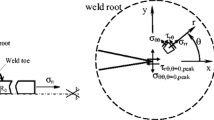

Depending on boundary conditions, welding parameters and plate thickness, high residual tresses may arise near the weld toe of a welded joint. Compressive or tensile residual stresses significantly influence the fatigue strength of the joints in the high-cycle regime. If the weld toe is modelled as a sharp, zero-radius V-shaped notch, the residual stress fields can be expressed in terms of residual notch stress intensity factors (R–NSIFs) calculated in the elastic or elastic-plastic fields. The possibility to quantify the intensity of the residual singular stress field by means of the R–NSIFs allows the designer to estimate the influence of residual stresses on the fatigue life of welded joints. In this work, the influence of residual stresses on the fatigue resistance of Al-alloy butt-welded joints is estimated by using the local stain energy density approach. Values predicted by the proposed method show a good agreement with experimental data taken from literature.

Similar content being viewed by others

References

J. F. Throop and H. S. Reemsnyder, Residual Stress Effects in Fatigue, ASTM STP 776 (1981).

T. R. Gurney, Fatigue of Welded Structures, Cambridge University Press, Cambridge, UK (1979).

M. Ross, “Experiments for the determination of the influence of residual stresses on the fatigue strength of structures,” Weld. Res. BWRA, 4, No. 5, 83–93 (1950).

W. Soete and R. van Crombrugge, “A study of the fatigue strength of welded joints,” Rev. Soudure Lastijdscrift, 2 (1950).

W. Soete and R. van Crombrugge, “A study of the fatigue strength of welded joints,” Rev. Soudure Lastijdscrift, 4 (1950).

W. Soete and R. van Crombrugge, “A study of the fatigue strength of welded joints,” Rev. Soudure Lastijdscrift, 2 (1951).

W. M. Wilson and A. B. Wilder, Fatigue Tests of Butt Welds in Structural Steel Plates, Bulletin No. 310, University of Illinois Engineering Experiment Station (1939).

I. V. Kudryavstev, “The influence of internal stresses on the fatigue endurance of steel,” in: Proc. of the IMechE Conf. on Fatigue, Institution of Mechanical Engineers, London (1956), pp. 317–325.

V. I. Trufyakov, “Welded joints and residual stresses,” Avtomat. Svarka, No. 5, 90–103 (1956).

V. I. Trufyakov, “Welded joints and residual stresses,” Br. Weld. J., 5, No. 11, 491–498 (1958).

M. L. Williams, “Stress singularities resulting from various boundary conditions in angular corners of plates in extension,” J. Appl. Mech., 19, No. 4, 526–528 (1952).

P. Lazzarin and R. Tovo, “A notch intensity factor approach to the stress analysis of welds,” Fatigue Fract. Eng. Mater. Struct., 21, 1089–1103 (1998).

T. Boukharouba, T. Tamine, L. Nui, et al., “The use of notch stress intensity factor as a fatigue crack initiation parameter,” Eng. Fract. Mech., 52, 503–512 (1995).

Y. Verreman and B. Nie, “Early development of fatigue cracking at manual fillet welds,” Fatigue Fract. Eng. Mater. Struct., 19, 669–681 (1996).

B. Atzori, P. Lazzarin, and R. Tovo, “From a local stress approach to fracture mechanics: a comprehensive evaluation of the fatigue strength of welded joints,” Fatigue Fract. Eng. Mater. Struct., 22, 369–381 (1999).

P. Lazzarin and P. Livieri, “Notch stress intensity factors and fatigue strength of aluminium and steel welded joints,” Int. J. Fatigue, 23, 225–232 (2001).

P. Livieri and P Lazzarin, “Fatigue strength of steel and aluminium welded joints based on generalised stress intensity factors and local strain energy values,” Int. J. Fract., 133, 247–276 (2005).

D. Radaj, “State-of-the-art review on extended stress intensity factor concepts,” Fatigue Fract. Eng. Mater. Struct., 37, 1–28 (2014).

P. Ferro, F. Berto, and P. Lazzarin, “Generalized stress intensity factors due to steady and transient thermal loads with applications to welded joints,” Fatigue Fract. Eng. Mater. Struct., 29, 440–453 (2006).

A. Anca, A. Cardona, J. Risso, and V. D. Fachinotti, “Finite element modeling of welding processes,” Appl. Math. Model., 35, 688–707 (2011).

P. Ferro, F. Bonollo, and A. Tiziani, “Methodologies and experimental validations of welding process numerical simulation,” Int. J. Comput. Mater. Sci. Surf. Eng., 3, 114–132 (2010).

P. Ferro, H. Porzner, A. Tiziani, and F. Bonollo, “The influence of phase transformation on residual stresses induced by the welding process – 3D and 2D numerical models,” Model. Simul. Mater. Sci. Eng., 14, 117–136 (2006).

P. Ferro and N. Petrone, “Asymptotic thermal and residual stress distribution due to transient thermal loads,” Fatigue Fract. Eng. Mater. Struct., 32, 936–948 (2009).

P. Ferro, “Influence of phase transformations on the asymptotic residual stress distribution arising near a sharp V-notch tip,” Model. Simul. Mater. Sci. Eng., 20, 085003 (2012), doi:10.1088/0965-0393/20/8/085003.

D. Frank, J. Romanoff, and H. Remes, “Fatigue strength assessment of laser stake-welded web-core steel sandwich panels,” Fatigue Fract. Eng. Mater. Struct., 36, 724–737 (2013).

P. Lazzarin and R. Zambardi, “A finite-volume-energy based approach to predict the static and fatigue behavior of components with sharp V-shaped notches,” Int. J. Fract., 112, 275–298 (2001).

P. Ferro, “The local strain energy density approach applied to pre-stressed components subject to cyclic load,” Fatigue Fract. Eng. Mater. Struct., 37, 1268–1280 (2014).

L. Bertini, V. Fontanari and G. Straffellini, “Influence of post weld treatments on fatigue behaviour of Al-alloy welded joints,” Int. J. Fatigue, 20, 749–755 (1998).

R. Gross and A. Mendelson, “Plane elastoplastic analysis of V-notched plates,” Int. J. Fract. Mech., 8, 267–276 (1972).

F. Berto and P. Lazzarin, “A review of the volume-based strain energy density approach applied to V-notches and welded structures,” Theor. Appl. Fract. Mech., 52, 183–194 (2009).

F. Berto and P. Lazzarin, “Fatigue strength of structural components under multi-axial loading in terms of local energy density averaged on a control volume,” Int. J. Fatigue, 33, 1055–1065 (2011).

F. Berto, P. Lazzarin, and C. Marangon, “Fatigue strength of notched specimens made of 40CrMoV13.9 under multiaxial loading,” Mater. Des., 54, 57–66 (2014).

F. Berto, A. Campagnolo, and P. Lazzarin, “Fatigue strength of severely notched specimens made of Ti–6Al–4V under multiaxial loading,” Fatigue Fract. Eng. Mater. Struct., 38, 503–517 (2015), doi:10.1111/ffe.12272.

F. Berto, P. Gallo, and P. Lazzarin, “High temperature fatigue tests of un-notched and notched specimens made of 40CrMoV13.9 steel,” Mater. Des., 63, 609–619 (2014).

F. Berto and P. Lazzarin, “Recent developments in brittle and quasi-brittle failure assessment of engineering materials by means of local approaches,” Mater. Sci. Eng. R Reports, 75, 1–48 (2014).

P. Lazzarin, A. Campagnolo, and F. Berto, “A comparison among some recent energy- and stress-based criteria for the fracture assessment of sharp V-notched components under Mode I loading,” Theor. Appl. Fract. Mech., 71, 21–30 (2014).

X. K. Zhu and Y. J. Chao, “Effects of temperature-dependent material properties on welding simulation,” Comput. Struct., 80, 967–976 (2002).

A. Barroso, J. Canas, R. Picon, et al., “Prediction of welding residual stresses and displacements by simplified models. Experimental validation,” Mater. Des., 31, 1338– 1349 (2010).

A. Bhatti Ayjwat, Z. Barsoun, H. Murakawa, and I. Barsoum, “Influence of thermo-mechanical material properties of different steel grades on welding residual stresses and angular distortion,” Mater. Des., 65, 878–889 (2015).

W. A. Monteiro (Ed.), Light Metal Alloys Applications, Ch. 2: R. R. Ambriz and D. Jaramillo, Mechanical Behavior of Precipitation Hardened Aluminum Alloys Welds, InTech (2014), ISBN: 978-953-51-1588-5, doi:10.5772/58418.

Ø. Grong, Metallurgical Modelling of Welding, 2nd edn, Cambridge University Press, Cambridge, UK (1997).

D. H. B. Mok and R. J. Pick, “Finite element study of residual stresses in a plate T-joint fatigue specimen,” Int. J. Fatigue, 13, 281–291 (1991).

S. Sarkani, V. Tritchkov, and G. Michaelov, “An efficient approach for computing residual stresses in welded joints,” Finite Elem. Anal. Des., 35, 247–268 (2000).

T. L. Teng, C. P. Fung, P. H. Chang, and W. C. Yang, “Analysis of residual stresses and distortions in T-joint fillet welds,” Int. J. Press. Vess. Piping, 78, 523–538 (2001).

J. Goldak, A. Chakravarti, and M. Birbby, “A new finite element model for welding heat sources,” Metall. Trans. B, 15, 299–305 (1984).

L. P. Pook, “A 50-year retrospective review of three-dimensional effects at cracks and sharp notches,” Fatigue Fract. Eng. Mater. Struct., 36, 699–723 (2013).

P. Lazzarin, M. Zappalorto, and F. Berto, “Three-dimensional stress fields due to notches in plates under linear elastic and elastic–plastic conditions,” Fatigue Fract. Eng. Mater. Struct., 38, 140–153 (2013), doi:10.1111/ffe.12138.

G. Mi, X. Zhan, Y. Wei, et al., “A thermal-metallurgical model of laser beam welding simulation for carbon steels,” Model. Simul. Mater. Sci. Eng., 23, 035010 (2015), doi:10.1088/0965-0393/23/3/035010.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 3, pp. 107 – 119, May – June, 2016.

Rights and permissions

About this article

Cite this article

Ferro, P., Berto, F. Quantification of the Influence of Residual Stresses on Fatigue Strength of Al-Alloy Welded Joints by Means of the Local Strain Energy Density Approach. Strength Mater 48, 426–436 (2016). https://doi.org/10.1007/s11223-016-9781-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-016-9781-0