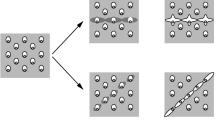

Experimental and computational methods to assess the fracture toughness of 15Kh2NMFA-A reactor vessel steel are analyzed based on the local fracture models: Rice–Tracey and developed in Pisarenko Institute of Problems of Strength of the National Academy of Sciences of Ukraine. The master curve was experimentally constructed, and parameters used in examined models were obtained. The Rice–Tracey model modification, which takes into account the averaging of the relative void radius in the vicinity of the crack tip, extending at each loading step, is shown to confirm a previously made assumption as to the fracture toughness assessment regardless of the finite element size near the crack tip. Since in the ductile-brittle transition region, the crack initiation is ductile, i.e., through void nucleation, growth, and coalescence, the fracture toughness assessment based on local ductile fracture models gained theoretical substantiation and demonstrated satisfactory agreement with experimental results.

Similar content being viewed by others

References

M. Holzmann, B. Vlach, and M. Brumovský, “Measurement of fracture toughness transition behavior of Cr-Ni-Mo-V pressure vessel steel using pre-cracked Charpy specimens,” Int J Pres Ves Pip, 76, 591–598 (1999).

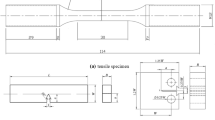

ASTM E 399-22. Standard Test Method for Linear-Elastic Plane-Strain Fracture Toughness KIc of Metallic Materials (2022).

V. T. Troshchenko, V. V. Pokrovskii, and V. G. Kaplunenko, “Prediction of crack resistance for heat-resistant steels taking into account the specimen size effect. Communication 1. Results of experimental investigations,” Strength Mater, 29, No. 1, 1–15 (1997). https://doi.org/https://doi.org/10.1007/BF02767570

ASTM E 1921–2018. Standard Test Method for Determination of Reference Temperature, T0, for Ferritic Steels in the Transition Range (2018).

ASTM E 1820-18. Standard Test Method for Measurement of Fracture Toughness (2019).

T. L. Anderson, Fracture Mechanics: Fundamentals and Applications, CRC Press, Boca Raton, FL (2005).

V. T. Troshchenko, V. V. Pokrovskii, and V. G. Kaplunenko, “Prediction of fracture toughness for heatresistant steels considering specimen dimensions. Report 2. Ductile fracture,” Strength Mater, 29, No. 2, 105–115 (1997). https://doi.org/https://doi.org/10.1007/BF02767585

J. R. Rice and D. M. Tracey, “On the ductile enlargement of voids in triaxial stress fields,” J Mech Phys Solids, 17, 201–217 (1969).

P. Bridgman, Studies of Large Plastic Flow and Fracture, McGraw-Hill, New York (1952).

M. Rakin, “Numerical modeling of ductile fracture initiation in structural steel,” Facta Universitatis, Ser. Mech Eng, No. 1, 939–946 (2001).

A. Sedmak, M. Rakin, M. Medjo, and B. Younise, “Micromechanical modelling of ductile fracture – local approach,” Metallurgical Mater Eng, 25, No. 4, 263–286 (2020).

V. G. Sidyachenko, “Application of the Rice–Tracey model for numerical three-dimensional simulation of ductile crack growth,” in: Reliability and Life of Machines and Structures [in Ukrainian], Issue 25, Kyiv (2005), pp. 153–164.

G. Bernauer and W. Brocks, “Micro-mechanical modeling of ductile damage and tearing – results of a European numerical round robin,” Fatigue Fract Eng Mater Struct, 25, 363–384 (2002).

B. K. Dutta and H. S. Kushwaha, “A modified damage potential to predict crack initiation: theory and experimental verification,” Eng Fract Mech, 71, 263–275 (2004).

ASTM E8/E8M-22. Standard Test Methods for Tension Testing of Metallic Materials (2022).

GOST 9450-76. Measurements Microhardness by Diamond Instruments Indentation [in Russian], Introduced on January 1, 1977.

DSTU ISO 6507-1:2007. Metallic Materials. Vickers Hardness Test. Part 1: Test Method (ISO 6507-1:2005) [in Ukrainian], Valid since April 1, 2009.

V. V. Pokrovskii, S. B. Kulishov, V. G. Sidyachenko, et al., “Prediction of the temperature dependence of fracture toughness of 12Cr–2Ni–Mo refractory steel,” Strength Mater, 41, No. 4, 399–406 (2009). https://doi.org/https://doi.org/10.1007/s11223-009-9140-5

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Mitsnosti, No. 3, pp. 60 – 75, May – June, 2023

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sidyachenko, V.G., Kotlyarenko, A.A. & Kurash, Y.P. Fracture Toughness Assessment of 15Kh2NMFA-A Steel Based on Local Fracture Models. Strength Mater 55, 503–515 (2023). https://doi.org/10.1007/s11223-023-00543-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-023-00543-2