle assessment and dynamic network data envelopment analysis. Sci Total Environ 705. https://doi.org/10.1016/j.scitotenv.2019.135977

Amirteimoori A (2011) An extended transportation problem : a DEA-based approach. CEJOR 19:513–521. https://doi.org/10.1007/s10100-010-0140-0

Aydin NS, Tirkolaee EB (2022).A systematic review of aggregate production planning literature with an outlook for sustainability and circularity. Environ Dev Sustain 1–42. https://doi.org/10.1007/s10668-022-02304-8

Babazadeh R, Razmi J, Rabbani M, Pishvaee MS (2015) An integrated data envelopment analysis-mathematical programming approach to strategic biodiesel supply chain network design problem J. Clean Prod 147:694–707. https://doi.org/10.1016/j.jclepro.2015.09.038

Babaei A, Khedmati M, Jokar MRA, Babaee Tirkolaee E (2022) Performance evaluation of omni-channel distribution network configurations considering green and transparent criteria under uncertainty. Sustainability 14(19):12607. https://doi.org/10.3390/su141912607

Bai X (2016). Two-Stage Multiobjective Optimization for emergency supplies allocation problem under integrated uncertainty. Math Problems Eng 13. https://doi.org/10.1155/2016/2823835

Bai Y, Hwang T, Kang S, Ouyang Y (2011) Biofuel refinery location and supply chain planning under traffic congestion. Transp Res Part B: Methodol 45(1):162–175. https://doi.org/10.1016/j.trb.2010.04.006

Charnes A, Cooper WW (1977) Goal programming and multiple objective optimization. Eur J Oper Res 1(1):39–54. https://doi.org/10.1016/S0377-2217(77)81007-2

del Mar Martínez-Bravo M, Martínez-del-Río J, Antolín-López R (2019) Trade-offs among urban sustainability, pollution and livability in European cities. J Clean Prod 224:651–660. https://doi.org/10.1016/j.jclepro.2019.03.110

Du J, Zhu J, Cook WD, & Huo J (2015). DEA models for parallel systems: game-theoretic approaches. Asia-Pac J Oper Res 32(2). https://doi.org/10.1142/S0217595915500086

Ebrahimi F, Saen RF, Karimi B (2021) Assessing the sustainability of supply chains by dynamic network data envelopment analysis: a SCOR-based framework. Environ Sci Pollut Res 28(45):64039–64067. https://doi.org/10.1007/s11356-021-12810-3

EU-council (2001) Council resolution on the integration of environment and sustainable development into the transport policy (report 7329/01). Brussels

Fathi A, Saen RF (2018) A novel bidirectional network data envelopment analysis model for evaluating sustainability of distributive supply chains of transport companies. J Clean Prod 184:696–708. https://doi.org/10.1016/j.jclepro.2018.02.256

Gao X, & Cao C (2020). Multi-commodity rebalancing and transportation planning considering traffic congestion and uncertainties in disaster response. Comp Ind Eng 149. https://doi.org/10.1016/j.cie.2020.106782

Goli A, Tirkolaee EB, Weber GW (2020) A perishable product sustainable supply chain network design problem with lead time and customer satisfaction using a hybrid whale-genetic algorithm. In Logistics operations and management for recycling and reuse. Springer, Berlin, Heidelberg, pp 99–124. https://doi.org/10.1007/978-3-642-33857-1_6

Govindan K, Fattahi M, Keyvanshokooh E (2017) Supply chain network design under uncertainty : a comprehensive review and future research directions. Eur J Oper Res 263(1):108–141. https://doi.org/10.1016/j.ejor.2017.04.009

Govindan K, Rajeev A, Padhi SS, Pati RK (2020) Supply chain sustainability and performance of firms: a meta-analysis of the literature. Transp Res Part E: Logist Transp Rev 137:101923. https://doi.org/10.1016/j.tre.2020.101923

Govindan K, Soleimani H, Kannan D (2015) Reverse logistics and closed-loop supply chain: a comprehensive review to explore the future. Eur J Oper Res 240(3):603–626. https://doi.org/10.1016/j.ejor.2014.07.012

Grigoroudis E, Petridis K, Arabatzis G (2014) RDEA : a recursive DEA based algorithm for the optimal design of biomass supply chain networks. Renew Energy 71:113–122. https://doi.org/10.1016/j.renene.2014.05.001

Guo Y, Shi Q, Guo C, Li J, You Z, Wang Y (2022) Designing a sustainable-remanufacturing closed-loop supply chain under hybrid uncertainty: cross-efficiency sorting multi-objective optimization. Comput Ind Eng 172:108639. https://doi.org/10.1016/j.cie.2022.108639

Hermoso-Orzaez MJ, Garcia-Alguacil M, Terrados Cepeda J, Brito P (2020) Measurement of environmental efficiency in the countries of the European Union with the enhanced data envelopment analysis method (DEA) during the period. Environ Sci Pollut Res 27:15691–15715. https://doi.org/10.1007/s11356-020-08029-3

Hillier GJ, Lieberman FS (2001) Introduction to operations research, 7th Edition. McGraw-Hill College, pp 1214

Hong J, & Mwakalonge JL (2020). Biofuel logistics network scheme design with combined data envelopment analysis approach. Energy 209. https://doi.org/10.1016/j.energy.2020.118342

Hosseini S, Ivanov D, Dolgui A (2019) Review of quantitative methods for supply chain resilience analysis. Transp Res Part E 125(March):285–307. https://doi.org/10.1016/j.tre.2019.03.001

Izadikhah M, Farzipoor R (2018) Computers and operations research assessing sustainability of supply chains by chance-constrained two-stage DEA model in the presence of undesirable factors. Comput Oper Res 100:343–367. https://doi.org/10.1016/j.cor.2017.10.002

Jahani N, Sepehri A, Vandchali HR, Tirkolaee EB (2021) Application of 4.0 industry in the procurement processes of supply chains: a systematic literature review. Sustainability 13(14):7520. https://doi.org/10.3390/su13147520

Jiang T, Zhang Y, Jin Q (2021) Sustainability efficiency assessment of listed companies in China: a super-efficiency SBM-DEA model considering undesirable output. Environ Sci Pollut Res 28:47588–47604. https://doi.org/10.1007/s11356-021-13997-1

Jouzdani J, Govindan K (2021) On the sustainable perishable food supply chain network design: a dairy products case to achieve sustainable development goals. J Clean Prod 278:123060. https://doi.org/10.1016/j.jclepro.2020.123060

Jouzdani J, Sadjadi SJ, Fathian M (2013) Dynamic dairy facility location and supply chain planning under traffic congestion and demand uncertainty : a case study of Tehran. Appl Math Model 37(18–19):8467–8483. https://doi.org/10.1016/j.apm.2013.03.059

Kalantary M, Saen RF (2018) Assessing sustainability of supply chains: an inverse network dynamic DEA model. Comput Ind Eng 135:1224–1238. https://doi.org/10.1016/j.cie.2018.11.009

Kalantary M, FarzipoorSaen R, ToloieEshlaghy A (2018) Sustainability assessment of supply chains by inverse network dynamic data envelopment analysis. Sci Iran 25(6):3723–3743. https://doi.org/10.24200/sci.2017.20017

Khisty CJ, Lall BK (2002) Transportation engineering: an Introduction. Prentice Hall, Lebanon, Indiana, USA, pp 840

Klimberg RK, Ratick SJ (2008) Modeling data envelopment analysis ( DEA ) efficient location / allocation decisions. Comput Oper Res 35:457–474. https://doi.org/10.1016/j.cor.2006.03.010

Krmac E, Djordjević B (2019) A new DEA model for evaluation of supply chains: a case of selection and evaluation of environmental efficiency of suppliers. Symmetry 11(4):565. https://doi.org/10.3390/sym11040565

Kumar M, Devika M, Pankaj K, & Usha G (2019). Sustainable transportation planning for a three-stage fixed charge multi-objective transportation problem. Ann Oper Res. https://doi.org/10.1007/s10479-019-03451-4

Lima-junior FR, Carpinetti LCR (2017) Quantitative models for supply chain performance evaluation : a literature review. Comput Ind Eng 113(July):333–346. https://doi.org/10.1016/j.cie.2017.09.022

Liu B (2009) Theory and practice of uncertain programming. Physica-Verlag Heidelberg

Lozano S, Adenso-Diaz B (2017) Network DEA-based biobjective optimization of product flows in a supply chain. Ann Oper Res 264:307–323. https://doi.org/10.1007/s10479-017-2653-6

Moheb-alizadeh H, Handfield R, & Warsing D (2021). Efficient and sustainable closed-loop supply chain network design : a two-stage stochastic formulation with a hybrid solution methodology. J Clean Prod 308. https://doi.org/10.1016/j.jclepro.2021.127323

Nagurney A (2021a) Optimization of supply chain networks with inclusion of labor: applications to COVID-19 pandemic disruptions. Int J Prod Econ 235:1–38. https://doi.org/10.1016/j.ijpe.2021.108080

Nagurney A (2021b) Supply chain game theory network modeling under labor constraints : applications to the COVID-19 pandemic. Eur J Oper Res 293(3):880–891. https://doi.org/10.1016/j.ejor.2020.12.054

Nagurney A (2021) Perishable food supply chain networks with labor in the COVID-19 pandemic. In Dynamics of Disasters. Springer, Cham, pp 173–193. https://doi.org/10.1007/978-3-030-64973-9_11

Omrani H, Adabi F, Adabi N (2017) Designing an efficient supply chain network with uncertain data : a robust optimization — data envelopment analysis approach. J Oper Res Soc 68(7):816–828. https://doi.org/10.1057/jors.2016.42

Omrani H, Keshavarz M, Ghaderi S (2018) Evaluation of supply chain of a shipping company in Iran by a fuzzy relational network data envelopment analysis model. Sci Iran 25(2):868–890. https://doi.org/10.24200/sci.2017.4415

Özkır V, Başlıgıl H (2012) Modelling product-recovery processes in closed-loop supply-chain network design. Int J Prod Res 50(8):2218–2233. https://doi.org/10.1080/00207543.2011.575092

Özmen A, Kropat E, Weber GW (2017) Robust optimization in spline regression models for multi-model regulatory networks under polyhedral uncertainty. Optimization 66(12):2135–2155. https://doi.org/10.1080/02331934.2016.1209672

Özmen A, Yılmaz Y, Weber GW (2018) Natural gas consumption forecast with MARS and CMARS models for residential users. Energy Econ 70:357–381. https://doi.org/10.1016/j.eneco.2018.01.022

Paksoy T, Özceylan E, Weber GW (2013) Profit oriented supply chain network optimization. CEJOR 21(2):455–478. https://doi.org/10.1007/s10100-012-0240-0

Pariazar M, Sir MY (2018) A multi-objective approach for supply chain design considering disruptions impacting supply availability and quality. Comput Ind Eng 121:113–130. https://doi.org/10.1016/j.cie.2018.05.026

Peidro D, Mula J, Poler R, Lario FC (2009) Quantitative models for supply chain planning under uncertainty: a review. Int J Adv Manuf Technol 43(3):400–420. https://doi.org/10.1007/s00170-008-1715-y

Pervin M, Roy SK, Weber GW (2018) Analysis of inventory control model with shortage under time-dependent demand and time-varying holding cost including stochastic deterioration. Ann Oper Res 260(1):437–460. https://doi.org/10.1007/s10479-016-2355-5

Petridis K, Kumar P, Emrouznejad A (2016) A branch and efficiency algorithm for the optimal design of supply chain networks. Ann Oper Res 253:545–571. https://doi.org/10.1007/s10479-016-2268-3

Rabbani M, Sabbaghnia A, Mobini M, Razmi J (2020) A graph theory-based algorithm for a multi-echelon multi-period responsive supply chain network design with lateral-transshipments. Oper Res Int J 20(4):2497–2517. https://doi.org/10.1007/s12351-018-0425-y

Savku E, Weber GW (2018) A stochastic maximum principle for a markov regime-switching jump-diffusion model with delay and an application to finance. J Optim Theory Appl 179(2):696–721. https://doi.org/10.1007/s10957-017-1159-3

Soheilirad S, Govindan K, Mardani A, Kazimieras E, Nilashi M, Zakuan N (2017) Application of data envelopment analysis models in supply chain management : a systematic review and meta-analysis. Ann Oper Res 271:915–969. https://doi.org/10.1007/s10479-017-2605-1

Soyster AL (1973) Convex programming with set-inclusive constraints and applications to inexact linear programming. Oper Res 21(3):1154–1157. https://doi.org/10.1287/opre.21.5.1154