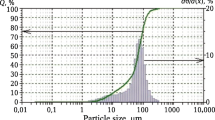

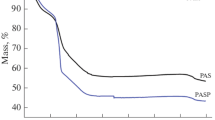

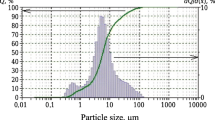

Results of new integrated technological approaches to synthesis of ultrafine α-alumina using commercially available metallurgical alumina as a raw material are presented. The effect of seven different modes for calcination of the initial γ-Al2O3 in the temperature range 1200 – 1600°C is studied. It is revealed that experimental regimes determine the size of the primary crystals and milling capacity of firing products. It is established that by varying temperature regimes it is possible to obtain intentionally both monomodal and multimodal powders.

Similar content being viewed by others

References

S. Ghose, C. Saigal, A. Maldhure, and S. K. Das, “Effect of reactive alumina on the physicomechanical properties of refractory castable,” Trans. Indian Ceram. Soc., 72(2), 113 – 118 (2013).

S. B. Gürelib and À. Altunib Gürelib, “Reactive alumina production for the refractory industry,” Powder Technology, 196, 115 – 121 (2009). DOI: https://doi.org/10.1016/j.powtec.2009.07.007.

A. M. Abyzov, “Aluminum oxide and alumina ceramics (Review). Part 2. Foreign manufacturers of alumina ceramics. Technologies and research in the field of alumina ceramics,” Refract. Ind. Ceram., 60(1), 33 – 42 (2019).

M. A. Trubitsyn, N. A. Volovicheva, L. B. Furda, et al., “Research in the area of preparing activated alumina. Part 1. Methods for preparing reactive alumina,” Refract. Ind. Ceram., 63(2), 130 – 136 (2022).

S. Ghose, C. Saigal, A. Maldhure, and S. K. Das, “Effect of reactive alumina on the physicomechanical properties of refractory castable,” Trans. Ind. Ceram. Soc., 72(2), 113 – 118 (2013).

Y. F. Hsu, S. F.Wang, and T.W. Cheng, “Effects of additives on the densification and microstructural evolution of fine Al2O3 powder,” Mater. Sci. Eng., 362, 300 – 308 (2003).

C. B. Reid, J. Forrester, H. J. Goodshaw, and G. J. Suaning, “Study in the mechanical milling of alumina powder,” Ceram. Int., 34(6), 1551 – 1556 (2008).

M. A. Wojcik, T. Gajda, J. Plewa, et al., “Effect of selected parameters on grinding process of alumina in the rotary-vibration mill,” Fizykochemiczne Problemy Mineralurgii, No. 31, 115 – 124 (1997).

T. Ban, K. Okada, T. Hayashi, and N. Otsuka, “Mechanochemical effects for some Al2O3 powders of dry grinding,” J. Mater. Sci., No. 27, 465 – 471 (1992).

A. Pearson and G. MacZura, US Pat. 3358937. Dry grinding of alumina, 10.11.1965.

G. R. Karagedov and A. L. Myz’, RF Patent 2625104, Method for preparing submicron aluminium alpha-oxide powder, No. 2016123040; Claim 09.06.16; Publ. 11.07.2017; Bull. No. 20.

M. A. Trubitsyn, N. A. Volovicheva, L. V. Furda, and N. S. Skrypnikov, “Study of the effect of production factors on grain size properties of sub-micron aluminium oxide in α-form,” Vestnik BGTU im V. G. Shukova, No. 12, 84 – 97 (2021).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 1, pp. 19 – 25, January, 2023.

Parts 1 – 3 of the article published in Novye Ogneupory Nos. 3, 4, and 7 of 2022 respectively.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Trubitsyn, M.A., Volovicheva, N.A., Furda, L.V. et al. Research in the Area of Preparing Activated Alumina. Part 4. New Technological Approaches for Synthesis of Ultrafine α-Al2O3. Refract Ind Ceram 64, 21–26 (2023). https://doi.org/10.1007/s11148-023-00798-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-023-00798-x