Abstract

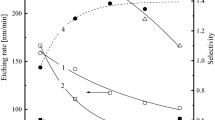

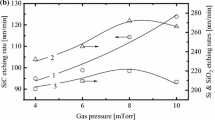

The comparative study of etching characteristics and mechanisms for TiO2 thin films in CF4 + Ar, Cl2 + Ar and HBr + Ar inductively coupled plasmas was carried out. The etching rates for TiO2, Si and photoresist were measured as functions of gas mixing ratios at fixed gas pressure (10 mTorr), input power (800 W) and bias power (300 W). It was found that the maximum TiO2 etching rate of ~130 nm/min correspond to pure CF4 plasma while an increase in Ar fraction in a feed gas results in the monotonic non-linear decrease in the TiO2 etching rates in all three gas mixtures. Plasma diagnostics by Langmuir probes and 0-dimensional (global) plasma modeling supplied the data on the densities of plasma actives specie as well as on particle and energy fluxes to the etched surface. It was concluded that, under the given set of experimental conditions, the TiO2 etching kinetics in all gas systems correspond to the ion-assisted chemical reaction with a domination of the chemical etching pathway. It was found also that the differences in the absolute TiO2 etching rates correlate with the energy thresholds for TiO2 + F, Cl or Br reaction, and the reaction probabilities for F, Cl and Br atoms exhibit the different changes with the ion energy flux according to the volatility of corresponding etching products.

Similar content being viewed by others

References

O’Regan B, Gratzel M (1991) Nature 353:737

Guglielmi M, Colombo P, Esposti LMD, Righini GC, Pellic S, Rigato V (1992) J. Non Cryst. Solids 147–148:641

Hsu YP, Chang SJ, Su YK, Chang CS, Shei SC, Lin YC, Kuo CH (2003) J Electron Mater 32:5

Pak TM, Lei TF, Chao TS (2001) Appl Phys Lett 78:1439

Choi K-R, Woo J-C, Joo Y-H, Chun Y-S, Kim C-I (2013) Vacuum 92:85

Joo Y-H, Woo J-C, Kim C-I (2012) Trans. Electr. Electron. Mater. 13(3):144

Choi K-R, Woo J-C, Joo Y-H, Chun Y-S, Kim C-I (2014) Trans. Electr. Electron. Mater. 15(1):32

Choi K-R, Woo J-C, Joo Y-H, Kim C-I (2013) Ferroelectrics 456:63

Garay AA, Hwang SM, Chung CW (2015) Thin Solid Films 587:20

Noemaun AN, Mont FKW, Cho J, Schubert EF, Kim GB, Sone C (2011) J Vac Sci Technol A 29:051302

Norasetthekul S, Park PY, Baik KH, Lee KP, Shin JH, Jeong BS, Shishodia V, Lambers ES, Norton DP, Pearton SJ (2001) Appl Surf Sci 185:27

Kim D, Efremov A, Jang H, Kang S, Yun SJ, Kwon K-H (2012) Jpn J Appl Phys 51:106201

Jang H, Efremov A, Kim D, Kang S, Yun SJ, Kwon K-H (2012) Plasma Chem. Plasma Proc. 32:333

Efremov AM, Kim DP, Kim CI, Trans IEEE (2004) Plasma Sci. 32:1344

Kwon K-H, Efremov A, Kim M, Min NK, Jeong J, Kim K (2010) Jpn J Appl Phys 49:031103

Johnson EO, Malter L (1950) Phys Rev 80:58

Sugavara M (1998) Plasma etching: fundamentals and applications. Oxford University Press, New York

Efremov A, Min N-K, Choi B-G, Baek K-H, Kwon K-H (2008) J Electrochem Soc 155:D777

Efremov AM, Kim D-P, Kim C-I (2004) Vacuum 75:133

Kwon K-H, Efremov A, Kim M, Min NK, Jeong J, Kim K (2010) J Electrochem Soc 157:H574

Efremov A, Kim Y, Lee H-W, Kwon K-H (2011) Plasma Chem. Plasma Proc. 31:259

Chun I, Efremov A, Yeom GY, Kwon K-H (2015) Thin Solid Films 579:136

Efremov AM, Kim G-H, Kim J-G, Bogomolov AV, Kim C-I (2007) Microelectron Eng 84:136

Efremov A, Choi B-G, Nahm S, Lee HW, Min N-K, Kwon K-H (2008) J. Korean Phys. Soc. 52:48

Bazin A, Pargon E, Mellhaoui X, Perret D, Mortini B, Joubert O (2008) Advances in resist materials and processing technology XXV. In: Henderson CL (ed) Proceedings of the SPIE, vol 6923, p 692337. http://proceedings.spiedigitallibrary.org/proceeding.aspx?articleid=831628

Pargon E, Menguelti K, Martin M, Bazin A, Chaix-Pluchery O, Sourd C, Derrough S, Lill T, Joubert O (2009) J Appl Phys 105:094902

Lieberman MA, Lichtenberg AJ (1994) Principles of plasma discharges and materials processing. Wiley, New York

Lide DR (1998-1999) Handbook of chemistry and physics. CRC Press, New York

Jin W, Vitale SA, Sawin HH (2002) J Vac Sci Technol A 20:2106

Gray DC, Tepermeister I, Sawin HH (1993) J Vac Sci Technol B 11:1243

Lee C, Graves DB, Lieberman MA (1996) Plasma Chem Plasma Proc 16:99

Mattox DM (2010) Handbook of physical vapor deposition (PVD) processing. Elsevier, Oxford

Ranjan R, Allain JP, Hendricks MR, Ruzic DN (2001) J Vac Sci Technol A 19:1004

Rossnage SM, Cuomo JJ, Westwood WD (1990) Handbookof plasma processing technology. Noyes Publications, Park Ridge

van Roosmalen AJ, Baggerman JAG, Brader SJH (1991) Dry etching for VLSI. Plenum Press, New York

Acknowledgments

This study was supported by the Industrial Technology Innovation Program (10054882, Development of dry cleaning technology for nanoscale patterns) funded by the Ministry of Trade, Industry and Energy (MOTIE, Republic of Korea).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, J., Efremov, A., Lee, B.J. et al. Etching Characteristics and Mechanisms of TiO2 Thin Films in CF4 + Ar, Cl2 + Ar and HBr + Ar Inductively Coupled Plasmas. Plasma Chem Plasma Process 36, 1571–1588 (2016). https://doi.org/10.1007/s11090-016-9737-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-016-9737-y