Abstract

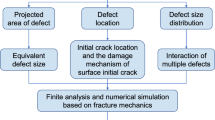

The chemical stability of oxide scales and the oxide growth kinetics are important factors to consider when choosing a material for high temperature application. Low oxide growth rates and good chemical stability are, however, not the only aspects to be taken into account. The mechanical stability of the oxide scale formed can also play a significant role, especially when external loads or fast heating or cooling rates come into play. In this work, experimental data on oxide scale failure and a defect based scale failure model are used to calculate mechanical stability diagrams for titanium oxide and iron oxide. For these diagrams the original η-c-approach is extended by a term characterizing the level of residual strains in the scale. In addition to titanium and iron oxide this extended approach is also applied to former measurement data on nickel oxide. With the stability diagrams developed it is possible to estimate the maximum tolerable strain for the oxide scale as a function of the physical defect situation in the scale. Metallographic inspection and 4-point bending tests are used to derive the mechanical stability parameter η and the parameter εr for the residual strain. Once these parameters are known, metallographic inspection alone is sufficient to estimate the remaining tolerable load or strain limit after a certain oxidation period.

Similar content being viewed by others

References

M. Schütze, Protective Oxide Scales and Their Breakdown, (Wiley, Chichester, 1997).

H. Echsler, S. Ito and M. Schütze, Oxidation of Metals 60, 241 (2003).

J. Armitt, D. R. Holmes, M. I. Manning, D. B. Meadowcroft and E. Metcalfe, The Spalling of Steam Grown Oxide from Superheater and Reheater Tube Steels, EPRI Report FP-686, (Electric Power Research Institute, Palo Alto, 1978).

J. Robertson and M. I. Manning, Materials Science and Technology 6, 81 (1990).

H. E. Evans and R. C. Lobb, Corrosion Science 24, 209 (1984).

H. E. Evans, G. P. Mitchell, R. C. Lobb and D. R. J. Owen, Proceedings of the Royal Society of London A 440, 1 (1993).

A. M. Chaze and C. Coddet, Oxidation of Metals 27, 1 (1987).

P. Hancock and J. R. Nicholls, Materials Science and Technology 4, 398 (1988).

M. M. Nagl and W. T. Evans, Journal of Materials Science 28, 6247 (1993).

M. M. Nagl, W. T. Evans and S. R. J. Saunders, Journal de Physique IV C9, 933 (1993).

P. L. Harrison, Corrosion Science 7, 789 (1967).

M. Schütze, P. F. Tortorelli and I. G. Wright, Oxidation of Metals 73, 389 (2010).

M. Schütze and M. Rudolphi, Materials Science Forum 696, 138 (2011).

M. Rudolphi and M. Schütze, Oxidation of Metals 79, 167 (2013).

A. Rahmel and J. Tobolski, Corrosion Science 5, 333 (1965).

A. A. Griffith, Philosophical Transactions of the Royal Society of London A 221, 163 (1921).

G. E. Dieter, Mechanical Metallurgy, (McGraw-Hill, Kogakusha, 1976).

G. R. Irwin, Fracture in Encyclopedia of Physics, vol. 5, (Springer, New York, 1958).

J. Li, S. Forberg and L. Hermansson, Biomaterials 12, 438 (1991).

M. M. Nagl, S. R. J. Saunders, W. T. Evans and D. J. Hall, Corrosion Science 35, 965 (1993).

J. Stringer, Acta Metallurgica 8, 758 (1960).

A. Zeller, F. Dettenwanger and M. Schütze, Intermetallics 10, 59 (2002).

Acknowledgments

The financial support of the German Research Foundation (DFG) under project no. SCHU 729/21-1 is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Rudolphi, M., Schütze, M. Investigations for the Validation of the Defect Based Scale Failure Diagrams—Part II: Extension of the Concept and Application to Nickel Oxide, Titanium Oxide and Iron Oxide. Oxid Met 84, 45–60 (2015). https://doi.org/10.1007/s11085-015-9540-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-015-9540-9