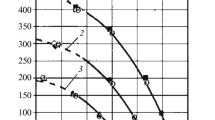

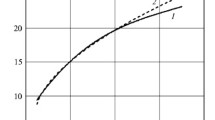

A new approach to the analysis of the heat work of glassmaking furnaces is proposed. A generalized equation of the thermal balance of a furnace at the boundaries between the smoke stack and the glass melt channel is obtained. Boundary conditions on the temperature for media whose heat content defines the cost items of the thermal balance are formulated. It is shown that the heat rate (specific consumption of heat) in melting of 1 kg glass influences the percentage content of the cost items of the generalized thermal balance. A calculation of the thermal balance of the melting area of a 320 t/day container glass furnace with specific consumption of heat 1000 kcal/kg is carried out.

Similar content being viewed by others

References

V. Ya. Dzuzer, V. S. Shvydkii, and Ye. B. Sadykov, “Theoretical heat consumption in glassmaking,” Steklo i Keramika, No. 7, 3 – 5 (2012); Glass and Ceramics, 69(7/8), 217 – 219 (2012).

V. Ya. Dzuzer, “Methods of increasing the energy efficiency of glassmaking furnaces,” Steklo i Keramika, No. 1, 11 – 14 (2012).

R. Beerkens, “Analysis of elementary process steps in industrial glass melting tanks — some ideas on innovations in industrial glass melting,” Ceramics — Silikaty, 52(4) 206 – 217 (2008).

K. Khoshmanesh, A. Z. Kouzani, S. Nahavandi, and A. Abbassi, “Reduction of fuel consumption in an industrial glass melting furnace,” Conference Paper: TENCON 2007 – 2007 IEEE Region 10 Conference (DOI: 10.1109/TENCON 2007.4428958).

V. Ya. Dzuzer, “Energy-efficient structure for the lining of the high-temperature regenerator of a glassmaking furnace,” Refractories and Industrial Ceramics, 55(1), 1 – 4 (2014).

V. Ya. Dzuzer and V. S. Shvydkii, “Boundary conditions for designing the lining of a glass-founding furnace with innovative parameters to improve technical efficiency,” Refractories and Industrial Ceramics, 56(6), 597 – 600 (2016).

V. Ya. Dzuzer and V. S. Shvydkii, Design of Energy-Efficiency Glassmaking Furnaces: Monograph [in Russian], Teplotekhnik, Moscow (2009), 340 pp.

The present article was written from the results of investigations conducted within the framework of the implementation of and with the support of the Program to Increase Competitiveness 5-100-2020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 2, pp. 15 – 18, February, 2017.

Rights and permissions

About this article

Cite this article

Dzyuzer, V.Y. Generalized Analysis of the Heat Work of Glassmaking Furnaces. Refract Ind Ceram 58, 25–28 (2017). https://doi.org/10.1007/s11148-017-0048-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0048-5