Abstract

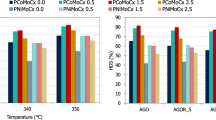

The Al2O3 supported monometallic Co, Ni and Mo and bimetallic CoMo and NiMo catalysts were compared in rapeseed oil hydrodeoxygenation (HDO) reaction after in situ sulfidation. The reaction was described by five pseudo-first order rate constants (k 1–k 5) for the simplified reaction scheme: triglycerides (Tgs) to octadecane (k 1); Tgs to oxygenates (Oxs; i.e., sum of fatty acids, fatty alcohols, and esters of fatty acids and fatty alcohols) (k 2); Tgs to heptadecane (k 3); Oxs to octadecane (k 4), and Oxs to heptadecane (k 5). The empirical pseudo-first order rate constant of the hydrocarbons (Hcs) product formation (k Hc ) increased in the order Ni/Al2O3 ~ Co/Al2O3 < CoMo/Al2O3 ~ Mo/Al2O3 ≪ NiMo/Al2O3 showing hence a significant synergy between Ni and Mo. All monometallic catalysts exhibited k 1 and k 3 practically zero and the reaction proceeded essentially through the formation of the oxygenated reaction intermediates (high k 2). The Co/Al2O3 and Ni/Al2O3 catalyzed selectively hydrodecarboxylation (HDC) of fatty acids (high k 5). Over Mo/Al2O3, the HDO pathway, however, was nearly the exclusive one (high k4). CoMo/Al2O3 and NiMo/Al2O3 catalysts yielded both HDO and HDC products suggesting partial synergy in the relative selectivity HDO/HDC between Co(Ni) and Mo.

Similar content being viewed by others

References

Baladincz P, Tóth C, Hancsók J (2012) Chem Eng Trans 29:1237–1242

Kubičková I, Kubička D (2010) Waste Biomass Valoriz 1:293–308

Kiatkittipong W, Phimsen S, Kiatkittipong K, Wongsakulphasatch S, Laosiripojana N, Assabumrungrat S (2013) Fuel ProcessTechnol 116:16–26

Hachemi I, Kumar N, Mäki-Arvela P, Roine J, Peurla M, Hemming J, Salonen J, Murzin DY (2017) J Catal 347:205–221

Jeništová K K, Hachemi I, Mäki-Arvela P, Kumar N, Peurla M, Čapek L, Wärnå J, Murzin DY (2017) Chem Eng J 316:401–409

Srifa A, Faungnawakij K, Itthibenchapong V, Viriya-empikul N, Charinpanitkul T, Assabumrungrat S (2014) Bioresour Technol 158:81–90

Hancsók J, Kasza T, Kovács S, Solymosi P, Holló A (2012) J Clean Prod 34:76–81

Şenol OI, Ryymin EM, Viljava TR, Krause AOI (2007) J Mol Catal A 268:1–8

Varakin AN, Salnikov VA, Nikulshina MS, Maslakov KI, Mozhaev AV, Nikulshin PA (2017) Catal Today 292:110–120

Nikul’shin PA, Sal’nikov VA, Pimerzin AA, Eremina YV, Koklyukhin AS, Tsvetkov VS, Pimerzin AA (2016) Pet Chem 56:56–61

Laurent E, Delmon B (1994) Appl Catal A 109:77–115

Szarvas T, Eller Z, Kasza T, Ollár T, Tétényi P, Hancsók J (2015) Appl Catal B 165:245–252

Ceclan RE, Pop A, Ceclan M (2012) Chem Eng Trans 29:1177–1182

Martins MI, Pires RF, Alves MJ, Hori CE, Reis MHM, Cardos VL (2013) Chem Eng Trans 32:817–822

Nascimento FP, Oliveira ARG, Paredes MLL, Costa ALH, Pessoa FLP (2013) Chem Eng Trans 32:829–834

Ignat RM, Kiss AA (2012) Chem Eng Trans 29:1141–1146

Smoláková L, Pöpperle L, Kocík J, Dubnová L, Horáček J, Čapek L (2017) Reac Kinet Mech Cat 121:209–224

Kubička D, Horáček L, Setnička M, Bulánek R, Zukal A, Kubičková I (2014) Appl Catal B 145:101–107

Coumans AE, Hensen EJM (2017) Appl Catal B 201:290–301

Zhou L, Lawal A (2017) Appl Catal A 532:40–49

Donnis B, Egeberg RG, Blom P, Knudsen KG (2009) Top Catal 52:229–240

Han Y, Stankovikj F, Garcia-Perez M (2017) Fuel Process Technol 159:328–339

Sugami Y, Minami E, Saka S (2017) Fuel 197:272–276

Kubička D, Kaluža L (2010) Appl Catal A 372:199–208

Furimsky E (2013) Catal Today 217:13–56

Costa PR (2007) PTQ Biofuels 2007:32–33

Neste Oil (2012) Neste Oil, Espoo. http://www.nesteoil.com/default.asp?path=1,41,11991,22708. Accessed 1 Oct 2012

Neste Oil (2012) Neste Oil, Espoo. http://www.nesteoil.com/default.asp?path¼1,41,11991,12243,13565. Accessed 1 Feb 2012

Hodge C (2006) Workshop on bioenergy. California Energy Commission. http://www.energy.ca.gov/bioenergy_action_plan/documents/2006-03-09_workshop/2006-03-09_NESTE_OIL.PDF. Accessed 9 March 2012

UOP (2012) UOP/ENI, Erkrath. http://www.uop.com/hydroprocessing-ecofining, Accessed 1 Oct 2012

Frey S (2011) Honeywell development of green jet fuel technology. In: IAE Bioenergy ExCo67 meeting, paper 08, Helsinki

Kalnes TN, Marker T, Shonnard D, Koers KP (2008) PTQ Biofuels 2008:7–11

Gosselink RW, Hollak SAW, Chang SW, Van Haveren J, De Jong KP, Bitter JH, Van Es DS (2013) ChemSusChem 6:1576–1594

Šimáček P, Kubička D, Šebor G, Pospíšil M (2010) Fuel 89:611–615

Kaluža L, Vít Z, Zdražil M (2005) Appl Catal A 282:247–253

Kaluža L, Gulková D, Vít Z, Zdražil M (2007) Appl Catal A 324:30–35

Acknowledgements

L.K. gratefully appreciates and acknowledges the financial support of the Czech Science Foundation (Grant No. 17-22490S).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kaluža, L., Kubička, D. The comparison of Co, Ni, Mo, CoMo and NiMo sulfided catalysts in rapeseed oil hydrodeoxygenation. Reac Kinet Mech Cat 122, 333–341 (2017). https://doi.org/10.1007/s11144-017-1247-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-017-1247-2