Abstract

This study aimed to investigate the compostability of wastewater treatment sludge and evaluate the effects on compost quality of adding cotton gin waste and peanut shell. For this purpose, treatment sludge was mixed with cotton gin waste in the ratios of 60:40 in M1 reactor and 80:20 in M2 reactor, while in M3 and M4 reactors, treatment sludge was mixed with peanut shell in the same proportions. The highest temperatures were reached in reactors M2 (65.2 °C) and M4 (68.7 °C) where 80% treatment sludge was added. These reactors also experienced the highest organic matter losses of 42.2% and 31.5%, respectively. It can be stated that a faster microbial decomposition and stabilization occurred in these reactors. It can be said that the composting process may be a preferable method for the management of treatment sludge and agricultural wastes. Furthermore, the outcomes of the study can serve the food industry and agriculture sector through effective bioconversion of organic waste.

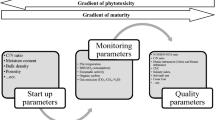

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The sludge generated in wastewater treatment plants contains significant amounts of valuable nutrients such as organic matter and trace elements. Due to these characteristics, it holds promising potential for agricultural applications and can be recycled by being used as soil amendments (Luo et al., 2024). However, if not properly treated, sludges can spread pathogens and pose a danger to the environment and human health by causing pollution, due to their harmful properties such as high moisture content, unstable forms, pathogenic microorganisms, and synthetic organic pollutants (Meng et al., 2021; Uçaroğlu & Alkan, 2016). For the disposal of sludges, various methods are used such as landfilling, incineration, gasification, hydrothermal carbonization, alkaline chemical usage, anaerobic digestion, and agricultural application (Liew et al., 2022). Composting has received significant attention as an effective and economical recovery and treatment method due to its effectiveness in removing pathogens and organic pollutants contained in sludges (Guo et al., 2020; Li et al., 2017; Yan et al., 2015).

Composting is a biological transformation technology that enables the biodegradation of organic waste by various microorganisms, converting unstable carbon and nitrogen forms into stable organic forms. It also ensures the elimination of pathogenic microorganisms, reduces waste volume, and produces compost, a biologically stable soil amendment material (Ruggieri et al., 2008; Zhu, 2006). This transformation is influenced by the characteristics of the raw materials used in the process, and therefore, the quality and maturity of the compost produced are determined by the raw materials used. In order for microbial degradation to occur in composting, it is necessary to create optimal conditions, particularly in terms of moisture, C/N ratio, and porosity (Ingelmo et al., 2012). Organic wastes with high moisture, low C/N ratio, and low porosity characteristics, such as treatment sludge, need to be composted with bulking agents (BA) that regulate these characteristics (Zhao et al., 2016).Agricultural wastes, which can be utilized to modify these properties, are a highly suitable alternative as bulking agents (Rigane & Medhioub, 2011). In composting, bulking agents are of great interest due to their ease of availability, their ability to provide an optimal microbial habitat, and the fact that they provide a carbon source. With these characteristics, they have the ability to facilitate microbial and enzymatic activities (Jiao et al., 2023). Several studies have been conducted on the composting of treatment sludge and agricultural waste, either separately or together. Researchers have investigated the composting of sewage sludge and shrub clippings (Margesin et al., 2006), wheat straw, plane leaf, corncob, and sunflower stalk with food industry sludge (Uçaroğlu & Alkan, 2016), sewage sludge with rape straw, wheat straw, maize straw, and rice straw (Zhao et al., 2016), almond shell, sesame bark, olive cake, olive mill wastewater sludge, and poultry manure (Rigane & Medhioub, 2011), concentrated depotassified beet vinasse and cotton gin waste (Dı́az et al., 2002), oil refinery sludge with shredded green waste (Fountoulakis et al., 2009), green wastes co-composting with olive mill wastewater sludge and coffee grounds (Fersi et al., 2019), and dewatered stabilized sludge with park and garden pruning waste (Al-Alawi et al., 2020).

Cotton gin waste (CW) and peanut shell (PS), which are agricultural residues, have been used in some composting studies (Dı́az et al., 2002; Erickson et al., 2010; Iqbal et al., 2010; Jackson et al., 2005; Tejada & Gonzalez, 2003; S. Zhang et al., 2019). In these studies, cotton bolls and peanut shells were composted alone or mixed with wastes such as different agricultural waste and animal manure. However, there is no study on composting these agricultural wastes together with treatment sludge (TS). In this study, food industry wastewater treatment sludge, which has a high organic load and significant nutrient elements, was composted using two different agricultural wastes (CW and PS) in two different ratios as bulking agents. The objective of this study was to determine the effectiveness of two different agricultural waste materials in composting food industry sludge, by monitoring the physical and chemical changes. The study also aimed to compare the utilization rates and determine the most suitable compost composition that ensures optimum stabilization. This study demonstrates that the food industry, which produces treatment sludge, can manage these wastes through the composting process, which enables their bioconversion.

2 Materials and Methods

2.1 Raw Compost Materials and Experimental Equipment

The wastewater treatment sludge was composted in aerobic reactors together with cotton gin waste and peanut shell. In the study, sludge obtained from a food industry treatment plant was used. In the food industry, which is involved in the processing of fruits and vegetables, the wastewater entering the treatment plant consists of domestic wastewater and process wastewater. The treatment sludge was taken from the filter press outlet. Cotton gin waste and peanut shell were used as bulking agents. The cotton gin waste was obtained from a cotton processing facility located in Şanlıurfa. The peanut shell was sourced from a nut factory located in Osmaniye. Bulking agents were ground to a suitable particle size (1–2 cm) for the composting process.

The aerobic composting process was carried out in batch reactors. Air was supplied to the reactors through an aquarium pump with the flow rate controlled by a rotameter, and the in-process air quantities were recorded. A time-controlled solenoid valve was used for aeration, providing 600–700 ml/min of air for 15 min every hour. The temperature inside the reactor was monitored using a temperature probe, and the in-process temperature values were recorded. To maintain the temperature of the waste mass and prevent heat exchange with the surroundings, the sides and bottom of the reactor were insulated. To ensure the homogeneous distribution of air within the waste, a grid was placed 5 cm above the reactor base. The aerated composting reactor was made of stainless-steel material with an internal diameter of 300 mm, a thickness of 10 mm, and a height of 450 mm. Its useful volume was 30 L.

2.2 Method

The treatment sludge was composted for 21 days in four separate reactors (M1, M2, M3, and M4) by mixing it with bulking agents (CW and PS). After the active composting phase, the material was removed from the reactors and matured until the 60th day. M1 and M2 reactors were filled with treatment sludge mixed with cotton gin waste as a bulking agent in the ratios of 60:40 and 80:20, respectively. In M3 and M4 reactors, the same ratios of treatment sludge and bulking agent were used, but peanut shells were added as the bulking agent. The mixture recipes are given in Table 1. To ensure the homogeneity and aeration of the compost mixture, the reactors were manually stirred on alternate days and on sampling days. To calculate the dry matter (DM) losses occurring in the reactors, the reactors were weighed at the beginning of the experiment, on each sampling day (2nd, 7th, and 14th days), and at the end of the experiment. Temperature and air values were continuously monitored using a SCADA program at a frequency of one data point per minute throughout the process.

2.3 Analytical Methods

Samples were taken from the mixtures in the reactors on days 0, 2, 7, 14, and 21 for experimental studies. For all compost samples, the initial TS and BA were analyzed in triplicate. Throughout the composting process, changes in temperature, pH, EC, DM, OM, total Kjeldahl nitrogen (TKN), carbon to nitrogen ratio (C/N), nitrate-nitrogen (NO3-N), ammonium-nitrogen (NH4-N) and free air space (FAS) parameters were monitored. pH and EC values of the TS, BA and compost samples were determined in a 1:10 distilled water extract (McLean, 1982; Rhoades, 1982). The DM content of the samples was calculated by weighing the weight loss of the samples dried at 105 °C, taking into account the volatile matter content calculated based on the combustion loss at 550 °C (APHA, AWWA 1998). As stated by several researchers, OM (%) was calculated as OM (%) = 100—ash (%) (Diaz et al., 2007; Khalil et al., 2011; Okalebo et al., 1993). Concentrations of readily oxidizable organic carbon (OC) for raw materials were determined spectrophotometrically at 590 nm after the samples were oxidized with a potassium dichromate solution (Nelson & Sommers, 1982). The concentrations of OC in the compost mixtures were calculated using the equation OC% = (100—ash%)/1.8, based on the ash content of the samples (Haug, 1993). In order to determine the concentrations of NH4-N and NO3-N, samples were extracted with 2 M potassium chloride (KCl), and the concentrations in these extracts were measured by steam distillation with magnesium oxide (MgO) and Devarda's alloy (Keeney & Nelson, 1982). TKN of the samples was determined by the Kjeldahl digestion method (Bremner & Mulvaney, 1982). FAS was determined using the method proposed by Madejón et al. (2002). OM losses (degradability coefficient) were calculated using the following equation based on the initial and final OM contents (Benito et al., 2003; Haug, 1993):

3 Results and Discussion

The results for the physical and chemical properties of treatment sludge and bulking agents are presented in Table 2. The treatment sludge was slightly basic, with a pH value of 8.45. The EC of the treatment sludge was 2.63 mS/cm. In addition, the results showed that the sludge was an important potential source of plant nutrients. The total Kjeldahl nitrogen and total phosphorus (TP) contents of the treatment sludge were 2.5% and 1.75%, respectively. However, while the organic matter content of the used bulking agents (CW and PS) was 83.5% and 85.8% respectively, the treatment sludge had a value of 67.6%. Similarly, the organic carbon content in the bulking agents was 31.6% and 33.0%, whereas the treatment sludge had a lower organic carbon content of 17.5%. The treatment sludge had a high moisture content (84.4%) and a low C/N ratio (7.1). Therefore, in order to obtain compost from this treatment sludge, it was necessary to mix it with bulking agents to provide a carbonaceous and fibrous material source and to regulate moisture and C/N ratio. The added bulking agents also provided a porous environment that allowed for air flow. Sharma and Yadav (2017) mentioned in their study that the bulking agent regulated the moisture of the environment and provided free air space.

The initial characterization of compost mixtures (M1, M2, M3, and M4) placed in the compost reactors is given in Table 3. The pH values in all reactors were in the range of 6 to 7, which are suitable for the composting process. Additionally, due to the addition of regulatory bulking agents to the reactors, there was a significant increase in organic matter and carbon contents, as well as a decrease in moisture content. The optimal moisture range for the biodegradation of different compost mixtures is between 50 and 70% (Richard et al., 2002). The initial moisture values of the reactors were within the appropriate range, ranging from 53 to 69%. By mixing bulking agents having a moisture content of approximately 20% with treatment sludge having a high moisture content (84.4%), the initial moisture values in the reactors could be reduced depending on the mixture ratio. The regulatory bulking agents, due to their high C/N ratio values (39.0 and 61.1), increased the C/N ratios of the mixtures when added to the treatment sludge with a low C/N ratio (7.1). The initial C/N ratios in the reactors were in the range of 20 to 30. Values of C/N ratio within 15–30 are recommended for composting (Haug, 1993). The initial C/N values in all reactors were within the recommended range.

3.1 Temperature Changes

Temperature is one of the most important parameters affecting the dynamics of the composting process. Variations in substrate temperature provide crucial information for evaluating composting performance. During the composting process, an increase in temperature occurs due to the presence of organic matter in the environment and the fermentation process driven by microbial activity (Vráblová et al., 2024; Zhang et al., 2012). In terms of compliance with legal requirements, reaching thermophilic temperatures is important to eliminate pathogens and sterilize the waste in the composting process. The temperatures in the composting reactors and ambient temperatures are shown in Fig. 1. In the M1 and M2 reactors, where cotton gin waste was used as a bulking agent, the maximum temperatures measured were 53.3 °C and 65.2 °C, respectively. In the M3 and M4 reactors, where peanut shell was used as a bulking agent, the maximum temperatures measured were 58.5 °C and 68.7 °C, respectively. In the reactors where peanut shell was used as the bulking agent (M3 and M4), the temperature increased more compared to the reactors (M1 and M2) where cotton gin waste was used. According to the United States Environmental Protection Agency (USEPA), for pathogen control, the waste should remain for at least 5 days at 40 °C in the reactor, and during this period, the temperature should exceed 55 °C for 4 h (USEPA, 1993). Anand and Apul (2014) stated that in a well-functioning composting process, the optimum temperatures should be in the range of 40–65˚C, while González et al. (2019) indicated that for a high biological degradation rate, the temperature should be between 45–55 °C. In the M1 reactor (60% TS + 40% CW), the temperature remained above 40 °C for approximately 6 days but did not reach 55 °C. In the M2 reactor (80% TS + 20% CW), the temperature remained above 40 °C for 13 days, and during this period, it exceeded 55 °C for approximately 2.5 days. In the M3 reactor (60% TS + 40% PS), the temperature remained above 40 °C for approximately 9 days and exceeded 55 °C for approximately 1.5 days. In the M4 reactor (80% TS + 20% PS), the temperature remained above 40 °C for approximately 10.5 days, and during this period, it exceeded 55 °C for approximately 1.5 days. When examining the temperature records, it can be observed that all reactors stayed in the thermophilic phase above 40 °C for more than 5 days, and that only the M1 reactor did not reach 55 °C, while the other reactors remained above 55 °C for a sufficient duration.

According to these results, considering the USEPA criteria, significant pathogen removal and microbial stabilization were achieved in the M2, M3, and M4 reactors. In the reactors where bulking agents were used at a rate of 80% (M2 and M4), higher temperatures were reached, and the reactors remained in the thermophilic phase for a longer period (10–13 days), indicating that the reactors achieved a high rate of biological degradation.

In the composting study conducted by Vráblová et al. (2024), it was reported that the mixtures remained in the range of 45–55 °C for approximately 10–25 days and achieved a high rate of biological degradation. In the study conducted by González et al. (2019), it was stated that increasing the retention time in dynamic compost piles from 4 to 14 days resulted in higher biological degradation, which could shorten the maturation period, allowing for more material processing. In their study, Wu et al. (2021) stated that the thermophilic phase duration was 11–12 days in successful compost trials, which increased microbial activity and accelerated the decomposition of organic matter. Although the highest temperature (68.7 °C) was reached in the reactor where 20% peanut shell was used (M4), the reactor with the same proportion of cotton gin waste (M2) remained in the thermophilic phase for a longer period. In the M2 and M4 reactors, where there was a higher proportion of treatment sludge, the higher amount of easily degradable organic matter led to an increase in the microbial population in the environment and resulted in higher temperatures being generated, thus prolonging the thermophilic phase compared to the other reactors. When the temperature exceeds 65 °C in the composting process, most thermophilic microorganisms cannot tolerate this high temperature, leading to a decrease in composting activity (Germer et al., 2010). It is believed that when the temperature in the M4 reactor exceeded 65 °C, the microorganisms were harmed and composting activity decreased, resulting in a shorter duration of the thermophilic phase compared to the M2 reactor.

3.2 The Effect of Bulking Agents on the Variation of Physical and Chemical Parameters

3.2.1 pH

pH plays an important role in influencing the biochemical reactions throughout the composting process. Various types of microorganisms are involved in composting, and each group of microorganisms has a specific pH range in which they thrive. The pH range is typically between 6 and 8 for bacteria, while fungi prefer an acidic environment. The pH value fluctuates during the process and reaches values between 7.8 and 8.0 at the end of composting (Graves & Hattemer, 2010). Studies have shown that the optimum pH range for active organisms in the composting process, especially during the breakdown of glucose and proteins, is around 7–8. It has also been determined that glucose degrades more rapidly within pH values of 6–9 (Nakasaki et al., 1993). In this study, the pH variations throughout the composting process are presented in Fig. 2(a). When the cotton gin waste and peanut shell, used as bulking agents with lower pH values of 5.7 and 5.6, respectively, where mixed with treatment sludge having a higher pH value of 8.5, the initial pH values of the compost mixtures were balanced in the ideal range of 6.0–7.0 for the composting process. Treatment sludges generally increase the soil pH when applied to the soil (Achkir et al., 2023). Therefore, mixing treatment sludge with bulking agent in the composting process has a positive effect. During the active composting phase (21 days), an increase in pH values was observed in all reactors due to the temperature rise. The pH values reached 7.1, 7.4, 7.0, and 7.6 for M1, M2, M3, and M4 reactors, respectively. In the maturation phase, on the 60th day, the pH values slightly increased further, ranging between 7.7 and 7.9 for all reactors. The pH increases at the end of the process were due to ammonification (Negi et al., 2020). The decreases in pH values observed during the process indicate the possible formation of organic acids as a result of organic matter decomposition, and the organic acids generated through microbial activity are then broken down, leading to an increase in pH values (Diaz et al., 2007). Throughout the composting process and after maturation, the pH values of the obtained composts in all reactors were within the preferred range.

3.2.2 Electrical Conductivity (EC)

The compost obtained at the end of the composting process is used as a soil amendment for various purposes such as agricultural production, erosion control, rehabilitation of old mining sites and quarries, remediation of contaminated areas, etc. The quality of the obtained compost determines its purpose of use. Electrical conductivity is an indicator of the concentration of dissolved salts and ion levels in the compost, and it is an influential factor in plant growth and development, as well as an important determinant of compost quality. Generally, at the beginning, organic matter decomposition accelerates with strong microbial activity, resulting in the rapid production of organic acids and various ions, thereby increasing the EC value (Gao et al., 2010). During the thermophilic phase, significant amounts of NH3 and CO2 are released from the environment due to high temperature and high pH. This leads to the conversion of small molecular organic acids and some salt ions into macromolecules, resulting in a decrease in EC (Yuan et al., 2016). Furthermore, this decrease may be attributed to the adsorption of cations onto the substrate, which can lead to the precipitation of ionic salts into carbonates (Zhou et al., 2018). The changes in EC in the reactors are shown in Fig. 2(b). In all reactors, there was a decreasing trend in EC throughout the process. In all reactors, the expected increase in EC at the beginning could not be observed due to the transition to the thermophilic phase before the 2nd day. However, starting from the 2nd day, a decrease in EC values was observed due to the formation of macromolecules and salt adsorption. At the end of the maturation phase (60th day), the EC values measured in M1, M2, M3, and M4 reactors were 6.6, 5.3, 2.7 and 2.6 mS/cm, respectively. Due to the higher EC value (6.22 mS/cm) of cotton gin waste added to reactors M1 and M2 compared to the EC value (3.52 mS/cm) of peanut shell added to reactors M3 and M4, the EC value in M1 and M2 reactors remained higher throughout the process. In general, the EC value for mature compost is considered to be below 3 mS/cm in some studies (Aydın Temel, 2023; Ma et al., 2022). An EC value above 4 mS/cm can lead to adverse effects in plants such as wilting and low germination rates (Yao et al., 2015). A high EC value has a phytotoxic effect due to its potential to damage plant roots and interfere with nutrient uptake, resulting in reduced crop yield (Aycan Dümenci et al., 2021). According to this, the compost obtained from M3 and M4 reactors is suitable for agricultural use in terms of the EC parameter. The compost obtained from M1 and M2 reactors, considering the EC parameter, can be utilized for non-agricultural applications.

3.2.3 Mineralization and Maturity

In the composting process, the necessary nutrients and energy sources for microorganisms are provided by water-soluble organic matter. As a result of the mineralization of organic matter carried out by microorganisms, reductions in organic matter content occur (Banegas et al., 2007; Uçaroğlu & Alkan, 2016). The increase in temperature plays a vital role in enhancing microbial activity and effectively decomposing organic matter in composting (Wei et al., 2019). In this study, it was determined that there was an organic matter loss of 22.1%, 42.2%, 24.8%, and 31.5% in reactors M1, M2, M3, and M4, respectively, calculated using the formula of the degradation coefficient. It was determined that the highest organic matter loss occurred in reactor M2, where the thermophilic phase lasted the longest (13 days), indicating that microbial decomposition and mineralization were more pronounced compared to the other reactors. The lowest organic matter loss occurred in the M1 reactor, which had the shortest duration of the thermophilic phase (6 days). Similarly, Patil et al. (2023) stated that in composting studies of swine lagoon sludge, the highest organic matter loss occurred during the prolonged thermophilic phase. During the composting process, organic matter losses between 30 and 60% are expected (Diaz et al., 2007). In this study, it was found that mineralization occurred to a greater extent in the M2 and M4 reactors, which contained 80% treatment sludge, leading to higher organic matter losses in those reactors. Moreover, organic materials with high cellulose and lignin content are difficult to degrade by microorganisms (Şevik et al., 2018). Twice as much agricultural waste with high cellulose content was added to M1 and M3 reactors compared to the other reactors.

The C/N ratio is used as an indicator of stability and maturity in composting. In a well-functioning composting process, reductions in the C/N ratio occur as a result of the release of CO2 due to the mineralization of organic carbon (Uçaroǧlu, 2014). In general, if compost is intended to be used as fertilizer, it is desired to have an initial C/N ratio between 20 and 40 in the composting process (Wilkinson and Victoria 1998). In this study, the initial C/N ratios in all reactors were within the desired range (Table 3). The changes in the C/N ratio during the active composting process in the reactors are shown in Fig. 3(a). Decreases in C/N ratios of 19.8%, 39.1%, 25.3%, and 34.6% were observed in the M1, M2, M3, and M4 reactors, respectively, and at the end of the process, the ratios decreased to 19.4, 14.2, 22.8, and 16.8, respectively. Stoffella and Kahn (2001) reported that this value, which is generally an indicator of stabilization, should be between 15 and 20, but that the ideal value is 10. Considering these results, it can be stated that there was a significant decrease in the C/N ratio in the M2 and M4 reactors, where 20% bulking agent was used. These reactors contained a higher proportion of treatment sludge, which contained easily degradable carbon for microorganisms. It can be said that the decrease in carbon content, resulting from the consumption of easily degradable carbon by microorganisms and the longer duration of the thermophilic phase in reactors M2 and M4 compared to the other reactors, led to greater reductions in the C/N ratio. According to the USEPA, the C/N ratio of mature compost should be below 25 (Herity, 2003). Barral Silva et al. (2007), in their study, considered C/N values of 17 and below as indicators of stable compost. According to Keller (1961), ratios below 20 were referred to as stable compost. After the 21-day active composting phase, the C/N ratio in all reactors decreased to levels compliant with the USEPA criteria (C/N ≤ 25) and values stated in the scientific studies. The decrease in C/N ratio will continue during the maturation stage after active composting.

Some researchers have also used the parameter (C/N)final/(C/N)initial as an indicator of stabilization (Epstein, 2017; Iglesias Jiménez & Perez Garcia, 1989; Ji et al., 2023). Iglesias Jiménez and Perez Garcia (1989) observed that the (C/N)final/(C/N)initial value ranged from 0.49 to 0.85, while Epstein (2017) stated that better stabilization was achieved when this value remained between 0.47 and 0.85. Ji et al. (2023) mentioned that the C/N ratio of mature compost should be ≤ 23, and that preferably, (C/N)final/(C/N)initial should be ≤ 0.8. In this study, the (C/N)final/(C/N)initial values were calculated as 0.80, 0.61, 0.76, and 0.66 for reactors M1, M2, M3, and M4, respectively. These values are consistent with the values mentioned by the aforementioned researchers. Considering the (C/N)final/(C/N)initial values of the compost obtained after the active composting phase in all reactors, it can be stated that they achieved a sufficient level of stabilization.

Nitrogen is also an important nutrient source for microorganisms in composting. Organic nitrogen is decomposed by microbial activity and becomes available for metabolic processes. During the composting process, gaseous nitrogen losses generally occur as ammonia, but occasionally they can also occur as nitrogen and nitrous oxides (Rihani et al., 2010). The changes in TKN during active composting in this study are presented in Fig. 3b. The initial TKN values ranged from 1.0% to 1.5% in all reactors. Depending on the quantity and type of waste, as well as the aeration rate, increases and decreases in TKN values can be observed during the composting process (de Guardia et al., 2010). At the end of the 21st day, TKN values increased in all reactors. The dry weights decreased after active composting due to the decomposition of organic matter, resulting in an increase in TKN percentages (Khalil et al., 2011). Similar to this study, Banegas et al. (2007), Uçaroǧlu (2014) and Rihani et al. (2010) observed significant decreases in organic matter and corresponding increases in nitrogen percentages in their studies. For the obtained compost to be considered mature compost, Herity (2003) suggested that the nitrogen value should be between 1 and 3%, while Hoitink (1993) recommended it to be in the range of 0.4% to 3.5%. At the end of the 21st day, the TKN value in all reactors ranged from 1.8% to 2.0%. It can be stated that the compost obtained from all reactors is compliant with the criteria for mature compost in terms of nitrogen content.

The occurrence of nitrate-nitrogen (NO3-N) in compost, along with a decrease in ammonium-nitrogen (NH4-N) concentration, is indicative of nitrification and is considered an indicator of compost maturity. Therefore, the nitrification index (NH4-N/NO3-N) is a useful parameter for determining the degree of maturity (Brinton, 2016). In this study, at the end of the maturation phase (60th day), the nitrification index was calculated as 2.3, 2.4, 3.1, and 3.3 for reactors M1, M2, M3, and M4, respectively. When the nitrification index is < 0.5, it is defined as highly mature compost, between 0.5 and 3 as mature compost, and > 3 as immature compost (Brinton, 2016). It can be accepted that the compost obtained from the M1 and M2 reactors, where cotton gin waste was used, reached sufficient maturity after the maturation phase, while the compost obtained from the M3 and M4 reactors, where peanut shell was used, did not reach sufficient maturity. It can be concluded that a longer maturation period is required for the compost obtained in reactors M3 and M4.

The nitrifying-enriched activated sludge (NAS) technology, which provides nutrient control in activated sludge management, can also be utilized for composting treatment sludges with a low C/N ratio. With this technology, it may be possible to enhance the efficiency of nitrification processes occurring during sludge composting. Autotrophic microorganisms become widespread and provide ammonium removal. By applying NAS technology, fewer regulatory additives can be used and more sewage sludge can be disposed of by composting ((Lalthlansanga et al., 2023).

3.2.4 Free Air Space (FAS)

The presence of free air space allows for the circulation of air in the composting environment and provides oxygen for microorganisms. Therefore, it is an important physical characteristic in composting. Regardless of the waste type and technology used, a minimum of 20–30% of free air space (FAS) is required to ensure sufficient oxygen supply in composting (Abad et al., 2001; Spinosa & Vesilind, 2001). Table 3 presents the FAS values in the reactors. In reactors where the moisture content is high, as expected, the FAS value is lower (Haug, 1993; Huet et al., 2012; Madejón et al., 2002). In this study, it was determined that apart from moisture, the type of bulking agent used also had a different effect on FAS. Reactors using cotton gin waste (M1 and M2) had higher FAS compared to reactors using peanut shells (M3 and M4). Due to the different densities and particle sizes of the various bulking agents used, the relationship between moisture content and free air space can vary (Epstein, 2017). Although the FAS values in reactors M2 and M4 were slightly lower compared to the FAS ratio given in the literature, these reactors had higher temperatures due to a higher content of easily degradable organic carbon, which led to increased microbial activity and greater mineralization. Due to the higher FAS ratio (17.5%) in reactor M2 compared to the FAS ratio (15.6%) in reactor M3, more oxygen was provided for microorganisms. Thus, a longer thermophilic phase (13 days) and a higher organic matter loss (42.2%) occurred in reactor M2.

4 Conclusions

This study investigated the management of sludge generated from a food industry treatment plant, along with agricultural wastes (cotton gin waste and peanut shell), through the composting process. In the reactors (M2 and M4) where cotton gin waste and peanut shell were added at a rate of 20%, thermophilic temperatures were reached, and the highest OM loss and C/N ratio reduction occurred in these reactors. Although higher temperatures were observed in the reactor (M4) where peanut shell was utilized, a higher degree of mineralization occurred in the reactor (M2) where cotton gin waste was used due to the longer duration of the thermophilic phase. In conclusion, both agricultural wastes, cotton gin waste and peanut shell, can be used as bulking agents in the composting of treatment sludge. The highest-quality compost was obtained from the composting of a mixture consisting of 20% cotton gin waste and 80% treatment sludge. In the composting of peanut shells with treatment sludge, it might be possible to achieve better results by composting them together in different ratios and under different control conditions.

Data Availability

All the data is presented in the manuscript.

References

Abad, M., Noguera, P., & Burés, S. (2001). National inventory of organic wastes for use as growing media for ornamental potted plant production: Case study in Spain. Bioresource Technology, 77(2), 197–200. https://doi.org/10.1016/S0960-8524(00)00152-8

Achkir, A., Aouragh, A., El Mahi, M., Lotfi, E. M., Labjar, N., El Bouch, M., et al. (2023). Implication of sewage sludge increased application rates on soil fertility and heavy metals contamination risk. Emerging Contaminants, 9(1). https://doi.org/10.1016/j.emcon.2022.100200

Al-Alawi, M., El Fels, L., Benjreid, R., Szegi, T., Hafidi, M., Simon, B., & Gulyas, M. (2020). Evaluation of the performance of encapsulated lifting system composting technology with a GORE(R)cover membrane: Physico-chemical properties and spectroscopic analysis. Environmental Engineering Research, 25(3), 299–308. https://doi.org/10.4491/eer.2019.061

Anand, C. K., & Apul, D. S. (2014). Composting toilets as a sustainable alternative to urban sanitation - A review. Waste Management, 34(2), 329–343. https://doi.org/10.1016/j.wasman.2013.10.006

APHA, AWWA, W. (1998). Standart methods for the examination of water and wastewater (20th editi.). Baltimore, USA: Copyright by American Public Health Association.

Aycan Dümenci, N., Cagcag Yolcu, O., Aydın Temel, F., & Turan, N. G. (2021). Identifying the maturity of co-compost of olive mill waste and natural mineral materials: Modelling via ANN and multi-objective optimization. Bioresource Technology, 338, 125516. https://doi.org/10.1016/j.biortech.2021.125516

Aydın Temel, F. (2023). Evaluation of the influence of rice husk amendment on compost quality in the composting of sewage sludge. Bioresource Technology, 373(January), 128748. https://doi.org/10.1016/j.biortech.2023.128748

Banegas, V., Moreno, J. L., Moreno, J. I., García, C., León, G., & Hernández, T. (2007). Composting anaerobic and aerobic sewage sludges using two proportions of sawdust. Waste Management, 27(10), 1317–1327. https://doi.org/10.1016/j.wasman.2006.09.008

Barral Silva, M. T., Menduíña, A. M., Seijo, Y. C., & Viqueira, F. D. F. (2007). Assessment of municipal solid waste compost quality using standardized methods before preparation of plant growth media. Waste Management and Research, 25(2), 99–108. https://doi.org/10.1177/0734242X07075514

Benito, M., Masaguer, A., Moliner, A., Arrigo, N., & Palma, R. M. (2003). Chemical and microbiological parameters for the characterisation of the stability and maturity of pruning waste compost. Biology and Fertility of Soils, 37(3), 184–189. https://doi.org/10.1007/s00374-003-0584-7

Bremner, J. M., & Mulvaney, C. S. (1982). Nitrogen - total. Methods of soil analysis. Part 2. Chemical and microbiological properties. Madison, Wisconsin: American Society of Agronomy, Soil Science Society of America.

Brinton, W. (2016). Compost Quality Standards & Guidelines : An International View Final Report, (May), 1–44.

de Guardia, A., Mallard, P., Teglia, C., Marin, A., Le Pape, C., Launay, M., et al. (2010). Comparison of five organic wastes regarding their behaviour during composting: Part 2, nitrogen dynamic. Waste Management, 30(3), 415–425. https://doi.org/10.1016/j.wasman.2009.10.018

Diaz, L. F., De Bertoldi, M., & Bidlingmaier, W. (2007). Compost Science and Technology. Elsevier. https://books.google.com.tr/books?id=iSLFlAEACAAJ

Dı́az, M. J., Madejón, E., López, F., López, R., & Cabrera, F. (2002). Composting of vinasse and cotton gin waste by using two different systems. Resources, Conservation and Recycling, 34(4), 235–248. https://doi.org/10.1016/S0921-3449(01)00109-4

Epstein, E. (2017). The Science of Composting. CRC Press. https://books.google.com.tr/books?id=1EoPEAAAQBAJ

Erickson, M. C., Liao, J., Boyhan, G., Smith, C., Ma, L., Jiang, X., & Doyle, M. P. (2010). Fate of manure-borne pathogen surrogates in static composting piles of chicken litter and peanut hulls. Bioresource Technology, 101(3), 1014–1020. https://doi.org/10.1016/j.biortech.2009.08.105

Fersi, M., Mbarki, K., Gargouri, K., Mechichi, T., & Hachicha, R. (2019). Assessment of organic matter biodegradation and physico-chemical parameters variation during co-composting of lignocellulosic wastes with Trametes trogii inoculation. Environmental Engineering Research, 24(4), 670–679. https://doi.org/10.4491/eer.2018.341

Fountoulakis, M. S., Terzakis, S., Georgaki, E., Drakopoulou, S., Sabathianakis, I., Kouzoulakis, M., & Manios, T. (2009). Oil refinery sludge and green waste simulated windrow composting. Biodegradation, 20(2), 177–189. https://doi.org/10.1007/s10532-008-9211-5

Gao, M., Li, B., Yu, A., Liang, F., Yang, L., & Sun, Y. (2010). The effect of aeration rate on forced-aeration composting of chicken manure and sawdust. Bioresource Technology, 101(6), 1899–1903. https://doi.org/10.1016/j.biortech.2009.10.027

Germer, J., Boh, M. Y., Schoeffler, M., & Amoah, P. (2010). Temperature and deactivation of microbial faecal indicators during small scale co-composting of faecal matter. Waste Management, 30(2), 185–191. https://doi.org/10.1016/j.wasman.2009.09.030

González, D., Colón, J., Gabriel, D., & Sánchez, A. (2019). The effect of the composting time on the gaseous emissions and the compost stability in a full-scale sewage sludge composting plant. Science of the Total Environment, 654, 311–323. https://doi.org/10.1016/j.scitotenv.2018.11.081

Graves, R. E., & Hattemer, G. M. (2010). Chapter 2 Composting. Environmental Engineering National Engineering Handbook, (November), 1–65.

Guo, X., Liu, H., & Zhang, J. (2020). The role of biochar in organic waste composting and soil improvement: A review. Waste Management, 102, 884–899. https://doi.org/10.1016/j.wasman.2019.12.003

Haug, R. T. (1993). The Practical Handbook of Compost Engineering. Taylor \& Francis. https://books.google.com.tr/books?id=MX%5C_jbemODmAC

Herity, L. (2003). A Study of the Quality of Waste Derived Compost in Ireland. Environmental Engineering, (September), 155.

Hoitink H. A. (1993). Science and Engineering of Composting: Design, Environmental, Microbiological and Utilization Aspects. (H. A. Hoitink, Ed.) (First Edit.). Oardc.

Huet, J., Druilhe, C., Trémier, A., Benoist, J. C., & Debenest, G. (2012). The impact of compaction, moisture content, particle size and type of bulking agent on initial physical properties of sludge-bulking agent mixtures before composting. Bioresource Technology. https://doi.org/10.1016/j.biortech.2012.03.031

Iglesias Jiménez, E., & Perez Garcia, V. (1989). Evaluation of city refuse compost maturity: A review. Biological Wastes, 27(2), 115–142. https://doi.org/10.1016/0269-7483(89)90039-6

Ingelmo, F., Molina, M. J., Soriano, M. D., Gallardo, A., & Lapeña, L. (2012). Influence of organic matter transformations on the bioavailability of heavy metals in a sludge based compost. Journal of Environmental Management, 95(SUPPL.), S104–S109. https://doi.org/10.1016/j.jenvman.2011.04.015

Iqbal, M. K., Shafiq, T., & Ahmed, K. (2010). Characterization of bulking agents and its effects on physical properties of compost. Bioresource Technology, 101(6), 1913–1919. https://doi.org/10.1016/j.biortech.2009.10.030

Jackson, B. E., Wright, A. N., Cole, D. M., & Sibley, J. L. (2005). Cotton Gin Compost as a Substrate Component in Container Production of Nursery Crops. Journal of Environmental Horticulture, 23(3), 118–122. https://doi.org/10.24266/0738-2898-23.3.118

Ji, Z., Zhang, L., Liu, Y., Li, X., & Li, Z. (2023). Evaluation of composting parameters, technologies and maturity indexes for aerobic manure composting: A meta-analysis. Science of the Total Environment, 886, 163929. https://doi.org/10.1016/j.scitotenv.2023.163929

Jiao, M., Ren, X., Zhan, X., Hu, C., Wang, J., Syed, A., et al. (2023). Exploring gaseous emissions and pivotal enzymatic activity during co-composting of branch and pig manure: The effect of particle size of bulking agents. Bioresource Technology, 382, 129199. https://doi.org/10.1016/j.biortech.2023.129199

Keeney, D. R., & Nelson, D. W. (1982). Nitrogen - inorganic forms. Methods of soil analysis. Part 2. Chemical and microbiological properties. Madison, Wisconsin: American Society of Agronomy, Soil Science Society of America.

Keller, P. (1961). Methods to evaluate maturity of compost. Compost Sci., 2(7), 20–26.

Khalil, A. I., Hassouna, M. S., El-Ashqar, H. M. A., & Fawzi, M. (2011). Changes in physical, chemical and microbial parameters during the composting of municipal sewage sludge. World Journal of Microbiology and Biotechnology, 27(10), 2359–2369. https://doi.org/10.1007/s11274-011-0704-8

Lalthlansanga, C., Pottipati, S., Sreeram Meesala, N., Mohanty, B., & Kalamdhad, A. S. (2023). Evaluating the potential of biodegradation of swine manure through rotary drum composting utilizing different bulking agents. Bioresource Technology, 388, 129751. https://doi.org/10.1016/j.biortech.2023.129751

Li, W., Wu, C., Wang, K., Meng, L., & Lv, L. (2017). Nitrogen loss reduction by adding sucrose and beet pulp in sewage sludge composting. International Biodeterioration and Biodegradation. https://doi.org/10.1016/j.ibiod.2017.03.013

Liew, C. S., Yunus, N. M., Chidi, B. S., Lam, M. K., Goh, P. S., Mohamad, M., et al. (2022). A review on recent disposal of hazardous sewage sludge via anaerobic digestion and novel composting. Journal of Hazardous Materials, 423, 126995. https://doi.org/10.1016/j.jhazmat.2021.126995

Luo, C., Li, S., Ren, P., Yan, F., Wang, L., Guo, B., et al. (2024). Enhancing the carbon content of coal gangue for composting through sludge amendment: A feasibility study. Environmental Pollution, 348, 123439. https://doi.org/10.1016/j.envpol.2024.123439

Ma, R., Liu, Y., Wang, J., Li, D., Qi, C., Li, G., & Yuan, J. (2022). Effects of oxygen levels on maturity, humification, and odor emissions during chicken manure composting. Journal of Cleaner Production, 369(December 2021). https://doi.org/10.1016/j.jclepro.2022.133326

Madejón, E., Jesús Díaz, M., López, R., & Cabrera, F. (2002). New approaches to establish optimum moisture content for compostable materials. Bioresource Technology, 85(1), 73–78. https://doi.org/10.1016/S0960-8524(02)00030-5

Margesin, R., Cimadom, J., & Schinner, F. (2006). Biological activity during composting of sewage sludge at low temperatures. International Biodeterioration and Biodegradation. https://doi.org/10.1016/j.ibiod.2005.12.001

McLean, E. O. (1982). Soil pH and lime requirement. Methods of soil analysis. Part 2. Chemical and microbiological properties. Madison, Wisconsin: American Society of Agronomy, Soil Science Society of America.

Meng, L., Li, W., Zhao, Y., Chen, L., Zhang, S., & Zhang, X. (2021). Insights into influences of sucrose amendment on nitrification and denitrification in sewage sludge composting. Chemosphere, 276, 130245. https://doi.org/10.1016/j.chemosphere.2021.130245

Nakasaki, K., Yaguchi, H., Sasaki, Y., & Kubota, H. (1993). Effects Of pH Control On Composting Of Garbage. Waste Management & Research, 11(2), 117–125. https://doi.org/10.1006/wmre.1993.1013

Negi, S., Mandpe, A., Hussain, A., & Kumar, S. (2020). Collegial effect of maggots larvae and garbage enzyme in rapid composting of food waste with wheat straw or biomass waste. Journal of Cleaner Production, 258, 120854. https://doi.org/10.1016/j.jclepro.2020.120854

Nelson, D. W., & Sommers, L. E. (1982). Total carbon, organic carbon, and organic matter. Methods of soil analysis. Part 2. Chemical and microbiological properties. Madison, Wisconsin: American Society of Agronomy, Soil Science Society of America.

Okalebo, J. R., Gathua, K. W., & Woomer, P. L. (1993). Laboratory methods of soil and plant analysis. A working manual, TSBF. Soil Science Society of East Africa Publication, (1), 88.

Patil, P., Sharara, M., Shah, S., Kulesza, S., & Classen, J. (2023). Impacts of utilizing swine lagoon sludge as a composting ingredient. Journal of Environmental Management, 327, 116840. https://doi.org/10.1016/j.jenvman.2022.116840

Rhoades, J. D. (1982). Soluble salts. Methods of soil analysis. Part 2. Chemical and microbiological properties. Madison, Wisconsin: American Society of Agronomy, Soil Science Society of America.

Richard, T. L., (Bert) Hamelers, H. V. M., Veeken, A., & Silva, T. (2002). Moisture relationships in composting processes. Compost Science and Utilization, 10(4), 286–302. https://doi.org/10.1080/1065657X.2002.10702093

Rigane, M. K., & Medhioub, K. (2011). Assessment of properties of Tunisian agricultural waste composts: Application as components in reconstituted anthropic soils and their effects on tomato yield and quality. Resources, Conservation and Recycling, 55(8), 785–792. https://doi.org/10.1016/j.resconrec.2011.03.012

Rihani, M., Malamis, D., Bihaoui, B., Etahiri, S., Loizidou, M., & Assobhei, O. (2010). In-vessel treatment of urban primary sludge by aerobic composting. Bioresource Technology, 101(15), 5988–5995. https://doi.org/10.1016/j.biortech.2010.03.007

Ruggieri, L., Gea, T., Artola, A., & Sánchez, A. (2008). Influence of different co-substrates biochemical composition on raw sludge co-composting. Biodegradation, 19(3), 403–415. https://doi.org/10.1007/s10532-007-9146-2

Şevik, F., Tosun, İ, & Ekinci, K. (2018). The effect of FAS and C/N ratios on co-composting of sewage sludge, dairy manure and tomato stalks. Waste Management, 80, 450–456. https://doi.org/10.1016/j.wasman.2018.07.051

Sharma, D., & Yadav, K. D. (2017). Bioconversion of flowers waste: Composing using dry leaves as bulking agent. Environmental Engineering Research, 22(3), 237–244. https://doi.org/10.4491/eer.2016.126

Spinosa, L., & Vesilind, P. A. (2001). Sludge into Biosolids. IWA Publishing. https://books.google.com.tr/books?id=5KD-Gzuyw78C

Stoffella, P.J., & Kahn, B.A. (2001). Compost Utilization in Horticultural Cropping Systems (1st ed.). CRC Press. https://doi.org/10.1201/9780367801236

Tejada, M., & Gonzalez, J. L. (2003). Effects of the application of a compost originating from crushed cotton gin residues on wheat yield under dryland conditions. European Journal of Agronomy, 19(2), 357–368. https://doi.org/10.1016/S1161-0301(02)00089-8

Uçaroǧlu, S. (2014). Use of sunflower stalks as a bulking agent in sewage sludge composting. Fresenius Environmental Bulletin, 23(6), 1302–1308.

Uçaroğlu, S., & Alkan, U. (2016). Composting of wastewater treatment sludge with different bulking agents. Journal of the Air and Waste Management Association, 66(3), 288–295. https://doi.org/10.1080/10962247.2015.1131205

USEPA. (1993). Standards for the use and disposal of sewage; final rules. Washington. https://nepis.epa.gov/Exe/ZyNET.exe/20003O8D.TXT ZyActionD=ZyDocument&Client=EPA&Index=1991+Thru+1994&Docs=&Query=&Time=&EndTime=&SearchMethod=1&TocRestrict=n&Toc=&TocEntry=&QField=&QFieldYear=&QFieldMonth=&QFieldDay=&IntQFieldOp=0&ExtQFieldOp=0&XmlQuery=

Vráblová, M., Smutná, K., Chamrádová, K., Vrábl, D., Koutník, I., Rusín, J., et al. (2024). Co-composting of sewage sludge as an effective technology for the production of substrates with reduced content of pharmaceutical residues. Science of the Total Environment, 915, 169818. https://doi.org/10.1016/j.scitotenv.2023.169818

Wei, Y., Wu, D., Wei, D., Zhao, Y., Wu, J., Xie, X., et al. (2019). Improved lignocellulose-degrading performance during straw composting from diverse sources with actinomycetes inoculation by regulating the key enzyme activities. Bioresource Technology, 271, 66–74. https://doi.org/10.1016/j.biortech.2018.09.081

Wilkinson, K., & Victoria, E. (Eds.). (1998). Composting green organics : guide to best practice, a guide to achieving best practice in Victoria / Kevin Wilkinson ...[et al.]. East Melbourne [Vic.]: EcoRecycle.

Wu, X., Wang, J., Shen, L., Wu, X., Amanze, C., & Zeng, W. (2021). Effect of bamboo sphere amendment on the organic matter decomposition and humification of food waste composting. Waste Management, 133, 19–27. https://doi.org/10.1016/j.wasman.2021.07.030

Yan, L., Li, Z., Bao, J., Wang, G., Wang, C., & Wang, W. (2015). Diversity of ammonia-oxidizing bacteria and ammonia-oxidizing archaea during composting of municipal sludge. Annals of Microbiology, 65(3), 1729–1739. https://doi.org/10.1007/s13213-014-1012-y

Yao, R.-J., Yang, J.-S., Wu, D.-H., Xie, W.-P., Cui, S.-Y., Wang, X.-P., et al. (2015). Determining soil salinity and plant biomass response for a farmed coastal cropland using the electromagnetic induction method. Computers and Electronics in Agriculture, 119, 241–253. https://doi.org/10.1016/j.compag.2015.10.020

Yuan, J., Chadwick, D., Zhang, D., Li, G., Chen, S., Luo, W., et al. (2016). Effects of aeration rate on maturity and gaseous emissions during sewage sludge composting. Waste Management, 56, 403–410. https://doi.org/10.1016/j.wasman.2016.07.017

Zhang, S., Wen, J., Hu, Y., Fang, Y., Zhang, H., Xing, L., et al. (2019). Humic substances from green waste compost: An effective washing agent for heavy metal (Cd, Ni) removal from contaminated sediments. Journal of Hazardous Materials, 366(November 2018), 210–218. https://doi.org/10.1016/j.jhazmat.2018.11.103

Zhang, Z. J., Wang, H., Zhu, J., Suneethi, S., & Zheng, J. G. (2012). Swine manure vermicomposting via housefly larvae (Musca domestica): The dynamics of biochemical and microbial features. Bioresource Technology, 118, 563–571. https://doi.org/10.1016/j.biortech.2012.05.048

Zhao, X. lan, Li, B. qiong, Ni, J. pai, & Xie, D. ti. (2016). Effect of four crop straws on transformation of organic matter during sewage sludge composting. Journal of Integrative Agriculture. https://doi.org/10.1016/S2095-3119(14)60954-0

Zhou, Y., Selvam, A., & Wong, J. W. C. (2018). Chinese medicinal herbal residues as a bulking agent for food waste composting. Bioresource Technology, 249, 182–188. https://doi.org/10.1016/j.biortech.2017.09.212

Zhu, N. (2006). Composting of high moisture content swine manure with corncob in a pilot-scale aerated static bin system. Bioresource Technology, 97(15), 1870–1875. https://doi.org/10.1016/j.biortech.2005.08.011

Acknowledgements

The authors are grateful to Abdullah Cataltas for his experimental efforts.

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK). This study was supported by the Bursa Uludag University Scientific Research Projects Commission (Project Number: 2009/19).

Author information

Authors and Affiliations

Contributions

S.U: Project administration, Writing- review & editing. Y.A: Data collection and curation, Drafting the manuscript.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ucaroglu, S., Atalay, Y. Wastewater Treatment Sludge and Agricultural Wastes: Management by Composting Process. Water Air Soil Pollut 235, 363 (2024). https://doi.org/10.1007/s11270-024-07142-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-024-07142-0