Abstract

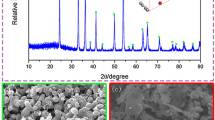

A simple and fast method of preparation of vanadium carbide (V8C7) nanopowders using mechanical alloying assisted microwave heating method was demonstrated. The micron-sized V2O5 and nano-sized carbon black were used as starting materials. The as-prepared powders were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), thermogravimetric and differential scanning calorimetry (TG-DSC), transmission electron microscopy (TEM), and X-ray photoelectron spectroscopy (XPS) techniques. The experimental results show that the V8C7 powders can be obtained by microwave heating at 1 100 °C for 1 h (34wt% C). The synthesized powders show good dispersion and are mainly composed of spherical or near-spherical particles with a mean diameter of about 30 nm. The XPS spectra show that the surface of the specimen mainly consists of V, C, and O three species elements.

Similar content being viewed by others

References

Zhong L, Zhang X, Chen S, et al. Fe–W–C Thermodynamics and Insuit Reparation of Tungsten Carbide–reinforced Iron–based Surface Composites by Solid–phase Diffusion[J]. Int. J. Refract. Met. Hard Mater., 2016, 57: 42–47

Gautam GS, Kumar KCH. Elastic, Thermochemical and Thermophysical Properties of Rock Salt–type Transition Metal Carbides and Nitrides: A First Principles Study[J]. Alloys Compd., 2014, 587(10): 380–386

Toth LE. Transition Metal Carbides and Nitrides[M]. New York: Academic Press, 1971

Kawakami M, Kitamura K. Segregation Layers of Grain Growth Inhibitors at WC/WC Interfaces in VC–doped Submicron–grained WCCo Cemented Carbides[J]. Int. J. Refract. Met. Hard Mater., 2015, 52: 229–234

García J, Pinto H, Ramos–Moore E, et al. In–situ High Temperature Stress Analysis of Ti(C,N) Coatings on Functionally Graded Cemented Carbides by Energy Dispersive Synchrotron X–ray Diffraction[J]. Int. J. Refract. Met. Hard Mater., 2016, 56: 27–34

Zhao X, Huang L, Li H, et al. Highly Dispersed VO/TiO Modified with Transition Metals (Cu, Fe, Mn, Co) as Efficient Catalysts for The Selective Reduction of NO with NH3[J]. Cata., 2015, 36(11): 1 886–1 899

Zhang YF, Fan MJ, Ling H, et al. Fabrication of V2O3/C Core–shell Structured Composite and VC Nanobelts by The Thermal Treatment of VO2/C Composite[J]. Appl. Surf. Sci., 2012, 258: 9 650–9 655

Chen Y, Zhang H, Ye H, et al. A Simple and Novel Route to Synthesize Nano–vanadium Carbide Using Magnesium Powders, Vanadium Pentoxide and Different Carbon Source[J]. Int. J. Refract. Met. Hard Mater., 2011, 29(4): 528–531

Wang H, Zeng M, Liu J, et al. One–step Synthesis of Ultrafine WC–10Co Hardmetals with VC/V2O5 Addition by Plasma Assisted Milling[ J]. Int. J. Refract. Met. Hard Mater., 2015, 48(8): 97–101

Tripathy PK, Sehra JC, Kulkarni AV. On the Carbonitrothermic Reduction of Vanadium Pentoxide[J]. Mater. Chem.A, 2001, 11(2): 691–695

Gupta CK, Krishnamurthy N. Extractive Metallurgy of Vanadium[M]. Amsterdam: Elsevier; 1992

Praveen S, Basu J, Kashyap S, et al. Exceptional Resistance to Grain Growth in a Nanocrystalline Co–Cr–Fe–Ni High Entropy Alloy at High Homologous Temperatures[J]. Alloys Compd., 2015, 662: 361

Zhang B, Li ZQ. Synthesis of Vanadium Carbide by Mechanical Alloying[ J]. Alloys Compd., 2005, 392(1–2): 183–186

Kapoor R, Oyama ST. Synthesis of Vanadium Carbide by Temperature Programmed Reaction[J]. Solid State Chem., 1995, 120(2): 320–326

Claridge JB, York APE, Brungs AJ, et al. Temperature–Programmed Reaction Synthesis of Early Transition Metal Carbide and Nitride Catalyst Materials from Oxide Precursors.[J]. Chem. Mater., 2000, 31(12): 132–137

Lee JS, Locatelli S, Oyama ST, et al. Turnover Rates for The Hydrogenolysis of N–butane[J]. Cata., 1990, 125(1): 157–170

Zhao Z, Zuo H, Liu Y, et al. Effects of Additives on Synthesis of Vanadium Carbide (VC) Nanopowders by Thermal Processing of The Precursor[J]. Int. J. Refract. Met. Hard Mater., 2009, 27(6): 971–975

Zhao Z, Liu Y, Cao H, et al. A Novel Method to Synthesize Vanadium Carbide (V8C7) Nanopowders by Thermal Processing NH4VO3, C6H12O6 and Urea[J]. Alloys Compd., 2009, 468(1): 58–63

Schwarzkopf P, Kieffer P. Refractory Hard Metals[M]. MacMillan, New York, 1953

Zhu M, Dai LY, Gu NS, et al. Synergism of Mechanical Milling and Dielectric Barrier Discharge Plasma on the Fabrication ofNnano–powders of Pure Metals and Tungsten Carbide[J]. Alloys Compd., 2009, 478(1): 624–629

Huang Z, Gotoh M, Hirose Y. Improving Sinterability of Ceramics Using Hybrid Microwave Heating[J]. Mater. Proc. Technol., 2009, 209(5): 2 446–2 452

Zhao Z, Chen F, Wang M, et al. Synthesis of Chromium Carbide Nanopowders Via a Microwave Heating Method[J]. Int. J. Refract. Met. Hard Mater., 2015, 51: 212–215

Cheng J, Agrawal D, Zhang Y, et al. Microwave Sintering of Transparent Alumina[J]. Mater. Lett., 2002, 56(4): 587–592

Hassan MN, Mahmoud MM, El–Fattah A A, et al. Microwave–assisted Preparation of Nano–hydroxyapatite for Bone Substitutes[J]. Ceramics Int., 2016, 42(3): 3 725–3 744

Liu Y, Min FF, Zhu JB, et al. Effect of Nanometer Al2O3 Powder on Microstructure and Properties of Alumina Ceramics by Microwave Sintering[J]. Mater. Sci. Eng. A, 2012, 546(6): 328–330

Li ZR, Cao ZQ, Fang MX. Study on Thermodynamic Principle of Preparation of VC by Carbon–Heat Reducing[J]. Adv. Mater. Res., 2011, 125(6): 328–330

Mahajan M, Singh K, Pandey OP. Single Step Synthesis of Nano Vanadium Carbide–V 8C 7, phase[J]. Int. J. Refract. Met. Hard Mater., 2013, 36(1): 106–110

Chatterjee P, Gupta SPS, Sen S. Microstructural Transformation of Vanadium Pentoxide Powder Obtained by High–energy Vibrational Ball–milling[J]. J. Appl. Crystallogr., 2001, 34(3): 381–386

Zhao Z, Zuo H, Liu Y, et al. Effects of Additives on Synthesis of Vanadium Carbide (VC) Nanopowders by Thermal Processing of the Precursor[J]. Int. J. Refract. Met. Hard Mater., 2009, 27(6): 971–975

Olvera JNR, Paredes GJG, Serrano AR, et al. Synthesis and Characterization of a MoWC–WC–NiC Nanocomposite Via Mechanical Alloying and Sintering[J]. Powder Technol., 2015, 27: 292–300

Loginov PA, Levashov EA, Kurbatkina VV, et al. Evolution of the Microstructure of Cu–Fe–Co–Ni Powder Mixtures Upon Mechanical Alloying[J]. Powder Technol., 2015, 276: 166–174

Yan L, Wu E. The Preparation of Ultrafine V 8C 7, Powder and Its Phase Reactions[J]. Int. J. Refract. Met. Hard Mater. 2007, 25(2): 125–127

Matyi RJ, Schwartz LH, Butt JB. Particle Size, Particle Size Distribution, and Related Measurements of Supported Metal Catalysts[J]. Catal. Rev. Sci. Eng., 1987, 29(1): 41–99

Meunier F, Delporte P, Heinrich B, et al. Synthesis and Characterization of High Specific Surface Area Vanadium Carbide; Application to Catalytic Oxidation[J]. J. Catal., 1997, 169(169): 33–44

Choi JG. The Surface Properties of Vanadium Compounds by X–ray Photoelectron Spectroscopy[J]. J. Appl. Surf. Sci., 1999, 148(1–2): 64–72

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Natural Science Foundation of China (21404032), the Program for Science & Technology Innovation Talents in Universities of Henan Province (16HASTIT011), the Funding Scheme for Young Teachers of Higher School in Henan Province (2014GGJS-062), the Fundamental Research Funds for the Henan Provincial Colleges and Universities (2014YWQQ19), the Development of Science and Technology Plan Projects of Zhengzhou City (20140771) and the Foundation of Henan University of Technology ( 2014JCYJ13), China

Rights and permissions

About this article

Cite this article

Yang, B., Zheng, H., Zhao, Z. et al. Synthesis of Vanadium Carbide Nanopowders via Mechanical Alloying and Microwave Heating Methods. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 34, 332–336 (2019). https://doi.org/10.1007/s11595-019-2056-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-019-2056-4