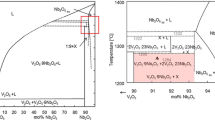

The evolution of microstructural and phase transformations during nitriding of mechanically preactivated vanadium disilicide powder is investigated by X-ray diffraction, chemical analysis, and transmission electron microscopy. It is established that, in the initial stage of nitriding (1000–1100°C), the phase formation is accompanied by the dispersion of near-surface zones of VSi2 particles and the formation of V2N and α-modification silicon nitride. With increase in the nitriding temperature, the phase formation is accompanied by the delamination of particles and the formation of mainly VN and silicon nitride of α- and α-modifications. Nitriding of a mechanically activated vanadium disilicide powder at 1400°C enables synthesizing a fine silicon nitride–vanadium nitride composite powder in a single process. The synthesized powder is formed as loose aggregates consisting of 50 nm particles.

Similar content being viewed by others

References

L. A. Krushinskaya, G. N. Makarenko, I. I. Timofeeva, et al., “Production of highly dispersed Si3N4–TiN composite powders. I. Effect of mechanical activation on nitriding of titanium silicide,” Nanostruc. Materialoved., No. 1, 98–104 (2006).

L. A. Krushinskaya, G. N. Makarenko, G. S. Oleinik, et al., “Production of highly dispersed Si3N4–TiN composite powders. II. Structure and phase transformations during nitriding of titanium silicide,” Nanostruc. Materialoved., No. 1, 84–90 (2007).

G. N. Makarenko, L. A. Krushinskaya, V. B. Fedorus, et. al., “Production and properties of AlN–BN composite,” Powder Metall. Met. Ceram., 49, Nos. 11–12, 670–674 (2010).

H. Borodianska, L. Krushinskaya, G. Makarenko, et al., “Si3N4–TiN nanocomposite by nitration of TiSi2 and consolidation by hot pressing and spark plasma sintering,” J. Nanosci. Nanotechnol., 9, 6381–6389 (2009).

S. Guicciardi, C. Melandri, V. Medri, and A. Belossi, “Effect of testing temperature and thermal treatment on some mechanical properties of a Si3N4–TiN composite,” Mater. Sci. Eng., A360, 35–45 (2003).

Z. Guo, G. Blugan, R. Kirchner, et al., “Microstructure and electrical properties of Si3N4–TiN composites sintered by hot pressing and spark plasma sintering,” Ceram. Int., 33, 1223–1229 (2007).

A. Belossi, S. Guicciardi, and A. Tamprieri, “Development and characterization of electro-conductive Si3N4–TiN composites,” J. Eur. Ceram. Soc., 13, No. 6, 551–559 (1992).

T. Ya. Kosolapova (ed.), Properties, Production, and Application of Refractory Compounds [in Russian], Metallurgiya, Moscow (1986), p. 928.

T. S. Bartnitskaya, P. P. Pikuza, I. I. Timofeeva, et al., “Formation of silicon nitride from silica,” Powder Metall. Met. Ceram., 22, No. 7, 523–527 (1983).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 54, No. 5–6 (503), pp. 3–10, 2015.

Rights and permissions

About this article

Cite this article

Krushinskaya, L.A., Makarenko, G.N., Kotko, A.V. et al. Phase Formation During Nitriding of Vanadium Disilicide. Powder Metall Met Ceram 54, 253–258 (2015). https://doi.org/10.1007/s11106-015-9707-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-015-9707-6