Abstract

Active bump-type foil bearings (ABFBs) enhance the rotordynamic characteristics of rotor–bearing systems with the advantage of controllable mechanical preloads. However, the coupling of controllable mechanical preloads, compressible gas film, and foil structures induce strong nonlinear characteristics and affect the dynamic responses of rotor. In this study, a nonlinear theoretical model that considers the gyroscopic effect of rotor, nonlinear Reynolds equation, complicated foil structures, and dynamic motions of active substructures is presented. This model is verified by a corresponding rotordynamic test. The nonlinear dynamic responses of a rotor–ABFB system are discussed on the basis of waterfall plots, orbit simulations, and Poincaré maps of rotor center, fast Fourier transform, minimum film thickness, and power loss during one cycle of journal orbit. The effects of voltage on piezoelectric actuators, nominal clearance, width of flexure hinge, and static load on the nonlinear rotordynamic responses of rotor are analyzed to provide guidelines on selecting the design and control parameters of rotor–ABFB systems.

Similar content being viewed by others

Abbreviations

- \(A_\mathrm{b}\) :

-

Area of one bump

- B :

-

Center point on the fixed end of the flexure hinge B

- \({B}'\) :

-

Center point on the free end of the flexure hinge B

- \(\overline{c_\mathrm{b}}\) :

-

Dimensionless damping of the bump foil

- \(c_{\varphi }\) :

-

Rotational compliance of the flexure hinge B (rad/(N m))

- C :

-

Nominal clearance (m)

- \(C_{\varphi }\) :

-

Structure damping of the lever amplifier (N s/m)

- \(d_{33}\) :

-

Piezoelectric coefficient of the PZT (m/V)

- E :

-

Young’s modulus (Pa)

- \(\{F\}\) :

-

Force matrix of foil structure (N)

- \(F_{0}\) :

-

Output force of the PZTs (N)

- \(F_\mathrm{G}\) :

-

Static load of rotor (N)

- \(F_{N}\) :

-

Preload of the lock screw (N)

- \(F_{p}\) :

-

Force from the output side of the lever amplifier (N)

- \(\overline{h}\) :

-

Dimensionless film thickness (\(=h/C\))

- \(K_{\varphi \mathrm{equal}}\) :

-

Equivalent rotational stiffness of the lever amplifier (N/rad)

- \(K_\mathrm{b}\) :

-

Stiffness of one bump derived from the simplified link-spring model (N/m)

- \(k_\mathrm{b}\) :

-

Average stiffness of bump foil derived from the link-spring model (\(\hbox {N}/\hbox {m}^{3}\))

- \(\overline{k_\mathrm{b}}\) :

-

Dimensionless stiffness of the bump foil

- \(k_\mathrm{p}\) :

-

Equivalent stiffness of the two PZTs in parallel (N/m)

- \(I_\mathrm{T}\) :

-

Translational inertia moment of rotor (\(\hbox {kg m}^{2}\))

- \(I_\mathrm{P}\) :

-

Polar inertia moment of rotor (kg m\(^2\))

- \(I_{\varphi }\) :

-

Moment of inertia of the lever amplifier along the Z-axis

- L :

-

Bearing cartridge axial length (m)

- \(M_{z\mathrm{equal}}\) :

-

Equivalent moment of the lever amplifier (N m)

- \(M_{\xi \_U}\) :

-

Moments in \(\xi \) directions caused by unbalanced (N m)

- \(M_{\psi \_U}\) :

-

Moments in \(\psi \) directions caused by unbalanced (N m)

- \(M_{\xi \_\mathrm{JB}}\) :

-

Moments in \(\xi \) directions caused by the journal ABFB and the journal GFB(N m)

- \(M_{\psi \_\mathrm{JB}}\) :

-

Moments in \(\psi \) directions caused by the journal ABFB and the journal GFB(N m)

- \(O_\mathrm{B}\) :

-

Bearing center

- \(O_\mathrm{J}\) :

-

Journal center

- \(\overline{p}\) :

-

Dimensionless pressure (\(=p/p_{a}\))

- R :

-

Journal radius (m)

- \({R}'\) :

-

Radius of bearing inner surface (m)

- t :

-

Time (s)

- \(\overline{t}\) :

-

Dimensionless time (\(=\upsilon t\))

- \(t_{2}\) :

-

Width of flexure hinge B (m)

- U :

-

Voltage on PZTs (V)

- x, y, z :

-

Horizontal, vertical, and axial coordinate

- \(\overline{z}\) :

-

Dimensionless axial coordinate (\(=z/R\))

- \(Z^{A}\) :

-

Distance between center of bearing A to end surface of rotor

- \(Z^{B}\) :

-

Distance between center of bearing B to end surface of rotor

- \(Z_\mathrm{G}\) :

-

Distance between rotor CG to end surface of rotor

- \(\upsilon \) :

-

Excitation frequency (rad/s)

- \(\overline{\delta }\) :

-

Dimensionless deformation of the top foil

- \(\varepsilon \) :

-

Eccentricity ratio

- \(\xi \) :

-

Rotational conical motion of rotor around the X-axis

- \(\psi \) :

-

Rotational conical motion of rotor around the Y-axis

- \(\varphi \) :

-

Rotational deformation angle of flexure hinge B (rad)

- \(\Delta u_{p}\) :

-

Actual deformation of the electrified PZT(m)

- \(\Delta u_{p0}\) :

-

Initial compression of the equivalent spring for the electrified PZT (m)

- \(\theta \) :

-

Circumferential coordinate of calculation domain (rad)

- \(\theta _{\min }\) :

-

Attitude angle of rotor center (rad)

- \(\theta _{n}\) :

-

The center angle position of the nth lever amplifiers (rad)

- \(\theta _{p}\) :

-

Pitch angle between two lever amplifiers (rad)

- \(\theta _{s}\) :

-

Circumferential span of a lever amplifier (rad)

- \(\Lambda \) :

-

Bearing number (\(=\frac{6\mu \omega }{p_{a}}(\frac{R}{C})^{2}\))

- \(\tau \) :

-

Time increment (s)

- \(\tau _{\mathrm{s}}\) :

-

Shear stress of the gas film (Pa)

- \(\mu \) :

-

Air viscosity (Pa s)

- \(\omega \) :

-

Rotating angular speed (rad/s)

- \(\omega _\mathrm{e}\) :

-

Excitation frequency (rad/s)

- \(\eta \) :

-

Structural loss factor of the bump foil

- i:

-

Station sequence number along the circumferential direction

- G:

-

Represents the gravity center of rotor

- n :

-

Sequence number of the lever amplifier

- A :

-

Represents the bearing A

- B :

-

Represents the bearing B

References

Dellacorte, C.: Oil-free shaft support system rotordynamics: past, present and future challenges and opportunities. Mech. Syst. Signal Process. 29(5), 67–76 (2012)

Heshmat, H., Walowit, J.A., Pinkus, O.: Analysis of gas-lubricated foil journal bearings. J. Tribol. 105(4), 647 (1983)

DellaCorte, C., Radil, K.C., Bruckner, R.J., Howard, B.S.: Design, fabrication, and performance of open source generation I and II compliant hydrodynamic gas foil bearings. Tribol. Trans. 51(3), 254–264 (2008)

Shi, M., Feng, K., Hu, J., Zhu, J., Cui, H.: Near-field acoustic levitation and applications to bearings: a critical review. Int. J. Extreme Manuf. 1(3), 032002 (2019)

Andrés, L.S., Kim, T.H.: Forced nonlinear response of gas foil bearing supported rotors. Tribol. Int. 41(8), 704–715 (2008)

Bonello, P., Hassan, M.F.B.: An experimental and theoretical analysis of a foil-air bearing rotor system. J. Sound Vib. 413, 395–420 (2018)

Hoffmann, R., Liebich, R.: Characterisation and calculation of nonlinear vibrations in gas foil bearing systems—an experimental and numerical investigation. J. Sound Vib. 412, 389–409 (2018)

Guo, Z., Feng, K., Liu, T., Lyu, P., Zhang, T.: Nonlinear dynamic analysis of rigid rotor supported by gas foil bearings: effects of gas film and foil structure on subsynchronous vibrations. Mech. Syst. Signal Process. 107, 549–566 (2018)

Rubio, D., Andrés, L.S.: Bump-type foil bearing structural stiffness: experiments and predictions. J. Eng. Gas Turbines Power 128(3), 653–660 (2006)

Guo, Z., Lyu, P., Feng, K., Liu, W.: Measurement and prediction of nonlinear dynamics of a gas foil bearing supported rigid rotor system. Measurement 121, 205–217 (2018)

Von Osmanski, S., Larsen, J.S., Santos, I.F.: A fully coupled air foil bearing model considering friction—theory & experiment. J. Sound Vib. 400, 660–679 (2017)

Lez, S.L., Arghir, M., Frene, J.: A dynamic model for dissipative structures used in bump-type foil bearings. Tribol. Trans. 52(1), 36–46 (2009)

Le Lez, S., Arghir, M., Frene, J.: A new bump-type foil bearing structure analytical model. In: ASME Turbo Expo 2007: Power for Land, Sea, and Air. American Society of Mechanical Engineers (2007)

Feng, K., Guo, Z.: Prediction of dynamic characteristics of a bump-type foil bearing structure with consideration of dynamic friction. Tribol. Trans. 57(2), 230–241 (2014)

Feng, K., Kaneko, S.: Analytical model of bump-type foil bearings using a link-spring structure and a finite-element shell model. ASME J. Tribol. 132(2), 021706 (2010)

Larsen, J.S., Santos, I.F.: On the nonlinear steady-state response of rigid rotors supported by air foil bearings—theory and experiments. J. Sound Vib. 346(1), 284–297 (2015)

Kim, D., Nicholson, B., Rosado, L., Givan, G.: Rotordynamics performance of hybrid foil bearing under forced vibration input. J. Eng. Gas Turbines Power 140(1), 1–12 (2017)

Feng, K., Zhao, X., Huo, C., Zhang, Z.: Analysis of novel hybrid bump-metal mesh foil bearings. Tribol. Int. 103, 529–539 (2016)

Lee, Y.B., Kim, T.H., Kim, C.H., Lee, N.S., Choi, D.H.: Dynamic characteristics of a flexible rotor system supported by a viscoelastic foil bearing (VEFB). Tribol. Int. 37(9), 679–687 (2004)

Heshmat, H., Shapiro, W., Gray, S.: Development of foil journal bearings for high load capacity and high speed whirl stability. J. Tribol. 104(2), 149–156 (1982)

Kim, T.H., Andrés, L.S.: Effects of a mechanical preload on the dynamic force response of gas foil bearings: measurements and model predictions. Tribol. Trans. 52(4), 569–580 (2008)

Kim, D.: Parametric studies on static and dynamic performance of air foil bearings with different top foil geometries and bump stiffness distributions. J. Tribol. 129(2), 354–364 (2007)

Sim, K., Lee, Y.B., Kim, T.H.: Effects of mechanical preload and bearing clearance on rotordynamic performance of lobed gas foil bearings for oil-free turbochargers. Tribol. Trans. 56(2), 224–235 (2013)

Sim, K., Lee, Y., Kim, T., Lee, J.: Rotordynamic performance of shimmed gas foil bearings for oil-free turbochargers. J. Tribol. 134(3), 031102 (2012)

Hoffmann, R., Liebich, R.: Experimental and numerical analysis of the dynamic behaviour of a foil bearing structure affected by metal shims. Tribol. Int. 115, 378–388 (2017)

Park, J., Sim, K.: A feasibility study of controllable gas foil bearings with piezoelectric materials via rotordynamic model predictions. J. Eng. Gas Turbines Power 141(2), 021027 (2019)

Sadri, H., Schlums, H., Sinapius, M.: Investigation of structural conformity in a three-pad adaptive air foil bearing with regard to active control of radial clearance. J. Tribol. 141(8), 1 (2019)

Feng, K., Guan, H., Zhao, Z., Liu, T.: Active bump-type foil bearing with controllable mechanical preloads. Tribol. Int. 120, 187–202 (2017)

Guan, H., Liu, T., Zhang, T., Feng, K., Guo, Z.: Vibration control for rotor mounted on a novel active bump type foil bearing with controllable mechanical preloads (51142): V07BT34A028 (2018)

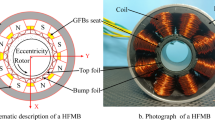

Guan, H., Feng, K., Cao, Y., Huang, M., Wu, Y., Guo, Z.: Experimental and theoretical investigation of rotordynamic characteristics of a rigid rotor supported by an active bump-type foil bearing. J. Sound Vib. 466, 115049 (2020)

Chen, W.J.: Introduction to Dynamics of Rotor-Bearing Systems. Trafford, Victoria (2005)

Wu, Y., Feng, K., Zhang, Y., Liu, W., Li, W.: Nonlinear dynamic analysis of a rotor-bearing system with porous tilting pad bearing support. Nonlinear Dyn. 94(2), 1391–1408 (2018)

Yamamoto, T., Ishida, Y.: Linear and Nonlinear Rotordynamics, vol. 85. Wiley, New York (2013)

Bently, D.E., Hatch’Charles, T.: Fundamentals of rotating machinery diagnostics. Mech. Eng. CIME 125(12), 53–54 (2003)

Cengel, Y.A.: Fluid Mechanics. Tata McGraw-Hill Education, New York (2010)

Wang, C.-C.: Application of a hybrid numerical method to the nonlinear dynamic analysis of a micro gas bearing system. Nonlinear Dyn. 59(4), 695–710 (2010)

Liu, W., Kai, F., Peng, L.: Bifurcation and nonlinear dynamic behaviours of a metal mesh damped flexible pivot tilting pad gas bearing system. Nonlinear Dyn. 91(4), 655–677 (2017)

Acknowledgements

This work was supported by the National Key R&D Program of China (2018YFB2000100), the National Natural Science Foundation of China (51875185), and the Foundation of Hunan Province (2018JJ1006).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

This work is original research and approved by all authors. The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Modified assembly clearance for ABFB

As shown in Fig. 19, the radial displacements of the stations on one-lever amplifier are varied with their circumferential positions. Linear interpolation is used to simulate the corresponding assembly clearance within the circumferential span of lever amplifier. The modified assembly clearance is calculated by using the following equation

where C is the nominal bearing clearance. \(\Delta R_{a}^{n}\) and \(\Delta R_{b}^{n}\) are the radial displacements of the two edges along the circumferential direction of the lever amplifier. Subscripts a and b stand for the two edges along each lever amplifier, and superscript n stands for the sequence number of the lever amplifier. Points a and b are the stations of the mesh, and \(\Delta R_{a}^{n}\) and \(\Delta R_{b}^{n}\) can be calculated with Eq. (20). Both of them are determined by the angle location and angle region of the lever amplifier. When the geometry of the lever amplifier is selected, their initial values are determined by U and the preload of the lock screw. Besides, \(w=\theta _{s} /\theta _{p}\) is the circumferential span parameter of lever amplifier.

Appendix B: Static load tests and parameters of tested ABFB and GFB

The results of static load tests of tested ABFB and GFB are shown in Fig. 20. The hysteresis curves of ABFB are in coincidence with that of GFB. Both tested bearings have identical clearance of \(40\ \upmu \hbox {m}\). The parameters of the two bearings are shown in Table 3.

Rights and permissions

About this article

Cite this article

Guan, HQ., Feng, K., Yu, K. et al. Nonlinear dynamic responses of a rigid rotor supported by active bump-type foil bearings. Nonlinear Dyn 100, 2241–2264 (2020). https://doi.org/10.1007/s11071-020-05608-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11071-020-05608-4