Abstract

This work develops an elastic-viscoplastic constitutive formulation to the mechanical behavior of polycrystalline FCC metals subjected to high-strain-rate cold deformation, with application to aluminum AA1050. Following a phenomenological approach, the model can account for important macroscopic features related to the mechanical response of ductile metals subjected to high-velocity plastic deformations, such as: (i) strain-hardening; (ii) strain-rate-hardening; and (iii) instantaneous flow stress rate-sensitivity. As a novelty of this proposal, memory effects corresponding to past strain-rate history are considered to affect both the level and rate of material hardening. Another new aspect is the phenomenological representation of both the thermal activation and dislocation drag mechanisms influencing the instantaneous flow stress response. The model calibration and its validation are performed based upon experimental data for commercial pure aluminum AA1050 for wide strain and strain-rate ranges. In comparison with experiments, the proposed model provides suitable predictions for both continuous and sequential compression tests. Overall, due to its relative simplicity and constitutive capabilities, the proposed model proves to be a potential constitutive alternative to simulate engineering problems involving dynamic plastic deformations.

Similar content being viewed by others

Notes

It is worth mentioning that the present approach extends the formulation given by dos Santos et al. (2016), in which only parameter \(A_{\infty }\) was rate-dependent.

We remark that to obtain adequate stress versus strain results from force–displacement data, careful corrections, considering the time delay between displacement and load data acquisition during high-velocity tests, have to be performed. See, for instance, the numerical analysis reported by dos Santos (2016).

References

Anand, L.: Constitutive equations for the rate-dependent deformation of metals at elevated temperatures. J. Eng. Mater. Technol. 104, 12–17 (1982)

Andrade-Campos, A., Menezes, L.F., Teixeira-Dias, F.: Large deformation processes on AA1050-O aluminium at elevated temperatures. In: Advanced Materials Forum II. Trans Tech Publications., pp. 723–727 (2004)

Bambach, M., Heppner, S., Steinmetz, D., Roters, F.: Assessing and ensuring parameter identifiability for a physically-based strain hardening model for twinning-induced plasticity. Mech. Mater. 84, 127–139 (2015)

Bamman, D.J., Chiesa, M.L., Johnson, G.C.: Modeling large deformation and failure in manufacturing process. In: Tatsumi, T., Wannabe, E., Kambe, T. (eds.) Theoretical and Applied Mechanics, pp. 359–376 (1996)

Bell, J.F.: Plane stress, plane strain, and pure shear at large finite strain. Int. J. Plast. 4, 127–148 (1988)

Beyerlein, I.J., Tomé, C.N.: Modeling transients in the mechanical response of copper due to strain path changes. Int. J. Plast. 23, 640–664 (2007)

Bodner, S.R., Partom, Y.: Constitutive equations for elastic-viscoplastic strain-hardening materials. J. Appl. Mech. 42, 385 (1975)

Bodner, S.R., Rubin, M.B.: Modeling of hardening at very high strain rates. J. Appl. Phys. 76, 2742–2747 (1994)

Brown, S.B., Kim, K.H., Anand, L.: An internal variable constitutive model for hot working of metals. Int. J. Plast. 5, 95–130 (1989)

Chaboche, J.L.: Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int. J. Plast. 5, 247–302 (1989)

Chaboche, J.L.: A review of some plasticity and viscoplasticity constitutive theories. Int. J. Plast. 24, 1642–1693 (2008)

Chen, W., Wang, F., Kitamura, T., Feng, M.: A modified unified viscoplasticity model considering time-dependent kinematic hardening for stress relaxation with effect of loading history. Int. J. Mech. Sci. 133, 883–892 (2017)

Chiem, C., Duffy, J.: Strain rate history effects and observations of dislocation substructure in aluminum single crystals following dynamic deformation. Mater. Sci. Eng. 57, 233–247 (1983)

Coleman, B.D., Gurtin, M.E.: Thermodynamics with internal state variables. Rep. Prog. Phys., 47, 597–613 (1967)

dos Santos, T.: Experimental characterization and constitutive modeling of viscoplastic effects in high strain-rate deformation of polycrystalline FCC metals. PhD thesis, Universidade Federal do Rio Grande do Sul, Brasil (2016)

dos Santos, T., Alves, M.K., Rossi, R.: A constitutive formulation and numerical procedure to model rate effects on porous materials at finite strains. Int. J. Mech. Sci. 93, 166–180 (2015a)

dos Santos, T., Ramos, G.R., Rossi, R.: A note on overstress and over-thermodynamic forces derivation for elasto-viscoplastic media: thermodynamic analysis of an isothermal relaxation process. Int. J. Eng. Sci. 93, 13–30 (2015b)

dos Santos, T., Rosa, P.A., Maghous, S., Rossi, R.: A simplified approach to high strain rate effects in cold deformation of polycrystalline FCC metals: constitutive formulation and model calibration. Int. J. Plast. 82, 76–96 (2016)

dos Santos, T., Outeiro, J.C., Rossi, R., Rosa, P.: A new methodology for evaluation of mechanical properties of materials at very high rates of loading. Proc. CIRP 58, 481–486 (2017). 16th CIRP Conference on Modelling of Machining Operations (16th CIRP CMMO)

dos Santos, T., Rossi, R., Maghous, S., Rosa, P.A.: Experimental procedure and simplified modeling for the high strain-rate and transient hardness evolution of aluminum aa1050. Mech. Mater. 122, 42–57 (2018)

Duvaut, G., Lions, J.: Inequalities in Mechanics and Physics. Grundlehren der mathematischen. Springer, Berlin (1976)

Estrin, Y., Mecking, H.: A unified phenomenological description of work hardening and creep based on one-parameter models. Acta Metall. 32, 57–70 (1984)

Eterovic, A.L., Bathe, K.J.: A hyperelastic-based large strain elasto-plastic constitutive formulation with combined isotropic-kinematic hardening using the logarithmic stress and strain measures. Int. J. Numer. Methods Eng. 30, 1099–1114 (1990)

Follansbee, P.S.: High strain rate deformation of fcc metals and alloys. In: Murr, L.E., Staudhammer, K.P., Meyers, M.A. (eds.) Metallurgical Applications of Shock-Wave and High-Strain Rate Phenomena, pp. 451–479. Dekker, New York (1986)

Follansbee, P., Kocks, U.: A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an internal state variable. Acta Metall. 36, 81–93 (1988)

Fourmeau, M., Børvik, T., Benallal, A., Lademo, O., Hopperstad, O.: On the plastic anisotropy of an aluminium alloy and its influence on constrained multiaxial flow. Int. J. Plast. 27, 2005–2025 (2011)

Freed, A., Sandor, B.: The plastic compressibility of 7075-t651 aluminum-alloy plate. Exp. Mech. 26, 119–121 (1986)

Gao, C., Zhang, L.: Constitutive modelling of plasticity of fcc metals under extremely high strain rates. Int. J. Plast. 32–33, 121–133 (2012)

Geier, M., José, M., Rossi, R., Rosa, P., Martins, P.: Interference-fit joining of aluminium tubes by electromagnetic forming. Adv. Mater. Res. 853, 488–493 (2014)

Germain, P., Son Nguyen, Q., Suquet, P.: Continuum thermodynamics. J. Appl. Mech. 50, 1010–1020 (1983)

Hall, R.B.: Combined thermodynamics approach for anisotropic, finite deformation overstress models of viscoplasticity. Int. J. Eng. Sci. 46, 119–130 (2008)

Halphen, B., Son Nguyen, Q.: Sur les matériaux standard généralisés. J. Méc. 14, 39–63 (1975)

Hansen, N., Barlow, C.: Plastic deformation of metals and alloys. In: Hono, D.E.L. (ed.) Physical Metallurgy 5th edn. pp. 1681–1764. Elsevier, Oxford (2014)

Hansen, N., Jensen, D.: Flow stress anisotropy caused by geometrically necessary boundaries. Acta Metall. Mater. 40, 3265–3275 (1992)

Higashi, K., Mukai, T., Kaizu, K., Tsuchida, S., Tanimura, S.: Strain rate dependence on mechanical properties in some commercial aluminum alloys. J. Phys. IV Fr. 01, 341–346 (1991)

Ho, K.: Effect of the rate dependence of nonlinear kinematic hardening rule on relaxation behavior. Int. J. Solids Struct. 45, 821–839 (2008)

Ho, K.: Thermodynamic formulation of a viscoplastic constitutive model capturing unusual loading rate sensitivity. Int. J. Eng. Sci. 100, 162–170 (2016)

Horstemeyer, M.F., Bammann, D.J.: Historical review of internal state variable theory for inelasticity. Int. J. Plast. 26, 1310–1334 (2010). Special Issue in Honor of David L. McDowell

Huang, F., Tao, N.: Effects of strain rate and deformation temperature on microstructures and hardness in plastically deformed pure aluminum. J. Mater. Sci. Technol. 27, 1–7 (2011)

Jordan, J., Siviour, C., Sunny, G., Bramlette, C., Spowart, J.: Strain rate-dependant mechanical properties of OFHC copper. J. Mater. Sci. 48, 7134–7141 (2013)

Kestin, J., Rice, J.: Paradoxes in the Application of Thermodynamics to Strained Solids. Technical report, Division of Engineering, Brown University (1969)

Kistler-Data-Sheet: SlimLine sensors – measurement of dynamic and quasistatic forces, \(0\dots 3\) kN up to \(0\dots 80\) kN. Kistler Group (2016)

Klepaczko, J.: Thermally activated flow and strain rate history effects for some polycrystalline f.c.c. metals. Mater. Sci. Eng. 18, 121–135 (1975)

Klepaczko, J., Chiem, C.: On rate sensitivity of f.c.c. metals, instantaneous rate sensitivity and rate sensitivity of strain hardening. J. Mech. Phys. Solids 34, 29–54 (1986)

Kocks, U.: Laws for work-hardening and low-temperature creep. J. Eng. Mater. Technol. 98 Ser H, 76–85 (1976)

Kocks, U., Mecking, H.: Physics and phenomenology of strain hardening: the FCC case. Prog. Mater. Sci. 48, 171–273 (2003)

Kocks, U.F., Argon, A.S., Ashby, M.F.: Thermodynamics and kinetics of slip. Prog. Mater. Sci. 19, 1–271 (1975)

Krempl, E., Gleason, J.M.: Isotropic viscoplasticity theory based on overstress (VBO). The influence of the direction of the dynamic recovery term in the growth law of the equilibrium stress. Int. J. Plast. 12, 719–735 (1996)

Lea, L., Jardine, A.: Characterisation of high rate plasticity in the uniaxial deformation of high purity copper at elevated temperatures. Int. J. Plast. 102, 41–52 (2018)

Lee, E.H.: Elastic-plastic deformation at finite strains. J. Appl. Mech. 36, 1–6 (1969)

Lubliner, J.: A maximum-dissipation principle in generalized plasticity. Acta Mech. 52, 225–237 (1984)

Luo, Z., Zhang, H., Hansen, N., Lu, K.: Quantification of the microstructures of high purity nickel subjected to dynamic plastic deformation. Acta Mater. 60, 1322–1333 (2012)

Ma, A., Roters, F.: A constitutive model for fcc single crystals based on dislocation densities and its application to uniaxial compression of aluminium single crystals. Acta Mater. 52, 3603–3612 (2004)

Macdougall, D.: Determination of the plastic work converted to heat using radiometry. Exp. Mech. 40, 298–306 (2000)

Mamalis, A., Manolakos, D., Kladas, A., Koumoutsos, A.: Electromagnetic forming and powder processing: trends and developments. Appl. Mech. Rev. 57, 299–324 (2004)

Mandel, J.: Equations constitutives et directeurs dans les milieux plastiques et viscoplastiques. Int. J. Solids Struct. 9, 725–740 (1973)

Mao, Z., An, X., Liao, X., Wang, J.: Opposite grain size dependence of strain rate sensitivity of copper at low vs high strain rates. Mater. Sci. Eng. A 738, 430–438 (2018)

Miguélez, M., Soldani, X., Molinari, A.: Analysis of adiabatic shear banding in orthogonal cutting of Ti alloy. Int. J. Mech. Sci. 75, 212–222 (2013)

Molinari, A., Ravichandran, G.: Constitutive modeling of high-strain-rate deformation in metals based on the evolution of an effective microstructural length. Mech. Mater. 37, 737–752 (2005)

Nemat-Nasser, S., Isaacs, J.: Direct measurement of isothermal flow stress of metals at elevated temperatures and high strain rates with application to Ta and Ta–W alloys. Acta Mater. 45, 907–919 (1997)

Nemat-Nasser, S., Li, Y.: Flow stress of f.c.c. polycrystals with application to OFHC Cu. Acta Mater. 46, 565–577 (1998)

Nemat-Nasser, S., Ni, L., Okinaka, T.: A constitutive model for fcc crystals with application to polycrystalline OFHC copper. Mech. Mater. 30, 325–341 (1998)

Nes, E.: Modelling of work hardening and stress saturation in FCC metals. Prog. Mater. Sci. 41, 129–193 (1997)

Neugebauer, R., Bouzakis, K.D., Denkena, B., Klocke, F., Sterzing, A., Tekkaya, A., Wertheim, R.: Velocity effects in metal forming and machining processes. CIRP Ann. 60, 627–650 (2011)

Perić, D.: On a class of constitutive equations in viscoplasticity: formulation and computational issues. Int. J. Numer. Methods Eng. 36, 1365–1393 (1993)

Perzyna, P.: The constitutive equations for rate sensitive plastic materials. Q. Appl. Math. 20, 321–332 (1963)

Perzyna, P.: Fundamental Problems in Viscoplasticity. Advances in Applied Mechanics, vol. 9, pp. 243–377. Elsevier, Amsterdam (1966)

Perzyna, P.: Thermodynamic Theory of Viscoplasticity. Advances in Applied Mechanics, vol. 11, pp. 313–354. Elsevier, Amsterdam (1971)

Rashid, M.M., Gray, G.T. III, Nemat-Nasser, S.: Heterogeneous deformations in copper single crystals at high and low strain rates. Philos. Mag. A 65, 707–735 (1992)

Regazzoni, G., Kocks, U., Follansbee, P.: Dislocation kinetics at high strain rates. Acta Metall. 35, 2865–2875 (1987)

Rice, J.: Inelastic constitutive relations for solids: an internal-variable theory and its application to metal plasticity. J. Mech. Phys. Solids 19, 433–455 (1971)

Ristinmaa, M., Wallin, M., Ottosen, N.S.: Thermodynamic format and heat generation of isotropic hardening plasticity. Acta Mech. 194, 103–121 (2007)

Rittel, D., Wang, Z.G., Merzer, M.: Adiabatic shear failure and dynamic stored energy of cold work. Phys. Rev. Lett. 96, 075502 (2006)

Rittel, D., Landau, P., Venkert, A.: Dynamic recrystallization as a potential cause for adiabatic shear failure. Phys. Rev. Lett. 101, 165501 (2008)

Rittel, D., Zhang, L., Osovski, S.: The dependence of the Taylor–Quinney coefficient on the dynamic loading mode. J. Mech. Phys. Solids 107, 96–114 (2017)

Rodríguez-Martínez, J.: Advanced Constitutive Relations for Modeling Thermo-viscoplastic Behaviour of Metallic Alloys Subjected to Impact Loading. PhD thesis (2010)

Rodríguez-Martínez, J., Rodríguez-Millán, M., Rusinek, A., Arias, A.: A dislocation-based constitutive description for modeling the behavior of FCC metals within wide ranges of strain rate and temperature. Mech. Mater. 43, 901–912 (2011)

Rollett, A., Kocks, U., Stout, M., Embury, J., Doherty, R.: Strain hardening at large strains. In: Kettunen, P., Lepisto, T., Lehtonen, M. (eds.) Strength of Metals and Alloys (ICSMA 8), pp. 433–438. Pergamon, Oxford (1989)

Rusinek, A., Jankowiak, T.: Constitutive relations under impact loadings: experiments, theoretical and numerical aspects. In: Dynamic Behavior of Materials. Constitutive Relations and Applications, pp. 87–135. Springer, Vienna (2014)

Rusinek, A., Rodríguez-Martínez, J.: Thermo-viscoplastic constitutive relation for aluminium alloys, modeling of negative strain rate sensitivity and viscous drag effects. Mater. Des. 30, 4377–4390 (2009)

Salvado, F.C., Teixeira-Dias, F., Walley, S.M., Lea, L.J., Cardoso, J.B.: A review on the strain rate dependency of the dynamic viscoplastic response of FCC metals. Prog. Mater. Sci. 88, 186–231 (2017)

Silva, C., Rosa, P., Martins, P.: Innovative testing machines and methodologies for the mechanical characterization of materials. Exp. Tech. 40, 569–581 (2016)

Tanner, A.B., McDowell, D.L.: Deformation, temperature and strain rate sequence experiments on OFHC Cu. Int. J. Plast. 15, 375–399 (1999)

Tjøtta, S., Mo, A.: A constitutive model for cold deformation of aluminium at large strains and high strain rates. Int. J. Plast. 9, 461–478 (1993)

Tong, W., Clifton, R.J., Huang, S.: Pressure-shear impact investigation of strain rate history effects in oxygen-free high-conductivity copper. J. Mech. Phys. Solids 40, 1251–1294 (1992)

Voce, E.: The relationship between stress and strain for homogeneous deformation. J. Inst. Met. 74, 537–562 (1948)

Wang, W.M., Sluys, L.J., de Borst, R.: Viscoplasticity for instabilities due to strain softening and strain-rate softening. Int. J. Numer. Methods Eng. 40, 3839–3864 (1997)

Wang, B., Liu, Z., Su, G., Song, Q., Ai, X.: Investigations of critical cutting speed and ductile-to-brittle transition mechanism for workpiece material in ultra-high speed machining. Int. J. Mech. Sci. 104, 44–59 (2015)

Yan, S., Yang, H., Li, H., Yao, X.: A unified model for coupling constitutive behavior and micro-defects evolution of aluminum alloys under high-strain-rate deformation. Int. J. Plast. 85, 203–229 (2016)

Zenasni, Z., Haterbouch, M., Atmani, Z., Atlati, S., Zenasni, M., Nasri, K., Oussouaddi, O.: Physics-based plasticity model incorporating microstructure changes for severe plastic deformation. C. R., Méc. 347, 601–614 (2019)

Zener, C., Hollomon, J.H.: Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 15, 22–32 (1944)

Zhang, B., Shim, V.: Effect of strain rate on microstructure of polycrystalline oxygen-free high conductivity copper severely deformed at liquid nitrogen temperature. Acta Mater. 58, 6810–6827 (2010)

Acknowledgements

TdS wishes to acknowledge the doctoral scholarship support of CAPES, Coordenação de Aperfeiçoamento de Pessoal de Nível Superior of Brazil. Process number BEX 7023/15-4. RR wishes to acknowledge the support of CNPq, Conselho Nacional de Desenvolvimento Científico e Tecnológico of Brazil, grant number 306058/2018-9.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Illustration of the strain-rate-dependent hardening evolution

Appendix: Illustration of the strain-rate-dependent hardening evolution

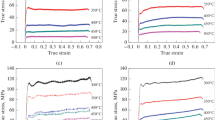

Graphical illustrations of the strain-rate influence on the material hardening evolution are schematically shown in Fig. 13. Figure 13(a) shows the strain-rate influence on the flow stress versus strain response by means of a rate-dependent hardening saturation \(A_{\infty }\), for \(\delta \) constant and \(c=0\). This figure shows a sequential test in which a high-strain-rate loading is followed by unloading and subsequent quasistatic reloading. This curve (solid-line) is compared with quasistatic loading (dashed-line). The comparison shows the past strain-rate influence on the hardening saturation \(A_{\infty }\), where \(A_{\infty }\left (\dot{\varepsilon }\right )\) is greater than the quasi-static value \(A_{\infty }^{lwr}\). Therefore, the quasistatic curve is not recovered by the quasistatic reloading. Furthermore, since \(\dot{\varepsilon }<\dot{\varepsilon }_{up}\), then \(A_{\infty }\left (\dot{\varepsilon }\right )< A_{\infty }^{up}\). Figure 13(b) shows the role played by the rate-dependent parameter \(\delta \left (\dot{\varepsilon }\right )\) on the hardening evolution, for \(A_{\infty }\) constant and \(c=0\). In summary, the higher the imposed strain-rate, the faster the hardening saturation \(A_{\infty }\) is reached.

Rights and permissions

About this article

Cite this article

dos Santos, T., Rossi, R., Maghous, S. et al. Mechanical characterization and constitutive modeling of aluminum AA1050 subjected to high strain-rates. Mech Time-Depend Mater 26, 347–375 (2022). https://doi.org/10.1007/s11043-021-09491-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-021-09491-3