Abstract

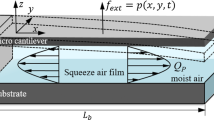

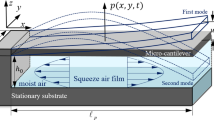

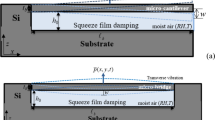

In this study, the effects of temperature (T) and relative humidity (RH) of moist air are discussed on the quality factors (Q-factor) of micro-electro-mechanical-system (MEMS) cantilever resonators in atmospheric pressure (p = 101,325 Pa). The dominant squeeze film damping (SFD) of MEMS cantilever resonators is studied by solving the modified molecular gas lubrication (MMGL) equation. Dynamic viscosity and Poiseuille flow rate of moist air are utilized to modify the MMGL equation as functions of temperature and relative humidity for wide range of accommodation coefficients (ACs). In atmospheric pressure, dynamic viscosity changes more significantly with temperature and relative humidity than that of Poiseuille flow rate. The dominant thermoelastic damping (TED) and support loss are also included to obtain the Q-factor in wide range of cantilever sizes (length, width, and thickness). Thus, dependence of Q-factors of MEMS cantilever resonators on temperature and relative humidity is discussed for wide range of ACs and cantilever sizes in atmospheric pressure. The results show that Q-factor could be increase at higher temperature and relative humidity or lower ACs. Dependence of Q-factor on temperature and relative humidity enhances considerably in greater length, greater width, and smaller thickness of cantilever. Maximum Q-factors with temperature and relative humidity can be obtained for wide range of ACs and cantilever sizes in atmospheric pressure.

Similar content being viewed by others

Abbreviations

- ACs:

-

Accommodation coefficients

- AFM:

-

Atomic force microscope

- d :

-

Diameter of cross section of gas molecule

- D :

-

Inverse Knudsen number

- D p :

-

Cantilever flexural rigidity

- E :

-

Young’s modulus

- f :

-

Enhancement factor

- FEM:

-

Finite element method

- h 0 :

-

Gas film spacing

- i :

-

Complex number

- K n :

-

Knudsen number

- L b :

-

Cantilever length

- MEMS:

-

Micro-electro-mechanical-systems

- MMGL:

-

Modified molecular gas lubrication

- n a :

-

Number of moles of dry air

- n v :

-

Number of moles of water vapor

- N a :

-

Avogadro’s number

- p :

-

Total atmospheric pressure

- p 0 :

-

Reference pressure of gas

- p sv :

-

Saturation pressure of water vapor

- p v :

-

Partial pressure of water vapor

- Q-factor :

-

Quality factor

- Q P :

-

Poiseuille flow rate

- \(\tilde{Q}_{P}\) :

-

Poiseuille flow rate for gas rarefied flow

- Q sup :

-

Quality factor of support loss

- Q SFD :

-

Quality factor of SFD

- Q total :

-

Total quality factor

- Q TED :

-

Quality factor of TED

- R :

-

Gas constant

- RH :

-

Relative humidity

- sup :

-

Support loss

- SFD:

-

Squeeze film damping

- t :

-

Time

- T :

-

Temperature

- T 0 :

-

Reference temperature

- TED:

-

Thermoelastic damping

- T b :

-

Cantilever thickness

- T b_max :

-

Cantilever thickness at maximum Qtotal

- w :

-

Transverse displacement

- W b :

-

Cantilever width

- x sv :

-

Molar fraction of saturated water vapor

- x v :

-

Mole fraction of water vapor

- µ :

-

Dynamic viscosity

- µ a :

-

Viscosity of dry air

- µ v :

-

Viscosity of water vapor

- λ :

-

Mean free path of gas

- λ 0 :

-

Reference mean free path of gas

- \(\overline{\lambda }\) :

-

Eigen-value

- δ :

-

Damping factor

- δ SFD :

-

Damping factor of SFD

- ω :

-

Resonant frequency

- ν :

-

Poisson’s ratio

- α :

-

Surface accommodation coefficient

- \(\rho\) :

-

Gas density

- \(\rho_{m}\) :

-

Material density

References

Alunda, B. O., & Lee, Y. J. (2020). Review: Cantilever-Based Sensors for High Speed Atomic Force Microscopy. Sensors. https://www.mdpi.com/1424-8220/20/17/4784.

Kim, S., Kihm, K. D., & Thundat, T. (2010). Fluidic applications for atomic force microscopy (AFM) with microcantilever sensors. Experiments in Fluids. https://doi.org/10.1007/s00348-010-0830-3

Takahashi, H., Dung, N. M., Matsumoto, K., & Shimoyama, I. (2012). Differential pressure sensor using a piezoresistive cantilever. Journal of Micromechanics and Microengineering. https://doi.org/10.1088/0960-1317/22/5/055015

Toda, M., Inomata, N., Ono, T., & Voiculescu, I. (2017). Cantilever beam temperature sensors for biological applications. IEEJ Transactions on Electrical and Electronic Engineering. https://doi.org/10.1002/tee.22360

Baller, M. K., Lang, H. P., Fritz, J., Gerber, C., Gimzewski, J. K., Drechsler, U., Rothuizen, H., Despont, M., Vettiger, P., Battiston, F. M., & Ramseyer, J. P. (2000). A cantilever array-based artificial nose. Ultramicroscopy. https://doi.org/10.1016/S0304-3991(99)00123-0

Lang, H. P., Hegner, M., & Gerber, C. (2005). Cantilever array sensors. Materialstoday. https://doi.org/10.1016/S1369-7021(05)00792-3

Gupta, A., Akin, D., & Bashir, R. (2004). Single virus particle mass detection using microresonators with nanoscale thickness. Applied Physics Letters. doi, 10(1063/1), 1667011.

Long, Z., Kou, L., Sepaniak, M. J., & Hou, X. (2013). Recent advances in gas phase microcantileverbased sensing. Reviews in Analytical Chemistry. https://doi.org/10.1515/revac-2012-0034

Su, M., Li, S., & Dravid, V. P. (2003). Microcantilever resonance-based DNA detection with nanoparticle probes. Applied Physics Letters. doi, 10(1063/1), 1576915.

Amin, E., Habib, B. G., & Mousa, S. (2019). A novel biosensor based on micromechanical resonator array for lab-on-a-chip applications. Sensing and Imaging. https://doi.org/10.1007/s11220-019-0261-z

Nallathambi, A., & Shanmuganantham, T. (2016). Stress and sensitivity analysis of cantilever based MEMS sensor for environmental applications. Journal of Research in Engineering and Applied Sciences. https://doi.org/10.46565/jreas.2016.v01i01.003

Chen, Q., Fang, J., Ji, H. F., & Varahramyan, K. (2008). Micromachined SiO2 microcantilever for high sensitive moisture sensor. Microsystem Technologies. https://doi.org/10.1007/s00542-007-0489-8

Touaib, R., Koten, H., & Boydak, O. (2020). Parametric study of an organic rankine cycle using different fluids. Emerging Science Journal. https://doi.org/10.28991/esj-2020-01216

Kostikov, Y. A., & Romanenkov, A. M. (2020). Approximation of the multidimensional optimal control problem for the heat equation (applicable to computational fluid dynamics (CFD)). Civil Engineering Journal. https://doi.org/10.28991/cej-2020-03091506

Waghmare, M. V., Madhekar, S. N., & Matsagar, V. A. (2020). Influence of nonlinear fluid viscous dampers on seismic response of RC elevated storage tanks. Civil Engineering Journal, 6, 98–118.

Kim, D., Hong, S., Jang, J., & Park, J. (2017). Determination of fluid density and viscosity by analyzing flexural wave propagations on the vibrating micro-cantilever. Sensors. https://doi.org/10.3390/s17112466

Riesch, C., Reichel, E. K., Keplinger, F., & Jakoby, B. (2008). Characterizing vibrating cantilevers for liquid viscosity and density sensing. Journal of Sensors. https://doi.org/10.1155/2008/697062

Singh, P., & Yadava, R. D. S. (2020). Stochastic resonance induced performance enhancement of MEMS cantilever biosensors. Journal of Physics D: Applied Physics. https://doi.org/10.1088/1361-6463/ab98c4

Tamayo, J., Humphris, A. D. L., Malloy, A. M., & Miles, M. J. (2001). Chemical sensors and biosensors in liquid environment based on microcantilevers with amplified quality factor. Ultramicroscopy. https://doi.org/10.1016/S0304-3991(00)00082-6

Cyril, V., Isabelle, D., Stephen, M. H., Fabien, J., & Andreas, H. (2008). Analysis of resonating microcantilevers operating in a viscous liquid environment. Sensors and Actuators A. https://doi.org/10.1016/j.sna.2007.07.010

Fischeneder, M., Kucera, M., Hofbauer, F., Pfusterschmid, G., Schneider, M., & Schmid, U. (2018). Q-factor enhancement of piezoelectric MEMS resonators in liquids with active feedback. Sensors and Actuators B Chemical. https://doi.org/10.1016/j.snb.2018.01.001

Blake, N. J., & Raj, M. (2012). Biosensing using dynamic-mode cantilever sensors: A review. Biosensors and Bioelectronics. https://doi.org/10.1016/j.bios.2011.10.054

Schneider, M., Pfusterschmied, G., Patocka, F., & Schmid, U. (2020). High performance piezoelectric AlN MEMS resonators for precise sensing in liquids. e & i Elektrotechnik und Informationstechnik. https://doi.org/10.1007/s00502-020-00794-w

Hosaka, H., Itao, K., & Kuroda, S. (1995). Damping characteristics of beam-shaped micro-oscillators. Sensors and Actuators A: Physical. https://doi.org/10.1016/0924-4247(95)01003-J

Li, W. L. (1999). Analytical modelling of ultra-thin gas squeeze film. Nanotechnology. https://doi.org/10.1088/0957-4484/10/4/314

Lee, J. W. (2011). Analysis of fuid-structure interaction for predicting resonant frequencies and quality factors of a microcantilever on a squeeze-film. Journal of Mechanical Science and Technology. https://doi.org/10.1007/s12206-011-0820-2

Bao, M., & Yang, H. (2007). Squeeze film air damping in MEMS. Sensors and Actuators A: Physical. https://doi.org/10.1016/j.sna.2007.01.008

Pandey, A. K., & Pratap, R. (2007). Effect of flexural modes on squeeze film damping in MEMS cantilever resonators. Journal of Micromechanics and Microengineering. https://doi.org/10.1088/0960-1317/17/12/013

Zener, C. (1937). Internal friction in solids I. Theory of internal friction in reeds. Physical Review. https://doi.org/10.1103/PhysRev.52.230

Zener, C. (1938). Internal friction in solids II. General theory of thermoelastic internal friction. Physical Review. https://doi.org/10.1103/PhysRev.53.90

Lifshitz, R., & Roukes, M. L. (2000). Thermoelastic damping in micro- and nanomechanical systems. Physical Review B. https://doi.org/10.1103/PhysRevB.61.5600

Zhou, H., Li, P., & Zuo, W. (2016). Thermoelastic damping in microwedged cantilever resonator with rectangular cross-section. in: IEEE 2016 int. conf. on mechatronics and automation (ICMA). https://doi.org/10.1109/ICMA.2016.7558801.

Hao, Z., Erbil, A., & Ayazi, F. (2003). An analytical model for support loss in micromachined beam resonators with in-plane flexural vibrations. Sensors and Actuators A: Physical. https://doi.org/10.1016/j.sna.2003.09.037

Jandak, M., Neuzil, T., Schneider, M., & Schmid, U. (2016). Investigation on different damping mechanisms on the Q factor of MEMS resonators. Procedia Engineering. https://doi.org/10.1016/j.proeng.2016.11.308

Tsilingiris, P. T. (2008). Thermophysical and transport properties of humid air at temperature range between 0 and 100 C. Energy Conversion and Management. https://doi.org/10.1016/j.enconman.2007.09.015

Nieva, P. M., McGruer, N. E., & Adams, G. G. (2006). Design and characterization of a micromachined Fabry-Perot vibration sensor for high-temperature applications. Journal of Micromechanics and Microengineering. https://doi.org/10.1088/0960-1317/16/12/015

Kim, B., Hopcroft, M. A., Candler, R. N., Jha, C. M., Agarwal, M., Melamud, , et al. (2008). Temperature dependence of quality factor in MEMS resonators. Journal of Microelectromechanical Systems. https://doi.org/10.1109/JMEMS.2008.924253

Ghaffari, S., Ng, E. J., Ahn, C. H., Yang, Y., Wang, S., Hong, V. A., & Kenny, T. W. (2014). Accurate modeling of quality factor behavior of complex silicon MEMS resonators. Journal of Microelectromechanical Systems. https://doi.org/10.1109/JMEMS.2014.2374451

Hwang, C. C., Fung, R. F., Yang, R. F., Weng, C. I., & Li, W. L. (1996). A new modified Reynolds equation for ultrathin film gas lubrication. IEEE Transactions on Magnetics. https://doi.org/10.1109/20.486518

Li, W. L. (2002). A database for couette flow rate considering the effects of non-symmetric molecular interactions. Journal of Tribology. doi, 10(1115/1), 1479700.

Li, W. L. (2003). A database for interpolation of Poiseuille flow rate for arbitrary Knudsen number lubrication problems. Journal of the Chinese Institute of Engineers. https://doi.org/10.1080/02533839.2003.9670799

Li, W. L. (2004). Modeling of head/disk interface—an average flow model. Tribology Letters. https://doi.org/10.1023/B:TRIL.0000044518.79255.03

Li, W. L. (2008). Squeeze film effects on dynamic performance of MEMS μ-mirrors-consideration of gas rarefaction and surface roughness. Microsystem Technologies. https://doi.org/10.1007/s00542-007-0479-x

Porodnov, B. T., Suetin, P. E., Borisov, S. F., & Akinshin, V. D. (1974). Experimental investigation of rarefied gas flow in different channels. Journal of Fluid Mechanics. https://doi.org/10.1017/S0022112074002485

Arkilic, E. B. (2017). Measurement of the mass flow and tangential momentum accommodation coeffcient in silicon micromachined channels, Dissertation, M.I.T, Cambridge, UK.

Hosseinian, E., Theillet, P. O., & Pierron, O. N. (2013). Temperature and humidity effects on the quality factor of a silicon lateral rotary micro-resonator in atmospheric air. Sensors and Actuators A: Physical. https://doi.org/10.1016/j.sna.2012.09.020

Hosseinzadegan, H., Pierron, O. N., & Hosseinian, E. (2014). Accurate modeling of air shear damping of a silicon lateral rotary micro-resonator for MEMS environmental monitoring applications. Sensors and Actuators A: Physical. https://doi.org/10.1016/j.sna.2014.06.008

Jan, M. T., Ahmad, F., Hamid, N. H. B., Khir, M. H. B. M., Shoaib, M., & Ashraf, K. (2016). Experimental investigation of temperature and relative humidity effects on resonance frequency and quality factor of CMOS-MEMS paddle resonator. Microelectronics Reliability. https://doi.org/10.1016/j.microrel.2016.05.007

Hasan, M. H. (2018). Influence of environmental conditions on the response of MEMS resonators, Dissertation, University of Nebraska-Lincoln.

Nguyen, C. C., & Li, W. L. (2016). Effect of gas rarefaction on the quality factors of micro-beam resonators. Microsystem Technologies. https://doi.org/10.1007/s00542-016-3068-z

Nguyen, C. C., & Li, W. L. (2016). Effects of surface roughness and gas rarefaction on the quality factor of micro-beam resonators. Microsystem Technologies. https://doi.org/10.1007/s00542-016-3140-8

Nguyen, C. C., & Li, W. L. (2017). Influences of temperature on the quality factors of micro-beam resonators in gas rarefaction. Sensors and Actuators A: Physical. https://doi.org/10.1016/j.sna.2017.04.050

Nguyen, C. C., Ngo, V. K. T., Le, H. Q., & Li, W. L. (2018). Influences of relative humidity on the quality factors of MEMS cantilever resonators in gas rarefaction. Microsystem Technologies. https://doi.org/10.1007/s00542-018-4239-x

Phan, M. T., Trinh, X. T., Le, Q. C., Ngo, V. K. T., & Nguyen, C. C. (2020). Effect of Environmental Conditions on Quality Factors of MEMS Cantilever Beam Resonator in Gas Rarefaction. Sensing and Imaging. https://doi.org/10.1007/s11220-020-00329-9

Greenspan, L. (1976). Functional equations for the enhancement factors for CO2-free moist air. Journal of Research of the National Bureou of Stondards – A. Physics and Chemistry. https://doi.org/10.6028/jres.080A.007

Tan, Z. (2014). Air pollution and greenhouse gases From Basic Concepts to Engineering Applications for Air Emission Control. Green Energy and Technology. Springer.

Leissa, A. W. (1969). Vibration of Plates, In: NASA, (pp. 1–6), Washington DC.

COMSOL Multiphysics 5.5. (2021). Thermoelastic Damping in a MEMS Resonator, https://www.comsol.com/model/thermoelastic-damping-in-a-mems-resonator-1439. License Date to February 1, 2021.

Acknowledgements

This research was supported by the Institute for Computational Science and Technology (ICST), Contract Number: 08/2019/HĐ-KHCNTT in October 24th, 2019 and series number: 082019-311. Also, this research was supported by the annual projects of The Research Laboratories of Saigon High Tech Park in 2021 according to Decision No. 35/QĐ-KCNC in February 24th, 2021 and Contract Number: 01/2021/HĐNVTX-KCNC-TTRD in March 02nd, 2021 of Management Board of Saigon High Tech Park (Project number 1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A

In Fig.

13, Q-factor of TED (QTED) is plotted as functions of thickness (Tb) and length of cantilever (Lb) for different temperature (T = 20 °C and 100 °C) in 1st mode of vibration. The present results of QTED is calculated by the modes of Zener [29, 30] (Eq. 14 in [52]) in wide range of length (Lb) and thickness (Tb) in 1st mode of cantilever. The results showed that QTED decreases to a minimum value then increases as thickness of cantilever (Tb) increases (seen in Fig. 13a). In Fig. 13b, the results showed that QTED decreases to a minimum value and then increases as length of cantilever (Lb) decreases. Minimum values of QTED are obtained because TED is very dominant at smaller Lb and greater Tb in the 1st mode of vibration. The present results of QTED, which are calculated by the models of Zener [29, 30] (Eq. (14) in [52]), can be almost the same with those obtained results of QTED by Lifshitz and Roukes [31] (LR model) (Eq. (15) in [52]), and the FEM in COMSOL Multiphysics 5.5 [58] (Sect. 2.3 in [52]) in wide range of length and thickness of cantilever. The obtained results can be used to calculate the total Q-factor (Qtotal) in wide range of thickness and length of cantilever in atmospheric pressure (p = 101,325 Pa).

Appendix B

In Fig.

14, Q-factor of support loss (Qsup) is plotted as functions of thickness (Tb) and length of cantilever (Lb) in 1st mode of vibration. The present results of Qsup are calculated by the theoretical model of Hao et al. [33] (Eq. (18) in [52]). The results showed that Qsup decreases as thickness of cantilever (Tb) increases (seen in Fig. 14a). Also, Qsup decreases as length of cantilever (Lb) decreases (seen in Fig. 14b). Thus, Qsup decreases as thickness (Tb) increases and length of cantilever (Lb) decreases because the support loss increases and becomes dominantly as Tb increases and Lb decreases in the 1st mode of vibration. The obtained results can be used to calculate the total Q-factor (Qtotal) in wide range of thickness and length of cantilever in atmospheric pressure (p = 101,325 Pa).

Rights and permissions

About this article

Cite this article

Le, Q.C., Phan, M.T., Trinh, X.T. et al. Temperature and Relative Humidity Dependence of Quality Factors of MEMS Cantilever Resonators in Atmospheric Pressure. Sens Imaging 22, 36 (2021). https://doi.org/10.1007/s11220-021-00359-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11220-021-00359-x