Abstract

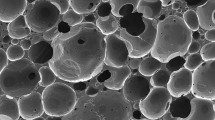

Time-dependent stress–strain relationship as well as crashworthiness of polyurethane foam was investigated under constant impact energy with different velocities, considering inertia and strain-rate effects simultaneously during the impact testing. Even though the impact energies were same, the percentage in increase in densification strain due to higher impact velocities was found, which yielded the wider plateau region, i.e. growth in crashworthiness. This phenomenon is analyzed by the microstructure of polyurethane foam obtained from scanning electron microscopy. The equations, coupled with the Sherwood–Frost model and the impulse-momentum theory, were employed to build the constitutive equation of the polyurethane foam and calculate energy absorption capacity of the foam. The nominal stress–strain curves obtained from the constitutive equation were compared with results from impact tests and were found to be in good agreement. This study is dedicated to guiding designer use polyurethane foam in crashworthiness structures such as an automotive bumper system by providing crashworthiness data, determining the crush mode, and addressing a mathematical model of the crashworthiness.

Similar content being viewed by others

References

Apostol, D.A., Constantinescu, D.M.: Temperature and speed of testing influence on the densification and recovery of polyurethane foams. Mech. Time-Depend. Mater. 17, 111–136 (2013)

Beer, F.P., Johnston, E.R. Jr.: Vector Mechanics for Engineers: Dynamics. McGraw-Hill, Toronto (1981)

Beheshti, H.K., Lankarani, H.: An investigation in crashworthiness evaluation of aircraft seat cushions at extreme ranges of temperature. J. Mech. Sci. Technol. 24, 1105–1110 (2010)

Chao, L.B., Ping, Z.G., Jian, L.T.: Low strain rate compressive behavior of high porosity closed-cell aluminum foams. Sci. China, Technol. Sci. 55, 451–463 (2012)

Espadas-Escalante, J.J., Avilés, F.: Anisotropic compressive properties of multiwall carbon nanotube/polyurethane foams. Mech. Mater. 91, 167–176 (2015)

Gibson, L.J., Ashby, M.F.: Cellular Solids: Structure and Properties. Cambridge University Press, Cambridge (1998)

Jeong, K.Y.: Constitutive modeling of polymeric foams having a four-parameter modulus function with strain rate sensitivity. J. Mech. Sci. Technol. 30, 683–688 (2016)

Jeong, K.Y., Cheon, S.S., Basit, M.B.: A constitutive model for polyurethane foam with strain rate sensitivity. J. Mech. Sci. Technol. 26, 2033–2038 (2012)

Kumar, B.R.B., Singh, A.K., Doddamani, M., Luong, D.D., Gupta, N.: Quasi-static and high strain rate compressive response of injection-molded cenosphere/HDPE syntactic foam. JOM 68, 1861–1871 (2016)

Lepik, Ü.: Dynamic buckling of elastic-plastic beams including effects of axial stress waves. Int. J. Impact Eng. 25, 537–552 (2001)

Lin, Y., Qin, J., Chen, R., Lu, F., Lu, L.: Time-resolved dynamic friction testing of a polyurethane foam against a polymer/clay nano-composite under impact loading. Tribol. Lett. 56, 37–45 (2014)

Lopatnikov, S.L., Gama, B.A., Gillespie, J.W.: Modeling the progressive collapse behaviour of metal foams. Int. J. Impact Eng. 34, 587–595 (2007)

Mamalis, A.G., Robinson, M., Manolakos, D.E., Demosthenous, G.A., Ioannidis, M.B., Carruthers, J.: Crashworthy capability of composite material structures. Compos. Struct. 37, 109–134 (1997)

Marsavina, L., Sadowski, T.: Dynamic fracture toughness of polyurethane foam. Polym. Test. 27, 941–944 (2008)

Michel, F.S., Chazeau, L., Cavaillé, J.Y., Chabert, E.: Mechanical properties of high density polyurethane foams: I. Effect of the density. Compos. Sci. Technol. 66, 2700–2708 (2006a)

Michel, F.S., Chazeau, L., Cavaillé, J.Y., Chabert, E.: Mechanical properties of high density polyurethane foams: II. Effect of the filler size. Compos. Sci. Technol. 66, 2709–2718 (2006b)

Mukai, T., Miyoshi, T., Nakano, S., Somekawa, H., Higashi, K.: Compressive response of a closed-cell aluminum foam at high strain rate. Scr. Mater. 54, 533–537 (2006)

Paul, A., Ramamurty, U.: Strain rate sensitivity of a closed-cell aluminium foam. Mater. Sci. Eng. A 281, 1–7 (2000)

Pawlikowski, M.: Non-linear approach in visco-hyperelastic constitutive modelling of polyurethane nanocomposite. Mech. Time-Depend. Mater. 18, 1–20 (2014)

Pellegrino, A., Tagarielli, V.L., Gerlach, R., Petrinic, N.: The mechanical response of a syntactic polyurethane foam at low and high rates of strain. Int. J. Impact Eng. 75, 214–221 (2015)

Saha, M.C., Mahfuz, H., Chakavarty, U.K., Uddin, M., Kabir, M.E., Jeelani, S.: Effect of density, microstructure, and strain rate on compression behavior of polymeric foams. Mater. Sci. Eng. A 406, 328–336 (2005)

Serban, D.A., Weissenborn, O., Geller, S., Marsavina, L., Gude, M.: Evaluation of the mechanical and morphological properties of long fibre reinforced polyurethane rigid foams. Polym. Test. 49, 121–127 (2016)

Sherwood, J.A., Frost, C.C.: Constitutive modeling and simulation of energy absorbing PU foam under impact loading. Polym. Eng. Sci. 32, 1138–1146 (1992)

Song, B., Lu, W.Y., Syn, C.J., Chen, W.: The effects of strain rate, density, and temperature on the mechanical properties of polymethylene diisocyanate (PMDI)-based rigid polyurethane foams during compression. J. Mater. Sci. 44, 351–357 (2009)

Taher, S.T., Zahari, R., Ataollahi, S., Mustapha, F., Basri, S.N.: A double-cell foam-filled composite block for efficient energy absorption under axial compression. Compos. Struct. 89, 399–407 (2009)

Tan, P.J., Reid, S.R., Harrigan, J.J., Zou, Z., Li, S.: Dynamic compressive strength properties of aluminium foams. Part I—experimental data and observations. J. Mech. Phys. Solids 53, 2174–2205 (2005)

Wu, G.H., Dou, Z.Y., Sun, D.L., Jiang, L.T., Ding, B.S., He, B.F.: Compression behaviors of cenosphere–pure aluminum syntactic foams. Scr. Mater. 56, 221–224 (2007)

Zarei, H., Kröger, M.: Optimum honeycomb filled crash absorber design. Mater. Des. 29, 193–204 (2008)

Zhang, G., Wang, B., Ma, L., Wu, L., Pan, S., Yang, J.: Energy absorption and low velocity impact response of polyurethane foam filled pyramidal lattice core sandwich panels. Compos. Struct. 108, 304–310 (2014)

Acknowledgements

This work was supported by the National Research Foundation of Korea (KR) under the grant number of D00011.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare to have no conflict of interest.

Rights and permissions

About this article

Cite this article

Basit, M.M., Cheon, S.S. Time-dependent crashworthiness of polyurethane foam. Mech Time-Depend Mater 23, 207–221 (2019). https://doi.org/10.1007/s11043-018-9391-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-018-9391-2