Abstract

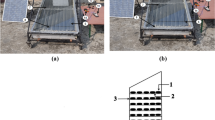

In this study, a heat storage–based hybrid greenhouse dryer has been developed and analysed for drying bitter gourd flakes under the climatic condition of Ranchi, India. Proposed heat storage–based hybrid greenhouse dryer consists of a solar air heater with a 2.12-m2 area, greenhouse dryer and DC fan to induce and force the air. The significant objective of the present study is to analyse the drying efficiency, drying kinetics, property analysis, economic analysis, embodied energy and CO2 mitigation of the hybrid greenhouse dryer for drying of bitter gourd flakes. An experiment was performed simultaneously on proposed system and open sun drying for the proper comparative analysis. Moisture contents reduced from 88.14 to 10.14% in 6 h in proposed dryer and 88.14 to 11.01% in 15 h for open system. Thus, significant drying time is reduced in proposed system by 8 h as compared to open system. Environmental impact analysis shows that the energy payback time was found to be 0.4907 years only. Cost of the proposed system dryer is 22664.30 INR. The total embodied energy is found 1591.07 kWh and earned carbon credit ranges from 16844.76 to 67379.05 INR, while CO2 mitigation was 46.28 tonnes for 35 years of expected lifetime. Seven standard mathematical models for drying of bitter gourd flakes were studied. Ahmad and Prakash model was found to be the best as compared to other models. The metal contents of dried bitter gourd flakes were also examined. Bitter gourd dried in proposed dryers possesses superior metal content as compared to open systems. Impact analysis demonstrates that the hybrid greenhouse dryer is more suitable for reducing post-harvest loss with environmental sustainability.

Similar content being viewed by others

Abbreviations

- A rm :

-

area of room (m2)

- AE o :

-

annual energy output (W)

- A tr :

-

area of tray (m2)

- CO 2emmision/yr :

-

emission rate of CO2 per year (kg)

- DE o :

-

daily energy output (W)

- DE i :

-

daily energy input (W)

- E m :

-

embodied energy (kWh)

- EPBT :

-

energy payback time (year)

- h lh :

-

latent heat of evaporation (KJ/kg)

- I grd :

-

solar radiation (W/m2)

- LT :

-

lifetime (Yr)

- M eqm :

-

equilibrium moisture content

- M fnl :

-

final moisture content

- M ini :

-

initial moisture content

- M ins :

-

instantaneous moisture content

- M ratio :

-

moisture ratio

- N day :

-

average annual sunny days

- η hgd :

-

drying system efficiency (%)

- N hr :

-

daily sunny hour (h)

- W hr :

-

hourly weight of bitter gourd (kg/h)

- W ini :

-

initial weight of bitter gourd (kg)

- W ttl :

-

total removal of water content (kg)

- eqm:

-

equilibrium

- fnl:

-

final

- grd:

-

global radiation

- hgd:

-

hybrid greenhouse dryer

- hr:

-

hourly

- ini:

-

initial

- ins:

-

instantaneous

- lh:

-

latent heat

- pbt:

-

payback time

- rm:

-

room

- tr:

-

tray

- ttl:

-

total

References

Abubakar S, Umaru S, Anafi FO, Abubakar AS, Kulla DM (2018a) Design and performance evaluation of a mixed-mode Solar Crop Dryer. FUOYE J Eng Technol 3(1):22–26

Abubakar S, Anafi FO, Kaisan MU, Narayan S, Umar S, Umar UA (2019) Comparative analyses of experimental and simulated performance of a mixed-mode solar dryer. Proceedings of the Institution of Mechanical Engineers, Part C. J Mech Eng Sci 234(7):1393–1402. https://doi.org/10.1177/2F0954406219893394

Abubakar S, Umaru S, Kaisan MU, Umar UA, Ashok B, Nanthagopal K (2018b) Development and performance comparison of mixed-mode solar crop dryers with and without thermal storage. Renewable Energy 128:285–298. https://doi.org/10.1016/j.renene.2018.05.049

Ahmad A, Prakash O (2019) Thermal analysis of north wall insulated greenhouse dryer at different bed conditions operating under natural convection mode. Environ Progress & Sustain Energy 38(6):1–12. https://doi.org/10.1002/ep.13257

Ahmad A, Prakash O (2020) Performance evaluation of a solar greenhouse dryer at different bed conditions under passive mode. J Solar Energy Eng 142(1):1–10. https://doi.org/10.1115/1.4044194

Ahmad A, Prakash O (2021) Development of mathematical model for drying of crops under passive greenhouse solar dryer. Mater Today: Proc ISSN 2214-7853:1–4. https://doi.org/10.1016/j.matpr.2021.05.180

Akpinar EK (2010) Drying of mint leaves in a solar dryer and under open sun: modelling, performance analyses. Energy Conversion Manag 51(12):2407–2418. https://doi.org/10.1016/j.enconman.2010.05.005

Arslan D, Özcan MM (2011) Drying of tomato slices: changes in drying kinetics, mineral contents, antioxidant activity and color parameters Secado de rodajas de tomate: cambios en cineticos del secado, contenido en minerales, actividad antioxidante y parametros de color. CyTA-J Food 9(3):229–236. https://doi.org/10.1080/19476337.2010.522734

Amin M, Chetpattananondh P, Chang CK, Sami SK, Khan MN (2021) Drying characteristics and impacts on quality of marine Chlorella sp. biomass and extracts for fuel applications. J Environ Chem Eng, 106386. https://doi.org/10.1016/j.jece.2021.106386

Babu AK, Kumaresan G, Raj VAA, Velraj R (2018) Review of leaf drying: mechanism and influencing parameters, drying methods, nutrient preservation, and mathematical models. Renewable Sustain Energy Rev 90:536–556. https://doi.org/10.1016/j.rser.2018.04.002

Banout J, Ehl P, Havlik J, Lojka B, Polesny Z, Verner V (2011) Design and performance evaluation of a double-pass solar drier for drying of red chilli (Capsicum annum L.). Solar Energy 85(3):506–515. https://doi.org/10.1016/j.solener.2010.12.017

Bhardwaj AK, Kumar R, Chauhan R, Kumar S (2020) Experimental investigation and performance evaluation of a novel solar dryer integrated with a combination of SHS and PCM for drying chilli in the Himalayan region. Thermal Sci Eng Progress 20:100713. https://doi.org/10.1016/j.tsep.2020.100713

Bhardwaj AK, Kumar R, Kumar S, Goel B, Chauhan R (2021) Energy and exergy analyses of drying medicinal herb in a novel forced convection solar dryer integrated with SHSM and PCM. Sustain Energy Technol Assessments 45:101119. https://doi.org/10.1016/j.seta.2021.101119

Čiplienė A, Novošinskas H, Raila A, Zvicevičius E (2015) Usage of hybrid solar collector system in drying technologies of medical plants. Energy Convers Manag 93:399–405. https://doi.org/10.1016/j.enconman.2015.01.051

Chauhan PS, Kumar A, Nuntadusit C (2018) Thermo-environomical and drying kinetics of bitter gourd flakes drying under north wall insulated greenhouse dryer. Solar Energy 162:205–216. https://doi.org/10.1016/j.solener.2018.01.023

Doymaz I (2007) Air-drying characteristics of tomatoes. J Food Eng 78(4):1291–1297. https://doi.org/10.1016/j.jfoodeng.2005.12.047

El-Sebaii AA, Shalaby SM (2013) Experimental investigation of an indirect-mode forced convection solar dryer for drying thymus and mint. Energy Conversion Manag 74:109–116. https://doi.org/10.1016/j.enconman.2013.05.006

Fudholi A, Sopian K, Yazdi MH, Ruslan MH, Gabbasa M, Kazem HA (2014) Performance analysis of solar drying system for red chili. Solar Energy 99:47–54. https://doi.org/10.1016/j.solener.2013.10.019

Fudholi A, Sopian K, Bakhtyar B, Gabbasa M, Othman MY, Ruslan MH (2015) Review of solar drying systems with air based solar collectors in Malaysia. Renewable Sustain Energy Rev 51:1191–1204. https://doi.org/10.1016/j.rser.2015.07.026

Jain D, Tewari P (2015) Performance of indirect through pass natural convective solar crop dryer with phase change thermal energy storage. Renewable Energy 80:244–250. https://doi.org/10.1016/j.renene.2015.02.012

Kant K, Shukla A, Sharma A, Kumar A, Jain A (2016) Thermal energy storage based solar drying systems: a review. Innov Food Sci Emerg Technol 34:86–99. https://doi.org/10.1016/j.ifset.2016.01.007

Khanlari A, Sözen A, Şirin C, Tuncer AD, Gungor A (2020) Performance enhancement of a greenhouse dryer: analysis of a cost-effective alternative solar air heater. J Cleaner Product 251:119672. https://doi.org/10.1016/j.jclepro.2019.119672

Kiburi FG, Kanali CL, Kituu GM, Ajwang PO, Ronoh EK (2020) Performance evaluation and economic feasibility of a solar-biomass hybrid greenhouse dryer for drying Banana slices. Renewable Energy Focus 34:60–68. https://doi.org/10.1016/j.ref.2020.06.009

Lopez A, Iguaz A, Esnoz A, Virseda P (2000) Thin-layer drying behaviour of vegetable wastes from wholesale market. Drying Technol 18(4-5):995–1006. https://doi.org/10.1080/07373930008917749

Mishra S, Verma S, Chowdhury S, Dwivedi G (2021) Analysis of recent developments in greenhouse dryer on various parameters-a review. Mater Today: Proc 38:371–377. https://doi.org/10.1016/j.matpr.2020.07.429

Prasad J, Vijay VK (2005) Experimental studies on drying of Zingiber officinale, Curcuma longa l. and Tinospora cordifolia in solar-biomass hybrid drier. Renewable Energy 30(14):2097–2109. https://doi.org/10.1016/j.renene.2005.02.007

Prakash O, Kumar A (2014) Environomical analysis and mathematical modelling for tomato flakes drying in a modified greenhouse dryer under active mode. Int J Food Eng 10(4):669–681. https://doi.org/10.1515/ijfe-2013-0063

Prakash O, Laguri V, Pandey A, Kumar A, Kumar A (2016) Review on various modelling techniques for the solar dryers. Renewable Sustain Energy Rev 62:396–417. https://doi.org/10.1016/j.rser.2016.04.028

Sacilik K, Keskin R, Elicin AK (2006) Mathematical modelling of solar tunnel drying of thin layer organic tomato. J Food Eng 73(3):231–238. https://doi.org/10.1016/j.jfoodeng.2005.01.025

Sarbu I, Sebarchievici C (2018) A comprehensive review of thermal energy storage. Sustainability 10(1):191. https://doi.org/10.3390/su10010191

Sethi VP, Dhiman M (2020) Design, space optimisation and modelling of solar-cum-biomass hybrid greenhouse crop dryer using flue gas heat transfer pipe network. Solar Energy 206:120–135. https://doi.org/10.1016/j.solener.2020.06.006

Shalaby SM, Bek MA (2014) Experimental investigation of a novel indirect solar dryer implementing PCM as energy storage medium. Energy Conversion Manag 83:1–8. https://doi.org/10.1016/j.enconman.2014.03.043

Sharma N, Garcha S, Singh S (2019) Potential of Lactococcus lactis subsp. lactis MTCC 3041 as a bio-preservative. Journal of Microbiology. Biotechnol Food Sci 2019:168–171

Singh V, Hedayetullah M, Zaman P, Meher J (2014) Post-harvest technology of fruits and vegetables: an overview. J Postharvest Technol 2(2):124–135

Singh P, Gaur MK (2021a) Environmental and economic analysis of novel hybrid active greenhouse solar dryer with evacuated tube solar collector. Sustain Energy Technol Assessments 47:101428. https://doi.org/10.1016/j.seta.2021.101428

Singh P, Gaur MK (2021b) Heat transfer analysis of hybrid active greenhouse solar dryer attached with evacuated tube solar collector. Solar Energy 224:1178–1192. https://doi.org/10.1016/j.solener.2021.06.050

Singh S, Kumar S (2012) Testing method for thermal performance based rating of various solar dryer designs. Solar Energy 86(1):87–98. https://doi.org/10.1016/j.solener.2011.09.009

Suárez MH, Rodríguez ER, Romero CD (2007) Mineral and trace element concentrations in cultivars of tomatoes. Food Chem 104(2):489–499. https://doi.org/10.1016/j.foodchem.2006.11.072

Taiwo A, Bart-Plange A (2016) Factors responsible for post-harvest losses and their effects on rice producing farmers: a case study of Afife and Aveyime rice projects in the Volta region of Ghana. Int Res J Eng Technol 3(4):2395–0056

Vijayan S, Arjunan TV, Kumar A (2020) Exergo-environmental analysis of an indirect forced convection solar dryer for drying bitter gourd slices. Renewable Energy 146:2210–2223. https://doi.org/10.1016/j.renene.2019.08.066

Wang J, Xiong YS, Yu Y (2004) Microwave drying characteristics of potato and the effect of different microwave powers on the dried quality of potato. Eur Food Res Technol 219(5):500–506. https://doi.org/10.1007/s00217-004-0979-1

Acknowledgements

The authors acknowledge CIF, BIT, Mesra, Ranchi, for providing support in this research.

Availability of data and materials

The datasets used and/or analysed during the current study are available from the corresponding author on reasonable request.

Funding

Not applicable

Author information

Authors and Affiliations

Contributions

Asim Ahmad: conceptualization, methodology, investigation, data curation, writing—original draft.

Om Prakash: validation, supervision, writing—review and editing.

Anil Kumar: investigation, review and editing.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ahmad, A., Prakash, O. & Kumar, A. Drying kinetics and economic analysis of bitter gourd flakes drying inside hybrid greenhouse dryer. Environ Sci Pollut Res 30, 72026–72040 (2023). https://doi.org/10.1007/s11356-021-17044-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-17044-x