Dense HfB2– 30 vol.% SiC ceramics were obtained from commercially available powders by the hot-pressing method. Their basic physicomechanical properties were measured: the flexural strength at room temperature was 300 – 700 MPa, the Vickers microhardness reached 20 GPa, the critical stress intensity factor was up to 5.9 MPa·m1/2. Thermal expansion and resistance to oxidation were measured in a wide temperature range.

Similar content being viewed by others

Notes

This also leads to the fact that the temperature of the eutectics HfB2–MoSi2, HfB2–SiC, HfB2–B4C, HfB2–C, HfB2–HfC is strictly higher by 100 – 200°C than in the corresponding pairs with zirconium diboride.

Over the past five years, no more than 200 research papers have been published on the synthesis of initial powders, sintering, and the study of the properties of HfB2-based ceramics.

The density of HfB2 is close to the density of molybdenum (10.2 g/cm3) and high-temperature alloys based on it.

For HP it is better to use special grades of highly disperse SiC powders.

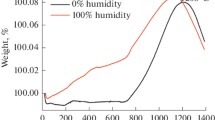

Statistics for 12 samples measuring 3.0 × 4.0 × 45.0 mm. Despite the different densities, no difference in mass gain was observed between the UHTC samples in terms of resistance to oxidation.

The calculated density of such a coating is ~ 2.0 g/cm3, as in the case of glass with a composition of 65% SiO2 – 35% B2O3. For reference: the density of amorphous SiO2 and B2O3 is 2.21 and 1.87 g/cm3, respectively.

References

Ultra-High Temperature Ceramics. Materials for Extreme Environment Applications, Ed. byW. G. Fahrenholtz, E. J.Wuchina, W. E. Lee, and Y. Zhou, Wiley, New Jersey (2014) 441 p.

T. H. Squire and J. Marschall, “Material property requirements for analysis and design of UHTC components in hypersonic application,” J. Europ. Ceram. Soc., 30, 2239 – 2251 (2010).

M. Mallik, A. J. Kailath, K. K. Ray, and R. Mitra, “Electrical and thermophysical properties of ZrB2 and HfB2 based composites,” J. Europ. Ceram. Soc., 32, 2545 – 2555 (2012).

J. Marschall, D. C. Erlich, H. Manning, et al., “Microhardness and high-velocity impact resistance of HfB2/SiC and ZrB2/SiC composites,” J. Mater. Sci., 39, 5959 – 5968 (2004).

L. Weng, W. Han, and Ch. Hong, “Fabrication and thermal shock resistance of HfB2 – SiC composite with B4C additives,” Materials Science-Poland, 29, 248 – 252 (2011).

J.-X. Liu, G.-J. Zhang, F.-F. Xu, et al., “Densification, microstructure evolution and mechanical properties of WC doped HfB2–SiC ceramics,” J. Europ. Ceram. Soc., 35, 2707 – 2714 (2015).

P. S. Sokolov, A. V. Arakcheev, I. L. Mikhal’chik, et al., “Ultra-high-temperature ceramics based on ZrB2–SiC: preparation and basic properties” [in Russian], Novye Ogneupory, No. 1, 33 – 39 (2017).

L. A. Chevykalova, I. Yu. Kelina, I. L. Mikhal’chik, et al., “Preparation of ultra-high temperature ceramic material based on zirconium boride by SPS method,” Refract. Ind. Ceram., 54(6), 455 – 462 (2013).

E. Zapata-Solvas, D. D. Jayaseelan, H. T. Lin, et al., “Mechanical properties of ZrB2- and HfB2-based ultra-high temperature ceramics fabricated by spark plasma sintering,” J. Europ. Ceram. Soc., 33, 1373 – 1386 (2013).

F. Monteverde, “Ultra-high temperature HfB2 – SiC ceramics consolidation by hot-pressing and spark plasma sintering,” J. Alloys Compd., 428, 197 – 205 (2007).

G.-J. Zhang, W.-M. Guo, D.-W. Ni, and Y.-M. Kan, “Ultra-high temperature ceramics (UHTCs) based on ZrB2- and HfB2 systems: powder synthesis, densification and mechanical properties,” Journal of Physics: Conference Series, 176, 012041 (2009).

S. J. Lee, E. S. Kang, S. S. Baek, and D. K. Kim, “Reactive hot-pressing and oxidation behavior of Hf-based ultra-high-temperature ceramics,” Surf. Rev. Lett., 17, 215 – 221 (2010).

F. Monteverde, C. Melandri, and S. Guicciardi, “Microstructure and mechanical properties of an HfB2 – 30 vol.% SiC composite consolidated by spark plasma sintering,” Mater. Chem. Phys., 100, 513 – 519 (2006).

F. Monteverde and A. Bellosi, “Microstructure and properties of an HfB2 – SiC composite for ultra-high temperature application,” Adv. Eng. Mater., 6, 331 – 336 (2004).

T. I. Serebryakova, V. A. Neronov, and P. D. Peshev, High-Temperature Borides [in Russian], Metallurgiya, Moscow (1991) 368 p.

G. G. Gnesin, Silicon Carbide Materials [in Russian], Metallurgiya, Moscow (1977) 216 p.

H. Wang, D. Chen, C. A. Wang, et al., “Preparation and characterization of high-toughness ZrB2/Mo composites by hot-pressing process,” Int. J. Refract. Met. & Hard Mater., 27, 1024 – 1026 (2009).

M. Singh and R. Asthana, “Joint of ZrB2-based ultra-high temperature ceramic composites to Cu-clad-molybdenum for advanced aerospace application,” International Journal of Applied Ceramics Technology, 6, 113 – 133 (2009).

V. I. Rumyantsev, N. Yu. Kovelenov, N. Yu. Korableva, et al., “Consolidation of Ceramic Composite Materials in the TiN-TiB2 System” [in Russian] (2011), www.virial.ru.

E. Zapata-Solvas, D. D. Jayaseelan, P. M. Brown, and W. E. Lee, “Effect of oxidation on room temperature strength of ZrB2- and HfB2-based ultrahigh temperature ceramics,” Advances in Applied Ceramics, 114, 407 – 417 (2015).

E. P. Simonenko, “New approaches to the synthesis of refractory nanocrystalline carbides and oxides and the production of ultra-high-temperature ceramic materials based on hafnium diboride” [in Russian], dis., (2016) www.igic.rac.ru.

D. V. Grashchenkov, O. Yu. Sorokin, Yu. E. Lebedeva, and M. L. Vaganova, “Features of sintering of refractory ceramics based on HfB2 by hybrid spark plasma sintering” [in Russian], Zh. Prikl. Khim., 88(3), 379 – 386 (2015).

The authors thank N. A. Golubeva, G. M. Bagreeva, P. Yu. Yakushkia, and A. P. Metleva for their help and assistance in carrying out the research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 5, pp. 48 – 55, May 2017.

Rights and permissions

About this article

Cite this article

Sokolov, P.S., Arakcheev, A.V., Mikhal’chik, I.L. et al. Ultra-High-Temperature Ceramics Based on HfB2 – 30% SiC: Production and Basic Properties. Refract Ind Ceram 58, 304–311 (2017). https://doi.org/10.1007/s11148-017-0101-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0101-4