Abstract

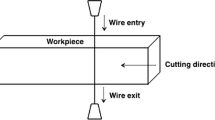

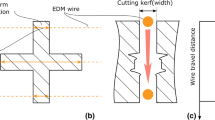

The contour method was applied to obtain residual stress fields in a laser-peened 2.0-mm-thick Al2024-T351 sample. In order to remove the effects of near-surface wire electro-discharge machining (EDM) cutting artefacts on the measured residual stresses, sacrificial blocks were attached to both surfaces of the thin sample with a polymer-based glue doped with silver particles. A data analysis routine based on bivariate spline smoothing was conducted to obtain a 2D residual stress map. The results were compared with incremental hole drilling, and X-ray diffraction and layer removal techniques. The results are in good agreement in terms of the magnitudes and the location of the peak stresses, with the exception of the contour method results. Owing to the low thickness of the samples, the data analysis is very sensitive to the parameters used in the spline fitting, leading to fluctuation in the results. It is concluded that the contour method can be applied to thin samples, however, extra attention is required. Since the uncertainty is higher compared to the conventional contour method results, it is good practice to compare the results with at least one other experimental method.

Similar content being viewed by others

References

Prime MB, Gonzales AR (2000) The contour method: simple 2-D mapping of residual stresses. In: Webster GA (ed) Sixth international conference on residual stresses. Maney Publishing, Oxford, pp 617–624

Ahmad B, Fitzpatrick M (2015) Effect of ultrasonic peening and accelerated corrosion exposure on the residual stress distribution in welded marine steel. Metall Mater Trans A 46(3):1214–1226. doi:10.1007/s11661-014-2713-3

Hosseinzadeh F, Toparli MB, Bouchard PJ (2012) Slitting and contour method residual stress measurements in an edge welded beam. J Press Vessel Technol 134:0114021–0114026

Evans A, Johnson G, King A, Withers PJ (2007) Characterization of laser peening residual stresses in Al 7075 by synchrotron diffraction and the contour method. J Neutron Res 15(2):147–154

Moat RJ, Pinkerton AJ, Li L, Withers PJ, Preuss M (2011) Residual stresses in laser direct metal deposited Waspaloy. Mater Sci Eng A 528(6):2288–2298. doi:10.1016/j.msea.2010.12.010

Araujo de Oliveira J, Fitzpatrick ME, Kowal J (2014) Residual stress measurements on a metal matrix composite using the contour method with brittle fracture. Adv Mater Res 996:349–354. doi:10.4028/www.scientific.net/AMR.996.349

DeWald A, Hill M (2006) Multi-axial contour method for mapping residual stresses in continuously processed bodies. Exp Mech 46(4):473–490

Kartal ME, Liljedahl CDM, Gungor S, Edwards L, Fitzpatrick ME (2008) Determination of the profile of the complete residual stress tensor in a VPPA weld using the multi-axial contour method. Acta Mater 56(16):4417–4428

Coratella S, Sticchi M, Toparli MB, Fitzpatrick ME, Kashaev N. Application of the eigenstrain approach to predict the residual stress distribution in laser shock peened AA7050-T7451 samples. Surf Coat Technol 273:39–49. doi: 10.1016/j.surfcoat.2015.03.026

Prime MB, Newborn MA, Balog JA (2003) Quenching and cold-work residual stresses in aluminum hand forgings: contour method measurement and FEM prediction. Mater Sci Forum 426–432:435–440

Pagliaro P, Prime M, Swenson H, Zuccarello B (2010) Measuring multiple residual-stress components using the contour method and multiple cuts. Exp Mech 50(2):187–194. doi:10.1007/s11340-009-9280-3

Pagliaro P, Prime M, Robinson JS, Clausen B, Swenson H, Steinzig M, Zuccarello B (2011) Measuring inaccessible residual stresses using multiple methods and superposition. Exp Mech 51(7):1123–1134. doi:10.1007/s11340-010-9424-5

Toparli MB, Fitzpatrick M, Gungor S (2015) Determination of multiple near-surface residual stress components in laser peened aluminum alloy via the contour method. Metall Mater Trans A 46(9):4268–4275. doi:10.1007/s11661-015-3026-x

Prime MB, Kastengren AL (2010) The contour method cutting assumption: error minimization and correction. In: Proulx T (ed) SEM annual conference & exposition on experimental and applied mechanics. Indianapolis, Indiana USA, June 7 - 9, 2010. p paper # 507

Toparli MB, Fitzpatrick ME, Gungor S (2013) Improvement of the contour method for measurement of near-surface residual stresses from laser peening. Exp Mech 53(9):1705–1718. doi:10.1007/s11340-013-9766-x

Clauer AH (1996) Laser shock peening for fatigue resistance. In: Gregory JK, Rack HJ, Eylon D (eds) Proceedings of surface performance of titanium, TMS Warrendale, The Metal Society of AIME, pp 217–230

Obata M, Sano Y, Mukai N, Yoda M, Shima S, Kanno M (1999) Effects of laser peening on residual stress and stress corrosion cracking for type 304 stainless steel. In: Nakonieczny A (ed) The seventh international conference on shot peening. Warsaw, Poland. pp 387-394

Peyre P, Fabbro R (1995) Laser shock processing: a review of the physics and applications. Opt Quant Electron 27(12):1213–1229

Peyre P, Fabbro R, Merrien P, Lieurade HP (1996) Laser shock processing of aluminium alloys. Application to high cycle fatigue behaviour. Mater Sci Eng A 210(1–2):102–113

Richter-Trummer V, Moreira PMGP, Ribeiro J, Tavares de Castro PMS (2011) The contour method for residual stress determination applied to an AA6082-T6 friction stir butt weld. Mater Sci Forum 681:177–181. doi:10.4028/www.scientific.net/MSF.681.177

Toparli MB (2012) Analysis of residual stress fields in aerospace materials after laser peening. The Open University, Milton Keynes

Fitzpatrick ME, Fry AT, Holdway P, Kandil FA, Suominen L (2005) Determination of residual stresses by X-ray diffraction - Issue 2. Measurement Good Practice Guide No: 52. The National Physical Laboratory (NPL)

Clausen B, Lorentzen T, Leffers T (1998) Self-consistent modelling of the plastic deformation of f.c.c. polycrystals and its implications for diffraction measurements of internal stresses. Acta Mater 46(9):3087–3098

Grant PV, Lord JD, Whitehead P (2006) The measurement of residual stresses by the incremental hole drilling technique - issue 2. Measurement good practice guide No: 53. The National Physical Laboratory (NPL)

Schajer GS (1988) Measurement of non-uniform residual stresses using the hole-drilling method. Part II---practical application of the integral method. J Eng Mater Technol 110(4):344–349

Prime M, Sebring R, Edwards J, Hughes D, Webster P (2004) Laser surface-contouring and spline data-smoothing for residual stress measurement. Exp Mech 44(2):176–184

Johnson G (2008) Residual stress measurements using the contour method. University of Manchester

Dorman M, Toparli MB, Smyth N, Cini A, Fitzpatrick ME, Irving PE (2012) Effect of laser shock peening on residual stress and fatigue life of clad 2024 aluminium sheet containing scribe defects. Mater Sci Eng A 548:142–151

Acknowledgments

The authors would like to thank to Dr Domenico Furfari of Airbus Deutschland and Professor José Ocaña of Universidad Politecnica Madrid for the samples and laser peening. Special thanks to Professor Philip Withers and Mr Abdulsameea Jilabi of Manchester University for the surface contour measurements by laser profilometer. MEF is grateful for funding from the Lloyd’s Register Foundation, a charitable foundation helping to protect life and property by supporting engineering-related education, public engagement and the application of research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Toparli, M.B., Fitzpatrick, M.E. Development and Application of the Contour Method to Determine the Residual Stresses in Thin Laser-Peened Aluminium Alloy Plates. Exp Mech 56, 323–330 (2016). https://doi.org/10.1007/s11340-015-0100-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-015-0100-7