Abstract

Background

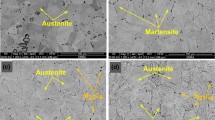

At certain temperatures and strain rates, low carbon steels, as well as some aluminum and magnesium-based alloys, exhibit plastic flow instability at the onset of their respective yield points, known as the Lüders phenomena. Such phenomenon is recognized by a distinct yield point and subsequent plateau on the stress-strain curve, and takes the form of a band when full-field tensile strain contours are observed experimentally.

Objective

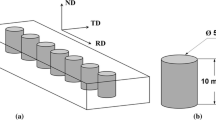

This paper aims to investigate the specimen thickness dependence of the Lüders effect in AISI 1524 hot-rolled steel alloy. Sixteen samples were cut from hot-rolled plates and uniaxial testing in conjunction with digital image correlation were performed to gain insight and quantify the Lüders band’s spatial characteristics during the extent of the plateau. More specifically, 1 mm, 2 mm, 3 mm, and 4 mm thick flat specimens of mild steel were tested under identical conditions, most notably strain rate, in order to isolate and understand the effect of specimen thickness.

Results

Results revealed that both the Lüders band width and velocity depend on the specimen thickness. An increase in specimen thickness resulted in an increase in Lüders band width, and an increase in Lüders band velocity on 1524 steel alloy. Moreover, the angle at which the Lüders band appeared on the front surface of the specimen with respect to the different thicknesses revealed the 3D nature of the band’s formation.

Conclusions

The obtained results and observations suggested a 3D nature of the band’s formation in AISI 1524; whereby nucleation takes place at the core of the material before propagating in the thickness direction towards the structure’s surface. Moreover, it was concluded that the Lüders band special features, width and velocity is dependent on a structure’s thickness.

Similar content being viewed by others

Data Availability

The data that supports the findings of this study is available from the corresponding author upon request.

References

Ananthan V, Hall E (1991) Macroscopic aspects of Lüders band deformation in mild steel. Acta Metallurgica et Materialia 39(12):3153–3160

Kyriakides S, Miller JE (2000) On the Propagation of Luders Bands in Steel Strips. J Appl Mech 67(4):645–654

Onodera R, Nonomura M, Aramaki M (2000)Stress Drop, Luders Strain and Strain Rate during Serrated Flow. J Japan Ins Metals Mater 64(12):1162-1171

Nagarajan S, Narayanaswamy R, Balasubramaniam V (2013) An Insight into Lüders Deformation Using Advanced Imaging Techniques. J Mater Eng Perform 22:3085–3092

Cottrell AH, Bilby BA (1949) Dislocation Theory of Yielding and Strain Ageing of Iron. In Proc Phys Soc Section A 62(1)

Rešković S, Jandrlić I, Vodopivec F (2016) Influence of Testing Rate on Lüders Band Propagation in Niobium Microalloyed Steel. Metalurgija 55(2):157–160

Cai Y-L, Yang S-L, Fu S-H, Zhang Q-C (2016) The Influence of Specimen Thickness on the Lüders Effect of a 5456 Al-Based Alloy: Experimental Observations. Metals 6(5):120

Sun HB, Yoshida F, Ohmori M, Ma X (2003) Effect of strain rate on Lüders band propagating velocity and Lüders strain for annealed mild steel under uniaxial tension. Mater Lett 57:4535–4539

Zhang J, Jiang Y (2005) Luders bands propagation of 1045 steel under multiaxial stress state. Mater Lett 21:651–670

Brlić T, Rešković S, Vodopivec F, Jandrlić I (2018) Lüders Bands at the Beginning of the Plastic Flow of Materials. Metalurgija 47(10):357–359

Ren SC, Morgeneyer TF, Mazière M, Forest S (2021) Effect of Lüders and Portevin–Le Chatelier localization bands on plasticity and fracture of notched steel specimens studied by DIC and FE simulations. Int J Plast 136

Johnson DH (2012) Lüders Bands in RPV Steel. In Ph.D Dissertation, Department of Eng. and Appl. Sc., Cranfield University, Cranfield

Zhang W, Kyriakides S (2022) Evolution of Lüders banding under axial loading and reverse loading. Int J Solids Struct

ASTM (2021) ASTM E415-21: Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry. ASTM Int

ASTM (2021) Standard Test Methods for Determining Average Grain Size. ASTM Int

Tsuchidaa N, Masuda H, Harada Y, Fukaura K, Tomato Y, Nagai K (2008) Effect of ferrite grain size on tensile deformation behavior of a ferrite-cementite low carbon steel. Mater Sci Eng A 488(1–2):446–452

Correlated Solutions, Inc. Vic-3D 9 Manual and Testing Guide. https://correlated.kayako.com/article/60-vic-3d-9-manualand-testing-guide

Tsuchida N, Tomato Y, Nagai K, Fukaura K (2006) A simple relationship between Lüders elongation and work-hardening rate at lower yield stress. Scripta Mater 54(1):57–60

ASTM (2022) ASTM E8/E8M-22: Standard Test Methods for Tension Testing of Metallic Materials. ASTM Int

Qiu H, Inoue T, Ueji R (2020) Experimental measurement of the variables of Lüders deformation in hot-rolled steel via digital image correlation. Mater Sci Eng A 790

Qiu H, Inoue T, Ueji R (2020) In-Situ Observation of Lüders Band Formation in Hot-Rolled Steel via Digital Image Correlation. Metals 10(4):530

Wang XG, He BB, Liu CH, Jiang C, Huang MX (2019) Extraordinary Lüders-strain-rate in medium Mn steels. Materialia 6

Shariat BS, Li Y, Yang H, Wang Y, Liu Y (2022) On the Lüders band formation and propagation in NiTi shape memory alloys. J Mater Sci Technol 116:22–29

Johnson D, Edwards M, Chard-Tuckey P (2015) Microstructural effects on the magnitude of Lüders strains in a low alloy steel. Mater Sci Eng A 625:36–45

Acknowledgements

The authors would like to thank S. Raviprakash and Abhishek G. from Pyrodynamics for their technical assistance with DIC. The authors are also grateful to Dr. Priyank Upadhyaya and Sudip Baul from BITS Pilani, Dubai Campus for allowing access to their Digital Microscope for this study.

Funding

This research received no specific grant from any funding agency.

Author information

Authors and Affiliations

Contributions

Conceptualization: [Wael A. Samad]; Methodology: [Joost H. van der Heijde & Wael A. Samad]; Material Preparation [Joost H. van der Heijde]; Experimentation [Joost H. van der Heijde & Wael A. Samad]; Formal analysis and investigation: [Joost H. van der Heijde & Wael A. Samad]; Writing - original draft preparation: [Joost H. van der Heijde]; Writing - review and editing: [Joost H. van der Heijde & Wael A. Samad]; Supervision: [Wael A. Samad].

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personalrelationships that could have appeared to influence the findings reported in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

van der Heijde, J.H., Samad, W.A. The Effect of Specimen Thickness on the Lüders Phenomena in AISI 1524 Steel Alloy: Experimental Observations Using DIC. Exp Mech 63, 885–896 (2023). https://doi.org/10.1007/s11340-023-00951-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00951-0