Abstract

Purpose

Respiratory disorders pose a major threat to the morbidity and mortality to public health. Here we reviewed the nanotechnology based pulmonary drug delivery using metered dose inhalers.

Methods

Major respiratory diseases such as chronic obstructive pulmonary diseases (COPD), asthma, acute lower respiratory tract infections, tuberculosis (TB) and lung cancer. At present, common treatments for respiratory disorders include surgery, radiation, immunotherapy, and chemotherapy or a combination. The major challenge is development of systemic delivery of the chemotherapeutic agents to the respiratory system. Conventional delivery of chemotherapy has various limitation and adverse side effected. Hence, targeted, and systemic delivery need to be developed. Towards this direction nanotechnology, based controlled, targeted, and systemic drug delivery systems are potential candidate to enhance therapeutic efficacy with minimum side effect. Among different route of administration, pulmonary delivery has unique benefits such as circumvents first pass hepatic metabolism and reduces dose and side effects.

Results

Respiratory disorders pose a major threat to the morbidity and mortality to public health globally. Pulmonary delivery can be achieved through various drug delivery devices such as nebulizers, dry powder inhalers, and metered dose inhalers. Among them, metered dose inhalers are the most interesting and first choice of clinician over others. This review focused on nanotechnology based pulmonary drug delivery using metered dose inhalers. This report focused on delivery of various types of therapeutics using nanocarriers such as polymeric nanoparticles and micelles, dendrimers, lipid nanocarriers such as liposomes, solid lipid nanostructures and nanostructured lipid carriers, and other using metered dose inhalers discussed comprehensively. This report provides insight about the effect of parameters of MDI such as co-solvent, propellants, actuators shape, nozzle diameters, and jet lengths, and respiratory flow rate, and particle size of co-suspension of drug on aerodynamics and lung deposition of formulation. This review also provided the insight about various metered dose inhalers market scenario and digital metered dose inhalers.

Conclusion

This report concluded the clinical potential of metered dose inhalers, summary of current progress and future perspectives towards the smart digital metered dose inhalers development.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Respiratory disorders pose a major threat to the morbidity and mortality to public health globally (1–4) Approximately 2 billion population of the globe is exposed to the environmental toxins from various sources including fireplaces for cooking/warming, incinerators, tobacco in smoke form etc. Additionally, 4 million people die globally from chronic respiratory diseases (5–7). According to The Forum of the International Respiratory Society, there exist five major respiratory disease, the “big five,” which include chronic obstructive pulmonary disease (COPD), asthma, acute lower respiratory tract infections, tuberculosis (TB), and lung cancer (8–11). Out of these “big five” around 65 million people suffer from COPD 3 million die annually, making it the third leading cause of death worldwide. Around 14% of all children are affected with asthma globally. Pneumonia is a leading cause of death among under- five age children and overall millions of people die with pneumonia every year. TB is one of the commonest and lethal infectious disease with which around 10 million people are affected and 1.4 million die annually. Lung cancer being the most fatal cancer kills 1.6 million people approximately each year (8,12,13).

Despite the huge burden of these respiratory diseases in terms of mortality and morbidity worldwide, there has not been enough public awareness and attention. The research funding have also not gained much momentum compared to other disease entities such as cardiovascular disease, cancer, stroke, diabetes, and Alzheimer’s disease (14,15). In last couple of decades, nanotechnology/nanoparticles offered various effective drug delivery systems and development of devices towards the management of respiratory diseases.

In last two decades, nanoparticles gained attention in many fields such as semiconductor, biomedical, chemical, and environmental (16,17,18,19) Nanoparticles with size below 100 nm shows unique properties due to dominance of quantum effect and highly increase of surface area, which makes them suitable for novel applications such as electronics, communication, energy, defense and biomedical including drug delivery (16,20,21). According to Ostwald-Freundlich equation due to enormous surface area increases saturation solubility and increases dissolution kinetics according to Noyes-Whitney equation (22,23). The drug concentration at absorption site achieved quickly due to large surface area releases drug rapidly. Various techniques have developed such as chemical modification, nanonization, stabilization of amorphous particles, and formulation of emulsion.

Nanoparticles extensively used in various delivery routes including oral, intravenous, transdermal, and ocular. However, rare in pulmonary delivery. Among different route of administration, pulmonary delivery has unique benefits such as circumvents first pass hepatic metabolism and reduces dose and side effects. It also allows delivery of therapeutics to diseases such as asthma, COPD, and cystic fibrosis. Due to large pulmonary surface area, thin epithelium layer and rich blood supply make fast absorption, which makes pulmonary delivery attractive. It is more patient’s compliance due to non-invasive nature (24–26).

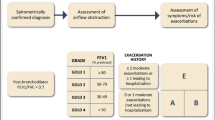

The pulmonary drug delivery system has been well established. The number of pMDI devices have been developed and available commercially. Despite the development of pulmonary delivery using pMDI incidents and deaths due to respiratory diseases (COPD, asthma, acute lower respiratory tract infections, tuberculosis (TB), and lung cancer) are increasing every year. Consequently, the investigation of effective drug delivery system and advanced pMDI need to be investigated. An efficient, targeted, and sustained drug delivery system can be achieved through nanocarriers. This review focused on the pulmonary drug delivery devices, especially delivery of various types of drug delivery systems such as polymeric nanocarriers, dendrimers, lipid nanocarriers and others using metered dose inhalers discussed comprehensively (Fig. 1). This review will provide the effect of parameters of MDI on aerodynamics and lung deposition of formulation. This report describes about various metered dose inhalation devices in the market and concluded the review with clinical applications of MDI and future perspectives towards next generation pMDI.

Schematic of nanotechnology based pulmonary drug delivery system using metered dose inhalers to treat various respiratory disorders, advantages, and marketed devices. Reproduced with permission from ref. (27–31). Copyright 2020 Springer open access, 2019 Elsevier, 2020 Springer, 2021 Elsevier, and 2021 MDPI Open access respectively.

Pulmonary Drug Delivery

Pulmonary drug delivery has been very beneficial for the treatment of asthma and chronic obstructive pulmonary disease (COPD) for many decades (5). It is one of the very important areas for research and development as it renders the maximum therapeutic efficacy in patients by directly targeting drug in the lungs with rapid onset of action (32,33). This reduces the total dose compared to oral formulation, for instance, salbutamol dosages are reduced by a factor of 10 to 20 (34–36). The unwanted systemic effects are also minimized due to maximum pulmonary specificity (37). In the market, there are variety of therapeutic inhaler devices available, namely, pressurized metered dose inhalers (pMDIs), dry powder inhalers (DPIs), soft mist inhalers (SMIs), and nebulizers (38,39). systematic reviews and meta-analyses evidences have indicated comparatively equal effects among nebulizers, pMDIs, and DPIs for delivery of bronchodilators and glucocorticoids provided they are used correctly (40–43).

Dry Powder Inhalers

Bell and colleagues were introduces in 1971 the first inhaler device which used in DPI technology (44). Then, advanced DPI devices has been developed for patients with COPD and Asthma. The formulations of inhaled dry powders are loose agglomerates of micronized drug particles, with aerodynamic particle sizes below 5 μm. The carrier based interactive mixtures with micronized drug particles adherent to the surface of large lactose carriers. The powder formulation is aerosolized a DPI device, where the drug particles are separated from the carrier or de-agglomerates drug particles, and the dose delivered into the patient’s deep lungs. DPI broadly classified into three different categories such as single dose DPIs, multiple dose DPI, and active or power assisted DPIs (45). Single dose DPIs are breath-activated in which capsule is perforated in the device with needles fixed to pressure buttons. It depends on patient’s respiratory flow to make sure the delivery of drug. Multiple dose DPIs are an alternative to single dose DPIs. Multiple doe devices are again multi-dose DPI devices and multi-unit DPI devices (46). To overcome the issue of lack of enough inhalation flow of patients with COPD, power assisted DPI devices have been developed (47). These devices able to be activated at low flow and produce a better lung deposition. To disperse the drug battery driven impellers and vibrating piezoelectric crystals are incorporate. The major benefits of DPIs are do not needed co-ordination of inhalation with activation and not need hand strength. Elderly patients with Parkinson’s disease and joint pain, and complications after stroke must prime and load DPIs. Clinical studies also show excellent patient’ compliance (47).

Nebulizers

Nebulizers especially needed for diseases demand high pulmonary doses and patients unable to achieve necessary flow rate. Based on the mechanism of convention of drug solution into aerosol, nebulizers are three types such as Jet nebulizer, ultrasonic nebulizer, and vibrating mesh nebulizer (48). Jet nebulizer is widely used in which compressed gas used to disperse liquid medication into aerosol droplets. Longer treatment time and mechanical force and noisy are the limitation. Ultrasonic nebulizers work silently and portable. However not compatible with thermal sensitive medication such as protein due to ultrasound heats the medication (49). Vibrating mesh nebulizer is the newest technology, which offer benefits of rapid treatment time, minimal residual volume, and greater aerosol delivery (50). The major limitation is high cost. All these devices produce aerosol continuously, so large amount of medication is loss during exhalation. However, the major limitation are they are bulkier, longer administration time and lower delivery efficiency (51). However, recently advanced technology based nebulizers have been developed and commercially available such as Activaero AKITA® and Philips I-Neb® nebulizer systems (52,53).

Soft Mist Inhalers

Soft mist inhalers (SMI, eg, Respimat) incorporate microelectronic dosimetric systems. When an SMI is manually primed, a fixed amount of drug solution is drawn up into the dosing system through a nozzle that has two narrow outlet channels etched using microchip technology. The SMI aerosol has a high fine particle fraction, a low velocity, and more sustained duration than a pMDI (54,55). The SMI form two or three times more pulmonary deposition than a pMDI (56,57).

Metered Dose Inhalers

Among the various pulmonary drug delivery devices, metered dose inhalers are most promising technique. Recent progress in material sciences, nanotechnology, biotechnology, particle engineering and allied sciences open a door for improving the use of metered dose inhalation therapy (58,59). The nano-science-based metered dose inhalable formulations help to improve therapy results and prevent adverse side effects (60,61). Various drug delivery systems such as polymeric nanocarriers (62,63) such as polymeric nanoparticles and micelles, dendrimers, and lipid based nanocarriers (64,65) has been integrated with MDI, to probe pulmonary delivery process and therapeutic outcome are used to deliver the drug to treat the pulmonary diseases. Figure 2 Showed the various nanocarriers used in metered dose inhaler (27). This is section we have comprehensively discussed the pulmonary delivery of various nanoparticles using metered dose inhalers.

various nanocarrier used to deliver the therapeutics using metered dose inhaler. Reproduced with permission from ref. (27). Copyright 2020 Springer open access.

Polymeric Nanocarriers

Polymeric nanocarriers are one of the widely studied nanocarriers for various drug delivery applications including cancer, HIV, COVID-19, and inflammatory bowel diseases (66,67). The most used polymeric nanocarriers are micelles and polymeric nanoparticles. Polymeric nanoparticles extensively explored for their excellent potential as a carrier for delivery of drug to treat various diseases (68). Functional polymeric nanoparticles can be design through modification and functionalization of polymer before making nanoparticles. Drug and therapeutic agent can be delivering to the site of action (deep lungs) through encapsulating into the polymer (Fig. 3) (28). Drug loaded nanoparticles can be prepared through encapsulation the drug into polymeric matrix (69,70). The most widely studies polymers are polyhydroxyalkanoates, poly-(lactic-co-glycolic-acid) (PLGA) cyclodextrins, poly (lactic acid), polyanhydrides, poly (ortho esters), chitosan, and poly (phosphoesters). Polymers can be modified easily ass a stimulus responsive through introducing suitable chemical bonds (71,72). Polymeric nanoparticles showed less toxic than the inorganic nanoparticles (73). Drug release kinetics can be controlled through controlling the polymers physicochemical properties. Polymeric nanoparticles widely used in metered dose inhalation-based drug delivery.

Schematic view of delivery of therapeutics through loading into the polymeric nanoparticles by metered dose inhaler. Reproduced with permission from ref. (28). Copyright 2019 Elsevier.

Chitosan is gaining significant interested in drug delivery due to biodegradable, biocompatible, non-toxic and mucadhesive properties. It is reported that chitosan increases the uptake of macromolecules by opening of tight junctions of epithelial cells. Previous studies reported the tripolyphosphate cross-linked chitosan nanoparticles not suitable for pMDI system due to difference in density of particles and propellants. To overcome this issue, Sharma et al. (2012) carefully formulated and characterized cross-linked chitosan-based NPs-based pMDIs to deliver small molecules to the peripheral airways (74). Mainly, cross-linked chitosan (5%) NPs were fabricated using sodium tripolyphosphate (1%) and polyethylene glycol (PEG) 1000 (30%) by the ionic gelation method. Further, to formulate pMDIs, cross-linked chitosan NPs were dispersed in the propellant, hydrofluoroalkane (HFA) 227. Smooth-surfaced, spherical-shaped NPs showed hydrodynamic diameter and zeta potential of 193.3 nm and + 28.2 mV, respectively. The cationic cross-linked chitosan-PEG 1000 NPs showed non-aggregated behavior at the lung pH. The cross-linked chitosan-PEG 1000 NPs exhibited good physical stability and dispersibility in propellant HFA-227, while cross-linked chitosan-PEG 600 and 5000 NPs readily sediment or creamed when dispersed in propellant HFA-227. The addition of PEG during NPs production modified NPs surface properties and offered good steric stabilization prior to dispersion in HFA-227 (72,74). Furthermore, the amphiphilic nature of PEG with apt molecular weight improves the dispersion properties of crosslinked chitosan NPs. Fluorescein 5-isothiocyanate (FITC)-labeled cross-linked chitosan NPs were used to understand the aerodynamic performance. FITC-labeled cross-linked chitosan NPs demonstrated hydrodynamic diameter and zeta potential of 203 nm and + 24 mV, respectively. During aerodynamic assessment using next-generation impactor (NGI) at 30 L/min, cross-linked chitosan-PEG 1000 NPs showed fine particle fraction (FPF) of 34% with a mass median aerodynamic diameter (MMAD) of 4.92 μm. Moreover, the cross-linked chitosan NPs, chitosan-PEG 600 NPs and cross-linked chitosan-PEG 5000 NPs demonstrated FPF of 5.7%, 11.8% and 17%, respectively (Fig. 4a). During the aerodynamic assessment, the cross-linked chitosan-PEG 1000 NPs showed best dispersibility and deposition from a pMDI due to a combination of reasons (i) PEG 600 is a small liquid molecule, which is not well retained within the cross-linked chitosan NPs and (ii) PEG 5000 possess a much longer chain length thus less solvated and finally result in higher aggregation. Briefly, the study points out that cross-linked chitosan-PEG 1000-based NPs are promising carriers to deliver small molecules and therapeutic agents to the peripheral airways using pMDIs (74).

Fine particle fraction of pMDI formulations of a) chitosan and chitosan–PEG nanoparticles, b) formulations using cineole, cineole:n-heptane 9:1 and cineole:n-heptane 4:1, during 26-week storage. The schematic diagram about the forming process of ARM-NPs. (A) The TBA/water 1:4 system; (B) the TBA/water 3:2 system; (1) before freeze-drying; (2) during freeze-drying; (3) after adding ethanol absolute. Reproduced with permission from ref. (74–76). Copyright 2012, 2012, 2016, Elsevier, Elsevier, Taylor & Frances respectively.

At present, common treatments for lung cancer include surgery, radiation, immunotherapy, and chemotherapy or a combination. The major challenge is systemic delivery of the chemotherapeutic agents to the lung tumor. In recent studies, nanocarriers delivered the chemotherapeutic to the site of disease and showed enhanced treatment efficacy. One of the promising strategies for targeted deliver is polymeric nanoparticles and polymeric drug conjugates. Several polymers are stimuli responsive such as thermal responsive, pH responsive, and enzyme responsive, reactive oxygen species responsive. Such stimuli responsive polymers are more interesting in targeted delivery of drugs. Through chemical modification stimuli responsive behavior can introduced to a polymer for example imine bond. Rao et al. (2017) prepared pH-sensitive NPs using methoxy-PEG (mPEG)-doxorubicin (DOX) conjugates (mPEG-1 K DOX) for effective treatment of lung cancer and directly formulate in propellant-MDIs to achieve site-specific action. The pH-sensitive mPEG-1 K DOX conjugated NPs were fabricated using the precipitation method and Schiff base re-arrangement technique (77,78). The NPs showed mean particle size and DOX loading of 104 nm and 32.7%, respectively. The pH-sensitive mPEG-1 K DOX conjugated NPs showed accelerated DOX release (85%) in an acidic setting (pH 5.5; endosomal/lysosomal pH) compared to the physiological environment (pH 7.4). During an in-vitro cytotoxicity study using human lung adenocarcinoma cells, NPs showed ~24-fold lower IC50 values than NPs fabricated using mPEG-5 K. Besides, NPs follow a similar trend in cellular internalization rate and extent. Furthermore, pH-sensitive mPEG-1 K DOX conjugated NPs dispersed into propellant HFA 227 with co-solvent ethanol to formulate pMDIs. During in-vitro aerodynamic analysis, NPs showed FPF and MMAD of 63.5% and 1.6 μm, respectively (77). The molecular weight of mPEG (1 K, 2 K, and 5 K Da) demonstrated a significant impact on the physical and biological properties of the NPs. With a decrease in PEG chain length, in-vitro release rate, cellular internalization, and in-vitro cytotoxic potency to lung cancer cells of NPs improve. Likewise, the pMDI formulations of NPs with shorter PEG chains show getter dispersibility and aerodynamic performance. Briefly, pulmonary administration of polymer-drug conjugates-based pMDI has excellent potential in clinical settings while dealing with lung cancer (77).

There ae various formulation has been developed for metered dose inhalation. However, the efficacy of formulation mainly depends on physicochemical properties especially stability and aerosolization. Hence, only limited number of formulations are more effective for MDI. It is very important to study the effect of various parameters on aerosolization behavior to design the desire formulation. The most widely used stabilization strategies are such as use of ethanol as co-solvent, which increase the surfactant solubility and stability. The surfactant used in pMDI are dipalmitoylphosphatidylcholine (DPPC), span 85 and oleic acid to improve the physical stability of nanoparticles suspended in HFA propellant. However, storage stability is the matter of concern. Recently, it is reported that cinnamaldehyde, cineole and citral utilized for stabilization. Tan et al. (2012) formulated thymopentin NPs-based pMDI and thoroughly studied it for aerosolization performance. Thymopentin NPs were fabricated using the bottom-up, freeze-drying process by lactose and lecithin in tert-butyl alcohol/water co-solvent system and washing off excess lecithin in a lyophilized matrix by centrifugation (75). The water content and lecithin concentration had a significant impact on the particle size and polydispersity index of NPs. The 33.3% (v/v) water in the co-solvent system and 20.0% (w/v) lecithin in the organic phase formulated small, spherical-shaped thymopentin NPs with a mean particle size of ~150 nm and polydispersity index of 0.1. Fabricated thymopentin NPs were transferred into a plastic-coated glass bottle equipped with a 50 μL valve; subsequently, HFA 134a propellant was added to developed pMDI and, lastly, n-heptane/cineol mixture was added to provide good dispersibility to suspension-type pMDI (75). During aerosolization study using twin stage impinger (60 L/min), thymopentin NPs pMDI exhibited FPF more than 55% with minimum deposition on the pMDI actuator. During 26 weeks of storage, thymopentin NPs pMDI showed a relative thymopentin concentration of >97% with FPF 47% (Fig. 4b). In summary, the aerosolization performance and 6 months storage stability of suspension-type pMDI showed that the thymopentin NPs were mainly deposited to region matching to lower pulmonary airways and signifying a good pulmonary drug delivery option (75).

Another type of polymeric nanocarriers are polymeric micelles. Polymers with hydrophobic and hydrophilic parts formed micelles in aqueous solution through self-assembly. The polymeric micelles formation mechanism is showed in Fig. 5 (29). The core of micelles is hydrophobic which encapsulate the drugs. Generally, the hydrophilic shells are composed of poly (ethylene glycol) PEG, poly (vinyl alcohol) PVA, PVP, PAAm, PG. all these polymers approved for drug delivery use. The hydrophobic core mainly composes of polyesters such as PGA, PCL, PDLLA, PEO, and PPO (29). In last two decades significant progress has been done through development of various types of modified micelles with interesting functional properties. Several polymeric micelles used for delivery of anticancer drugs are at preclinical and clinical phase development. Pham et al. comprehensively documented a review about the polymeric micelles for pulmonary drug delivery (29). Polymeric micelles again two types such as convention and functional polymeric micelles. Function polymeric micelles showed the functional properties such as cell penetration, targeting, stimuli-responsiveness, and mucadhesive. Polymeric micelles can be prepared through direct dissolution, oil in water emulsification, thin-film hydration/solvent evaporation, dialysis, and freeze-drying (79). The properties of polymers such as compose of both hydrophilic and hydrophobic segments, low critical micelle concentration, biocompatibility, biodegradability, high solubility in water, non-toxic and non-immunogenic are the ideal for micelles preparation for pulmonary drug delivery (29). Pharm et al. summarized the literature of polymeric micelles based delivery of various drug using metered dose inhalers in the form of table (29). Huang et al. developed anhydrous reverse micelle nanoparticles to overcome the sedimentation instability of peptide-containing pressurized metered dose inhalers. The micelles prepared through freeze-drying and lipid inversion method. The formulated anhydrous reverse micelles showed the Size 147 nm, 0.152 polydispersity (PDI) index. Figure 4c showed the schematic diagram about the forming process of ARM-NPs. (A) The TBA/water 1:4 system; (B) the TBA/water 3:2 system; (1) before freeze-drying; (2) during freeze-drying; (3) after adding ethanol absolute. They showed 46.99% fine particle fraction suitable for metered dose inhalers. They showed 12-week sedimentation stability over 12 weeks are 4–6°C (76). there is great scope to explore the micelles for MDI for treatment for pulmonary diseases.

Mechanism of formation of polymeric micelles. Reproduced with permission from ref. (29). Copyright 2020 Springer.

Dendrimers

Dendrimers are branched macromolecules with monodispersed architectures. Dendrimers compose of three distinct structural constituents such as core, internal layers and terminal functional group. The dendrimers can synthesize through click chemistry, multicomponent reactions, and cycloaddition methods (80). Drug delivery and targeting using dendrimers made significant progress in last few years. In Fig. 6 we showed the various biomedical application of dendrimers (30). Dendrimers are widely using in therapeutics, imaging, monitoring, diagnosis and treatment of various diseases (81). Poly(amidoamine) (PAMAM) densrimers are widely studies as nanocarriers due to large density and surface functional group. Conjugation of drug to dendrimers enhanced solubility and bioavailability (82). Bielski and co-workers (2017) developed triphenylphosphonium (TPP) decorated 4th generation (G4) poly(amidoamine) dendrimer to explore the in-vitro transfection efficiency of siRNA within a pulmonary epithelium and their aerosol formulations in pMDI. TPP was conjugated to the G4-dendrimer using amid chemistry, whereas siRNA was conjugated to the TPP-G4-dendrimer by electrostatic interactions (dendriplexes). The TPP density and N/P ratio exhibited a remarkable influence on the in-vitro transfection efficiency of siRNA (83). In the present study, dendriplexes conjugated with 12 TPP molecules and an N/P ratio of 30 showed the most effective in-vitro gene knockdown efficiency using lung alveolar epithelial (A549) cells. Dendriplexes showed a marked 2-fold improvement in in-vitro transfection efficiency of siRNA compared to unmodified dendriplexes. Dendriplexes demonstrated zeta potential, hydrodynamic diameter and polydispersity index of 40 mV, 363 nm and 0.36, respectively. Inhalable dendriplexes micro particles were formulated using mannitol carrier by spray drying technique (83). Smooth, spherical shape spray-dried nanocomplexes showed good percent yield (76%) and high loading efficiency (75.1%) with a geometrical diameter and solvated diameter of 2.4 and 4.2 μm, respectively. Nanocomplexes pMDI (63 μL metering valve) was prepared using HFA-227 propellant, which showed FPF and MMAD 50.3% and 3.8 μm, respectively using Andersen Cascade Impactor (ACI) at 28.3 L/min. The nanocomplexes pMDI demonstrated a marked 1.3-fold improvement in % FPF compared to nanocomplexes DPI. Accordingly, the TPP conjugated G4-dendrimer offers a unique platform to improve siRNA’s biological efficacy during pulmonary delivery (83).

various biomedical applications of dendrimers. Reproduced with permission from ref. (30). Copyright 2021 Elsevier.

Bharatwaj et al. (2014) fabricated core-shell structures containing three-amine-terminated poly (amidoamine) dendrimers using poly (D,L-lactide-co-glycolide) (PLGA). They systematically characterized dendrimers for in-vitro cellular transport and uptake using the human airway epithelial cell line (Calu-3) model and aerosol properties by multistage cascade impactor. Initially, fluorescein isothiocyanate (FITC) was tagged onto dendrimers using isothiocyanate chemistry; subsequently, FITC tagged dendrimers were loaded into biodegradable polymeric matrices of PLGA using a modified double emulsion solvent evaporation method (core-shell nanoparticles) (85). Smooth spheres of lyophilized core-shell NPs (245 nm) showed a zeta potential of −10 mV with a loading efficacy of 7.8%. An in-vitro study using 1 X mucus containing Hank’s balanced salt solution (pH 7.3) core-shell NPs exhibited a sustained release profile attributable to diffusion processes from PLGA polymeric matrices. Core-shell NPs did not show any toxic effect on the Calu-3 cell monolayers after 48 h of exposure (85). Core-shell NPs showed apparent permeability similar to a paracellular marker (dextran) across the airway epithelial model. Core-shell NPs assist in modulating the transport and cellular internalization pattern of dendrimers. Core-shell NPs showed effective transport across the lung epithelium during 5 h of the experiment (5 h). The aerodynamic analysis of core-shell NPs pMDI (HFA 227) using ACI (28.3 L/min) showed satisfactory FPF (55%) and MMAD (3 μm). To sum up, core-shell NPs pMDI is a crucial alternative to modulate the cellular uptake and transport of drug substances and may thus be explored to attain desired local or systemic drug delivery (85).

Among the various dendrimers, polyester based dendrimers are alleviate toxicity issues, that associated with non-biodegradable dendrimers. Polyesters degrade in the physiological environment and readily cleared. Heyder et al. (2017) investigated the cellular internalization, transport and aerodynamic performance of biodegradable polyester dendrimers-based pMDIs using pulmonary epithelium and multistage cascade impactor. Generation three (G3) and four (G4) polyester dendrimers were primarily conjugated to FITC. FITC conjugated G3 (0.8 nm) and G4 (1.3 nm) polyester dendrimers showed zeta potential of −2.3 and − 1.3 mV, respectively. PEGylated (PEG 1000) G4 polyester dendrimers showed mean particle size and zeta potential of 4.2 nm and 0.0 mv, respectively. In physiological buffer solution (pH 7.4), PEGylated generation G4 polyester dendrimers did not show any significant degradation until day 5 and after 30 days dendrimer showed a degradation profile similar to the unmodified dendrimer (86). During in-vitro transport study using polarized Calu-3 cell monolayers, PEGylated G4 polyester dendrimers showed a marked 4.05 and 2.31-fold higher transport from the apical to the basolateral side during 5 h. PEGylated G4 polyester dendrimers promote the dendrimers’ interaction with membrane junction proteins and consequently revise the permeation. In in-vitro cellular uptake, lower generation (G3 and G4 polyester dendrimers) favors the rate and extent of uptake compared to PEGylated G4 polyester dendrimers (86). Likewise, PEGylation and higher generation tend to retard the rate and extent of cellular internalization. Respirable PEGylated G4 polyester dendrimers-based pMDI was fabricated using propellant HFA-227 (1.5 mg of dendrimer/mL of HFA) and 1% v/v ethanol. Aerosol performance using ACI (28.3 L/min) showed satisfactory FPF (88.5%), MMAD (1.6 μm) and GSD (1.7) for dendrimers-based pMDI. The good aerodynamic values can be credited to improved solvation of the dendrimers by the HFA used in the preparation of pMDI (86). Briefly, PEGylation of polyester dendrimers significantly influences degradation, cellular uptake, cellular internalization and aerodynamic performance. These combined cellular and aerodynamic results advocate that dendrimer generation and PEGylation can be utilized to modify their interaction with pulmonary epithelium and to develop their formulation in portable pMDI delivery devices (86). However, further detailed studies need to be conduct to explore the polyester dendrimers and their efficacy in in-vitro and in-vivo.

Several studies demonstrated PEGylated dendrimers increase the transepithelial transport of therapeutic drug and the rate of delivery depends on the dendrimers generation, surface groups, surfact charge, and attached ligands. Zhong and co-workers (2017) assessed the effects of PEGylation degree and DOX payload on pH-sensitive generation 3 (G3), amine-terminated poly (amidoamine) dendrimer (G3-NH2-mPEG1000-nDOX conjugates). Moreover, acid-labile G3-NH2-PEG1000-DOX dendrimers-based pMDIs were studied for pulmonary drug delivery (84). DOX molecules were linked to G3-NH2-mPEG1000 dendrimers using a cis-aconityl spacer. During the in-vitro release study, G3-NH2-mPEG1000-nDOX dendrimers showed >85% DOX release at acidic pH (pH 4.5; lysosomal pH), whereas, cis-aconityl spacer linked DOX was very stable at extracellular/physiological pH (7.4) and showed only 8% DOX released at 200 h. G3-NH2-mPEG1000-nDOX dendrimers exhibited a more significant DOX transport (the apical to the basolateral side) across the polarized Calu-3 cell monolayers ac compared to non-PEGylated dendrimers (84). G3-NH2-mPEG1000-DOX dendrimers showed more efficient transport across the pulmonary epithelium than the non-PEGylated counterpart during the cellular internalized study. In the present case, PEG does not act as a permeation enhancer to open tight intercellular junctions; however, it was more efficiently trapped by the mucus layer and thus effectively internalized by the epithelial cells (84). Moreover, orally inhalable formulations were developed using two methods; G3-NH2-PEG1000-DOX dendrimer conjugates were melted and solvated using propellant HFA-227 (Method A) and G3-NH2-PEG1000-DOX dendrimer pMDI with co-solvency technique (Method B). G3-NH2-PEG1000-DOX dendrimer pMDI (glass canister topped with 63 μL metering valve) prepared with Method A, and Method B showed solvation diameter of 27.3 and 26.1 nm, respectively (84). During ACI analysis (28.3 L/min), G3-NH2-PEG1000-DOX dendrimer pMDI prepared with Method A and Method B displayed FPF of 81.9% and 78.1%, respectively. Briefly, the PEGylation degree showed a significant impact on DOX is release and transport across the pulmonary epithelium. PEGylation degree can be used to tune the carrier properties during pulmonary drug delivery. Specifically, PEGylated dendrimer conjugate is a practical approach to treating lung metastases, primary lung cancer with metastatic sites and primary non-metastatic cancer as it can effectively control lung retention time (84).

Small interfering RNA (siRNA)-based therapies have great potential in treating respiratory diseases such as asthma, cystic fibrosis, and lung cancer. Accordingly, Conti and co-workers judiciously formulated four-amine-terminated poly (amidoamine) dendrimer-siRNA complexes (dendriplexes) to improve aerodynamic and biological potential siRNA. Dendriplexes exhibited mean particle size, polydispersity index and zeta potential of 246 nm, 0.4 and + 36 mV, respectively. Tiny, uniform dendriplexes showed mean particle size 285 nm in scanning electron microscopy with 96.2% siRNA complexation efficiency. RNase protection assay showed that dendriplexes effectively retain the siRNA native structure. In an in-vitro release study using phosphate buffer at pHs 7.4 and 5.0, dendriplexes showed >50% and < 10% siRNA release at the end of 22 days owing to change in electrostatic interactions with pH between negatively charged siRNA and positively charged dendrimers. Additionally, inhalable mannitol microparticles loaded dendriplexes (10 μg siRNA) were formulated using spray drying. Dendriplexes microparticles did not induce any undesirable irreversible aggregation of the dendriplexes and showed a 50% yield with satisfactory loading efficacy (230 ng siRNA/ mg of mannitol). Smooth surface, spherical dendriplexes microparticles (4.6 μm) were kept in a glass canister equipped with a 63 μL metering valve, and HFA-227 propellant was used to disperse the same. In-vitro gene knockdown study showed that HFA-227 propellant successfully preserves the siRNA’s biological activity (gene silencing). During aerodynamic assessment using ACI (28.3 L/min), dendriplexes microparticles showed FPF (48.9%), MMAD (2.6 μm) and GSD (3.8) suitable for deep pulmonary delivery. These results showed that the dendriplexes microparticles approach has better potential in delivering biological materials to pulmonary airways (87).

Lipid Based Nanocarriers

Among the various nanocarriers system, lipid-based nanoparticles have their own unique features. There are different lipid nanoparticles such as liposome, solid lipid nanoparticles, nanostructures lipid carriers, and self-emulsifying drug delivery systems (Fig. 7) (31,90,91). Liposomes are vesicular carriers are composing of lipid bilayers. Due to depot action drug encapsulated into the liposome offer extended therapeutic response. Liposomes offer flexibility to load both water-soluble, lipid soluble drugs, and gene delivery as well (92). Liposomes shows up to 24 hr. of retention time in lungs. Liposomes are used in delivery to the lungs include insulin, catalase, interleukin 2, budesonide, 9 NC, rifampicin, and polyethyleneimine-p 53 DNA (93). However, the clearance of the particles from respiratory tract is also more important. The particles clearance depends on physicochemical properties of particles. Age, exercise, influenza, and pneumonia are the major factor effect the clearance efficiency of deposited nanoparticles (94). Among other, solid lipid, nanocarriers are very interesting. In 1990s research groups of Muller et al., Gasco et al., and Westesen et al. developed first generation of solid lipid nanoparticles (95). SLNs are compose of lipid matrix stabilized with emulsifier or surfactant, and drug is loaded into lipid matrix. SLNs are range between 40 to 1000 nm. Physical stability, protection to drugs from degradation, controlled release, and low cytotoxicity are the major advantages of SLNs (96). SLNs are interesting for pulmonary delivery due to good tolerability in airways. SLNs easily aerosolized which offer deep lung deposition. Due to the adhesion, accumulation and retention of the SLNs in lungs offer prolonged release of drug, which minimize the dosing (60). Nanostructured lipid carriers have gained extended commercial attention in last 20 years. NLCs are more effective for delivery of cancer chemotherapeutics. If offer good stability, specificity, steadiness, normal tissue toxicity, and targetability (60). Bains et al. developed the novel low-energy nanotechnology process to prepare surfactant coated pDNA nanoparticles for gene delivery using pressurized metered dose inhaler. Lyophilized pDNA was-incorporated into pMDI with hydrofluoroalkane 134a propellant and cosolvent ethanol. In-vitro toxicity assay showed no significant loss of cell viability and biological functionality was studied using transfection analysis (97).

Schematic presentation of different lipid nanocarriers. Reproduced with permission from ref. (31). Copyright 2021 MDPI Open Access.

Biologics

Pulmonary delivery of biological substances (e.g., RNA, DNA, siRNA, proteins and peptides) has fascinated considerable attention in the last few years due to their application in managing severe respiratory conditions, including cancer, cystic fibrosis and tuberculosis (98,99). By understanding this application, Carli et al., (2018) focus on inhaled antibody systems. Immunoglobulin G powder was formulated using spray drying process and incorporated into pMDI to improve aerodynamic properties of the immunoglobulin G. Spray-dried wrinkled shape immunoglobulin G: mannitol (75:25) and immunoglobulin G: trehalose (75:25) particles showed mean particle size of 3.6 and 3.3 μm, respectively. The slot blot and circular dichroism analysis showed that co-spray-dried powder retains immunoglobulin G native structure. Spray-dried powders were kept in the aluminum canister (8 mL) equipped with a discontinuous Bespak BK357 valve and a dosing chamber of 63 μL. The suspension contains 40 mg of spray-dried powder in 14 g of HFA134a. During aerosolization analysis using twin stage impinger (28.3 L/min), immunoglobulin G/mannitol pMDI and immunoglobulin G/trehalose pMDI exhibited MMAD of 4.2 and 3.8 μm, respectively. The spray-dried immunoglobulin G/trehalose powder demonstrated the formation of immunoglobulin G/trehalose alloy with single glass transition (Tg) at 92°C compared to pure trehalose Tg (120°C). The difference in Tg signifies the relative stability of spray-dried powder. During 1 month of stability (40°C and 75% RH), spray-dried immunoglobulin G/trehalose powder efficiently retained its mean particle size (3.3 μm) and MMAD (3.7 μm). Similarly, spray-dried immunoglobulin G/mannitol powder showed a slight change in its mean particle size (5.1 μm) and MMAD (4.0 μm) during 1-month of storage. The reported spray drying process can formulate proteins/peptides-based pMDI to treat chronic pulmonary diseases (100). However, the biologicals delivery is limited investigation are reported. This may be due to physicochemical properties of biologicals. Advanced strategies need to be developed to overcome the limitation associated with biologics in MDI.

Miscellaneous pMDI Formulations

Along with above discussed drug delivery systems, various other formulations also investigated for delivery of drug using MDI. Vehring et al. (2012) fabricated co-suspensions of microcrystals and engineered microparticles for efficient and uniform delivery of drug actives (glycopyrrolate, formoterol fumarate dihydrate, and mometasone furoate) using pMDI. Initially, phospholipid/calcium chloride porous microparticles were produced using the spray drying method, while drug microcrystals were formulated using air-jet milling. Glycopyrrolate (1.7 μm), formoterol fumarate dihydrate (1.4 μm), mometasone furoate (1.0 μm) microcrystals and spray-dried porous microparticles (2.3 μm) showed mean particle size suitable for pulmonary drug delivery. Additionally, engineered microparticles showed a corrugated surface, and an amphiphilic particle surface formed a layer with a thickness of <100 nm. Surface corrugation and the amphiphilic nature of surfaces showed reduced cohesion between microparticles, which mainly assists in a low aggregation rate in the propellant. Drug microcrystals and porous microparticles were suspended into HFA 134a, and the suspension was filled into fluorinated ethylene polymer-coated 14 mL aluminum canisters equipped with 50 μL valves. In the co-suspensions, drug microcrystals and the corrugated surface of microparticles exhibited better adhesion due to the shape-fitting contact character. During aerodynamic analysis, co-suspensions demonstrated excellent colloidal stability, uniformity and agglomerates remain intact upon actuation. Thus, the aerodynamic outcome such as dose uniformity and fine particle fraction is reasonable and mainly governed by the properties of the engineered porous microparticles. In summary, duel or triple combination pMDI based on co-suspension technology is suitable for treating respiratory illnesses (101).

Young et al. (2009) probed the influence of binary particulates on the aerosolization performance of sibenadet hydrochloride pMDIs. Particularly, homogenous pMDI formulation, i.e., ≤ 1 particle per droplet (adhering to Stokes law), was formulated using HFA-134a propellant, micronized flat-shape sibenadet hydrochloride (3.16 μm; d0.5), rectangular-shape lactose (4.15 μm; d0.5) and mannitol (4.12 μm; d0.5) carriers. Aerodynamic analysis of sibenadet hydrochloride pMDI showed that the total dose (1–25 mg) had no considerable impact on the FPF. Sibenadet hydrochloride pMDI aerodynamic analysis suggested that the cohesion between sibenadet hydrochloride particles was reasonably small in the HFA propellant, and thus particles remain discrete entities, regardless of concentration. Aerodynamic analysis of binary particulates, i.e., sibenadet hydrochloride/lactose and sibenadet hydrochloride/mannitol pMDI, indicated that the ratio of the carrier: drug had a significant impact on the aerosol outcome. Sibenadet hydrochloride/lactose and sibenadet hydrochloride/mannitol pMDI showed a significant decrease in sibenadet hydrochloride aerosol performance when the concentration of lactose concentration and mannitol ≥50 and 96%, respectively. The decrease in aerosol performance of sibenadet hydrochloride with binary particulates was mainly attributed to relative interparticle interactions between the micronized carrier particles and sibenadet hydrochloride (Fig. 8) (102). In through-life aerodynamic testing, sibenadet hydrochloride pMDI and sibenadet hydrochloride/mannitol pMDI showed ~2-fold reduction in FPF due to increased canister surface area about the residual dose. Interestingly, sibenadet hydrochloride/lactose pMDI did not show any significant change in % FPF during through-life aerodynamic testing due to the formation of coarser particulate agglomerates and reduction in the effective surface area between the canister and residual dose. Lactose with high-surface free energy (87.01 mJ/m2) assists in forming cohesive agglomerates and directly affects the aerodynamic performance of sibenadet hydrochloride with a lower surface energy (33.31 mJ/m2), owing to adhesive bond formation onto or into the cohesive agglomerate. In summary, the surface energetics of carrier and drug need to regulate to control the interparticle interactions, degree of particle adhesion/cohesion, sedimentation rate and through-life aerosolization performance of formulations (102).

Schematic of the interactive mechanism of the sibenadet hydrochloride—only formulation and sibenadet hydrochloride: micronized particulates formulations. Numbers in brackets are surface energy of interaction in mJ/m2. Redesign the figure from ref. [102]. Copyright 2019 Elsevier.

Sawatdee et al. (2014) developed cyclodextrin (CD)-based sildenafil citrate pMDI to treat pulmonary hypertension. The sildenafil-CD (1:17) complex was primarily fabricated using dried ethanol and HP-β-CD, α-CD, γ-CD. Subsequently, pMDI was formulated using ethanol (solvent), PEG-400 (stabilizing agent), sorbitan monooleate (surfactant) and HFA-134a (propellant). Developed formulations were filled into 20 mm neck diameter glass canisters equipped with 50 μL metering valves. During delivered dose uniformity analysis, HP-β-CD-sildenafil, α-CD-sildenafil and γ-CD-sildenafil formulations showed a good, delivered dose of 107.9%, 104.6% and > 100%, respectively, as compared to the sildenafil pMDI (41.6%). During aerodynamic assessment using ACI at 28.3 L/min, after 1 month of storage, HP-β-CD-sildenafil, α-CD-sildenafil and γ-CD-sildenafil pMDI displayed FPF of 54.1, 45.8, 81.6%, respectively with MMAD of 2.06, 2.90 and 1.94 μm, respectively. Likewise, during 6 months of storage, HP-β-CD-sildenafil, α-CD-sildenafil and γ-CD-sildenafil pMDI effectively retained FPF (51.3, 57.9 and 72.3%) and MMAD (2.28, 2.35 and 2.02 μm), respectively. The γ-CD-sildenafil pMDI formulation showed higher % FPF because the formulation produced more consistent aerosol properties with the lowest variation within the assay content. In in-vivo assessment using chicken egg blood vessels, CD complexed sildenafil pMDIs showed 2.66-fold superior sildenafil concentration compared to a sildenafil pMDI. During the in-vivo vasodilation study, intravenously injected CD complexed sildenafil formulations showed 1.27 and 1.90-fold higher reduction in umbilical blood pressure than pMDI actuated CD complexed sildenafil formulation and sildenafil pMDI, respectively. Intravenous injection of sildenafil complex achieved a better contact to the smooth muscle cells of the blood vessel than sildenafil complex pMDI due to uneven distribution of the pMDI clouds across the blood vessel and intricacy to get to a specific control on the spraying area (103). Briefly, CD-based pMDI is a significant move towards successful pulmonary drug delivery.

Voswinckel et al. (2009) investigated the treprostinil MDI delivery for the treatment of pulmonary hypertension. Precisely, the Respimat® MDI device (“soft mist” technique) was used to deliver the treprostinil as it is appropriate for peripheral lung deposition. Physical aerosol characterization showed that treprostinil MDI generated the MMAD of <5 μm, and one puff of treprostinil MDI efficiently delivered a volume of 15 μL. During the clinical investigation, treprostinil MDI (30 to 60 μg) was delivered to subjects with moderate to severe pre-capillary pulmonary hypertension. Treprostinil MDI displayed a 1.16, 1.33 and 1.25-fold reduction in pulmonary vascular resistance at 30, 45 and 60 μg doses, respectively. Likewise, treprostinil MDI also exhibited a 1.20, 1.32 and 1.21-fold reduction in pulmonary artery pressure at 30, 45 and 60 μg dose, respectively. Treprostinil MDI showed similar pulmonary hemodynamics to the acute inhaled nitric oxide. Additionally, treprostinil MDI (30, 45 and 60 μg) exhibited similar results to 6 min continuous inhalation ultrasonic nebulizer inhalation of treprostinil (32, 48 and 64 μg). No impact on ventilation/perfusion matching by treprostinil was demonstrated in 5 patients with pre-existing gas exchange limitations by use of the multiple inert gas elimination technique. Overall inhalation of treprostinil MDI (2–3 puffs) produced selective pulmonary vasodilatation with a peak effect after 30 to 45 min and maintained hemodynamic action at the end of the 2 h. Treprostinil MDI showed satisfactory results for the treatment of pulmonary hypertension; however, a few crucial issues like ease of handling, patient autonomy, device size, and long-term efficacy of this formulation need to be probed in a controlled clinical study (88).

Saadat et al. (2013) formulated and judiciously characterized the clarithromycin-based macrolide solution pMDI for chemical and physical properties. Clarithromycin (0.2%) solution pMDI was prepared using HFA 134a/ethanol (10%) mixture and poured into a canister fitted with a 50 μL metering value. In the in-vitro aerodynamic study, clarithromycin pMDI presented good FPF (47.15%) and MMAD (1.71 μm) values. In stage-wise deposition assessment, clarithromycin pMDI demonstrated higher drug deposition within the actuator (9.9%) and induction port (39.1). The solution-based pMDIs usually follow high exit velocity and longer drying time of ethanol droplets, leading to more drug deposition in the actuator and induction port. Thus, 50% loss in the actuator and induction port is tolerable in the present case. The raw crystalline clarithromycin particles showed columnar surface morphology while atomized clarithromycin particles collected from stage 4 of cascade presented corrugated spherical morphology due to rapid propellant and co-solvent evaporation after auctation. Besides, the absence of any defined angular morphology of deposited clarithromycin particles confirms the material’s amorphous nature. Moreover, the clarithromycin pMDI formulation was physically stable for 30 days (storage at 4 and 37°C) with acceptable aerodynamic characteristics. In brief, the investigation showed the possibility of formulating a solution-based pMDI containing low-dose macrolide to manage lung inflammatory diseases (89).

Novel diclofenac solutions pMDI formulation was fabricated for therapy of cystic fibrosis. Two diclofenac pMDI were formulated i.e., low dose diclofenac pMDI (5% ethanol and 150 mcg of diclofenac) and high dose diclofenac pMDI (15% ethanol and 430 mcg of diclofenac) and stored in brim metal canister (8 mL) crimped with a 50 μL metering valve. Low and high dose diclofenac pMDI exhibited mean particle sizes of 3.2 and 5.1 μm, suitable for pulmonary drug delivery. In in-vitro delivered dose uniformity analysis (30 L/min), low and high-dose diclofenac pMDI showed delivered doses of 127.7 and 373.3 μg, respectively. Both low and high-dose diclofenac pMDI demonstrated acceptable delivered dose uniformity according to the European Pharmacopeia and thus confirming the suitability for inhaled delivery. During the in-vitro aerosol deposition study (30 L/min), low-dose diclofenac pMDI expressed FPF and MMAD of 23.1% and 2.43 μm, respectively. Whereas low dose diclofenac pMDI showed lower FPF and MMAD of 7.1% and 9.94 μm, respectively. Moreover, during anti-inflammatory activity assessment, the air-liquid interface cell culture model of the normal lung (NuLi-1) and cystic fibrosis (CuFi-1) airways revealed a considerable reduction in pro-inflammatory cytokines IL-6 and IL-8. Briefly, the present study indicates the potential of aerosolized low-dose diclofenac pMDI as a capable inhaled anti-inflammatory therapy for cystic fibrosis management (104).

Abdou et al. (2019) fabricated pMDI for the anti-migraine drug zolmitriptan to enhance its biopharmaceutical properties. Zolmitriptan pMDI was formulated using three different propellants, namely HFA 134a, HFA227 and HFA 134a: HFA 227 (1:1) with stabilizer oleic acid (1%) and dried ethanol (1%) to improve valve function. In an in-vitro aerosolization study, zolmitriptan pMDI containing HFA 134a showed a marked 1.7 and 1.45-fold improvement in % FPF compared to the other two zolmitriptan pMDI formulations. HFA 134a-based zolmitriptan pMDI displayed lower MMAD (3.47 μm) values with consistent drug content per actuation (> 94%). Additionally, HFA 134a-based zolmitriptan pMDI retained % FPF (40.4) and MMAD (3.54 μm) values within acceptable limit during 3-month storage. The vapor pressure of the propellant showed a notable impact on the physicochemical and aerodynamic characters of the pMDI formulations. During the in-vivo study, HFA 134a-based zolmitriptan pMDI (2.5 mg) was delivered to rats using an infant MDI spacer chamber modified with a fenestrated latex membrane. The HFA 134a-based zolmitriptan pMDI showed 1.96-fold lower Tmax (time to maximum plasma concentration), 1.19-fold higher Cmax (maximum serum concentration) and 1.25-time higher relative bioavailability compared to the oral tablet (2.5 mg). Briefly, pMDI formulations of anti-migraine drug-using HFA 134a propellant can be a suitable alternative for migraine therapy with a faster onset of action (105).

Ninbovorl et al. (2013) carefully investigate the formulation composition (water, ethanol and propellant) on stability and aerodynamic functioning of solution-based ipratropium bromide and fenoterol hydrobromide pMDI. Various combinations of solutions were filled in glass canisters topped with a 50 μL metering valve used to understand the formulation composition impact on stability and aerodynamic functioning of pMDIs. The micronized drug concentration, i.e., ipratropium bromide (1.0 mg) and fenoterol hydrobromide (2.5 mg) and solution fill volume (12 mL), were kept constant in pMDIs. The higher dielectric constant (ε) of ipratropium bromide (45.9) and fenoterol hydrobromide (59.1) compared to HFA 134a propellant (9.5) corroborated the lower solubility of drugs within the propellant system. Similarly, both drugs are weak bases, and a base is mostly ionic at low pH values and thus extremely soluble in an aqueous vehicle. Thus, formulation composition, pH, dielectric constant and vapor pressure are needed to control formulation stability and aerodynamic properties. The optimized formulation composition contains water (2.2%), ethanol (27.8%) and HFA 134a propellant (70%). The optimized formulation showed dielectric constant, pH and vapor pressure of 15.1, 3.48 and 331.11 kPa, respectively, with good physical stability, lowest content variability and acceptable delivered dose uniformity. Optimized formulation showed FPF of 49.6, 51.1 and 49.6% for fenoterol hydrobromide during initial, 3 and 6-month storage, respectively, while ipratropium bromide showed FPF of 53.7, 50.2, 46.7% during initial, 3 and 6-month storage, respectively. Similarly, both formulations showed lower MMAD values (< 2.5 μm) during storage of 6 months. In terms of delivered dose uniformity, both formulations consistently displayed delivered doses in the range of 90 to 110% during long-term storage for 6 months at 25°C. Briefly, the dielectric constant, vapor pressure of the co-solvents and propellant should be in an apt range to impart satisfactory physical stability and aerosol properties (106).

Sawatdee et al. (2020) formulated montelukast pMDI using HFA 134a and pre-mixed HFA-134a/HFA-227 propellant to understand the aerodynamic performance. Initially, PEG 400 was mixed with ethanol and sonicated for 5 min; subsequently, montelukast sodium (1.8 mg) was added to obtain a product concentrate. Afterward, montelukast concentrate was placed into the MDI canister equipped with 50 μL metering valves, and propellant was added to make a final volume of 6 mL. During aerodynamic assessment using ACI at 28.5 L/min, HFA 134a propellant containing montelukast pMDI displayed FPF and MMAD of 58.8% and 2.0 μm, respectively. Whereas pre-mixed HFA-134a/HFA-227 propellant (56:24) containing montelukast pMDI displayed FPF and MMAD of 48.6% and 2.81 μm, respectively. The concentrations of PEG 400 and ethanol also showed a notable impact on the aerodynamic properties of the montelukast pMDI. Increasing ethanol concentration produces large droplets and shows deposition of montelukast at the oropharyngeal region due to inertial impaction. This same fact is observed with PEG 400. In an in-vitro cytotoxicity study using MTT assay using human lung adenocarcinoma cells (A549), rat alveolar macrophage cells (NR8383) and human lung adenocarcinoma cells (Calu-3), montelukast pMDI retained more than 90% cell viability than negative control cells. After actuation, the quick evaporation of ingredients resulted in only a residual quantity of excipients deposited, causing low toxicity towards human lung airway cells. Furthermore, in in-vitro inflammatory potential assessment using NR8383 cells, montelukast pMDI formulated with different propellants showed lower tumor necrosis factor-α (TNF-α) and interleukin-1β (IL-1β) production. However, NR8383 cells incubated with a pre-mixed propellant showed significantly higher nitric oxide (NO) quantities than NR8383 cells incubated with a single HFA propellant. Briefly, the montelukast pMDI are non-toxic and are not expected to aggravate airway cells but, further in-vivo investigations are essential to conclude the safety of montelukast pMDI formulations (107).

Zhu et al. (2015) designed and developed theophylline pMDI to improve the treatment of chronic obstructive pulmonary disease (COPD). Theophylline pMDI was fabricated using ethanol (15%) and HFA 134a propellant with MDI canister equipped with a 50 μL metering valve. In-vitro aerosol performance of theophylline pMDI (5 actuations - 250 μg of theophylline) was investigated with ACI at 28.5 L/min, and theophylline pMDI showed MMAD and geometric standard deviation (GSD) of 1.3 μm and 2.1, respectively. Theophylline pMDI displayed fine particle dose (FPD) and FPF of 94.8 μg and 38%, respectively. During morphological study after aerosol actuation, theophylline particles were collected from Stage 5 of the ACI showed crystalline nature and spherical morphology (1–1.5 μm) with a hollow core. In an in-vitro cytotoxicity study using Calu-3 cells, theophylline pMDI showed half-maximal inhibitory concentration (IC50) of 2.5 mM and retained barrier integrity of the Calu-3 cells in 15-day transepithelial electrical resistance measurements (TEER) assessment. During in-vitro transport study using Calu-3 epithelium by the ACI equipped with the Snapwells (0.4 μm), theophylline pMDI (2–4 actuation) showed 1.25 μg of theophylline deposited within each Snapwell, which is well below the toxic concentrations of theophylline in Calu-3 cells. Further, 97.9% of deposited theophylline was transported across the Calu-3 cells within 180 minutes. Deposition study shows that theophylline reached the site of action (A3 Adenosine receptors) situated on the smooth muscle cells after 180 minutes to accomplish its therapeutic action. During in-vitro inflammatory analysis, theophylline pMDI exhibited 4.5 and 1.81-fold lower interleukin-8 (IL-8) levels compared to Calu-3 cells treated with TNF-α and plain theophylline, respectively. Briefly, theophylline pMDI formulation showed a reduction in the required dose for local treatment, thus reducing side effects (108).

MDI Devices: Effect of Various Parameters on Aerodynamics and Drug Deposition

MDI is a handheld pressurized inhalation system composed of a canister fitted with a valve and actuator to consistently deliver a specific drug dose to the patient using a propellant (109). Inhaler device design has a notable impact on the outcome of the drug delivery process and aerodynamic profile of a drug substance (110,111). Accordingly, selecting the suitable inhaler device is crucial in successfully treating chronic respiratory diseases. Few active researchers investigate the effect of pMDI inhaler components design on the aerodynamic performance of pMDIs, and such exciting case studies are described in the present section. The aerodynamic efficiency of pMDIs is mainly measured by the amount of drug deposited within the throat and the proportion of the emitted dose deposited within the lung (i.e., FPF). To comprehend this trend more carefully, Sheth et al. (2017) studied the aerodynamic performance of ten solution pMDI formulations containing a wide range of co-solvents with diverse chemical properties using by cascade impactor equipped with three different throat models, i.e., USP induction port (USP IP), Alberta Idealized Throat (AIT) and large volume chamber (LVC). USP IP and AIT were used to serve the current industry standard and an anatomically representative model, respectively, while LVC (AeroDryer Model 3242) was used to control this study. The pMDI formulations were prepared using a 0.3% (w/w) drug with varying co-solvent and HFA-134a propellant. Formulations were filled in aluminum canisters (17 mL) equipped with 50 μL metering valves by cold fill technique. During ACI analysis at 28.3 L/min, the aerodynamic performance of pMDI formulations showed that the concentration vapor pressure of the co-solvent and throat geometry have a considerable impact on throat deposition profile, FPF and MMAD. Decreasing the co-solvent vapor pressure or increasing the co-solvent concentration showed improved throat deposition and lower drug deposition on 0 to 7 stages of the ACI. During the assessment of throat geometry, solution pMDI formulations showed higher drug deposition within AIT than USP IP, while LVC showed superior FPF and residual particle MMAD values and lowest for the AIT. Moreover, the droplet lifetime (evaporation time; a discrete two-phase process) considerably influences throat deposition, and FPF represents that evaporation kinetics appreciably affects the pMDI drug delivery (Fig. 9). Briefly, propellant and co-solvent selection have a crucial impact on the amount of drug deposited within the throat and the lung (i.e., FPF) (112). Duke et al. (2021) studied the effect of novel actuator shapes on the aerodynamic fraction of pMDIs. A model ipratropium bromide, pMDI formulation was fabricated using HFA-134a propellant, 15% w/w co-solvent (ethanol) and filled into aluminum canisters fitted with 50 μL metering valves. Replaceable nozzle inserts to shape actuator designs were prepared using optically clear polycarbonate by a microinjection technique. Total 5 actuator shapes, i.e., control actuator (0.33 mm), single nozzle with a recess (0.33), twin nozzle with a recess (0.22), single nozzle (0.33 mm) and twin nozzle (0.22), were used to assess the aerodynamic fraction of pMDI. Internal recess lessens the length of the nozzle orifice without altering external dimensions. Single and twin nozzle acquire similar cross-section area; however, twin nozzle has two vertically oriented holes with a diameter of 0.22 mm. Results of aerodynamic analysis (FPF) using novel actuator shapes are as follow; twin nozzle (39.4%) > single nozzle (31.5%) > twin nozzle with recess (29.1%) > single nozzle with recess (25.6%) > control actuator (22.5%). Twin nozzle pMDI showed ~2-fold increase in FPF compared to control actuator-pMDI. The newly designed actuator displayed a significant impact on spray width and pattern. The high-speed in-vitro imaging showed that the twin hole nozzle generates a single jet because the flow from both orifices unites quickly upon leaving the nozzle (spray collapse phenomenon). Data propose that smaller orifices (0.22 mm) generate fine particles and higher sustained plume velocities cause higher fine particles at the periphery of the spray owing to improved shear. A small change in the pMDI device significantly impacts the drug deposition profile and improves formulation aerodynamic functioning (113).

Discrete two-stage evaporation process for droplets from solution and suspension pMDI. Redesign the figure from ref. [112]. Copyright 2017 Elsevier.

Newman and co-workers studied the drug deposited in the human respiratory tract for Berodual® (ipratropium bromide; 20 μg and fenoterol hydrobromide; 50 μg) formulation delivered from pMDI formulated using chlorofluorocarbons (CFC) and hydrofluoroalkane (HFA-134a and HFA-227). Additionally, the effect of actuator nozzle diameter on the deposition pattern of Berodual® containing HFA-134a was also probed. The CFC and HFA-227 formulations were suspensions, while the HFA-134a formulation was a solution. During in-vivo deposition study, two pMDI doses were delivered (ipratropium bromide; 420 μg and fenoterol hydrobromide; 100 μg) together with 10 MBq 99mTc and assessed using gamma scintigraphy to quantify the total amount of fenoterol deposited in the human respiratory tract because it proved complicated to measure the amounts of ipratropium bromide deposited. The CFC, HFA-227, and HFA-134a-based pMDI showed 8.0, 8.8 and 13.4 μg fenoterol deposition within the whole lung. Among the different pMDI formulations, HFA-134a pMDI showed the lowest oropharyngeal deposition (61.7 μg) compared to CFC (73.0 μg) and HFA-227 (70.4 μg) pMDI. In actuator nozzle diameter study using HFA-134a pMDI, 0.2, 0.25- and 0.3-mm actuator nozzle showed 18.0, 15.2 and 12.8 μg, fenoterol deposition within the whole lung. CFC pMDI equipped with a 0.6 mm actuator nozzle displayed 15.5 μg, fenoterol deposition within the whole lung. The pMDIs with decreasing nozzle diameter demonstrated better drug deposition due to the reduction in propellant droplet size during actuation. Briefly, results suggested that the total and regional lung deposition of HFA-based pMDIs is highly product-specific and that variation in in-vivo drug deposition can be obtained by changing both the formulation constituents and design of the actuator nozzle (114). Plaunt et al. (2021) developed and thoroughly characterized the treprostinil palmitil (prodrug) pMDI to treat pulmonary arterial hypertension. The solution-based treprostinil palmitil pMDI comprises phospholipids-polymer conjugate (DSPE-PEG2000, PEG 400, isopropyl alcohol and HFA-134a. During aerodynamic assessment treprostinil palmitil pMDI showed FPF of 74.2%, 61.8%, 56.1% and 33.5% using actuator jet lengths of 0.2 mm, 0.25 mm, 0.27 mm and 0.3 mm, respectively. Actuator design exhibited a significant impact on aerodynamic disposition pattern, and NGI stage deposition data (30 L/min) showed that reducing actuator size assist in reducing throat deposition and increase deposition on lower stages such as 4, 5, and 6. Thus, decreeing actuator size (actuator jet length and orifice diameter) showed increased FPF values. During in-vivo pharmacokinetic study using the hypoxic challenge model, once-daily administration of treprostinil palmitil pMDI showed satisfactory clinical outcome with therapeutic efficacy lasting at least 12 h with a notably higher cough threshold than the treprostinil alone. Overall, the prodrug pMDI formulation demonstrates a hopeful aerodynamic and preclinical profile that deserves further assessment for development to perform bench to bedside translational (115).

Ahookhosh et al. (2021) performed a numerical investigation of Ventolin® HFA pMDI (Albuterol sulfate) in a patient-derived human airway model at a broad range of inspiratory flow rates (30 to 120 L/min) and validated the same using in-vitro aerosol data. Furthermore, the effects of inhaler geometry on flow structure, particle deposition pattern in the tracheobronchial airways and the spray characteristics on overall deposition efficiency were assessed. Initially, the human airway model, i.e., the mouth-throat region (oral cavity, oropharynx, and larynx), the trachea, and the bronchial airways up to the 4th generation, was fabricated using computed tomography information of a healthy female. The surface structure and quality volume mesh were generated using the Octree and Delaunay triangulation method. A turbulent boundary layer profile with five layers of prism mesh was produced near the airway walls. The k-ω turbulence model with low-Reynolds number (LRN) corrections and Lagrangian discrete phase model (DPM) was used for airflow modeling and to inject the particles into the domain in an inconsistent manner. Numerical investigation showed an excellent agreement in in-vitro aerosol deposition and computational fluid dynamics (CFD) modeled in the tracheobronchial airway tract data. Increasing the inhalation flow rate (30 to 120 L/min) displayed high particle inertia and turbulence levels with superior particle deposition in the mouth-throat region, trachea and bronchial 3rd and 4th generation. An inhalation flow rate study at 60 L/min demonstrated the highest deposition fractions at the extrathoracic region (24.4%) and trachea (3.1%). The sum of particles deposited in the extrathoracic region depends on the turbulence level and vortex formation in the oral cavity and oropharynx. The particle deposition was superior in the right bronchial airways than the left bronchial airways because airway branches in the left lung are longer and narrower than the right lung, which eventually leads to a higher flow rate and thus superior particle deposition in the right lung. During spray characteristics assessment, spray velocity (100 m/s), spray cone angle (10°), and spray duration (0.1 sec) showed the optimum spray pattern. Mainly, spray cone angle plays a critical role and can change the deposition profile of inhaled particles in the airway model. In summary, CFD modeling can be effectively used to co-relate the drug deposition pattern and inhaler device geometry to realize clinically relevant challenges (116). Stein et al. (2015) explored the Monte Carlo simulation model to probe the aerodynamics of poly-dispersed micronized suspended drugs and initial droplets delivered from pMDI formulation. Experimental and simulated outcomes showed that aerodynamic particle size distribution of the suspended and dissolved ingredients of the formulation was mainly impacted by the amount of the suspended and dissolved drug, together with suspended drug particle size. Monte Carlo simulation model successfully calculated the particle size distributions of both the suspended and dissolved constituents of formulations. The simulation model showed an excellent correlation with experimental MMAD values with r2 value of 0.914. Simulation assessment showed that the suspended drug particles pursue a mono-modal, lognormal distribution. Suspended drug particles APSD was mainly influenced by the amount and size of the suspended drug particles compared to the concentration of dissolved drug particles. Dissolved drug particles displayed a bimodal, lognormal residual APSD experimentally and theoretically. The minor mode comprises residual particles made of dissolved drug particles only, whereas the larger mode comprises residual particles that include both suspended and dissolved drugs particles. Briefly, the simulation model can further used to investigate the APSD of pMDIs comprising several dissolved particles or co-suspension pMDIs where two drug particles are physically attached to perform as a single suspended particle (117).

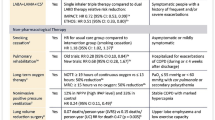

pMDIs Market Scenario

The global market of pMDI increasing rapidly due to development of science and technology which encouraging to patient to use. Various advanced MDI are available in market with price range suitable for lower middle-income families to high end. Corticosteroids and bronchodilators are the major drugs for treatment for chronic respiratory ailments. Inhaler devices such as dry powder inhalers, jet or ultrasonic nebulizers, soft mist inhalers and pMDIs are commonly prescribed by the clinical practitioner to deliver respiratory drugs. Several inhaler devices are available to clinicians and patients; each has distinct advantages and disadvantages. The advantages and disadvantages of pMDIs and clinical outcomes are depicted elsewhere. Undoubtedly, pMDIs are among the most frequently used dosage forms for treating respiratory diseases. The pMDIs are available with CFCs and HFA propellants. By knowing the environmental impact, by 2014, the CFC MDI market was exchanged with HFA MDIs. Table I denotes currently available pMDIs devices. As shown in Table I, pMDIs are available in mono-, double or triple combinations for topical delivery of drug substances.

Still, patient adherence and compliance to long-term pulmonary therapy is the obstacle healthcare practitioners face during regular clinical practices. The ultimate success of long-term pulmonary therapy is 90% education and 10% medication. Effective dialogue between the healthcare practitioner and patients during long-term pulmonary therapy is vital to increase the therapy success rate. The current means for effective patient education is the package insert, i.e., patient information leaflet or instruction card. However, in most cases, package inserts are unable to respond to the dilemma regarding patient adherence and compliance to long-term pulmonary therapy (140). Therefore, few scientists probed and explored the digital technology platform to facilitate a more informed dialogue between healthcare practitioners and patients during long-term pulmonary therapy.

Digital pMDIs Devices

In view of the above discussion, digital technology can enhance patient adherence and compliance to long-term inhalation therapy. Remote technology and e-healthcare technology are the alternative to overcome convention lamination. In very recently e-healthcare system gained the attention of biomedical researcher, healthcare providers and patients. Digital pMDIs can enhance clinical outcomes by improving therapy adherence and reducing patient errors via remote connectivity between patient and healthcare experts allied with the pMDI device, which offers several functions, such as step-by-step guidance for the proper usage of inhaler devices and real-time data recording and dose reminders. Various electronic and mechanical devices such as aerosol actuation counter, nebulizer chronolog, mechanical switches, Bluetooth Low Energy module and system on the chip have been explored and evaluated for the development of absolute digital inhaler. The electronic monitoring device’s role, function and vital clinical applications are described elsewhere (120,140). The currently available digital pMDIs devices are listed in Table I. Very recently, Hirose et al. (2021) fabricated a modified pMDI pinch gauge to measure the finger muscle strength needed to actuate pMDI formulation. Studies indicate that finger muscle strength should be measured while deciding a pMDI device for elderly asthma patients, and the use of a pMDI spacer is suggested in patients with weaker finger muscle strength (141). In this regard, the digital pMDIs device is a rapidly growing and promising approach that can offer patient-centered care with practical solutions for healthcare providers and patients and pharmaceutical organizations to improve patients’ quality of life.

Clinical Potential of pMDIs

There is considerable literature arguing the merits of MDI over other devices. We believe that MDI is the most convenient cheaper technique and are the first choice of clinicians. Moreover, the data suggested that the use of MDI are increasing in United States. Several pMDI are successfully developed and approved for clinical use. The first-generation devices are not equipped with dose counter. The FDA issues guidance in 2003 that pMDIs must be equipped with dose counter. Currently, several breath-actuated pMDI are available in the market. The Autohaler breath actuated device was developed in 1970s. then pMDI formulation Duohaler launched. Both devices can deposit nearly 20% of the dose in the lungs. Easi-Breathe is most widely used breath actuated device. MD-Turbo is the most recently introduced breath actuated inhaler and available in the United States. K-Haler is a work like Autohaler and EasiBreathe Device and simple and can be used in several formats. K-Haler available in the European market. Another breath-actuated pMDIs is Smartmist, it composes of microprocess to record the patient’s inhalation. The Europe and the United States approved the various metered dose inhalers such as Symbicort®, Asmanex® HFA, Dulera®, Xopenex®, Bevespi Aerosphere®, Breztri Aerosphere®, Atrovent®, Alvesco®, Advair®, Flovent®, Ventolin®, Proventil® HFA, ProAir®, QVAR®, Redihaler®, Primatene Mist, and Generic Albuterol Sulfate inhaler (142). However, the progress in still in process toward the development of electronic and digital pMDI devices with reasonable cost and easy to patient’s use.

Summary

This review has highlighted various metered dose inhalers for effective drug delivery and with the help of approximately one hundred appropriate and representative pieces of research. It is evident that polymeric nanocarriers, lipid based nanocarriers and dendrimers are the interesting nanocarriers due to desirable and tunable physicochemical properties. Among the several types of nanocarriers, polymeric nanoparticles, dendrimers, and liposomes are promising candidate for controlled, sustained, and targeted drug delivery systems to investigate nanotherapeutics. These nanocarriers easy fabrication and potential for scaling up, and it is also expedient to control size and feasibility of functionalization makes them priority.

This review concludes that polymeric nanoparticles, dendrimers, and liposomes are a good choice. However, the use of renewable biopolymers needs further investigation. Inorganic nanocarriers are not well established in pulmonary delivery due to the limitations of physicochemical properties, making them more challenging. Moreover, the toxicity of inorganic nanocarriers is a major concern that need to be address and thorough investigation and analysis are needed before implementing them in vivo and clinical studies.