Abstract

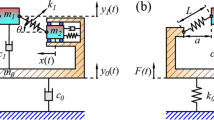

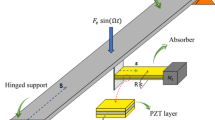

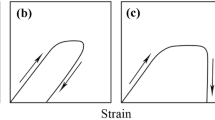

Friction dampers are widely used in vibration control of mechanical and civil architectures as a highly robust contact-based energy dissipation strategy. The energy dissipation principle of electromagnetic dampers is to convert the mechanical energy of vibration into electrical energy through a mechanical–magnetic–electric coupling mechanism and dissipate it through an external load circuit or store it in a battery or capacitor. It should be noted that the frictional energy dissipation is displacement dependent, while the electromagnetic energy dissipation is velocity dependent; hence, a synergistic energy dissipation with a combination of frictional and electromagnetic elements can be implemented to obtain satisfactory vibration suppression. This work presents a bi-stable energy scavenging inspired dynamic vibration absorber (DVA) consisting of negative stiffness spring components, electromagnetic conversion elements and friction pairs. The multiple periodic inter-well motion and chaotic motion are understood to illuminate the efficient energy shunt contributed by the bi-stable mechanism. The effects of mass ratio, potential barrier height and friction force on the energy scavenging and vibration suppression performance of this proposed prototype are parametrically analyzed. Numerical simulations have found that the bi-stable DVA with small mass ratio has a significant attenuation effect on the vibration energy of the host structure excited by harmonic excitation or transient shocks. The results indicate that an increase in the barrier height of the bi-stable oscillator leads to an increase in the optimal mass ratio required to achieve optimal energy dissipation efficiency. The small mass ratio bi-stable damper can achieve the best vibration suppression performance by actively regulating the friction force according to the change of ambient vibration. In addition, it is evident that the presence of critical friction minimizes the vibration displacement and energy of the host structure. However, when the friction force exceeds the critical threshold, the dynamic response of the host structure is amplified and the vibration energy increases, which is not conducive to vibration control. Therefore, implementing an appropriate friction force can improve the devastating dynamic response of the structure and facilitate the conversion of vibration energy into available energy.

Similar content being viewed by others

Data availability

Data in this work will be made available on reasonable request from the corresponding author.

Abbreviations

- m 1 :

-

Mass of the host structure, kg

- m 2 :

-

Mass of the bi-stable DVA, kg

- b 1 :

-

Linear viscous damping of the host structure, N s/m

- b 2 :

-

Linear viscous damping in the coupling, N s/m

- k 1 :

-

Linear stiffness of the host structure, N/m

- k 3 :

-

Linear stiffness term of the bi-stable DVA, N/m

- k 4 :

-

Cubic stiffness term of the bi-stable DVA, N/m3

- k f :

-

The grounded stiffness of the bi-stable DVA, N/m

- b f :

-

The grounded friction damping of the bi-stable DVA, N s/m

- R c :

-

Coil resistance, Ω

- R L :

-

Load resistance, Ω

- k e :

-

Transduction factor, T m

- b e :

-

Electromechanical damping coefficient, N s/m

- μ :

-

Mass ratio, 1

- λ :

-

Dimensionless linear viscous damping term of the host structure, 1

- ζ :

-

Dimensionless linear viscous damping term in the coupling, 1

- β :

-

Dimensionless electromechanical damping coefficient term, 1

- ξ :

-

Dimensionless negative linear stiffness of the bi-stable DVA, 1

- ξ f :

-

Dimensionless grounded stiffness of the bi-stable DVA, 1

- f v :

-

The nominal friction force, N

- f c :

-

The Coulomb friction force, N

- f s :

-

The maximum static friction force, N

- v s :

-

The Stribeck speed, m/s

- f ext :

-

The sum of all the external forces except friction, N

- F n :

-

The normal force of contact interface, N

- χ :

-

The empirical constant, 1

- η :

-

The lubricant viscosity, Pa s

- h :

-

The film thickness, m

- p :

-

The film pressure, Pa

- τ :

-

The dimensionless time, 1

- α :

-

Dimensionless distance between adjacent potential wells, 1

- P :

-

The harvested power, W

- γ :

-

Dimensionless force coefficient term, 1

- y 1 :

-

Displacement of the primary system, m

- y 2 :

-

Displacement of the bi-stable DVA mass, m

- F :

-

Amplitude of harmonic force, N

- ω :

-

Circular frequency of harmonic force, rad/s

- ω n :

-

Natural frequency of the primary system, rad/s

- Ω:

-

The frequency ratio, 1

- A :

-

Displacement of the primary system, m

- E k :

-

Remaining kinetic energy of the host structure, J

- Y r :

-

Amplitude of the host structure, m

- V 0 :

-

Initial velocity of an impulse, m/s

- \(\eta_{{\text{h}}}\) :

-

Efficiency of energy harvesting, %

- \(\eta_{{\text{k}}}\) :

-

Remaining kinetic energy ratio of the primary system, %

- E h :

-

The total harvested energy, J

- DVA:

-

Dynamic vibration absorber

- NES:

-

Nonlinear energy sink

- BMPA:

-

Bi-stable magneto-pieozelastic absorber

- VAEH:

-

Vibration absorber and energy harvester

- SPL:

-

Dound pressure level

- SAFD:

-

Semi-active friction damper

- LCFD:

-

Leverage-type controllable friction damper

- EHL:

-

Elastohydrodynamic lubrication

References

Baeg, K.-J., Lee, J.: Flexible electronic systems on plastic substrates and textiles for smart wearable technologies. Adv. Mater. Technol. 5, 2000071 (2020)

Wang, L., Jiang, K., Shen, G.: Wearable, implantable, and interventional medical devices based on smart electronic skins. Adv. Mater. Technol. 6(6), 2100107 (2021)

Wang, Q., Ruan, T., Xu, Q., et al.: Wearable multifunctional piezoelectric MEMS device for motion monitoring, health warning, and earphone. Nano Energy 89, 106324 (2021)

Yu, Y., Qiao, G., Ou, J.: Self-powered wireless corrosion monitoring sensors and networks. IEEE Sens. J. 10(12), 1901–1902 (2010)

Alavi, A.H., Hasni, H., Lajnef, N., et al.: Damage detection using self-powered wireless sensor data: an evolutionary approach. Measurement 82, 254–283 (2016)

Yildirim, T., Ghayesh, M.H., Li, W., et al.: A review on performance enhancement techniques for ambient vibration energy harvesters. Renew. Sustain. Energy Rev. 71, 435–449 (2017)

Fan, K., Liu, J., Wei, D., et al.: A cantilever-plucked and vibration-driven rotational energy harvester with high electric outputs. Energy Convers. Manage. 244, 114504 (2021)

Heidari, H., Monjezi, B.: Vibration control of imbalanced Jeffcott rotor by virtual passive dynamic absorber with optimal parameter values. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 232(23), 4278–4288 (2018)

Tso, M.H., Yuan, J., Wong, W.O.: Hybrid vibration absorber with detached design for global vibration control. J. Vib. Control 23(20), 3414–3430 (2017)

Mani, Y., Senthilkumar, M.: Shape memory alloy-based adaptive-passive dynamic vibration absorber for vibration control in piping applications. J. Vib. Control 21(9), 1838–1847 (2015)

Hunt, J.B., Nissen, J.C.: The broadband dynamic vibration absorber. J. Sound Vib. 83(4), 573–578 (1982)

Sun, S.S., Yildirim, T., Wu, J., et al.: Design and verification of a hybrid nonlinear MRE vibration absorber for controllable broadband performance. Smart Mater. Struct. 26(9), 095039 (2017)

Wang, F., Sun, X., Meng, H., et al.: Tunable broadband low-frequency band gap of multiple-layer metastructure induced by time-delayed vibration absorbers. Nonlinear Dyn. 107(3), 1903–1918 (2022)

Niu, M.Q., Chen, L.Q.: Analysis of a bio-inspired vibration isolator with a compliant limb-like structure. Mech. Syst. Signal Process. 179, 109348 (2022)

Niu, M.Q., Chen, L.Q.: Nonlinear vibration isolation via a compliant mechanism and wire ropes. Nonlinear Dyn. 107(2), 1687–1702 (2022)

Ahmadabadi, Z.N.: Nonlinear energy transfer from an engine crankshaft to an essentially nonlinear attachment. J. Sound Vib. 443, 139–154 (2019)

Huang, X., Yang, B.: Improving energy harvesting from impulsive excitations by a nonlinear tunable bi-stable energy harvester. Mech. Syst. Signal Process. 158, 107797 (2021)

Pilipchuk, V.N., Polczyński, K., Bednarek, M., et al.: Guidance of the resonance energy flow in the mechanism of coupled magnetic pendulums. Mech. Mach. Theory 176, 105019 (2022)

Ding, H., Chen, L.Q.: Designs, analysis, and applications of nonlinear energy sinks. Nonlinear Dyn. 100(4), 3061–3107 (2020)

Qiu, D., Li, T., Seguy, S., et al.: Efficient targeted energy transfer of bistable nonlinear energy sink: application to optimal design. Nonlinear Dyn. 92, 443–461 (2018)

Zhang, Y.W., Zhang, Z., Chen, L.Q., et al.: Impulse-induced vibration suppression of an axially moving beam with parallel nonlinear energy sinks. Nonlinear Dyn. 82(1), 61–71 (2015)

Kani, M., Khadem, S.E., Pashaei, M.H., et al.: Vibration control of a nonlinear beam with a nonlinear energy sink. Nonlinear Dyn. 83(1), 1–22 (2016)

Ahmadabadi, Z.N., Khadem, S.E.: Nonlinear vibration control and energy harvesting of a beam using a nonlinear energy sink and a piezoelectric device. J. Sound Vib. 333(19), 4444–4457 (2014)

Huang, X., Zhong, T.: Hydrokinetic energy harvesting from flow-induced vibration of a hollow cylinder attached with a bi-stable energy harvester. Energy Convers. Manage. 278, 116718 (2023)

Huang, X., Yang, B.: Towards novel energy shunt inspired vibration suppression techniques: principles, designs and applications. Mech. Syst. Signal Process. 182, 109496 (2023)

Huang, X.: Stochastic resonance in a piecewise bistable energy harvesting model driven by harmonic excitation and additive Gaussian white noise. Appl. Math. Model. 90, 505–526 (2021)

Huang, X., Yang, B.: Investigation on the energy trapping and conversion performances of a multi-stable vibration absorber. Mech. Syst. Signal Process. 160, 107938 (2021)

Rezaei, M., Talebitooti, R., Liao, W.H.: Exploiting bi-stable magneto-piezoelastic absorber for simultaneous energy harvesting and vibration mitigation. Int. J. Mech. Sci. 207, 106618 (2021)

Wang, X., Xu, Z., Wang, D., et al.: Dynamic and energetic characteristics comparison of a tri-stable vibration absorber and energy harvester using different permanent magnet arrays. Int. J. Struct. Stab. Dyn. 22, 2250062 (2022)

Wang, Z., Jiao, Y., Chen, Z.: Parameter study of friction damping ring for railway wheels based on modal analysis. Appl. Acoust. 153, 140–146 (2019)

Capozza, R., Vanossi, A., Vezzani, A., et al.: Suppression of friction by mechanical vibrations. Phys. Rev. Lett. 103(8), 085502 (2009)

Lu, X.D., Zhao, J., Mo, J.L., et al.: Suppression of friction-induced stick–slip behavior and improvement of tribological characteristics of sliding systems by introducing damping materials. Tribol. Trans. 63(2), 222–234 (2020)

Xiao, W., Li, J., Pan, T., et al.: Investigation into the influence of particles’ friction coefficient on vibration suppression in gear transmission. Mech. Mach. Theory 108, 217–230 (2017)

Xu, Z., Wang, M.Y., Chen, T.: Particle damping for passive vibration suppression: numerical modelling and experimental investigation. J. Sound Vib. 279(3–5), 1097–1120 (2005)

Gaul, L., Albrecht, H., Wirnitzer, J.: Semi-active friction damping of large space truss structures. Shock. Vib. 11(3–4), 173–186 (2004)

Gaul, L., Albrecht, H., Wirnitzer, J.: Semi-active friction damping of flexible lightweight structures//advances in smart technologies in structural engineering, pp. 25–43. Springer, Berlin (2004)

Park, Y., Kim, K.: Semi-active vibration control of space truss structures by friction damper for maximization of modal damping ratio. J. Sound Vib. 332(20), 4817–4828 (2013)

Ruangrassamee, A., Srisamai, W., Lukkunaprasit, P.: Response mitigation of the base isolated benchmark building by semi-active control with the viscous-plus-variable-friction damping force algorithm. Struct. Control. Health Monit. 13(2–3), 809–822 (2006)

Lu, L.Y., Lin, T.K., Jheng, R.J., et al.: Theoretical and experimental investigation of position-controlled semi-active friction damper for seismic structures. J. Sound Vib. 412, 184–206 (2018)

Stammers, C.W., Sireteanu, T.: Vibration control of machines by use of semi-active dry friction damping. J. Sound Vib. 209(4), 671–684 (1998)

Zhang, A., Sorokin, V., Li, H.: Dynamic analysis of a new autoparametric pendulum absorber under the effects of magnetic forces. J. Sound Vib. 485, 115549 (2020)

Pontes, B.R., Silveira, M., Mazotti, A.C., et al.: Contribution of electrical parameters on the dynamical behaviour of a nonlinear electromagnetic damper. Nonlinear Dyn. 79, 1957–1969 (2015)

Bednarek, M., Lewandowski, D., Polczyński, K., et al.: On the active damping of vibrations using electromagnetic spring. Mech. Based Des. Struct. Mach. 49(8), 1131–1144 (2021)

Behrens, S., Fleming, A.J., Moheimani, S.O.R.: Passive vibration control via electromagnetic shunt damping. IEEE/ASME Trans. Mechatron. 10(1), 118–122 (2005)

Kecik, K.: Simultaneous vibration mitigation and energy harvesting from a pendulum-type absorber. Commun. Nonlinear Sci. Numer. Simul. 92, 105479 (2021)

Kecik, K.: Assessment of energy harvesting and vibration mitigation of a pendulum dynamic absorber. Mech. Syst. Signal Process. 106, 198–209 (2018)

Wang, X., Xu, Z., Wang, D., et al.: Dynamic and energetic characteristics comparison of a tri-stable vibration absorber and energy harvester using different permanent magnet arrays. Int. J. Struct. Stab. Dyn. 22(06), 2250062 (2022)

Liu, C., Liao, B., Zhao, R., et al.: Large stroke tri-stable vibration energy harvester: modelling and experimental validation. Mech. Syst. Signal Process. 168, 108699 (2022)

Yang, P., Wen, S.: A generalized Reynolds equation for non-Newtonian thermal elastohydrodynamic lubrication. J. Tribol. 112(4), 631–636 (1990)

Huang, X., Zhang, X., Wang, Y.: Numerical simulation of ferrofluid-lubricated rough elliptical contact with start-up motion. Appl. Math. Model. 91, 232–260 (2021)

Gao, M., Wang, Y., Wang, Y., et al.: Experimental investigation of non-linear multi-stable electromagnetic-induction energy harvesting mechanism by magnetic levitation oscillation. Appl. Energy 220, 856–875 (2018)

Younesian, D., Alam, M.R.: Multi-stable mechanisms for high-efficiency and broadband ocean wave energy harvesting. Appl. Energy 197, 292–302 (2017)

Jafari, S., Ahmadi, A., Khalaf, A.J.M., et al.: A new hidden chaotic attractor with extreme multi-stability. AEU Int. J. Electron. Commun. 89, 131–135 (2018)

Yang, X., Lai, S.K., Wang, C., et al.: On a spring-assisted multi-stable hybrid-integrated vibration energy harvester for ultra-low-frequency excitations. Energy 252, 124028 (2022)

Funding

The work is supported by National Natural Science Foundation of China (52305103), Changsha Natural Science Foundation Project (kq2208025), Distinguished Young Scholars Fund of National Natural Science Foundation of China (52025082) and Key Support Project of National Natural Science Foundation of China - "Ye Qisun" Science Foundation (U2141242).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, X., Huang, Z., Hua, X. et al. Investigation on vibration mitigation methodology with synergistic friction and electromagnetic damping energy dissipation. Nonlinear Dyn 111, 18885–18910 (2023). https://doi.org/10.1007/s11071-023-08832-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-023-08832-w