Abstract

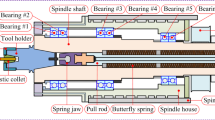

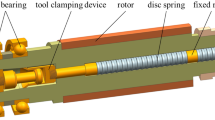

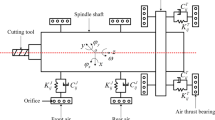

The thermal effect has a significant influence on the performance of angular contact ball bearings and thus affects the motion accuracy and stability of spindle-bearing system of computerized numerical control (CNC) lathe. In this paper, a comprehensive coupled CNC lathe spindle-bearing model considering the thermal effect is proposed to predict the dynamic characteristics of system. The spindle is modeled as Timoshenko’s beam by considering the centrifugal force and gyroscopic effects. The bearing is analyzed by a five degrees-of-freedom (DOF) quasi-static model considering the thermal effect in order to obtain the static deformations and thermal deformations of rolling bodies. The dynamic differential equation of system is established by the finite element method. Runge–Kutta integral method is used to solve the system equation numerically to study its nonlinear dynamic behaviors. The correctness of thermal model of CNC lathe spindle-bearing system is verified by testing the housing temperature. The simulation values of system response considering thermal effect or not are compared with the experimental results, which shows that the proposed model is feasible. Moreover, the effects of key parameters such as rotational speed, pulley eccentricity and bearing preload on the nonlinear characteristics of system are investigated. Single-periodic, multi-periodic, quasi-periodic and chaotic motions are observed by time history curve, 3-D frequency spectrum curve, phase diagram, Poincare section and bifurcation diagram under different operating conditions. The analytical model developed here can be also helpful to the design and optimization of CNC lathe spindle-bearing system.

Similar content being viewed by others

Data Availability

The datasets generated during and analyzed during the current study are available from the corresponding author on reasonable request.

References

Zhao, H.T., Yang, J.G., Shen, J.H.: Simulation of thermal behavior of a CNC machine tool spindle. Int. J. Mach. Tools Manuf. 47(6), 1003–1010 (2007). https://doi.org/10.1016/j.ijmachtools.2006.06.018

Xu, K.P., Wang, B., Zhao, Z.X., et al.: The influence of rolling bearing parameters on the nonlinear dynamic response and cutting stability of high-speed spindle systems. Mech. Syst. Signal PR. 136, 131–136 (2020). https://doi.org/10.1016/j.ymssp.2019.106448

Than, V.T., Huang, J.H.: Nonlinear thermal effects on high-speed spindle bearings subjected to preload. Tribol. Int. 96, 361–372 (2016)

Abele, E., Altintas, Y., Brecher, C.: Machine tool spindle units. CIRP Ann. Manuf. Technol. 59, 781–802 (2010). https://doi.org/10.1016/j.cirp.2010.05.002

Mayr, J., Jedrzejewski, J., Uhlmann, E., et al.: Thermal issues in machine tools. CIRP Ann. Manuf. Technol. 61, 771–791 (2012). https://doi.org/10.1016/j.cirp.2012.05.008

Xiang, S.T., Yao, X.D., Du, Z.C., Yang, J.G.: Dynamic linearization modeling approach for spindle thermal errors of machine tools. Mechatronics 53, 215–228 (2018). https://doi.org/10.1016/j.mechatronics.2018.06.018

Yan, K., Hong, J., Zhang, J.H., et al.: Thermal-deformation coupling in thermal network for transient analysis of spindle-bearing system. Int. J. Therm. Sci. 104, 1–12 (2016). https://doi.org/10.1016/j.ijthermalsci.2015.12.007

Zhang, Y.F., Li, X.H., Hong, J., et al.: Uneven heat generation and thermal performance of spindle bearings. Tribol. Int. 126, 324–335 (2018). https://doi.org/10.1016/j.triboint.2018.04.035

Wu, W., Hu, J.B., Yuan, S.H., et al.: Numerical and experimental investigation of the stratified air-oil flow inside ball bearings. Int. J. Heat Mass Tran. 103, 619–626 (2016)

Palmgren, A.: Ball and Roller Bearing Engineering, 3rd edn. Burbank Philadelphia, USA (1959)

Harris, T.A., Kotzalas, M.N.: Rolling bearing analysis: advanced concepts of bearing technology, 5th edn. CRC Press, Boca Raton (2006)

Brecher, C., Hassis, A., Rossaint, J.: Cage friction in high-speed spindle bearings. Tribol. Int. 57, 77–85 (2014)

Than, V.T., Wang, C.C., Ngo, T.T., et al.: Estimating time-varying heat sources in a high speed spindle based on two measurement temperatures. Int. J. Therm. Sci. 111, 50–65 (2017)

Tong, V.C., Hong, S.W.: Study on the running torque of angular contact ball bearings subjected to angular misalignment. P. I. Mech. Eng. J-J. Eng. 232, 890–909 (2018)

Oktaviana, L., Van-Canh, T., Hong, S.W.: Skidding analysis of angular contact ball bearing subjected to radial load and angular misalignment. J. Mech. Sci. Technol. 33, 837–845 (2019)

Zhang, X., Xu, H., Chang, W., et al.: Torque variations of ball bearings based on dynamic model with geometrical imperfections and operating conditions. Tribol. Int. 133, 193–205 (2019)

Pouly, F., Changenet, C., Ville, F.: Investigations on the power losses and thermal behavior of rolling element bearings. PIMechEngJ-JEng. 224, 925–933 (2010)

Jafar, T., Khonsari, M.M.: Experimental testing and thermal analysis of ball bearings. Tribol. Int. 60, 93–103 (2013). https://doi.org/10.1016/j.triboint.2012.10.009

Lin, C.W., Tu, J.F., Kamman, J.: An integrated thermal-mechanical-dynamic model to characterize motorized machine tool spindles during very high speed rotation. Int. J. Mach. Tool Manuf. 43, 1035–1050 (2003). https://doi.org/10.1016/S0890-6955(03)00091-9

Mohammed, A., Omar, S.M.: Analytical study of thermal variation impact on dynamics of a spindle bearing system. Proc. Inst Mech. Eng. Part K: J Multi-body Dyn. (2019). https://doi.org/10.1177/1464419319841687

Zheng, D.X., Chen, W.F., Li, M.M.: An optimized thermal network model to estimate thermal performances on a pair of angular contact ball bearings under oil-air lubrication. Appl. Therm. Eng. 131, 328–339 (2018). https://doi.org/10.1016/j.applthermaleng.2017.12.019

Zheng, D.X., Chen, W.F.: Thermal performances on angular contact ball bearing of high-speed spindle considering structural constraints under oil-air lubrication. Tribol. Int. 109, 593–601 (2017). https://doi.org/10.1016/j.triboint.2017.01.035

Zheng, D.X., Chen, W.F.: Effect of structure and assembly constraints on temperature of high-speed angular contact ball bearings with thermal network method. Mech. Syst. Signal PR. (2020). https://doi.org/10.1016/j.ymssp.2020.106929

Liu, J.L., Ma, C., Wang, S.L., et al.: Thermal-structure interaction characteristics of a high-speed spindle-bearing system. Int. J. Mach. Tool Manuf. 137, 42–57 (2021)

Ertürk, A., Özgüven, H.N., Budak, E.: Analytical modeling of spindle-tool dynamics on machine tools using Timoshenko beam model and receptance coupling for the prediction of tool point FRF. Int. J. Mach. Tool Manuf. 46, 1901–1912 (2006). https://doi.org/10.1016/j.ijmachtools.2006.01.032

Bai, C., Zhang, H., Xu, Q.: Subharmonic resonance of a symmetric ball bearing-rotor system. Int. J. Non-linear Mech. 50, 1–10 (2013). https://doi.org/10.1016/j.ijnonlinmec.2012.11.002

Sinou, J.-J.: Non-linear dynamics and contacts of an unbalanced flexible rotor supported on ballbearings. Mech. Mach. Theory. 44, 1713–1732 (2009). https://doi.org/10.1016/j.mechmachtheory.2009.02.004

Han, Q., Chu, F.: Parametric instability of flexible rotor-bearing system under time-periodic base angular motions. Appl. Math. Model. 39, 4511–4522 (2015). https://doi.org/10.1016/j.apm.2014.10.064

Li, Y.S., Chen, X.A., Zhang, P.: Dynamics modeling and modal experimental study of high speed motorized spindle. J. Mech. Sci. Technol. 31(3), 1049–1056 (2017). https://doi.org/10.1007/s12206-017-0203-4

Xi, S.T., Cao, H.R., Chen, X.F.: A dynamic modeling approach for spindle bearing system supported by both angular contact ball Bearing and floating displacement bearing. J. Manuf. Sci. E-T ASME. (2018). https://doi.org/10.1115/1.4038687

Li, H., Shin, Y.C.: Integrated dynamic thermo-mechanical modeling of high speed spindles, Part 1: Model Development. J Manuf Sci E-T ASME. 126, 148–158 (2004). https://doi.org/10.1115/1.1644545

Li, H., Shin, Y.C.: Analysis of bearing configuration effects on high speed spindles using an integrated dynamic thermo-mechanical spindle model. Int. J. Mach. Tool Manuf. 44, 347–364 (2004). https://doi.org/10.1016/j.ijmachtools.2003.10.011

Truong, D.S., Kim, B.S., Ro, S.K.: An analysis of a thermally affected high-speed spindle with angular contact ball bearings. Tribol. Int. (2021). https://doi.org/10.1016/j.triboint.2021.106881

Zheng, D.X., Chen, W.F., Zheng, D.T.: An enhanced estimation on heat generation of angular contact ball bearings with vibration effect. Int. J. Therm. Sci. (2021). https://doi.org/10.1016/j.ijthermalsci.2020.106610

Liu, J.L., Ma, C., Gui, H.Q., Wang, L.: Thermally-inducederrorcompensationofspindlesystembasedonlongshorttermmemoryneuralnetworks. Appl. Soft Comput. (2021). https://doi.org/10.1016/j.asoc.2021.107094

Cao, Y., Alyintas, Y.: A general method for the modeling of spindle-bearing systems. J. Mech. Design. 126, 557–566 (2004). https://doi.org/10.1115/1.1802311

Jones, A.B.: A general theory for elastically constrained ball and radial roller bearings under arbitrary load and speed conditions. ASME J. Basic Eng. 82, 309–320 (1960). https://doi.org/10.1016/j.ijmachtools.2006.08.006

Muzychka, Y., Yovanovitch, M.: Thermal resistance of model for non circular moving heat sourceson a half space. J. Heat Transf. 123, 624–632 (2001). https://doi.org/10.1115/1.1370516

Salerno, L.J., Kittel, P.: Thermal conductance of augmented pressed metallic contacts at liquid heliu temperatures. Cryogenics (1993). https://doi.org/10.1016/0011-2275(93)90002-6

Mohammadpour, M., Johns-Rahnejat, P.M., Rahenjat, H.: Roller bearing dynamics under transient thermal-mixed non-Newtonian elastohydrodynamic regime of lubrication. P I Mech. Eng. K-J Mul. 229, 407–423 (2015). https://doi.org/10.1177/1464419315569621

Latif, M.J.: Heat convection, 2nd edn. Springer-Verlag, Berlin (2009)

Holman, J.P.: Heat Transfer, 7th edn. McGraw-Hill, New York (1989)

Bjorklund, I.S., Kays, W.M.: Heat transfer between concentric rotating cylinders. Trans. ASME 81, 175–186 (1959). https://doi.org/10.1115/1.4008173

Wagner, C.: Heat transfer from a rotating disk in ambient air. J. Appl. Phys. 19, 837–839 (1948). https://doi.org/10.1063/1.1698216

Churchill, S.W., Chu, H.H.S.: Correlation equations for laminar and turbulent free convection from a vertical plate. Int. J. Heat Mass Transf. 18, 1323–1329 (1975). https://doi.org/10.1016/0017-9310(75)90222-7

Stein, J.L., Tu, J.F.: A state-space model for monitoring thermally induced preload in anti-friction spindle bearings of high-speed machine tools. J. Dyn. Syst. Meas. Control. 116, 372–386 (1994). https://doi.org/10.1115/1.2899232

Timoshenko, S., Goodier, J.N.: Theory of elasticity, 3rd edn. McGraw-Hill, New York (1969)

Zhang, X.N., Han, Q.K., Peng, Z.K., Chu, F.L.: A new nonlinear dynamic model of the rotor-bearing system considering preload and varying contact angle of the bearing. Commun. Nonlinear Sci. 22, 821–841 (2015). https://doi.org/10.1016/j.cnsns.2014.07.024

Gan, C.B., Wang, Y.H., Yang, S.X., et al.: Nonparametric modeling and vibration analysis of uncertain Jeffcott rotor with disc offset. Int. J. Mech. Sci. 78, 126–134 (2014). https://doi.org/10.1016/j.ijmecsci.2013.11.009

Chandra, N.H., Sekhar, A.S.: Swept sine testing of rotor-bearing system for damping estimation. J. Sound Vib. 333, 604–620 (2014). https://doi.org/10.1016/j.jsv.2013.09.009

Acknowledgements

We would like to express our appreciation to Chinese National Natural Science Foundation (U1708254) and National Key R & D Program of China (2019YFB2004400) for supporting this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, H., Zhang, Y., Li, C. et al. Nonlinear dynamic analysis of CNC lathe spindle-bearing system considering thermal effect. Nonlinear Dyn 105, 131–166 (2021). https://doi.org/10.1007/s11071-021-06613-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-021-06613-x