Abstract

Fixing atmospheric nitrogen for use as fertilizer is a crucial process in promoting plant growth and enhancing crop yields in agricultural production. Currently, the chemical production of nitrogen fertilizer from atmospheric N2 relies on the energy-intensive Haber–Bosch process. Therefore, developing a low-cost and easily applicable method for fixing nitrogen from the air would provide a beneficial alternative. In this study, we tested the utilization of dinitrogen pentoxide (N2O5) gas, generated from oxygen and nitrogen present in ambient air with the help of a portable plasma device, as a nitrogen source for the model plant Arabidopsis thaliana. Nitrogen-deficient plants supplied with medium treated with N2O5, were able to overcome nitrogen deficiency, similar to those provided with medium containing a conventional nitrogen source. However, prolonged direct exposure of plants to N2O5 gas adversely affected their growth. Short-time exposure of plants to N2O5 gas mitigated its toxicity and was able to support growth. Moreover, when the exposure of N2O5 and the contact with plants were physically separated, plants cultured under nitrogen deficiency were able to grow. This study shows that N2O5 gas generated from atmospheric nitrogen can be used as an effective nutrient for plants, indicating its potential to serve as an alternative nitrogen fertilization method for promoting plant growth.

Key message

We identified plasma-generated N2O5 gas as a promising nitrogen fertilizer with the capacity to promote agricultural production by utilizing atmospheric nitrogen.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

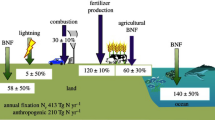

Nitrogen is an essential element for plant growth, and the availability of nitrogen directly impacts crop yield (Cui et al. 2018; Luo et al. 2020). Plants cannot directly utilize atmospheric nitrogen as a nitrogen source, and therefore they rely on nitrogen sources that have undergone nitrogen fixation, converting atmospheric nitrogen into a form that plants can absorb (Charles et al. 2010; Pikaar et al. 2017). The Haber–Bosch process has significantly increased the supply of nitrogen for crop production, leading to higher crop yields and supporting a larger population. Nitrogen fixation through this process surpasses the amounts of nitrogen fixed by living organisms (Pikaar et al. 2017). As the global population continues to grow, the demand for nitrogen fertilizers rises and will reach to 150 Mton by 2050 (Pikaar et al. 2022). However, the Haber–Bosch method has several drawbacks. Its production requires approximately 2% of the world’s annual energy consumption and emits over 300 million tons of CO2 due to the chemical conversion of highly stable N2 molecules through reactions at high temperatures and pressures (350–550 °C, 150–350 atm) (Patil et al. 2015). The requirement for large-scale facilities leads to high expenses and the need for construction sites. As a result, nitrogen fertilizers currently represent the largest cost factor in agriculture in industrialized countries and their use is becoming increasingly difficult in developing countries. Furthermore, a significant portion (50–75%) of the supplied nitrogen is not absorbed by plants and is instead lost through leaching into the soil. The nitrogen forms that remain in the soil are a cause of excessive accumulation in soil, which affects plant growth adversely (Liu et al. 2020). Consequently, there is a growing need to explore new, sustainable, and environmentally friendly alternatives to the Haber–Bosch method of nitrogen fixation and nitrogen supplementation (Cherkasov et al. 2015; Fradgley et al. 2021; Chen et al. 2021).

Plasma-based nitrogen fixation is gaining attention as an alternative procedure to supply nitrogen (Patil et al. 2015; Li et al. 2018). Plasma is a highly energetic state of matter that can generate nitrogen oxides by dissociating nitrogen and oxygen molecules present in air (Graves 2012; Ochi et al. 2017). This process can be performed under relatively moderate reaction conditions, such as atmospheric pressure and ambient temperature, and requires minimal energy consumption and start-up time to initiate the process which ensures compatibility with renewable energy sources. Therefore, plasma-based nitrogen fixation is being widely investigated as a promising approach for establishing sustainable agricultural systems (Graves 2012; Patil et al. 2015; Puač et al. 2018; Gao et al. 2022). Traditional plasma-based nitrogen fixation has been employed for the synthesis of NH3 and NOx (Bogaerts and Neyts 2018). More recently, a plasma device has been developed to generate dinitrogen pentoxide (N2O5) from atmospheric nitrogen and oxygen (Sasaki et al. 2021). N2O5 is a highly reactive compound that decomposes at high temperatures and is hygroscopic, readily reacting with water and rapidly converting into two nitrate ions (NO3−). This knowledge inspired us to investigate whether plasma-generated N2O5 gas could function as a nitrogen source for plant culture, i.e. an alternative form of nitrogen fixation.

In this study, we evaluated the potential of plasma-generated N2O5 gas as a nitrogen fertilizer. Addition of N2O5 gas to growth medium supported growth of plants cultured in otherwise nitrogen-deficient medium, however direct and prolonged exposure of plants to the gas itself inhibited growth. To overcome this problem, we successfully tested several alternative approaches for supplying plasma-generated N2O5 gas to the plants. We conclude that plasma-generation of N2O5 has potential to serve as a novel nitrogen fixation procedure that will allow the use of atmospheric nitrogen in agricultural production.

Methods

Plant growth conditions

In this research, a series of experiments were carried out using the model plant Arabidopsis thaliana. Plants were grown in a growth chamber (LPH-410S; Nippon Medical & Chemical Instruments Co. Ltd.) set to 16 h light, 8 h dark, 100–120 mmol of photons m−2 s−1 with daylight LEDs, and 22 °C, on vermiculite as substrate. To support growth, each plant was supplied with 100 ml/week of liquid medium by placing the pot holding the plants and vermiculite into a larger container containing the medium. Nitrate sufficient medium (+N medium) was composed of 1.4 M CaNO3, 0.35 M MgSO4–7H2O, 2 M KCl diluted 1000-fold in ultrapure water and 100 mM Fe[III]–EDTA diluted 10,000-fold. Micronutrients (70 mM H3BO3, 20 mM MnCl2–4H2O, 0.3 mM CuSO4–4H2O, 1 mM ZnSO4–7H2O, 0.2 mM K2MoO4, 0.1 mM CoCl2–6H2O) were prepared in 1000-fold dilutions. Nitrate-free medium (–N medium) was prepared in ultrapure water with 1.4 M CaCl2, 0.35 M MgSO4–7H2O, 2 M KCl diluted 1000-fold and 100 mM Fe[III]–EDTA diluted 10,000-fold. Micronutrients were prepared in a 1000-fold dilution.

Plasma gas generation with portable plasma N2O5 device

A portable plasma N2O5 generation device was used as previously described to produce N2O5 from air (Sasaki et al. 2021). N2O5 gas generated from dried air contained approximately 310 ppm of N2O5 and was delivered at a flow rate of 2 L/min. When the dry N2O5 gas (2 L/min) was mixed with humidified air (0.2 L/min), N2O5 gas was converted to HNO3 gas during a 21 s-reaction process in a perfluoroalkoxy alkanes tube (10-m length and 10-mm inner diameter). N2O5 gas and HNO3 gas were flown through a gas cell with 5 m long multi-optical path for Fourier-transform infrared spectroscopy (FT-IR) for gaseous composition analysis. The detailed quantification procedure was previously described (Kimura et al. 2019).

Supply of N2O5 to plants via liquid medium

Plants were grown with +N medium for 1 week, then pots were transferred to –N medium and grown for another 2 weeks (= nitrogen-deficient plants). To supply N2O5, 50 ml of –N medium per plant was placed in a container, and N2O5 gas was supplied for 1 (ca. 2 L), 4 (ca. 8 L) or 7 min (ca. 14 L). The plants with their pots were then transferred to this medium. The N2O5-dissolved medium was supplied every 3–4 days for a total of three times. The plants were grown for an additional 2 weeks after the last supply and then sampled. As a positive control, +N medium was supplied to nitrogen-deficient plants and, as a negative control, –N medium was supplied to nitrogen-deficient plants.

Supply of N2O5 gas to plants

Plants were grown on +N medium for 1 week, transferred to –N medium and then grown for another 2 weeks (= nitrogen-deficient plants). At that point, plants were placed with their pots into secondary containers, and exposed to N2O5 gas directly at approximately 300 ppm at 2 L/min for 1, 4, or 7 min every 3–4 days for a total of three times. After the final treatment, plants were grown for another 2 weeks and then sampled. For the mock treatment, dry air was supplied for 7 min to nitrogen-deficient plants.

Supply of N2O5 and HNO3 to plants

Plants were grown on +N medium for one week, transferred to –N medium and grown for 2 weeks more. The plants were then placed into secondary, conical containers and supplied with N2O5 gas or humidified gas containing HNO3 and N2O5 (see description of plasma gas generation above) for 4 min every 3–4 days for a total of three times. The plants were grown for another 2 weeks after the final treatment and before sampling.

Long-term exposure to a batch volume of N2O5 gas

Plants grown on –N medium for 2 weeks after sowing were used. N2O5 and HNO3 gases generated by the plasma device were supplied for 20 min into a 35 L container containing several 0.125 L boxes. A plant was then placed into each 0.125 L box, the box was quickly covered with a lid and placed in a growth chamber for 24 h. The lid was then opened, and the plants remained in the growth chamber, supplied with –N liquid medium until the next treatment. This gas treatment was repeated twice per week, for a total of six treatments. After the final treatment, plants were grown for one more week with –N medium before sampling.

Results

N2O5 is an effective nitrogen source for Arabidopsis thaliana

We employed an atmospheric pressure plasma portable device, which we recently developed, to selectively generate N2O5 gas from ambient air with low power consumption (< 100 W) (Sasaki et al. 2021). The composition of the generated gas was highly dependent on the humidity of the air used as substrate. When dry air was used with the device, most of the generated gas consisted of N2O5 (Fig. 1A, B). The resulting dry gas contained 311 ppm of N2O5. When the dry N2O5 containing air was mixed with humidified air, the N2O5 gas immediately converted to HNO3, and the main product was HNO3 (Fig. 1C, D). The resulting humidified gas contained 433 ppm of HNO3 and 73 ppm of N2O5.

Gaseous composition of plasma-generated N2O5 gas and HNO3 gas. A, B N2O5 gas was generated from extremely dry air using an atmospheric pressure plasma device, developed recently (Sasaki et al. 2021). C, D HNO3 gas was generated by mixing humidified air with the extremely dry N2O5 gas. A, C A typical Fourier-transform infrared spectroscopy (FT-IR) absorbance spectrum of the plasma-generated N2O5 gas and HNO3 gas (upper half). The best-fit spectrum was obtained with the least square error method. The best-fit spectrum was the summation of the absorbance spectra of the individual species, as shown by the downward absorbance proportional to each density (lower half). B, D Typical densities of individual gaseous reactive species in dry N2O5 gas B and in humidified HNO3 gas obtained from FT-IR spectra in A and C, respectively.

To evaluate the potential of N2O5 gas to be used as a nitrogen source for plant growth, we applied the generated N2O5 gas to nitrogen-free medium for 1, 4 or 7 min and used this medium to treat nitrogen-deficient plants (Fig. 2A). Specifically, after culturing plants with nitrogen-sufficient medium for 1 week, they were cultured with nitrogen-free medium for 2 weeks to induce nitrogen-deficiency (Fig. 2B and Supplemental Table S1). Then, the plants in the pots were supplied with medium that had been exposed to N2O5 gas (for 1, 4 or 7 min). Plants remained in this medium for 1 week and were then transferred back to medium without nitrogen source. Growth of plants treated with medium exposed to N2O5 gas for 1 or 4 min was similar to that of plants grown under nitrogen-deficient conditions (Fig. 2C, D). However, plants treated with medium exposed to N2O5 gas for 7 min grew as well as those grown with nitrogen-sufficient medium that contained Ca(NO3)2 (Fig. 2C, D). Furthermore, accumulation of anthocyanins, a symptom of nitrogen deficiency, decreased the longer the medium had been exposed to N2O5 (Fig. 2C). This suggested that plasma-generated N2O5 gas can be used as a nitrogen source for plant growth.

Plasma-generated N2O5 is an effective nitrogen source for plants. A Experimental set-up for the treatment of plants with N2O5 and the following plant culture. B Plants were initially grown with a nitrogen-sufficient medium containing Ca(NO3)2 (+N) for a week (gray box) and then shifted to nitrogen-deficient medium (N) for 2 weeks (white box). After that, plants were supplied with medium treated with N2O5 gas (for 1, 4 or 7 min, see Methods for details) every 3–4 days for a total of three times (green box). Following these treatments, the plants were grown on N medium for two more weeks (white box) before being photographed and sampled for phenotype analysis. For further details refer to Methods and Supplemental Table S1. C Photograph of plants taken at the end of the experiment. D Fresh weight of the plants. This experiment was repeated twice. The data are presented as mean ± s.d. of n ≥ 3 plants, analyzed using one-way ANOVA

Treating plants directly with plasma-generated N2O5 gas has negative effects on growth

We next investigated whether N2O5 gas could be used to promote plant growth by directly supplying it to the plants as a gas. Considering the quick conversion of N2O5 gas to NO3− in water (Fig. 1), we predicted that N2O5 gas might be readily absorbed by the vermiculite and plant tissues (leaves and stems). N2O5 gas generated by the same portable plasma device was applied to plants over a short period of time (1–9 min). Under those conditions, symptoms of plant damage were observed after about 4 min of treatment, and significant changes in the plants were evident after 7 min of the treatment (Fig. 3B). Plants exposed to the gas for 7 min began to wilt and change their leaf color within minutes (Fig. 3B and Supplemental Fig. S1). Therefore, the direct supply N2O5 through the portable plasma device had negative impacts on plant health.

Effects of direct supply of N2O5 gas to plant seedlings. A Experimental set-up for the treatment of plants with N2O5 and the following plant culture. B Plants grown for 1 week on +N medium were transferred to –N medium and grown for another 2 weeks. Then N2O5 gas was directly supplied to each plant for 1 to 9 min. Mock treatment consisted of dry air supplied to the plants for 9 min. C Photographs of plants, taken after one treatment

To supply a sufficient amount of nitrogen to the plants without prolonged direct exposure to N2O5 gas, we instead supplied N2O5 gas to the plants for a limited period of 1, 4, or 7 min at three separate times, 3–4 days apart (Fig. 4A, B and Supplemental Table S1). Reproductive-stage plants grown under nitrogen-deficient conditions were used for this experiment. Leave damage was observed in plants exposed to N2O5 gas for 4 min and 7 min, and fresh weight was reduced by 71% and 89% when plants were treated three times for 4 min and 7 min, respectively, compared to the mock-treated plants (Fig. 4C, D). However, plants exposed to N2O5 gas three times for 4 or 7 min had green leaves, and symptoms of nitrate deficiency disappeared (Fig. 4C). Plants exposed to N2O5 three times for 1 min showed accumulation of anthocyanin in their leaves although their fresh weight was almost the same as that of the mock-treated plants.

Direct exposure to plasma-generated N2O5 gas impaired plant growth. A Experimental set-up for the treatment of plants with N2O5 and the following plant culture. B Plants were grown on +N medium for 1 week (grey box), followed by growth on –N medium for two weeks (white box), and then treated with dry air (mock) or with N2O5 gas added directly to the vapor phase of the container. The gas was injected for 1, 4, or 7 min each time, every 3–4 days for a total of three times (green box). After the final treatment, the plants remained on –N medium for two more weeks (white box) before being photographed and sampled for phenotype analysis. C Photographs of plants taken at the end of the experiment. D Fresh weight of the plants. This experiment was repeated twice. The data are presented as mean ± s.d. of n = 3 plants, analyzed using one-way ANOVA. E Experimental set-up for the treatment of plants with dry or humidified N2O5 gas and the following plant culture, providing a simplified method of supplying N2O5 and HNO3 to plants. The experimental schedule was essentially the same as B except for the N2O5 treatment. Three-week-old plants were either exposed to generated N2O5 directly or to N2O5 that had been additionally passed through humid air for 4 min. The treatment was performed every 3–4 days for a total of three times before plants were photographed and sampled for phenotype analysis. F Photographs of plants taken at the end of the experiment. G Fresh weight of the plants. This experiment was repeated twice. The data are presented as mean ± s.d. of n = 3 independent plants P < 0.05, ns not significant (P > 0.05); Student t-test. Scale bars = 1 cm

We evaluated the effects of mixing N2O5 gas with moist air on plant growth (Fig. 4e) because under high humidity N2O5 was converted to HNO3 gas (Fig. 1). Air was pre-saturated with humidity by flowing through a Gas washing bottle bubbler, and then mixed with N2O5 gas (Fig. 4E). The resulting gas mixture was added to the plant growth chamber every 3–4 days for 4 min, a total of three times (Fig. 4B, Table S1). Control treatment with N2O5 mixed with dry air was done the same as shown in Fig. 2. When plants were exposed to N2O5 gas mixed with moist air, they produced less biomass but continued to look healthy without chlorosis (Fig. 4F). Plants treated with dry N2O5 gas had an 88% increase in fresh weight, compared with plants treated with the humidified N2O5 gas (Fig. 4G). These data suggested that treating plants with dry N2O5 gas was better for plant growth than treatment with N2O5 gas mixed with moist air.

Alternative modes of application of N2O5 to plants

The direct supply of N2O5 gas as shown in Figs. 3 and 4 inhibited the growth of plants. Therefore, we tested an alternative method of supplying nitrogen directly from the N2O5 generator to plants in nitrogen-free medium. For this, we physically separated the plant culture process from the treatment with N2O5 (Fig. 5A, B). First, N2O5 gas generated by the device (either mixed with dry or moist air) was introduced for 20 min into a container holding several smaller containers but no plants. After that, nitrogen-deficient plants were placed into the smaller containers which were covered with lids. Note that this process was feasible since N2O5 gas has a higher density than air. The covered containers with the plants were moved to a growth chamber. After 24 h, the lids were removed, and plants were again supplied with nitrogen-free medium (Fig. 5A). This procedure was repeated twice per week, for a total of six times, followed by an additional week of growth with nitrogen-free medium at the end (Fig. 5B and Supplemental Table S2). In this result, plants treated with dry air could hardly grow on vermiculite and this suggested vermiculite did not have sufficient amount of nitrogen for plant growth. Plants treated with N2O5 gas had increased fresh weight, similar to the plants treated with HNO3 gas (resulting from mixing N2O5 gas with moist air) (Fig. 5C, D). These results showed that supplying N2O5 gas to plants can be an effective method for supplying nitrogen fertilizers to plants without relying on traditional nitrogen fixation processes.

Supplementation of generated N2O5 to plants without direct exposure to N2O5 gas. A Experimental set-up for the treatment of plants with N2O5 and the following plant culture. B After germinating seeds on –N medium and growing them for 2 weeks (white box), the pots were placed in containers filled with plasma-generated N2O5 or HNO3 gas generated according to the process shown in Fig. 1B and containers remained sealed for one day. After that, the plant pots were removed from the containers and placed directly into the growth chamber for 2 or 3 days. This treatment cycle was repeated five times for a total of 6 treatments over the course of 3 weeks (green box, arrowheads indicate treatments). After the final treatment, plants were grown for another one week in a growth chamber (white box) before being photographed and sampled for phenotype analysis. Further details refer to Materials and Methods and Supplemental TableS2 . C Photographs of plants at the end of the experiment. Scale bars = 1 cm. D Fresh weight of the plants. This experiment was repeated twice. The data are presented as mean ± s.d. of n = 4 plants, analyzed using one-way ANOVA

Discussion

N2 in the air is an inert gas that is not readily available as a plant nutrient but instead requires conversion by energy-intensive conventional nitrogen fixation processes. Our study shows that N2O5 gas generated with a portable plasma device can be a new avenue of supplying a nitrogen source to plants. This method can be expected to be useful as an alternative nitrogen fertilization procedure to support plant growth while preventing the excessive use of conventional nitrogen fertilizers. However, direct administration of N2O5 to plants inhibited growth (Fig. 3). Hence, it was crucial for us to develop an effective method for delivering N2O5 to the plants. In this study, we explored various methods for administering N2O5 gas to plants. When plants were cultured using liquid medium that had been exposed to N2O5 gas, their growth was not impaired (Fig. 2). But repeated short-term application of the N2O5 gas directly from the plasma device to nitrogen-starved plants damaged shoot tissues and only partially improved plant growth (Fig. 4). These problems could be avoided by placing nitrogen-deficient plants into a chamber pre-filled with N2O5, and subsequently growing them in medium without a nitrogen source (Fig. 5). Our results demonstrated that plants could be grown from seeds on nitrogen-free medium, with nitrogen supplied from the air, in the form of N2O5 gas if the duration of contact with the plants or the concentration of the gas was reduced.

The portable plasma device used in this study consumes less than 100 W of power, which can be efficiently supplied from renewable energy sources, and the only material used is air. This device excels in its portability and ability to produce a nitrogen source from air using minimal power, without the need for large facilities. The device is an efficient N2O5 generator that can selectively produce N2O5, minimizing waste (Fig. 1) (Sasaki et al. 2021). On the other hand, the energy efficiency of nitrogen fixation by the plasma device is about 72 MJ/(mol N) (Sasaki et al. 2021), and that by the Haber–Bosch method is about 0.5 to 0.6 MJ/(mol N) (Rouwenhorst et al. 2021), indicating that the Haber–Bosch method is still superior to the portable plasma device in terms of energy efficiency per mole of nitrogen.

The generated N2O5 gas contained some impurities including O3 (Fig. 1), which is known to cause cell death and photosynthesis inhibition in Arabidopsis even at very low concentrations at the ppb level. As shown in Fig. 3 and 4, direct exposure of plants to N2O5 gas produced by the device resulted in growth impairment, potentially due to the presence of O3 or rapid acidification due to the chemical reaction of N2O5 and H2O. However, when the supply of plasma-generated N2O5 gas was more limited, the plants grew well (Fig. 5).

Foliar application of liquid fertilizers is used in modern agriculture. This technique is especially effective in plants with weakened roots and under continuous cloud cover (high humidity) where transpiration does not take place (Fernández et al. 2021; Naqve et al. 2021). Therefore, foliar application allows nitrogen to be supplied directly to the tissues that need it. Foliar nitrogen is supplied as water-soluble compounds including NO3−, NH4+, urea and amino acids (Lv et al. 2021). This method has the disadvantage of not supplying nitrogen uniformly due to high leaf overlap and plant density. In contrast, gaseous nitrogen fertilizers can even penetrate into small spaces between leaves. The chemical polarity of N2O5 is significantly lower than that of HNO3. This lower polarity may promote the infiltration of N2O5 across the leaf surface, consisting of the cuticular wax and cell wall layers. Once taken up into the cells, the buffering capacity of the cytoplasm may ameliorate any acidification resulting from the conversion of N2O5 to HNO3. This may explain why treatment with dry N2O5 was more effective in enhancing plant growth than when N2O5 was mixed with moist air (as shown in Fig. 4F, G). Moreover, it was recently reported that exposure of Arabidopsis thaliana to N2O5 gas leads to the induction of an immune response during a pathogen inoculation test (Tsukidate et al. 2022). This indicates that N2O5 is absorbed by the surface of the plant tissue. The immune-inducing effect of N2O5 also increases its superiority for use as a nitrogen fertilizer for plants. Our study supports the idea that air-derived N2O5 has potential to be used as a foliar nitrogen fertilizer altered to or with conventional nitrogen fertilizer although N2O5 was also absorbed by the soil and the medium.

In conclusion, we have successfully applied N2O5 gas as alternative nitrogen source that improves plant growth. This ability to directly utilize N2, which is abundantly present in the Earth’s atmosphere, as a gaseous nitrogen source is a promising development for plant cultivation and agriculture. The method established in this study will even make it feasible to reliably supply nitrogen to regions of the world where nitrogen fertilizer production has been challenging or impossible, such as in less developed regions.

Data availability

This ability to directly utilize N2, which is abundantly present in the Earth’s atmosphere, as a gaseous nitrogen source “may be” a promising development for plant cultivation and agriculture.

References

Bogaerts A, Neyts EC (2018) Plasma technology: an emerging technology for energy storage. ACS Energy Lett 3:1013–1027. https://doi.org/10.1021/acsenergylett.8b00184

Charles H, Godfray J, Beddington J, Crute I, Haddad L, Lawrence D, Muir J, Pretty J, Robinson S, Thomas S, Toulmin C (2010) Food security: the challenge of feeding 9 billion people. Science 327:812–818

Chen H, Yuan D, Wu A, Lin XLi X, (2021) Review of low-temperature plasma nitrogen fixation technology. Waste Dispos Sustain Energy 3:201–217

Cherkasov N, Ibhadon AO, Fitzpatrick P (2015) A review of the existing and alternative methods for greener nitrogen fixation. Chem Eng Process 90:24–33. https://doi.org/10.1016/j.cep.2015.02.004

Cui Z, Zhang H, Chen X, Zhang C, Ma W, Huang C, Zhang W, Mi G, Miao Y, Li X, Gao Q, Yang J, Wang Z, Ye Y, Guo S, Lu J, Huang J, Lv S, Sun Y, Liu Y, Peng X, Ren J, Li S, Deng X, Shi X, Zhangc Q, Yang Z, Tang L, Wei C, Jia L, Zhang J, He M, Tong Y, Tang Q, Zhong X, Liu Z, Cao N, Kou C, Ying H, Yin Y, Jiao X, Zhang Q, Fan M, Jiang R, Zhang F, Dou Z (2018) Pursuing sustainable productivity with millions of smallholder farmers. Nature 555:363–366. https://doi.org/10.1038/nature25785

Fernández V, Gil-Pelegrín E, Eichert T (2021) Foliar water and solute absorption: an update. Plant J 105:870–883. https://doi.org/10.1111/TPJ.15090

Fradgley NS, Bentley AR, Swarbreck SM (2021) Defining the physiological determinants of low nitrogen requirement in wheat. Biochem Soc Trans 49:609–616

Gao Y, Francis K, Zhang X (2022) Review on formation of cold plasma activated water (PAW) and the applications in food and agriculture. Food Res Int. https://doi.org/10.1016/j.foodres.2022.111246

Graves D (2012) The emerging role of reactive oxygen and nitrogen species in redox biology and some implications for plasma applications to medicine and biology. J Phys D Appl Phys. https://doi.org/10.1088/0022-3727/45/26/263001

Kimura Y, Takashima K, Sasaki S, Kaneko T (2019) Investigation on dinitrogen pentoxide roles on air plasma effluent exposure to liquid water solution. J Phys D Appl Phys 52:064003. https://doi.org/10.1088/1361-6463/aaf15a

Li S, Medrano JA, Hessel V, Gallucci F (2018) Recent progress of plasma-assisted nitrogen fixation research: a review. Processes. https://doi.org/10.3390/pr6120248

Liu X, Xu W, Du E, Tang A, Zhang Y, Zhang Y, Wen Z, Hao T, Pan Y, Zhang L, Gu B, Zhao Y, Shen J, Zhou F, Gao Z, Feng Z, Chang Y, Goulding K, Collett J, Vitousek P, Zhang F (2020) Environmental impacts of nitrogen emissions in China and the role of policies in emission reduction: reactive nitrogen issues in China. Philos Trans Royal Soc A. https://doi.org/10.1098/rsta.2019.0324

Luo L, Zhang Y, Xu G (2020) How does nitrogen shape plant architecture? J Exp Bot 71:4415–4427. https://doi.org/10.1093/jxb/eraa187

Lv X, Ding Y, Long M, Liang W, Gu X, Liu Y, Wen X (2021) Effect of foliar application of various nitrogen forms on starch accumulation and grain filling of wheat (Triticum aestivum L.) under drought stress. Front Plant Sci. https://doi.org/10.3389/fpls.2021.645379

Naqve M, Wang X, Shahbaz M, Fiaz S, Naqvi W, Naseer M, Mahmood A, Ali H (2021) Foliar spray of alpha-tocopherol modulates antioxidant potential of okra fruit under salt stress. Plants. https://doi.org/10.3390/plants10071382

Ochi A, Konishi H, Ando S, Sato K, Yokoyama K, Tsushima S, Yoshida S, Morikawa T, Kaneko T, Takahashi H (2017) Management of bakanae and bacterial seedling blight diseases in nurseries by irradiating rice seeds with atmospheric plasma. Plant Pathol 66:67–76. https://doi.org/10.1111/ppa.12555

Patil BS, Wang Q, Hessel V, Lang J (2015) Plasma N2-fixation: 1900–2014. Catal Today 256:49–66. https://doi.org/10.1016/j.cattod.2015.05.005

Pikaar I, Matassa S, Rabaey K, Bodirsky B, Popp A, Herrero M, Verstraete W (2017) Microbes and the next nitrogen revolution. Environ Sci Technol 51:7297–7303. https://doi.org/10.1021/acs.est.7b00916

Pikaar I, Cruz H, Hülsen T, Batstone D, Rabaey K, Avnimelech Y, Verstraete W (2022) Producing microbial-based protein from reactive nitrogen recovered from wastewater. IWA Publ. https://doi.org/10.2166/9781780409566

Puač N, Gherardi M, Shiratani M (2018) Plasma agriculture: a rapidly emerging field. Plasma Process Polym. https://doi.org/10.1002/ppap.201700174

Rouwenhorst KHR, Jardali F, Bogaerts A, Lefferts L (2021) From the Birkeland-Eyde process towards energy-efficient plasma-based NOX synthesis: a techno-economic analysis. Energy Environ Sci 14:2520–2534. https://doi.org/10.1039/D0EE03763J

Sasaki S, Takashima K, Kaneko T (2021) Portable Plasma device for electric N2O5 production from air. Ind Eng Chem Res 60:798–801. https://doi.org/10.1021/acs.iecr.0c04915

Tsukidate D, Takashima K, Sasaki S, Miyashita S, Kaneko T, Takahashi H, Ando S (2022) Activation of plant immunity by exposure to dinitrogen pentoxide gas generated from air using plasma technology. PLoS ONE. https://doi.org/10.1371/journal.pone.0269863

Acknowledgements

We thank Anke Reinders for critical reading.

Funding

This work was supported by Grants-in-Aid for Scientific Research (20KK0127, 21H04543, 21K19060, 21H05266, 21KK0268, 22K19121, 23KJ0172, 24H00495, 24H02253) from the Ministry of Education, Culture, Sports, Science and Technology and Moonshot R&M (JPMJMS2033) from Japan Science and Technology Agency, and FRiD Tohoku University (Project 1904).

Author information

Authors and Affiliations

Contributions

TY conducted all experiments and data analysis. ST and SS operated plasma devise and SS evaluated the plasma-related data. YI designed the concept and TY and YI planed the experiments. KT, TK, YI, NU supervised this study and analyzed the data. NU wrote and revised the manuscript with TY, and TY, SS, KT, TK and YI provided input to the manuscript and modified the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest with the contents of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yamanashi, T., Takeshi, S., Sasaki, S. et al. Utilizing plasma-generated N2O5 gas from atmospheric air as a novel gaseous nitrogen source for plants. Plant Mol Biol 114, 35 (2024). https://doi.org/10.1007/s11103-024-01438-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11103-024-01438-9