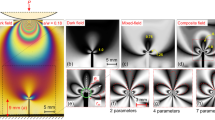

The mechanical state of the surface layer of the studied metal is controlled by correlation between the ray energy of a coherent light source reflected from the surface of the metal polycrystal and the amplitude of microplastic strains of the elastically deformed surface, based on the analysis of statistical characteristics of the discrete brightness distribution of the image elements of the reflected ray. The regularities of the effect of mechanical loading on the statistical characteristics of the discrete strains distribution under elastic deformation of the surface layer of austenitic steel specimens are defined. An analysis of the sequence of correlation characteristics of the surface deformation defects allows one to reveal a linear dependence of the distribution of the discrete properties of the deformed surface relief on the load intensity factor. The obtained correlation characteristics show that with an increased load the brightness amplitude of the speckle pattern image elements drops due to the increase in the mean-square relief amplitude of the surface deformation defects. By analyzing statistical characteristics of the deformed surface of austenitic steel specimens, quantitative parameters of the descriptive statistics of scattered damage are defined. The regularities of the elastoplastic strain effect on the distribution of discrete surface deformations are obtained. A nonparametric evaluation of the loading intensity factor effect on the sequence of terms in series of mean-square sampled values of damage correlation characteristics under cyclic and static loadings, as well as the determination of strain amplitudes and loading durations as damaging factors during elastoplastic deformation of austenitic steel specimens, are performed.

Similar content being viewed by others

References

V. E. Panin, T. F. Elsukova, A. V. Panin, et al.,“Mesoscopic structural levels of deformation in surface layers and fatigue fracture mode of polycrystals in alternating bending. Part I. Mesoscale substructure,” Fiz. Mesomekh., 7, No. 2, 5–17 (2004).

V. S. Ivanova, “An interdisciplinary analysis of dissipative state of physicochemical systems in the course of their evolution,” Metalloved. Term. Obrab. Metal., No. 9, 12–19 (2006).

A. A. Shanyavskii, A. L. Nikitin, T. Palin-Luc, and C. Bathias, “Scale hierarchy of low cycle, high cycle, and ultrahigh cycle fatigue in VT3-1 titanium alloy,” Fiz. Mesomekh., 17, No. 4, 58–68 (2014).

T. Yu. Yakovleva, Local Plastic Deformation and Fatigue of Metals [in Russian], Naukova Dumka, Kiev (2003).

C. Froustey, O. Naimark, M. Bannikov, and V. Oborin, “Microstructure scaling properties and fatigue resistance of pre-strained aluminium alloys (part 1: Al–Cu alloy),” Eur. J. Mech. A-Solid., 29, No. 6, 1008–1014 (2010).

M. V. Bannikov, O. B. Naimark, and V. A. Oborin, “Experimental investigation of crack initiation and propagation in high- and gigacycle fatigue in titanium alloys by study of morphology of fracture,” Frattura ed Integrità Strutturale, 10, No. 35, 50–56 (2016).

L. Aulbach, F. Salazar Bloise, M. Lu, and A. W. Koch, “Non-contact surface roughness measurement by implementation of a spatial light modulator,” Sensors (Basel), 17, No. 3, 596 (2017).

A. V. Byalonovich, “The accumulation of fatigue damage in the structure of the Kh18N10T alloy at room and high temperatures,” in: Reliability and Life of Machines and Structures [in Ukrainian], Issue 34, Kyiv (2011), pp. 124–130.

V. Guerriero, “Power law distribution: method of multi-scale inferential statistics,” J. Modern Mathem. Frontier, 1, No. 1, 21–28 (2012).

O. V. Voinalovich, G. G. Pisarenko, and A. M. Mailo, Method of Noncontact Measurement of Kinetic Characteristics of a Surface Layer Fracture of Metal Structures [in Ukrainian], Ukraine Patent No. 133430, Valid since April 10, 2019, Bull. No. 7.

N. Fujimura, T. Nakamura, and K. Takahashi, “Changing mechanisms of surface relief and the damage evaluation of low cycle fatigued austenitic stainless steel,” in: MATEC Web of Conferences, 12th Int. Fatigue Congr. (FATIGUE 2018), Article Number 04007 (2018), https://doi.org/10.1051/matecconf/ 201816504007.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 6, pp. 80 – 89, November – December, 2019.

Rights and permissions

About this article

Cite this article

Pisarenko, G.G., Mailo, A.N., Byalonovich, A.V. et al. Statistical Characteristics of Microplastic Strains of the Surface Layer of Austenitic Steel Under Monotonic and High-Cycle Loadings. Strength Mater 51, 879–886 (2019). https://doi.org/10.1007/s11223-020-00138-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-020-00138-1