Abstract

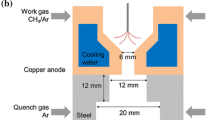

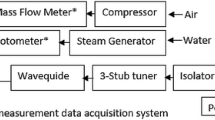

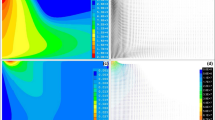

In this paper, we present a plasma rapid heater (PRH) designed to uniformly heat methane with electric arc thermal plasma and reduce loss rate. Our model uses a simplified and detailed mechanism to analyze the rapid and intense mixing process between a plasma mainstream and circumferential cold jets of methane in a hydrogen environment. The research focuses on three areas: the plasma mainstream section, the circumferential jet mixing chamber, and the reaction chamber. We investigate the characteristics of the mainstream and explore the impact of the jet momentum ratio on the mixing process and the losses from methane heating. We explain these phenomena using Damkohler numbers to demonstrate the relationship from a time-scale perspective. The findings indicate that an increased momentum ratio improves mixing, reduces temperature and material non-uniformity, and minimizes losses from pyrolysis during methane heating. Additionally, we provide a formula for calculating the penetration depth of the jet. The examination of Damkohler numbers also suggests that the momentum ratio primarily reduces methane losses by extending the reaction time scale. This work offers guidance on extending the usage of plasma heaters and integrating them into other industry processes in the future.

Similar content being viewed by others

Data Availability

The datasets used or analysed during the current study are available from the corresponding author on reasonable request.

References

Makogon YF, Holditch SA, Makogon TY (2007) J Petrol Sci Eng 56:14

Wang Q, Chen X, Jha AN, Rogers H (2014) Renew Sustain Energy Rev 30:1–28

Weiland P (2010) Appl Microbiol Biotechnol 85:849

Oni SI, Oyewo MA (2011) J Human Ecol 33(1):21

Horn R, Schloegl R (2015) Methane activation by heterogeneous catalysis. Catal Lett 145(1):23–39

Wang B, Albarracín-Suazo S, Pagán-Torres Y, Nikolla E (2017) Advances in methane conversion processes. Catal Today 285:147–158

Chein RY, Hsu WH, Yu CT (2017) Parametric study of catalytic dry reforming of methane for syngas production at elevated pressures. Int J Hydr Energy 42(21):14485–14500

An H, Cheng Y, Li TY, Li Y, Cheng Y (2018) Numerical analysis of methane pyrolysis in thermal plasma for selective synthesis of acetylene. Fuel Process Technol 172:195–199

Liu R, Hao Y, Wang T, Wang L, Bogaerts A, Guo H, Yi Y (2023) Hybrid plasma-thermal system for methane conversion to ethylene and hydrogen. Chem Eng J 463:142442

Holmen A, Olsvik O, Rokstad OA (1995) Pyrolysis of natural gas: chemistry and process concepts. Fuel Process Technol 42(2):249–267

Zhang HB, Cao TF, Cheng Y (2015) Preparation of few-layer graphene nanosheets by radio-frequency induction thermal plasma. Carbon 86:38–45

Xiaohang T (2017) Magnetic rotating arc plasma temperature diagnosis and its application to methane reforming reaction[D]. Zhejiang University, Zhejiang

Zhukov MF et al (2016) Arc plasma torch. Science Press, Beijing

Vadikkeettil Y, Amarnath P, Yugeswaran S, Ananthapadmanabhan PV (2022) Comparative study of plasma torch characteristics using air and carbon dioxide. IEEE Trans Plasma Sci 50(6):1395–1400. https://doi.org/10.1109/TPS.2021.3129593

Shicong B, Wenkang G, Minyou Y, Ping X, Xiaodong Z (2008) Characteristics and thermal efficiency of a non-transferred dc plasma spraying torch under low pressure. Plasma Sci Technol 10(6):701

Yan C, Tianyang Li, Yong J, Yi C (2016) Development and application progress of chemical conversion processes in super high temperature plasma. Chem Ind Eng Progr 35(6):1676–1686 ((in Chinese))

Young RM, Pfender E (1989) A novel approach for introducing particulate matter into thermal plasmas: the triple-cathode arc. Plasma Chem Plasma Process 9(4):465–481

PFENDER EMIL [US]. Multiple arc plasma device with continuous gas jet. Chinese Patent: US4818837 A, 1989.04.04

Schein J, Zierhut J, Dzulko M, Forster G, Landes KD (2007) Improved plasma spray torch stability through multi-electrode design. Contrib Plasma Phys 47(7):498–504

Oberste Berghaus J, Marple B, Moreau C (2006) Suspension plasma spraying of nanostructured WC-12Co coatings. In: 2006 international thermal spray conference (ITSC 2006)

Zhang Z, Wang C, Sun Q, Xia W (2021) Three-dimensional non-equilibrium modeling of a DC multi-cathode arc plasma torch. Plasma Sci Technol 23(7):075404

Xu X, Ren Z, Yang S (2021) Design and optimization of a hybrid excitation system for magnetically driven rotating DC arc plasma generators. IEEE Access 9:157012–157020

Gangoli SP, Gutsol AF, Fridman AA (2010) A non-equilibrium plasma source: magnetically stabilized gliding arc discharge: II. Electrical characterization. Plasma Sources Sci Technol 19(6):065003

Wang C, Cui H, Zhang Z, Xia W, Xia W (2017) Observation of arc modes in a magnetically rotating arc plasma generator. Contrib Plasma Phys 57(9):395–403

Ma J, Zhang M, Wu JH, Yang QW, Wen GD, Su BG, Ren QL (2017) Hydropyrolysis of n-hexane and toluene to acetylene in rotating-arc plasma. Energies 10(7):899

Li L (2008) Experimental study and numerical simulation of magnetically dispersed arc plasma. Univers Sci Technol China. https://doi.org/10.7666/d.y1270494. ((in Chinese))

Perambadur J, Klimenko AY, Rudolph V, Shukla P (2022) Investigation of plasma swirl dynamics and effects of secondary gas injection in a vortex gas stabilized DC arc plasma. Int J Heat Fluid Flow 95:0142-727X

Wu GQ, Li HP, Bao CY, Chen X, Li H-P (2009) Modeling of the heat transfer and flow features of the thermal plasma reactor with counter-flow gas injection. Int J Heat Mass Transfer 52:760–766

Zhang X, Liu Z, Tanaka M, Watanabe T (2021) Formation mechanism of amorphous silicon nanoparticles with additional counter-flow quenching gas by induction thermal plasma. Chem Eng Sci 230:116217

Zhou X et al (2023) Quasi-direct numerical simulations of the flow characteristics of a thermal plasma reactor with counter flow jet. Plasma Sci Technol. https://doi.org/10.1088/2058-6272/acb9d8

Smith GP, Golden DM, Frenklach M, Moriarty NW, Eiteneer B, Goldenberg M, Thomas Bowman C, Hanson RK, Song S, Gardiner WC, Jr., Lissianski VV, Qin Z http://combustion.berkeley.edu/gri-mech/

Yang WJ et al (2014) Experimental and numerical investigations of hydrogen–air premixed combustion in a converging–diverging micro tube. Int J Hydrogen Energy 39(7):3469–3476

Carlos Fernandez-Pello A (2002) Micropower generation using combustion: Issues and approaches. Proc Combust Inst 29(1):883–899

Chen T, Che H-Q (2019) Steady-state simulation of different discharge modes of argon arc under external magnetic field. Plasma Sources Sci Technol 28(12):125001

Pan Z, Ye L, Qian S, Sun Q, Wang C, Ye T, Xia W (2020) Comparison of Reynolds average Navier-Stokes turbulence models in numerical simulations of the DC arc plasma torch. Plasma Sci Technol 22(2):62–74

Menter FR, Esch T (2001) Elements of industrial heat transfer predictions. In: Proc. 16th Brazilian congress of mechanical engineering (Uberlandia, Brazil)

Gleizes A, Gonzalez JJ, Freton P (2005) Thermal plasma modelling. J Phys D Appl Phys 38(9):R153–R183

Zhou Q (2009) Numerical simulation of DC arc plasma torch. Fudan University, Shanghai. https://doi.org/10.7666/d.y1970249 ((in chinese))

Zhou QH, Yin HT, Li H, Xu X, Liu F, Guo SF, Chang XJ, Guo WK, Xu P (2009) The effect of plasma-gas swirl flow on a highly constricted plasma cutting arc. J Phys D-Appl Phys 42(9):095208

Pan Z, Chen X, Yuan X et al (2021) The effects of graphite particles on arc plasma characteristics. Plasma Chem Plasma Process 41(4):1183–1203

Zhu C, Chen X-H, Wang C, Song M, Xia W-D (2023) Calculation of thermodynamic properties and transport coefficients of Ar-C-Si plasma. Acta Phys. Sin. 72(12):1252021–12520212. https://doi.org/10.7498/aps.72.20222390

Chase MW, Davies CA, Downey JR, Frurip DJ, McDonald RA, Syverud AN https://janaf.nist.gov/

Acknowledgements

This work is supported by National Natural Science Foundation of China (No. 120350015) and Youth Fund of the National Natural Science Foundation of China (No. 12105282).

Funding

Youth Fund of the National Natural Science Foundation of China (No. 12105282) and National Natural Science Foundation of China (No. 12035015).

Author information

Authors and Affiliations

Contributions

SW: Conceptualization, Methodology, Software, Investigation, Formal analysis, Writing—original draft, Writing—review & editing. DK: Partial data processing. XC: Conceptualization, Funding acquisition, Resources, Supervision, Writing -review & editing. CW: Resources, Supervision. WX: Resources, Supervision, Data curation, Project administration. All authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

I declare that the authors have no competing interests as defined by Springer, or other interests that might be perceived to influence the results and/ or discussion reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, S., Kong, D., Chen, X. et al. Numerical Simulation Study on Plasma Rapid Heater of Methane. Plasma Chem Plasma Process 44, 95–114 (2024). https://doi.org/10.1007/s11090-023-10433-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-023-10433-9