Abstract

Background

Multiaxial dynamic loadings occur in many industrial cases and multiaxial dynamic test development is thus a crucial issue.

Objective

To meet this challenge, a biaxial compression Hopkinson bar set-up is designed.

Methods

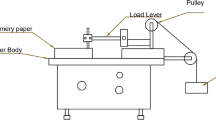

The set-up consists of a striker, an input bar, an internal output bar and a co-axial external output tube (surrounding the internal bar). The internal output bar measures the axial loading of the cross sample whereas the external output bar measures the transverse one via a mechanism. This mechanism uses two intermediate parts with inclined sliding surfaces.

Results

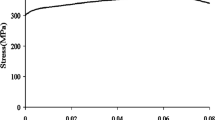

Gauges on the bars enable for force measurements in the set-up, and the sample displacement field is obtained by digital image correlation. Simple compression tests on cuboid samples inserted between the input bar and the internal output bar give the sample material behavior. Then, to determine the friction at the mechanism sliding surfaces, identical samples are inserted between the input bar and the external output bar, and are compressed.

Conclusions

Finally, the consistency of the measurements obtained during a biaxial compression test on a cross sample can be checked from the previously measured parameters and from numerical simulations.

Similar content being viewed by others

References

Durrenberger L (2007) Analyse de la pré-déformation plastique sur la tenue au crash d’une structure crash-box par approches expérimentale et numérique. PhD Report, Paul VERLAINE University of Metz. In French

Liu W (2015) Identification of strain rate dependent hardening sensitivity of metallic sheets under in-plane biaxial loading. PhD Report, INSA de Rennes

Guo Y, Efe M, Moscoso W, Sagapuram D, Trumble KP, Chandrasekar S (2012) Deformation field in large-strain extrusion machining and implications for deformation processing. Scr Mater 66:235–238

Chen W, Song B (2011) Split Hopkinson (Kolsky) Bar. Design, Testing and Applications. Springer Science & Business Media, LLC

Durand B, Delvare F, Bailly P, Picart D (2016) A split Hopkinson pressure bar device to carry out confined friction tests under high pressures. International Journal of Impact Engineering 88:54–60

Bailly P, Delvare F, Vial J, Hanus JL, Biessy M, Picart D (2011) Dynamic behavior of an aggregate material at simultaneous high pressure and strain rate: SHPB triaxial tests. International Journal of Impact Engineering 38:73–84

Albertini C, Cadoni E, Solomos G (2014) Advances in the Hopkinson bar testing of irradiated/non-irradiated nuclear materials and large specimens. Philosophical transactions of the Royal Society A. Mathematical, physical and engineering sciences, 372, 2015

Rittel D, Lee S, Ravichandran G (2002) A shear-compression specimen for large strain testing. Exp Mech 42(1):58–64

Hou B, Ono A, Abdennadher S, Pattofatto S, Li YL, Zhao H (2011) Impact behavior of honeycombs under combined shear-compression. Part I: Experiments International Journal of Solids and Structures 48(5):687–697

Lewis JL, Goldsmith W. A Biaxial Split Hopkinson Bar for Simultaneous Torsion and Compression. Review of Scientific Instruments, 44(811) (1973)

Stiebler K, Kunze HD, El-Magd E (1991) Description of the flow behavior of a high strength austenitic steel under biaxial loading by a constitutive equation. Nucl Eng Des 127:85–93

Philippon S, Voyiadjis GZ, Faure L, Lodygowski A, Rusinek A, Chevrier P, Dossou E (2011) A device enhancement for the dry sliding friction coefficient measurement between steel 1080 and VascoMax with respect to surface roughness changes. Exp Mech 51(3):337–358

Albertini C, Montagnani M (1980) Dynamic uniaxial and biaxial stress-strain relationships for austenitic stainless steels. Nucl Eng Des 57:107–123

Hummeltenberg A, Curbach M. Entwurf und Aufbau eines zweiaxialen Split-Hopkinson-Bars. Beton- und Stahlbetonbau, 107(5) (2012). In German

Grolleau V, Gary G, Mohr D (2008) Biaxial testing of sheet materials at high strain rates using viscoelastic bars. Exp Mech 48:293–306

Roux S, Hild F, Leclerc H (2012) Mechanical Assistance to DIC. Proceedings of Full-Field Measurements and Identification in Solid Mechanics. F. Hild and H. Espinosa eds., Procedia IUTAM 4, 159–168, Elsevier

Tomicevc Z, Hild F, Roux S (2013) Mechanics-aided digital image correlation. Journal of Strain Analysis 48(5):330–343

Acknowledgments

The authors thank their colleague F. Hild for his advice, which helped to improve the article.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Durand, B., Quillery, P., Zouari, A. et al. Exploratory Tests on a Biaxial Compression Hopkinson Bar Set-up. Exp Mech 61, 419–429 (2021). https://doi.org/10.1007/s11340-020-00665-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00665-7