Abstract

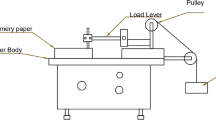

Do two different and independent methods of estimating the wear rate of a test sample yield the same numerical result? Numerical values of specific wear rates estimated on the basis of alternative methods using a set of dry sliding rotary-pin-on-disk experiments are presented. Wear rates of brass and aluminium alloy pins were estimated using gravimetric and wear scar area methods. Gravimetric and linear displacement methods were used to assess wear rates of ABS plastic and machinable wax pins. Scepticism about the estimated nominal values of wear rates is reduced when alternative assessment methods result in comparable numerical values, or values having the same order of magnitude. This is particularly useful when ranking competing materials for wear rates, when the differences in these rates are small. Uncertainties in individual test sample wear rates, and dispersion in the nominal values of wear rates are also computed to support the aforementioned observations.

Similar content being viewed by others

Data Availability

Data has been compiled, presented graphically, and tabulated in this manuscript.

Notes

Commercial products are identified for completeness. This does not constitute endorsement.

The large number of significant figures are carried in intermediate calculations to avoid being affected by round off errors [57]

References

Blau, P. J.: Needs and challenges in precision wear measurement. In ASTM Symposium on Precision Wear Measurements and Monitoring. Orlando, FL. Version: Jan 10, (1996)

Fink, M.: Wear oxidation a new component of wear. Trans. Am. Soc. Steel Treat. 18, 1026–1034 (1930)

Rosenberg, S.J., Jordan, L.: Influence of oxide films on the wear of steels. J. Res. Natl. Bureau Stand. 13, 269–280 (1934)

Archard, J.F., Hirst, W.: The wear of metals under unlubricated conditions. Proc. R. Soc. London A 236, 397–410 (1956). https://doi.org/10.1098/rspa.1956.0144

McKee, S.A.: An indentation method of measuring wear. J. Res. Natl. Bureau Stand. 39, 155–161 (1947)

Burwell, J.T., Strang, C.D.: On the empirical law of adhesive wear. J. Appl. Phys. 23(1), 18–28 (1952). https://doi.org/10.1063/1.1701970

Archard, J.F.: Contact and rubbing of flat surfaces. J. Appl. Phys. 24(8), 981–988 (1953). https://doi.org/10.1063/1.1721448

Sherge, M., Pöhlmann, K., Gervé, A.: Wear measurement using radionuclide-technique (rnt). Wear 254, 801–817 (2003). https://doi.org/10.1016/S0043-1648(03)00230-8

Novak, R., Polcar, T.: Tribological analysis of thin films by pin-on-disk: evaluation of friction and wear measurement uncertainty. Tribol. Int. 74, 154–163 (2014). https://doi.org/10.1016/j.triboint.2014.02.011

Iwai, Y., Honda, T., Miyajima, T., Yoshinaga, S., Higashi, M., Fuwa, Y.: Quantitative estimation of wear amounts by real time measurement of wear debris in lubricating oil. Tribol. Int. 43, 388–394 (2010). https://doi.org/10.1016/j.triboint.2009.06.019

Blau, P.J.: Mechanisms for transitional friction and wear behaviour of sliding metals. Wear 72, 55–66 (1981). https://doi.org/10.1016/0043-1648(81)90283-0

Czichos, H., Becker, S., Lexow, J.: Multilaboratory tribotesting: results from the Versailles advanced materials and standards programme on wear test methods. Wear 114(1), 109–130 (1987). https://doi.org/10.1016/0043-1648(87)90020-2

Almond, E.A., Gee, M.G.: Results from a U.K. interlaboratory project on dry sliding wear. Wear 120, 101–116 (1987). https://doi.org/10.1016/0043-1648(87)90136-2

Gee, M.G., Almond, E.A.: Effects of test variables in wear testing of ceramics. Mater. Sci. Technol. 4(10), 877–884 (1988). https://doi.org/10.1179/mst.1988.4.10.877

Czichos, H., Becker, S., Lexow, J.: International multilaboratory sliding wear tests with ceramics and steel. Wear 135, 171–191 (1989). https://doi.org/10.1016/0043-1648(89)90104-X

Burris, D.L., Sawyer, W.G.: Measurement uncertainties in wear rates. Tribol. Lett. 36, 81–87 (2009). https://doi.org/10.1007/s11249-009-9477-8

Burris, D.L., Sawyer, W.G.: Tribological sensitivity of PTFE/alumina nanocomposites to a range of traditional surface finishes. Tribol. Trans. 48, 147–143 (2005). https://doi.org/10.1080/05698190590923842

Schmitz, T.L., Action, J.E., Burris, D.L., Ziegert, J.C., Sawyer, W.G.: Wear-rate uncertainty analysis. ASME J. Tribol. 126, 802–808 (2004). https://doi.org/10.1115/1.1792675

Blau, P.J.: Lessons learned from the test-to-test variability of different types of wear data. Wear 376–377, 1830–1840 (2017). https://doi.org/10.1016/j.wear.2016.11.012

Welsh, N.C.: Frictional heating and its influence on the wear of steel. J. Appl. Phys. 28(9), 960–968 (1957). https://doi.org/10.1063/1.1722920

Antler, M.: Processes of metal transfer and wear. Wear 7, 181–203 (1964). https://doi.org/10.1016/S0043-1648(03)00230-8

Welsh, N.C.: The dry wear of steels i. the general pattern of behaviour. Philos. Trans. R. Soc. London Ser. A Math. Phys. Sci. 257(1077), 31–70 (1965). https://doi.org/10.1098/rsta.1965.0001

Suh, N.P., Jahanmir, S., II., Abrahamson, E.P., Turner, A.P.L.: Further investigation of the delamination theory of wear. ASME J. Lubr. Technol. 94(4), 631–637 (1974). https://doi.org/10.1115/1.3452511

Rabinowicz, E.: The wear coefficient - magnitude, scatter, uses. J. Lubr. Technol., Trans. ASME 103(2), 188–193 (1981). https://doi.org/10.1115/1.3251624

Rice, S.L., Wayne, S.F., Nowotny, H.: Specimen material reversal in pin-on-disc tribotesting. Wear 88, 85–92 (1983). https://doi.org/10.1016/0043-1648(83)90314-9

Whitenton, E.P., Blau, P.J.: A comparison of methods for determining wear volumes and surface parameters of spherically tipped sliders. Wear 124, 291–309 (1988). https://doi.org/10.1016/0043-1648(88)90219-0

Budinski, K.G.: Tribological properties of titanium alloys. Wear 151(2), 203–217 (1991). https://doi.org/10.1016/0043-1648(91)90249-T

Venkatesan, S., Rigney, D.A.: Sliding friction and wear of plain carbon steels in air and vacuum. Wear 153, 163–178 (1992). https://doi.org/10.1016/0043-1648(92)90268-D

Guicciardi, S., Melandri, F., de Luccini, G.: On data dispersion in pin-on-disk wear tests. Wear 252, 1001–1006 (2002). https://doi.org/10.1016/S0043-1648(02)00066-2

Jones, G.A.: On the tribological behaviour of mechanical seal face materials in dry line contact part I. Mech. Carbon. Wear 256, 415–432 (2004). https://doi.org/10.1016/s0043-1648(03)00539-8

Qu, J., Truhan, J.J.: An efficient method for accurately determining wear volumes of sliders with non-flat wear scars and compound curvatures. Wear 261, 848–855 (2006). https://doi.org/10.1016/j.wear.2006.01.009

Aksulu, M., Palabiyik, M.: Uncertainty of wear rate and coefficient of friction for a polymer wear experiment in a pad-on disc tribotester. In Proceedings of the 9th Biennial ASME Conference on Engineering Systems Design and Analysis, July 7–9, (2008)

Beheshti, A., Khonsari, M.M.: A thermodynamic approach for prediction of wear coefficient under unlubricated sliding condition. Tribol. Lett. 38, 347–354 (2010). https://doi.org/10.1007/s11249-010-9614-4

Amiri, M., Khonsari, M.M., Brahmeshwarkar, S.: On the relationship between wear and thermal response in sliding systems. Tribol. Lett. 38, 148–154 (2010). https://doi.org/10.1007/s11249-010-9584-6

Argibay, N., Swayer, W.G.: Low wear metal sliding electrical contacts at high current density. Wear 274–275, 229–237 (2012). https://doi.org/10.1016/j.wear.2011.09.003

Kandanur, S.S., Rafiee, M.A., Yavari, F., Schrameyer, M., Yu, Z.-Z., Blanchet, T.A., Koratkar, N.: Suppression of wear in graphene polymer composites. Carbon 50(9), 3178–3183 (2012). https://doi.org/10.1016/j.carbon.2011.10.038

Zammit, A., Abela, S., Wagner, L., Mhaede, M., Grech, M.: Tribological behaviour of shot peened Cu–Ni austempered ductile iron. Wear 302, 829–836 (2013). https://doi.org/10.1016/j.wear.2012.12.027

Bortoleto, E.M., Rovani, A.C., Seriacopi, V., Profito, F.J., Zachariadis, D.C., Machado, I.F.: Experimental and numerical analysis of dry contact in the pin on disc test. Wear 301, 19–26 (2013). https://doi.org/10.1016/j.wear.2012.12.005

Neis, P.D., Ferreira, N.F., da Silva, F.P.: Comparison between methods for measuring wear in brake friction materials. Wear 319, 191–199 (2014). https://doi.org/10.1016/j.wear.2014.08.004

Gebretsadik, D.W., Hardell, J., Prakash, B.: Friction and wear characteristics of different Pb-free bearing materials in mixed and boundary lubrication. Wear 340–341, 63–72 (2015). https://doi.org/10.1016/j.wear.2015.06.002

Liu, C., Man, Z., Zhou, F., Chen, K., Yu, H.: The wear an friction characters of polycrystalline diamond under wetting conditions. ASME J. Tribol. 141(2), 021607 (2019). https://doi.org/10.1115/1.4041397

Leonardi, M., Alemani, M., Straffelini, G., Gialanella, S.: A pin-on-disc study on the dry sliding behaviour of a cu-free friction material containing different types of natural graphite. Wear 442–443, 203157 (2020). https://doi.org/10.1016/j.wear.2019.203157

Maculotti, G., Goti, E., Genta, G., Mazza, L., Galetto, M.: Uncertainty-based comparison of coventional and surface-topography based methods of wear volume evaluation in pin-on-disc tribological tests. Tribol. Int. 165, 107260 (2022). https://doi.org/10.1016/j.triboint.2021.107260

Holm, R.: Electrical Contacts. H. Gerbers, Stockholm (1946)

Stachowiak, G.W., Batchelor, A.W.: Engineering Tribology, 4th edn. Butterworth-Heinemann, Waltham (2014)

Bahadur, S.: Wear research and development. ASME J. Lubr. Technol. 100, 449–454 (1978). https://doi.org/10.1115/1.3453249

Blau, P.J.: Fifty years of research on the wear of metals. Tribol. Int. 30(5), 321–331 (1997). https://doi.org/10.1016/S0301-679X(96)00062-X

Wallbridge, N.C., Dowson, D.: Distribution of wear rate data and a statistical approach to sliding wear theory. Wear 119, 295–312 (1987). https://doi.org/10.1016/0043-1648(87)90037-8

Lancaster, J.K.: The influence of substrate hardness on the formation and endurance of molybdenum disulphide films. Wear 10, 103–117 (1967). https://doi.org/10.1016/0043-1648(67)90082-8

Rabinowicz, E.: The least wear. Wear 100, 533–541 (1984). https://doi.org/10.1016/0043-1648(84)90031-0

Akbarzadeh, S., Khonsari, M.M.: On the applicability of Miner’s rule to adhesive wear. Tribol. Lett. 63, 29 (2016). https://doi.org/10.1007/s11249-016-0717-4

Lijesh, K.P., Khonsari, M.M.: On the applicability of Miner’s rule to adhesive wear. Tribol. Lett. 66, 105 (2018). https://doi.org/10.1007/s11249-018-1058-2

Fereidouni, H., Akbarzadeh, S., Khonsari, M.M.: On the assessment of variable loading in adhesive wear. Tribol. Int. 129, 167–176 (2019). https://doi.org/10.1016/j.triboint.2018.07.035

Avery, H.S.: The measurement of wear resistance. Wear 4(6), 427–449 (1961). https://doi.org/10.1016/0043-1648(61)90301-5

ISO: Guide to the Expression of Uncertainty in Measurement, 2nd edn. International Organization for Standardization, Geneva (1995)

Taylor, Barry N., Kuyatt, Chris E.: NIST Technical Note 1297, 1994 edition: Guidelines for evaluating and expressing the uncertainty of NIST measurement results. United States Department of Commerce Technology Administration, National Institute of Standards and Technology, Gaithersburg, MD (1994)

Dieck, R.H.: Measurement uncertainty models. ISA Trans. 36(1), 29–35 (1997). https://doi.org/10.1016/S0019-0578(97)00004-9

Queener, C.A., Smith, T.C., Mitchell, W.L.: Transient wear of machine parts. Wear 8, 391–400 (1965). https://doi.org/10.1016/0043-1648(65)90170-5

Blau, P.J.: On the nature of Running-in. Tribol. Int. 38(11–12), 1007–1012 (2005). https://doi.org/10.1016/j.triboint.2005.07.020

Blau, P.J.: Running-in: art or engineering? J. Mater. Eng. 13(1), 47–53 (1991). https://doi.org/10.1007/BF02834123

Blau, P.J.: How common is the steady-state? The implications of wear transitions for materials selection and design. Wear 332–333, 1120–1128 (2015). https://doi.org/10.1016/j.wear.2014.11.018

Mortazavi, V., Khonsari, M.M.: On the prediction of transient wear. ASME J. Tribol. 138(4), 041604 (2016). https://doi.org/10.1115/1.4032843

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

KCS: Experiments, data analysis, and manuscript writing. NVV: Experimental plan, material resources, manpower resources, and overall project supervision. PRC: Experimental plan, experimental resources, editing, and supervision of experiments. JKS: Conceptualization, supervision of uncertainty analysis, and manuscript writing. AB: Data analysis, comparative summary of the literature, and final manuscript writing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Solasa, K.C., Venkataraman, N.V., Choudhury, P.R. et al. On the Use of Alternative Measurement Methods in the Estimation of Wear Rates in Rotary-Pin-on-Disk Tribometry. Tribol Lett 72, 45 (2024). https://doi.org/10.1007/s11249-024-01841-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-024-01841-9