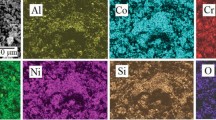

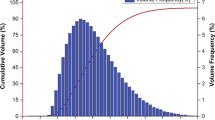

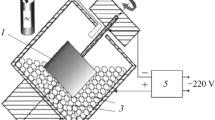

This paper examines the use of high-entropy alloys (HEAs) as materials for electrospark deposition (ESD). This method is known to produce high-quality protective coatings with a long service life. Arc-melted AlCrFeCoNiCux (x = 0 and 2 mole) cast alloys were used in the research. The HEA coatings were applied to steel 45 employing an Elitron-52A unit. The phase composition, hardness, and microstructure of the cast alloys and associated coatings were compared. The starting HEAs were found to have an inhomogeneous microstructure peculiar to the cast alloys and crystallize to form simple solid solutions with bcc and fcc phases. The AlCrFeCoNi alloy has higher hardness (6229 MPa) than the AlCrFeCoNiCu2 alloy does (5814 GPa). Studies of the structure and phase state of the samples showed that they consisted of an upper layer (coating), transition zone, and substrate with a ferrite–pearlite structure. The hardness, thickness, and continuity of the coatings increase with higher discharge energies Wd in ESD. At Wd = 0.13 J, the coating is 20 μm thick and has 70% continuity; at Wd = 4.6 J, the coating becomes 130 μm thick and is 100% continuous. In contrast to the cast alloys, the high-entropy coatings show higher microhardness: 6230 and 7320 MPa for AlCrFeCoNiCu2 and AlCrFeCoNi, respectively, at a discharge energy of 4.6 J. The coating thickness increases when copper is added to the electrode material. Simple solid solutions peculiar to high-entropy alloys form in both the cast alloys and the coatings. Unlike the cast alloys, the coatings are characterized by homogeneous microstructure.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, “Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes,” Adv. Eng. Mater., 6, No. 5, 299–303 (2004).

B.S. Murty, J.W. Yeh, S. Ranganathan, and P. P. Bhattacharjee, High-Entropy Alloys, Elsevier (2019), p. 388.

V.F. Gorban’, R.A. Shaginyan, M.O. Krapivka, S.O. Firstov, M.I. Danilenko, and I.V. Serdyuk, “Superhard vacuum coatings based on high-entropy alloys,” Powder Metall. Met. Ceram., 54, No. 11–12, 725–730 (2016).

D. Pogrebnjak, V.M. Beresnev, K.V. Smyrnova, Y.O. Kravchenko, P.V. Zukowski, and G.G. Bondarenko, “The influence of nitrogen pressure on the fabrication of the two-phase superhard nanocomposite (TiZrNbAlYCr) N coatings,” Mater. Lett., 211, 316–318 (2018).

A.D. Pogrebnjak, I.V. Yakushchenko, A.A. Bagdasaryan, O.V. Bondar, R. Krause-Rehberg, G. Abadias, G. Chartier, K. Oyoshi, Y. Takeda, V.M. Beresnev, and O.V. Sobol, “Microstructure, physical and chemical properties of nanostructured (Ti–Hf–Zr–V–Nb) N coatings under different deposition conditions,” Mater. Chem. Phys., 147, No. 3, 1079–1091 (2014).

Z. An, H. Jia, Y. Wu, P.D. Rack, A.D. Patchen, Y. Liu, Y. Ren, N. Li, and P.K. Liaw, “Solid-solution CrCoCuFeNi high-entropy alloy thin films synthesized by sputter deposition,” Mater. Res. Lett., 3, No 4, 203–209 (2015).

V.V. Chernyavsky, T.V. Vitryak, and A.I. Yurkova, “AlNiCoFeCrTiВх high-entropy alloy coatings resulted from electron beam welding,” in: Scientific Conferences of Ukraine. New Materials and Technology in Mechanical Engineering-2018 [in Ukrainian] (April 24–25, 2018), Igor Sikorsky Kyiv. Polytech. Inst., Kyiv (2018), p. 16; http://metalcasting.kpi.ua/2018/paper/view/13417.

H. Zhang, W. Wu, Y. He, M. Li, and S. Guo, “Formation of core–shell structure in high entropy alloy coating by laser cladding,” Appl. Surf. Sci., 363, 543–547 (2016).

V.B. Tarel’nik, A.V. Paustovskii, Y.G. Tkachenko, V.S. Martsinkovskii, A.V. Belous, E.V. Konoplyanchenko, and O.P. Gaponova, “Electrospark graphite alloying of steel surfaces: technology, properties, and application,” Surf. Eng. Appl. Electrochem., 54, No. 2, 147–156 (2018).

V.B. Tarelnikov, O.P. Gaponova, E.V. Konoplyanchenko, N.S. Evtushenko, and V.O. Gerasimenko, “Analysis of structural state of the surface layer after electrospark deposition. I. Formation of electrospark coatings on steel 45,” Metallofiz. Noveish. Tekhnol., 40, No. 2, 235–254 (2018).

G.V. Kirik, O.P. Gaponova, V.B. Tarelnyk, A.N. Myslyvchenko, and B. Antoszewski, “Quality analysis of aluminized surface layers produced by electrospark deposition,” Powder Metall. Met. Ceram., 56, No. 11–12, 688–696 (2018).

S. Cadney and M. Brochu, “Formation of amorphous Zr41.2Ti13.8Ni10Cu12.5Be22.5 coatings via the electrospark deposition process,” Intermetallics, 16, No. 4, 518–523 (2008).

Q.H. Li, T.M. Yue, Z.N. Guo, and X. Lin, “Microstructure and corrosion properties of AlCoCrFeNi high entropy alloy coatings deposited on AISI 1045 steel by the electrospark process,” Metall. Mater. Trans. A, 44, No. 4, 1767–1778 (2013).

N.A. Krapivka, S.A. Firstov, M.V. Karpets, A.N. Myslyvchenko, and V.F. Gorban’, “Phase formation and structurization in high-entropy alloys of the AlCrFeCoNiCux system (x = 0, 0.5, 1, 2, 3),” Fiz. Met. Metalloved., 116, No. 5, 496–504 (2015).

J. Dabrowa, G. Cieslak, M. Stygar, K. Berent, T. Kulik, and M. Danielewski, “Influence of Cu content on high temperature oxidation behavior of AlCoCrCuxFeNi high entropy alloys (x = 0; 0.5; 1),” Intermetallics, 84, 52–61 (2017).

M.V. Demchenko, O.P. Gaponova, O.M. Myslyvchenko, B. Antoszewski, and M.M. Bychenko, “Microstructure and properties of AlCrFeCoNiCux high-entropy alloys,” J. Eng. Sci., 5, No. 1, 11–15 (2018).

D. Karlsson, G. Lindwall, A. Lundbäck, M. Amnebrink, M. Boström, and L. Riekehr, “Binder jetting of the AlCoCrFeNi alloy,” Addit. Manuf., 27, 72–79 (2019).

C.S. Barrett and T.B. Massalski, Structure of Metals, Pergamon Press, Oxford, New York (1980).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 59, Nos. 3–4 (532), pp. 109–119, 2020.

Rights and permissions

About this article

Cite this article

Myslyvchenko, O., Gaponova, O., Tarelnyk, V. et al. The Structure Formation and Hardness of High-Entropy Alloy Coatings Obtained by Electrospark Deposition. Powder Metall Met Ceram 59, 201–208 (2020). https://doi.org/10.1007/s11106-020-00152-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00152-7