Abstract

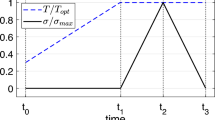

This paper presents a thermomechanical model for pseudoelastic shape memory alloys (SMAs) accounting for internal hysteresis effect due to incomplete phase transformation. The model is developed within the finite-strain framework, wherein the deformation gradient is multiplicatively decomposed into thermal dilation, rigid body rotation, elastic and transformation parts. Helmholtz free energy density comprises three components: the reversible thermodynamic process , the irreversible thermodynamic process and the physical constraints of both. In order to capture the multiple internal hysteresis loops in SMA, two internal variables representing the transition points of the forward and reverse phase transformation, \(\phi _s^f\) and \(\phi _s^r\), are introduced to describe the incomplete phase transformation process. Evolution equations of the internal variables are derived and linked to the phase transformation. Numerical implementation of the model features an Euler discretization and a cutting-plane algorithm. After validation of the model against the experimental data, numerical examples are presented, involving a SMA-based vibration system and a crack SMA specimen subjected to partial loading–unloading case. Simulation results well demonstrate the internal hysteresis and free vibration behavior of SMA.

Similar content being viewed by others

References

Wang, J., Moumni, Z., Zhang, W., Xu, Y., Zaki, W.: A 3D finite-strain-based constitutive model for shape memory alloys accounting for thermomechanical coupling and martensite reorientation. Smart Mater. Struct. (2017). https://doi.org/10.1088/1361-665X/aa6c17

Yu, C., Kang, G., Kan, Q.: A micromechanical constitutive model for grain size dependent thermo-mechanically coupled inelastic deformation of super-elastic NiTi shape memory alloy. Int. J. Plast. 105, 99–127 (2018). https://doi.org/10.1016/j.ijplas.2018.02.005

Moumni, Z., Zhang, Y., Wang, J., Gu, X.: A global approach for the fatigue of shape memory alloys. Shape Memory Superelast. 4, 385–401 (2018). https://doi.org/10.1007/s40830-018-00194-2

Dhala, S., Mishra, S., Tewari, A., Alankar, A.: Modeling of finite deformation of pseudoelastic NiTi shape memory alloy considering various inelasticity mechanisms. Int. J. Plast. 115, 216–237 (2019). https://doi.org/10.1016/j.ijplas.2018.11.018

Birman, V.: Review of mechanics of shape memory alloy structures. Appl. Mech. Rev. 50, 629–646 (1997)

Savi, M.A., Paiva, A.: Describing internal subloops due to incomplete phase transformations in shape memory alloys. Arch. Appl. Mech. 74, 637–647 (2005). https://doi.org/10.1007/s00419-005-0385-6

Tang, C., Wang, T., Huang, W., Sun, L., Gao, X.: Temperature sensors based on the temperature memory effect in shape memory alloys to check minor over-heating. Sens. Actuators A 238, 337–343 (2016). https://doi.org/10.1016/j.sna.2015.11.033

Dhanalakshmi, K.: Shape memory alloy wire for self-sensing servo actuation. Mech. Syst. Signal Process. 83, 36–52 (2017). https://doi.org/10.1016/j.ymssp.2016.05.042

Formentini, M., Lenci, S.: An innovative building envelope (kinetic façade) with Shape Memory Alloys used as actuators and sensors. Autom. Constr. 85, 220–231 (2018). https://doi.org/10.1016/j.autcon.2017.10.006

Rizzello, G., Mandolino, M.A., Schmidt, M., Naso, D., Seelecke, S.: An accurate dynamic model for polycrystalline shape memory alloy wire actuators and sensors. Smart Mater. Struct. 28, 25020 (2019)

Tang, T., Felicelli, S.D.: Micromechanical investigations of polymer matrix composites with shape memory alloy reinforcement. Int. J. Eng. Sci. 94, 181–194 (2015). https://doi.org/10.1016/j.ijengsci.2015.05.008

Song, S.-H., Lee, J.-Y., Rodrigue, H., Choi, I.-S., Kang, Y.J., Ahn, S.-H.: 35 Hz shape memory alloy actuator with bending-twisting mode. Sci. Rep. 6, 21118 (2016). https://doi.org/10.1038/srep21118

Mohd Jani, J., Leary, M., Subic, A.: Designing shape memory alloy linear actuators: a review. J. Intell. Mater. Syst. Struct. 28, 1699–1718 (2017). https://doi.org/10.1177/1045389X16679296

Huang, X., Kumar, K., Jawed, M.K., Mohammadi Nasab, A., Ye, Z., Shan, W., Majidi, C.: Highly dynamic shape memory alloy actuator for fast moving soft robots. Adv. Mater. Technol. 4, 1800540 (2019). https://doi.org/10.1002/admt.201800540

Wang, J., Zhang, W., Zhu, J., Xu, Y., Gu, X., Moumni, Z.: Finite element simulation of thermomechanical training on functional stability of shape memory alloy wave spring actuator. J. Intell. Mater. Syst. Struct. 30, 1239–1251 (2019). https://doi.org/10.1177/1045389X19831356

Xue, L., Dui, G., Liu, B., Xin, L.: A phenomenological constitutive model for functionally graded porous shape memory alloy. Int. J. Eng. Sci. 78, 103–113 (2014). https://doi.org/10.1016/j.ijengsci.2014.02.013

Mohd Jani, J., Leary, M., Subic, A., Gibson, M.A.: A review of shape memory alloy research, applications and opportunities. Mater. Des. 56, 1078–1113 (2014). https://doi.org/10.1016/j.matdes.2013.11.084

Qian, H., Li, H., Song, G.: Experimental investigations of building structure with a superelastic shape memory alloy friction damper subject to seismic loads. Smart Mater. Struct. 25, 125026 (2016). https://doi.org/10.1088/0964-1726/25/12/125026

Dutta, S.C., Majumder, R.: Shape memory alloy (SMA) as a potential damper in structural vibration control. In: Advances in Manufacturing Engineering and Materials. Springer, pp. 485–492 (2019). https://doi.org/10.1007/978-3-319-99353-9_51

Bogue, R.: Shape-memory materials: a review of technology and applications. Assem. Autom. 29, 214–219 (2009). https://doi.org/10.1108/01445150910972895

Zhang, Y., Moumni, Z., Zhu, J., Zhang, W.: Effect of the amplitude of the training stress on the fatigue lifetime of NiTi shape memory alloys. Scripta Mater. 149, 66–69 (2018). https://doi.org/10.1016/j.scriptamat.2018.02.012

Abdullah, E., Gaikwad, P., Azid, N., Abdul Majid, D., Mohd Rafie, A.: Temperature and strain feedback control for shape memory alloy actuated composite plate. Sens. Actuators A 283, 134–140 (2018). https://doi.org/10.1016/j.sna.2018.09.059

Spindler, C., Juhre, D.: Development of a shape memory alloy actuator using generative manufacturing. Int. J. Adv. Manuf. Technol. 97, 4157–4166 (2018). https://doi.org/10.1007/s00170-018-2153-0

Tanaka, K., Nishimura, F., Tobushi, H.: Phenomenological Analysis on Subloops in Shape Memory Alloys Due to Incomplete Transformations. J. Intell. Mater. Syst. Struct. 5, 487–493 (1994). https://doi.org/10.1177/1045389X9400500404

Lexcellent, C., Tobushi, H.: Internal loops in pseudoelastic behaviour of Ti–Ni shape memory alloys: experiment and modelling. Meccanica 30, 459–466 (1995). https://doi.org/10.1007/BF01557078

Tobushi, H., Endo, M., Ikawa, T., Shimada, D.: Pseudoviscoelastic behavior of TiNi shape memory alloys under stress-controlled subloop loadings. Arch. Mech. 55, 519–530 (2003)

Pieczyska, E.A., Tobushi, H., Nowacki, W.K., Gadaj, S.P., Sakuragi, T.: Subloop deformation behavior of TiNi shape memory alloy subjected to stress-controlled loadings. Mater. Trans. 48, 2679–2686 (2007). https://doi.org/10.2320/matertrans.MRA2007097

Takeda, K., Tobushi, H., Miyamoto, K., Pieczyska, E.A.: Superelastic deformation of TiNi shape memory alloy subjected to various subloop loadings. Mater. Trans. 53, 217–223 (2012). https://doi.org/10.2320/matertrans.M2011288

Rao, A., Ruimi, A., Srinivasa, A.R.: Internal loops in superelastic shape memory alloy wires under torsion: experiments and simulations/predictions. Int. J. Solids Struct. 51, 4554–4571 (2014). https://doi.org/10.1016/j.ijsolstr.2014.09.002

Boyd, J., Lagoudas, D.: A thermodynamical constitutive model for shape memory materials. Part I. The monolithic shape memory alloy. Int. J. Plast 12, 805–842 (1996). https://doi.org/10.1016/S0749-6419(96)00030-7

Bo, Z., Lagoudas, D.C.: Thermomechanical modeling of polycrystalline SMAs under cyclic loading, part IV: modeling of minor hysteresis loops. Int. J. Eng. Sci. 37, 1205–1249 (1999). https://doi.org/10.1016/S0020-7225(98)00116-5

Ortin, J., Delaey, L.: Hysteresis in shape-memory alloys. Int. J. Non Linear Mech. 37, 1275–1281 (2002). https://doi.org/10.1016/S0020-7462(02)00027-6

Matsuzaki, Y., Funami, K., Naito, H.: Inner loops of pseudoelastic hysteresis of shape memory alloys: Preisach approach, vol. 4699, pp. 355–364 (2002). https://doi.org/10.1117/12.474993

Ikeda, T., Nae, F.A., Naito, H., Matsuzaki, Y.: Constitutive model of shape memory alloys for unidirectional loading considering inner hysteresis loops. Smart Mater. Struct. 13, 916–925 (2004). https://doi.org/10.1088/0964-1726/13/4/030

Bernardini, D., Pence, T.J.: Uniaxial modeling of multivariant shape-memory materials with internal sublooping using dissipation functions. Meccanica 40, 339–364 (2005). https://doi.org/10.1007/s11012-005-2103-4

Kishore Kumar, M., Sakthivel, K., Sivakumar, S.M., Lakshmana Rao, C., Srinivasa, A.: Thermomechanical modeling of hysteresis in SMAs using the dissipationless reference response. Smart Mater. Struct. (2007). https://doi.org/10.1088/0964-1726/16/1/S04

Heintze, O., Seelecke, S.: A coupled thermomechanical model for shape memory alloys-From single crystal to polycrystal. Mater. Sci. Eng. A 481–482, 389–394 (2008). https://doi.org/10.1016/j.msea.2007.08.028

Müller, I.: Pseudo-elastic hysteresis in shape memory alloys. Phys. B 407, 1314–1315 (2012). https://doi.org/10.1016/j.physb.2011.06.088

Viet, N.V., Zaki, W., Umer, R., Xu, Y.: Mathematical model for superelastic shape memory alloy springs with large spring index. Int. J. Solids Struct. 185, 159–169 (2020)

Scalet, G., Niccoli, F., Garion, C., Chiggiato, P., Maletta, C., Auricchio, F.: A three-dimensional phenomenological model for shape memory alloys including two-way shape memory effect and plasticity. Mech. Mater. 136, 103085 (2019)

Müller, C., Bruhns, O.T.: A thermodynamic finite-strain model for pseudoelastic shape memory alloys. Int. J. Plast. 22, 1658–1682 (2006). https://doi.org/10.1016/j.ijplas.2006.02.010

Teeriaho, J.P.: An extension of a shape memory alloy model for large deformations based on an exactly integrable Eulerian rate formulation with changing elastic properties. Int. J. Plast. 43, 153–176 (2013). https://doi.org/10.1016/j.ijplas.2012.11.009

Xiao, H.: An explicit, straightforward approach to modeling SMA pseudoelastic hysteresis. Int. J. Plast. 53, 228–240 (2014). https://doi.org/10.1016/j.ijplas.2013.08.010

Reese, S., Christ, D.: Finite deformation pseudo-elasticity of shape memory alloys: constitutive modelling and finite element implementation. Int. J. Plast. 24, 455–482 (2008). https://doi.org/10.1016/j.ijplas.2007.05.005

Arghavani, J., Auricchio, F., Naghdabadi, R.: A finite strain kinematic hardening constitutive model based on Hencky strain: general framework, solution algorithm and application to shape memory alloys. Int. J. Plast. 27, 940–961 (2011). https://doi.org/10.1016/j.ijplas.2010.10.006

Paranjape, H.M., Manchiraju, S., Anderson, P.M.: A phase field: finite element approach to model the interaction between phase transformations and plasticity in shape memory alloys. Int. J. Plast. 80, 1–18 (2016). https://doi.org/10.1016/j.ijplas.2015.12.007

Wang, J., Moumni, Z., Zhang, W., Zaki, W.: A thermomechanically coupled finite deformation constitutive model for shape memory alloys based on Hencky strain. Int. J. Eng. Sci. 117, 51–77 (2017). https://doi.org/10.1016/j.ijengsci.2017.05.003

Dunne, F., Petrinic, N.: Introduction to Computational Plasticity. Oxford University Press, New York (2005)

Anand, L., Ames, N.M., Srivastava, V., Chester, S.A.: A thermo-mechanically coupled theory for large deformations of amorphous polymers. Part I: formulation. Int. J. Plast. 25, 1474–1494 (2009). https://doi.org/10.1016/j.ijplas.2008.11.004

Wang, J., Moumni, Z., Zhang, W.: A thermomechanically coupled finite-strain constitutive model for cyclic pseudoelasticity of polycrystalline shape memory alloys. Int. J. Plast. 97, 194–221 (2017). https://doi.org/10.1016/j.ijplas.2017.06.003

Qidwai, M.A., Lagoudas, D.C.: On thermomechanics and transformation surfaces of polycrystalline NiTi shape memory alloy material. Int. J. Plast. 16, 1309–1343 (2000). https://doi.org/10.1016/S0749-6419(00)00012-7

Lagoudas, D., Hartl, D., Chemisky, Y., Machado, L., Popov, P.: Constitutive model for the numerical analysis of phase transformation in polycrystalline shape memory alloys. Int. J. Plast. 32–33, 155–183 (2012). https://doi.org/10.1016/j.ijplas.2011.10.009

Funding

This study was funded by National Natural Science Foundation of China (11802241).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Gu, X., Xu, Y. et al. Thermomechanical modeling of nonlinear internal hysteresis due to incomplete phase transformation in pseudoelastic shape memory alloys. Nonlinear Dyn 103, 1393–1414 (2021). https://doi.org/10.1007/s11071-020-06121-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-020-06121-4