Abstract

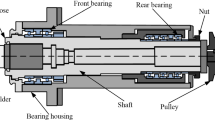

This paper proposes a new dynamic model of the aerostatic spindle, including radial and thrust bearing. The engineering calculation method of the hydrodynamic equation of the hydrostatic spindle is studied, and its validity is verified by comparing with the finite difference calculation results. Moreover, the dynamic model of the spindle is based on the lumped mass method, considering the gyroscopic effect, and through coupling with the bearing, a multi-degree-of-freedom fluid–structure interaction nonlinear dynamic model is constructed. This paper is the first to take the influence of the tilting motion of the spindle on the dynamic characteristics of the aerostatic bearing into consideration, and the engineering calculation method is used to solve the dynamic equation of the spindle in real-time. On the basis of the Runge–Kutta method, which is used to obtain the dynamic response of the spindle, this research studied the effects of air film thickness, radial bearing length, and air supply pressure on the motion response of the spindle system comprehensively.

Similar content being viewed by others

References

Nakamura T, Yoshimoto S (1996) Static tilt characteristics of aerostatic rectangular double-pad thrust bearings with compound restrictors. Tribol Int 29:145–152

Majumdar BC (1980) Externally pressurized gas bearings: a review. Wear 62:299–314

Yoshimoto S, Nakano Y, Kakubari T (1984) Static characteristics of externally pressurized gas journal bearings with circular slot restrictors. Tribol Int 17:199–203

Gao S, Cheng K, Chen S (2015) CFD based investigation on influence of orifice chamber shapes for the design of aerostatic thrust bearings at ultra-high speed spindles. Tribol Int 92:211–221

Li Y, Zhou K, Zhang Z (2015) A flow-difference feedback iteration method and its application to high-speed aerostatic journal bearings. Tribol Int 84:132–141

Pandian MC (1985) A new method for the numerical solution of the Reynolds equation for gas-lubricated slider bearings. J ENG MATH 19:3–19

Wang N, Chang C (1999) An application of Newton’s method to the lubrication analysis of air-lubricated bearings. Tribol T 42:419–424

Zhang J, Han D, Song M (2021) Theoretical and experimental investigation on the effect of supply pressure on the nonlinear behaviors of the aerostatic bearing-rotor system. Mech Syst Sig Process 158:107775

Guo Z, Feng K, Liu T (2018) Nonlinear dynamic analysis of rigid rotor supported by gas foil bearings: effects of gas film and foil structure on subsynchronous vibrations. Mech Syst Sig Process 107:549–566

Wang CC, Yau HT (2008) Application of a hybrid numerical method to the bifurcation analysis of a rigid rotor supported by a spherical gas journal bearing system. Nonlinear Dyn 51:515–528

Shi JH, Cao HR, Chen XF (2019) Effect of angular misalignment on the static characteristics of rotating externally pressurized air journal bearing. Sci China Technol Sci 62:1520–1533

Jiang S, Lin S, Xu C (2018) Static and dynamic characteristics of externally pressurized porous gas journal bearing with four degrees-of-freedom. J Tribol-T Asme 140:011702

Wang X, Zhou L, Huang M (2018) Numerical investigation of journal misalignment on the static and dynamic characteristics of aerostatic journal bearings. Measurement 128:314–324

Arumugam P, Swarnamani S, Prabhu BS (1997) Effects of journal misalignment on the performance characteristics of three-lobe bearings. Wear 206:122–129

Dal A, Karaçay T (2017) Effects of angular misalignment on the performance of rotor-bearing systems supported by externally pressurized air bearing. Tribol Int 111:276–288

Wang CC, Yau HT (2010) Theoretical analysis of high speed spindle air bearings by a hybrid numerical method. Appl Math Comput 217:2084–2096

Sun J, Guo CL (2004) Hydrodynamic lubrication analysis of journal bearing considering misalignment caused by shaft deformation. Tribol Int 37:841–848

Park JK, Kim KW (2004) Stability analyses and experiments of spindle system using new type of slot-restricted gas journal bearings. Tribol Int 37:451–462

Zhang SJ, To SC, Cheng F (2012) Dynamic characteristics of an aerostatic bearing spindle and its influence on surface topography in ultra-precision diamond turning. Int J Mach Tool Manu 62:1–12

Rajput AK, Sharma SC (2016) Combined influence of geometric imperfections and misalignment of journal on the performance of four pocket hybrid journal bearing. Tribol Int 97:59–70

Awasthi RK, Jain SC, Sharma SC (2006) Finite element analysis of orifice-compensated multiple hole-entry worn hybrid journal bearing. Finite Elem Anal Des 42:1291–1303

Miyatake M, Yoshimoto S (2010) Numerical investigation of static and dynamic characteristics of aerostatic thrust bearings with small feed holes. Tribol Int 43:1353–1359

Zhou Y, Chen X, Chen H (2016) A hybrid approach to the numerical solution of air flow field in aerostatic thrust bearings. Tribol Int 102:444–453

Shi J, Cao H, Jin X (2019) Investigation on the static and dynamic characteristics of 3-DOF aerostatic thrust bearings with orifice restrictor. Tribol Int 138:435–449

Chang SH, Chan CW, Jeng YR (2015) Numerical analysis of discharge coefficients in aerostatic bearings with orifice-type restrictors. Tribol Int 90:157–163

Chen D, Huo C, Cui X (2018) Investigation the gas film in micro scale induced error on the performance of the aerostatic spindle in ultra-precision machining. Mech Syst Sig Process 105:488–501

Jiang S, Yang S, Yin Z (2016) Static and dynamic characteristics of externally pressurized annular porous gas thrust bearings. J Tribol-T Asme 230:1221–1230

Gao Q, Qi L, Gao S (2021) A FEM based modeling method for analyzing the static performance of aerostatic thrust bearings considering the fluid-structure interaction. Tribol Int 156:106849

Zhou Y, Chen X, Cai Y (2018) Measurement of gas pressure distribution in aerostatic thrust bearings using pressure-sensitive film. Tribol Int 120:9–15

Luong TS, Potze WJ, Post B (2004) Numerical and experimental analysis of aerostatic thrust bearings with porous restrictors. Tribol Int 37:825–832

Xi S, Cao H, Chen X (2019) Dynamic modeling of spindle bearing system and vibration response investigation. Mech Syst Sig Process 114:486–511

Xu C, Jiang S (2015) Dynamic analysis of a motorized spindle with externally pressurized air bearings. J Vib Conterol 137(4):041001

Jang GH, Kim YJ (1999) Calculation of dynamic coefficients in a hydrodynamic bearing considering five degrees of freedom for a general rotor-bearing system. Tribol Int 120:26–34

Fedorynenko D, Kirigaya R, Nakao Y (2020) Dynamic characteristics of spindle with water-lubricated hydrostatic bearings for ultra-precision machine tools. Precis Eng 63:187–196

Zhang S, Yu J, To S (2018) A theoretical and experimental study of spindle imbalance induced forced vibration and its effect on surface generation in diamond turning. Int J Mach Tool Manu 133:61–71

Liu D (1990) Hydrostatic gas lubrication. Harbin Institute of Technology Press

Belforte G, Raparelli T, Viktorov V, Trivella A (2007) Discharge coefficients of orifice-type restrictor for aerostatic bearings. Tribol Int 40:512–521

Wang X, Zhou L, Huang M (2018) Numerical investigation of journal misalignment on the static and dynamic characteristics of aerostatic journal bearings. Measurement 128:187–196

Shi J, Cao H, Maroju NK (2020) Dynamic modeling of aerostatic spindle with shaft tilt deformation. J Manuf Sci E-T Asme 142:2

Acknowledgements

The work was supported by the National Natural Science Foundation of China (Grant No. 52075087), and the Fundamental Research Funds for the Central Universities (Grant No. N2003006, and N2203002).

Author information

Authors and Affiliations

Contributions

HL: Conceptualization, Data curation, Methodology, Validation, Writing-original draft. CL: Funding acquisition, Project administration, Resources, Supervision, Writing—review and editing. YW: Conceptualization, Investigation. YS: Formal analysis, Software. JH: Resources, Software. HM: Investigation, Software. MX: Formal analysis, Investigation. YZ: Funding acquisition, Project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, H., Li, C., Wang, Y. et al. Fluid–structure interaction dynamic analysis of aerostatic spindle. Meccanica 58, 2237–2267 (2023). https://doi.org/10.1007/s11012-023-01711-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-023-01711-z