Abstract

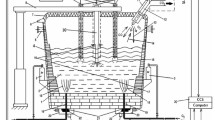

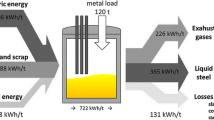

This paper considers equipment for ferrous metallurgy, one of the areas of which is cast iron and steel production, and later the production of such products as hot-rolled and cold-rolled sheet, pipe, and rebar. Working with metal melts is a complex, energy-intensive process, but expensive cooking coal, which is usually used in the production of cast iron, is a fuel, the usage of which is usually harmful to the environment and also affects the overall cost of the production. The article presents references to melting units with a torch immersed in the melt, and a new design of the unit operating on a carbon and hydrogen mixture is proposed. The energy-efficient unit allows conducting redox reactions, alloying, and degassing the melt within a single multi-stage device. The key to the entire process of working with the melt is the organization of the submerged combustion torch due to the presence of a perforated hearth in the design of the unit. This paper presents a method of calculating the perforated hearth, which will allow obtaining a carbon and hydrogen mixture at the wall-melt boundary. Based on the results of the calculation, a graph of the dependence of the number of perforation holes on the planned heat capacity of the hearth is presented in the text.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Baldauf-Sommerbauer, G., Lux, S., Siebenhofer, M.: Sustainable iron production from mineral iron carbonate and hydrogen. G. C. 23 (2016)

Pioro, L.S., Pioro, I.L., Kostyuk, T.O., Soroka, B.S.: Industrial Application of Submerged Combustion Melters. F. P., Kyiv-80, Ukraine, 240 p

Romenets, V.A., Valavin, V.C., Usachev, A.B., Karabasov, Y.S., Balasanov, A.V., Vandariev, S.V., Verein, V.G., Galkin, V.I., Zaitsev, A.K., Levin, M.Ya., Rekhersak, V.E., Pokhvisnev, Yu.V., Stomakhin, A.Ya., Chaikin, B.S., Yatsenko-Zhuk, A.D.: Process Romelt. In: V.A. (ed.). M.: MISIS P. h. “O. & M.”, p. 400 (2005)

Sapountz, F.M., Gracia, J.M., Weststrat, C.J., Fredricsso, H.O.A.: Electrocatalysts for the generation of hydrogen, oxygen and synthesis gas. P. E. & C. S. 58, 1–35 (2017)

Michael, A., Kinnon, M., Brower, J., Samuelsen, S.: The role of natural gas and its infrastructure in mitigating greenhouse gas emission, improving regional air quality, and renewable resource integration. P.E. & C. S. 64, 62–92 (2018)

Roger, F., Carreau, J.-L., Hobbes, P., Allou, A., Beauchamp, F.: Structure of strongly underexpanded gas jets submerged in liquids. N. E. & D. 273, 119–130 (2014)

Mattox, D.M.: Ch. 3—The «Good» Vacuum (Low Pressure). In: Processing Environment, Handbook of Physical Vapor Deposition (PVD) Pressing (Second Edition), pp. 73–14. William A. Publication (2010)

Zhu, B., Chattopadhyay, K.: Optimization of sampling location in the ladle during RH vacuum refining process. Vac. 152, 30–39 (2018)

Pivtsaev, V.V., Enders, V.V., Gulyaev, M.P.: Comparative efficiency of steel degassing during vacuuming at RH and VD units. In: Collection of S. W. of spec. of the Belarus, M. P., p. 360. Tekhnologiya, Minsk (2006)

Tesner, P.A.: Formation of carbon from the hydrocarbon gas phase. M., “Chemistry” (1972)

Neshporenko, E.G., Kartavtsev, S.V.: Questions of energy resource saving in the extraction of iron from ores: monograph, p. 153. GOU VPO “MSTU”, Magnitogorsk (2007)

Kartavtsev, S.V.: Intensive energy saving and technical progress of ferrous metallurgy: monograph, p. 311. GOU VPO “MSTU”, Magnitogorsk (2008)

Isaev, V.A.: Assessment of the energy intensity of the production of cast iron and steel. Electrician 6, 15–18 (2008)

Dzhigiris, D.D., Makhova, M.F.: Basics of the Production of Basalt Fibers and Products, p. 412. Teploenergetik, Moscow (2002)

Electronic resource. http://thermalinfo.ru/svojstva-gazov/gazy-raznye/dinamicheskaya-vyazkost-gazov-i-parov

Electronic resource. http://thermalinfo.ru/svojstva-gazov/organicheskie-gazy/svojstva-gazov-metanovogo-ryada

Electronic resource. https://www.fxyz.ru/spravochnye_dannye/termodinamicheskie_svojstva_veshchestv/koefficient_ob"emnogo_rasshireniya_gazov/

Electronic resource. http://thermalinfo.ru/svojstva-gazov/gazy-raznye/teploprovodnost-gazov

Tsvetkov, F.F., Kerimov, R.V., Velichko, V.I.: Task Book on Heat and Mass Transfer. MPEI P. H, Moscow (2008)

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Strogonov, K., Kornilova, L., Popov, A., Zdarov, A. (2022). Continuous Steelmaking Unit of Bubbling Type. In: Irina, A., Zunino, P. (eds) Proceedings of the International Symposium on Sustainable Energy and Power Engineering 2021. SUSE 2021. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-9376-2_6

Download citation

DOI: https://doi.org/10.1007/978-981-16-9376-2_6

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-9375-5

Online ISBN: 978-981-16-9376-2

eBook Packages: EngineeringEngineering (R0)