Abstract

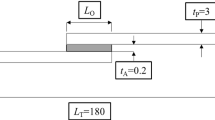

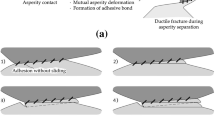

Material loss can result through sliding contact between solids, primarily due to wear process. Failure of interlocking asperities in contact, which can occur as a fracture-induced or plastic shearing mechanism, is a significant contributor in material wear. We developed an analytical model to predict asperity junction failure mechanisms as a function of material properties (fracture toughness and shear strength) and geometrical parameters (asperity height and width). The failure causes fracture-induced and plastic shearing below and above a threshold aspect ratio, respectively. This was validated by a wide range of configurations and materials using both finite element simulations and documented data from literature.

Graphical Abstract

Similar content being viewed by others

References

Archard, J.F.: Contact and rubbing of flat surfaces. J. Appl. Phys. 24, 981–988 (1953). https://doi.org/10.1063/1.1721448

Bhushan, B.: Contact mechanics of rough surfaces in tribology: multiple asperity contact. Tribol. Lett. 4, 1–35 (1998). https://doi.org/10.1023/A:1019186601445

Pham-Ba, S., Brink, T., Molinari, J.-F.: Adhesive wear and interaction of tangentially loaded micro-contacts. Int. J. Solids Struct. 188–189, 261–268 (2020). https://doi.org/10.1016/j.ijsolstr.2019.10.023

Lawn, B.R.: A model for the wear of brittle solids under fixed abrasive conditions. Wear 33(2), 369–372 (1975). https://doi.org/10.1016/0043-1648(75)90290-2

Moore, M., King, F.: Abrasive wear of brittle solids. Wear 60, 123–140 (1980). https://doi.org/10.1016/0043-1648(80)90253-7

Harish, A.B., Wriggers, P.: Modeling of two-body abrasive wear of filled elastomers as a contact-induced fracture process. Tribol. Int. 138, 16–31 (2019). https://doi.org/10.1016/j.triboint.2019.05.009

Brink, T., Molinari, J.-F.: Adhesive wear mechanisms in the presence of weak interfaces: insights from an amorphous model system. Phys. Rev. Mater. 3, 053604 (2019). https://doi.org/10.1103/PhysRevMaterials.3.053604

Suh, N.P.: The delamination theory of wear. Wear 25(1), 111–124 (1973). https://doi.org/10.1016/0043-1648(73)90125-7

Rozeanu, L.: Fatigue wear as a rate process. Wear 6(5), 337–340 (1963). https://doi.org/10.1016/0043-1648(63)90201-1

Tewari, A., Basu, B., Bordia, R.K.: Model for fretting wear of brittle ceramics. Acta Mater. 57(7), 2080–2087 (2009). https://doi.org/10.1016/j.actamat.2009.01.013

Watson, S.W., Friedersdorf, F.J., Madsen, B.W., Cramer, S.D.: Methods of measuring wear-corrosion synergism. Wear 181–183(2), 476–484 (1995). https://doi.org/10.1016/0043-1648(95)90161-2

Brach, S., Collet, S.: Criterion for critical junctions in elastic-plastic adhesive wear. Phys. Rev. Lett. 127, 185501 (2021). https://doi.org/10.1103/PhysRevLett.127.185501

Bowden, F., Tabor, D.: The Friction and Lubrication of Solids. Oxford University Press, Oxford (2001)

Maw, W., Stevens, F., Langford, S., Dickinson, J.: Single asperity tribochemical wear of silicon nitride studied by atomic force microscopy. J. Appl. Phys. 92, 5103 (2002). https://doi.org/10.1063/1.1510595

Gotsmann, B., Lantz, M.A.: Atomistic wear in a single asperity sliding contact. Phys. Rev. Lett. 125501, 101 (2008). https://doi.org/10.1103/PhysRevLett.101.125501

Merkle, A.P., Marks, L.D.: Liquid-like tribology of gold studied by in situ TEM. Wear 265, 1864 (2008). https://doi.org/10.1016/j.wear.2008.04.032

Bhaskaran, H., Gotsmann, B., Sebastian, A., Drechsler, U., Lantz, M.A., Despont, M., Jaroenapibal, P., Carpick, R.W., Chen, Y., Sridharan, K.: Ultralow nanoscale wear through atom-by-atom attrition in silicon-containing diamond-like carbon. Nat. Nanotechnol. 5, 181 (2010). https://doi.org/10.1038/nnano.2010.3

Mulvihill, D., Kartal, M., Nowell, D., Hills, D.: An elastic-plastic asperity interaction model for sliding friction. Tribol. Int. 44(12), 1679–1694 (2011). https://doi.org/10.1016/j.triboint.2011.06.018

Sato, T., Ishida, T., Jalabert, L., Fujita, H.: Real-time transmission electron microscope observation of nanofriction at a single Ag asperity. Nanotechnology 23(50), 505701 (2012). https://doi.org/10.1088/0957-4484/23/50/505701

Romero, P.A., Jarvi, T.T., Beckmann, N., Mrovec, M., Moseler, M.: Coarse graining and localized plasticity between sliding nanocrystalline metals. Phys. Rev. Lett. 113(36), 101 (2014). https://doi.org/10.1103/PhysRevLett.113.036101

Aghababaei, R., Brink, T., Molinari, J.-F.: Asperity-level origins of transition from mild to severe wear. Phys. Rev. Lett. 120, 186105 (2018). https://doi.org/10.1103/PhysRevLett.120.186105

Mishra, T., de Rooij, M., Shisode, M., Hazrati, J., Schipper, D.J.: An analytical model to study the effect of asperity geometry on forces in ploughing by an elliptical asperity. Tribol. Int. 137, 405–419 (2019). https://doi.org/10.1016/j.triboint.2019.05.015

Green, A.: Friction between unlubricated metals: a theoretical analysis of the junction model. Proc. R. Soc. 228, 191 (1955). https://doi.org/10.1098/rspa.1955.0043

Brockley, C.A., Fleming, G.K.: A model junction study of severe metallic wear. Wear 8(5), 374–380 (1965). https://doi.org/10.1016/0043-1648(65)90168-7

Byerlee, J.D.: Theory of friction based on brittle fracture. J. Appl. Phys. 38, 2928–2934 (1967). https://doi.org/10.1063/1.1710026

Liu, J., Notbohm, J.K., Carpick, R.W., Turner, K.T.: Method for characterizing nanoscale wear of atomic force microscope tips. ACS Nano 4, 3763 (2010). https://doi.org/10.1021/nn100246g

Bouchet, M.I.D.B., Matta, C., Vacher, B., Le-Mogne, T., Martin, J.M., Lautz, J.V., Ma, T., Pastewka, L., Otschik, J., Gumbsch, P., Moseler, M.: Energy filtering transmission electron microscopy and atomistic simulations of tribo-induced hybridization change of nanocrystalline diamond coating. Carbon 87, 317–329 (2015). https://doi.org/10.1016/j.carbon.2015.02.041

Vahdat, V., Grierson, D.S., Turner, K.T., Carpick, R.W.: Mechanics of interaction and atomic-scale wear of amplitude modulation atomic force microscopy probes. ACS Nano 7, 3221–3235 (2013). https://doi.org/10.1021/nn305901n

Liu, J., Jiang, Y., Grierson, D.S., Sridharan, K., Shao, Y., Jacobs, T.D.B., Falk, M.L., Carpick, R.W., Turner, K.T.: Tribochemical wear of diamond-like carbon-coated atomic force microscope tips. ACS Appl. Mater. Interface 9, 35341–35348 (2017). https://doi.org/10.1021/acsami.7b08026

Bernal, R.A., Carpick, R.W.: Visualization of nanoscale wear mechanisms in ultrananocrystalline diamond by in-situ TEM tribometry. Carbon 154, 132–139 (2019). https://doi.org/10.1016/j.carbon.2019.07.082

Aghababaei, R., Warner, D.H., Molinari, J.-F.: Critical length scale controls adhesive wear mechanisms. Nat. Commun. 7, 11816 (2016). https://doi.org/10.1038/ncomms11816

Aghababaei, R.: On the origins of third-body particle formation during adhesive wear. Wear 426–427(Part B), 1076–1081 (2019). https://doi.org/10.1016/j.wear.2018.12.060

Aghababaei, R.: Effect of adhesion on material removal during adhesive wear. Phys. Rev. Mater. 3(6), 2476–2485 (2019). https://doi.org/10.1103/PhysRevMaterials.3.063604

Collet, S., Molinari, J.-F., Brach, S.: Variational phase-field continuum model uncovers adhesive wear mechanisms in asperity junctions. J. Mech. Phys. Solids 145, 104130 (2020). https://doi.org/10.1016/j.jmps.2020.104130

Xu, H., Komvopoulos, K.: A fracture mechanics analysis of asperity cracking due to sliding contact. Int. J. Solids Struct. 171, 1–9 (2019). https://doi.org/10.1016/j.ijsolstr.2019.05.005

Carollo, V., Paggi, M., Reinoso, J.: The steady-state archard adhesive wear problem revisited based on the phase field approach to fracture. Int. J. Fract. 215, 39–48 (2019). https://doi.org/10.1007/s10704-018-0329-0

Aghababaei, R., Budzik, M.: Fracture modes of brittle junctions under shear. Ext. Mech. Lett. 35, 100644 (2020). https://doi.org/10.1016/j.eml.2020.100644

Suo, Z., Hutchinson, J.: Interface crack between two elastic layers. Int. J. Fract. 43, 1–18 (1990). https://doi.org/10.1007/BF00018123

Jensen, H., Thouless, M.: Effects of residual stresses in the blister test. Int. J. Solids Struct. 30(6), 779–795 (1993). https://doi.org/10.1016/0020-7683(93)90040-E

Malekan, M., Budzik, M.K., Jensen, H.M., Aghababaei, R.: Fracture analyses of surface asperities during sliding contact. Tribol. Int. 159, 106939 (2021). https://doi.org/10.1016/j.triboint.2021.106939

Williams, M.: Stress singularities resulting from various boundary conditions in angular corners of plates in extension. J. Appl. Mech. 19, 526–528 (1952). https://doi.org/10.1115/1.4010553

Seweryn, A.: Brittle fracture criterion for structures with sharp notches. Eng. Fract. Mech. 47, 673–681 (1994). https://doi.org/10.1016/0013-7944(94)90158-9

Carpinteri, A.: Stress-singularity and generalized fracture toughness at the vertex of re-entrant corners. Eng. Fract. Mech. 26, 143–155 (1987). https://doi.org/10.1016/0013-7944(87)90086-5

Carpinteri, A., Cornetti, P., Pugno, N., Sapora, A., Taylor, D.: A finite fracture mechanics approach to structures with sharp V-notches. Eng. Fract. Mech. 75, 1736–1752 (2008). https://doi.org/10.1016/j.engfracmech.2007.04.010

Carpinteri, A., Paggi, M., Pugno, N.: Numerical evaluation of generalized stress-intensity factors in multi-layered composites. Int. J. Solids Struct. 43, 627–641 (2006). https://doi.org/10.1016/j.ijsolstr.2005.06.009

Hibbeler, R.C.: Mechanics of Materials, 10th edn. Pearson Education Inc, Boston (2017)

Malekan, M.: Fracture loads of sharp and blunt asperities under normal and tangential loading. Tribol. Int. 177, 107949 (2023). https://doi.org/10.1016/j.triboint.2022.107949

Johnson, G.R., Cook, J.R.: Constitutive model and data for metals subjected to large strains, high strain rates, and high temperatures. In: Proceedings of 7th Symposium on Ballistics, Netherlands (1983)

Krasauskas, P., Kilikevicius, S., Česnavicius, R., Pacenga, D.: Experimental analysis and numerical simulation of the stainless AISI 304 steel friction drilling process. Mechanika 20(6), 590–595 (2014). https://doi.org/10.5755/j01.mech.20.6.8664

Tounsi, N., Vincenti, J., Otho, A., Elbestawi, M.A.: From the basic mechanics of orthogonal metal cutting toward the identification of the constitutive equation. Int. J. Mach. Tools Manuf. 42, 12 (2002). https://doi.org/10.1016/S0890-6955(02)00046-9

Gupta, N.K., Iqbal, M.A., Sekhon, G.S.: Experimental and numerical studies on the behavior of thin aluminum plates subjected to impact by blunt- and hemispherical-nosed projectiles. Int. J. Impact Eng. 32(12), 1921–1944 (2006). https://doi.org/10.1016/j.ijimpeng.2005.06.007

Johnson, G.R., Cook, W.H.: Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 21, 31–48 (1985). https://doi.org/10.1016/0013-7944(85)90052-9

Khurshudov, A., Kato, K.: Wear of the atomic force microscope tip under light load, studied by atomic force microscopy. Ultramicroscopy 60, 11–16 (1995). https://doi.org/10.1016/0304-3991(95)00071-8

Chung, K.-H., Kim, D.-E.: Fundamental investigation of micro wear rate using an atomic force microscope. Tribol. Lett. 15, 135–144 (2003). https://doi.org/10.1023/A:1024457132574

Chung, K.-H., Lee, Y.-H., Kim, D.-E.: Characteristics of fracture during the approach process and wear mechanism of a silicon AFM tip. Ultramicroscopy 102, 161–171 (2005). https://doi.org/10.1016/j.ultramic.2004.09.009

Tao, Z., Bhushan, B.: Surface modification of AFM silicon probes for adhesion and wear reduction. Tribol. Lett. 21, 1–16 (2006). https://doi.org/10.1007/s11249-005-9001-8

Norman, T.L., Nivargikar, S.V., Burr, D.B.: Resistance to crack growth in human cortical bone is greater in shear than in tension. J. Biomech. 29(8), 1023–1031 (1996). https://doi.org/10.1016/0021-9290(96)00009-7

Tarigopula, V., Hopperstad, O.S., Langseth, M., Clausen, A.H., Hild, F., Lademo, O.-G., Eriksson, M.: A study of large plastic deformations in dual phase steel using digital image correlation and fe analysis. Exp. Mech. 48, 181–196 (2008). https://doi.org/10.1007/s11340-007-9066-4

An, Y.G., Vegter, H., Heijne, J.: Development of simple shear test for the measurement of work hardening. J. Mater. Proc. Technol. 209, 4248–4254 (2009). https://doi.org/10.1016/j.jmatprotec.2008.11.007

Yin, Q., Zillmann, B., Suttner, S., Gerstein, G., Biasutti, M., Tekkaya, A.E., Wagner, M.F.-X., Merklein, M., Schaper, M., Halle, T., Brosius, A.: An experimental and numerical investigation of different shear test configurations for sheet metal characterization. Int. J. Solids Struct. 51, 1066–1074 (2014). https://doi.org/10.1016/j.ijsolstr.2013.12.006

Yin, Q., Soyarslan, C., Isik, K., Tekkaya, A.E.: A grooved in-plane torsion test for the investigation of shear fracture in sheet materials. Int. J. Solids Struct. 66, 121–132 (2015). https://doi.org/10.1016/j.ijsolstr.2015.03.032

Jia, L.-J., Ikai, T., Shinohara, K., Ge, H.: Ductile crack initiation and propagation of structural steels under cyclic combined shear and normal stress loading. Construct. Build. Mater. 112, 69–83 (2016). https://doi.org/10.1016/j.conbuildmat.2016.02.171

Gorji, M.B., Mohr, D.: Micro-tension and micro-shear experiments to characterize stress-state dependent ductile fracture. Acta Mater. 131, 65–76 (2017). https://doi.org/10.1016/j.actamat.2017.03.034

Starman, B., Vrhb, M., Koca, P., Halilovic, M.: Shear test-based identification of hardening behaviour of stainless steel sheet after onset of necking. J. Mater. Proc. Technol. 270, 335–344 (2019). https://doi.org/10.1016/j.jmatprotec.2019.03.010

Liu, Y., Kang, L., Ge, H.: Experimental and numerical study on ductile fracture of structural steels under different stress states. J. Construct. Steel Res. 158, 381–404 (2019). https://doi.org/10.1016/j.jcsr.2019.04.001

Xing, J., Qiu, C., Wang, M., Yang, N.: Uniaxial failure mechanism and design strength of high-strength welded hollow spherical joint. Eng. Struct. 256, 113897 (2020). https://doi.org/10.1016/j.engstruct.2022.113897

Huang, X., Ge, J., Zhao, J., Zhao, W.: A continuous damage model of q690d steel considering the influence of lode parameter and its application. Construct. Build. Mater. 262, 120067 (2020). https://doi.org/10.1016/j.conbuildmat.2020.120067

Zhu, Y., Kiran, R., Xing, J., Pan, Z., Li, L.: A modified micromechanics framework to predict shear involved ductile fracture in structural steels at intermediate and low-stress triaxialities. Eng. Fract. Mech. 225, 106860 (2020). https://doi.org/10.1016/j.engfracmech.2019.106860

Aghababaei, R., Malekan, M., Budzik, M.: Cutting depth dictates the transition from continuous to segmented chip formation. Phys. Rev. Lett. 127, 235502 (2021). https://doi.org/10.1103/PhysRevLett.127.235502

Zhu, P., Zhang, Q., Xu, H., Ouyang, Y.: Experimental and numerical investigation on plasticity and fracture behaviors of aluminum alloy 6061–t6 extrusions. Arch. Civ. Mech. Eng. 21, 88 (2021). https://doi.org/10.1007/s43452-021-00225-3

Qin, S., Novak, T.C., Vailhe, M.K., Liu, Z.-K., Beese, A.M.: Plasticity and fracture behavior of inconel 625 manufactured by laser powder bed fusion: comparison between as-built and stress relieved conditions. Mater. Sci. Eng. A 806, 140808 (2021). https://doi.org/10.1016/j.msea.2021.140808

Reyne, B., Herault, D., Thuillier, S., Manach, P.-Y.: Quality of the strain state in simple shear testing using field measurement techniques. Int. J. Mech. Sci. 208, 106660 (2021). https://doi.org/10.1016/j.ijmecsci.2021.106660

Tancogne-Dejean, T., Roth, C.C., Morgeneyer, T.F., Helfen, L., Mohr, D.: Ductile damage of AA2024-T3 under shear loading: mechanism analysis through in-situ laminography. Acta Mater. 205, 116556 (2021). https://doi.org/10.1016/j.actamat.2020.116556

Bucci, R.H.: ASM Handbook, Volume 19: Fatigue and Fracture (1996)

Svoboda, A., Wedberg, D., Lindgren, L.-E.: Simulation of metal cutting using a physically based plasticity model. Model. Simul. Mater. Sci. Eng. 18, 075005 (2010). https://doi.org/10.1088/0965-0393/18/7/075005

Delrio, F.W., Boer, M.P.D., Knapp, J.A., Clews, P.J., Dunn, M.L.: The role of van der waals forces in adhesion of micromachined surfaces. Nat. Mater. 4, 629–634 (2005). https://doi.org/10.1038/nmat1431

Lubrecht, A.A., Dwyer-Joyce, R.S., Ioannides, E.: Analysis of the influence of indentations on contact life. In: Dowson, D., Taylor, C.M., Godet, M. (eds.) Proceedings of the 18th Leeds-Lyon Symposium on Tribology (Wear Particles - from the Cradle to the Grave). Elsevier, Amsterdam (1990)

Acknowledgements

We thank anonymous reviewers for insightful comments and suggestions on earlier drafts of this work, which helped to improve the quality of the manuscript.

Funding

The author declares that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The author has no relevant financial or non-financial interests to disclose.

Ethics approval and consent to participate:

The article follows the guidelines of the Committee on Publication Ethics (COPE) and involves no studies on human or animal subjects.

Consent for publication

Not applicable. The article involves no studies on humans.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Malekan, M. Transition from Plastic Shearing to Fracture of Asperity Junctions: Role of a Critical Aspect Ratio. Tribol Lett 71, 26 (2023). https://doi.org/10.1007/s11249-023-01699-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-023-01699-3