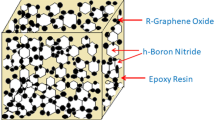

Micro-crack bridging and an optimal regime for dispersion of carbon nanotubes (CNTs) in the E-glass fabric reinforced polymer (GFRP) matrix are considered. The purpose of CNT dispersion in the glass fabric is to achieve the enhanced mechanical and tunable thermal/dielectric properties. The requirement for such conducting composites compared to high-cost carbon fabric is well recognized. The results are validated with the help of a theoretical model. The model relates the stiffness degradation of the composites and the existence of matrix cracks in the composites. Finite element simulation of a representative volume element of a laminate shows the effect of CNTs on the micro-cracks and the effective stiffness. The results obtained from the theoretical and finite element simulations are correlated to the experimental data and explain the increased strength due to the addition of CNT. This study shows that certain processing conditions in combination with the effect of dispersant agents reduce the porosity, residual stress and present a consistent dispersion strengthening effect with as low as 0.1 wt% CNT addition, resulting in improved tensile and compressive properties. The treatment of CNTs with ethanol reduces the Van der Waals forces among CNTs and the epoxy matrix viscosity. Enhancement in the CNT-GFRP stiffness and strength appears primarily due to effective micro-crack bridging and changes in the load transfer path.

Similar content being viewed by others

References

P. Kim, L. Shi, A. Majumdar, and P. L. McEuen, “Thermal transport measurements of individual multiwalled nanotubes,” Phys. Rev. Lett., 87, 215502 (2001).

E. T. Thostenson and T. W. Chou, “On the elastic properties of carbon nanotube-based composites: modeling and characterization,” J. Phys. D. Appl. Phys., 36, No. 5, 573–582 (2003).

M. F. Yu, O. Lourie, M. J. Dyer, K. Moloni, T. F. Kelly, and R. S. Ruoff, “Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load,” Science, 287, No. 5453, 637-640 (2000).

M. F. Yu, B. S. Files, S. Arepalli, and R. S. Ruoff, “Tensile loading of ropes of single-wall carbon nanotubes and their mechanical properties,” Phys. Rev. Lett., 84, No. 24, 5552-5555 (2000).

S. E. Lee, S. Cho, and Y. S. Lee, “Mechanical and thermal properties of MWCNT-reinforced epoxy nano-composites by vacuum-assisted resin transfer molding,” Carbon Lett., 15, No. 1, 32-37 (2014).

K. B. Kancherla, D. B. Subbappa, S. R. Hiremath, B. Raju, and D. R. Mahapatra, “Enhancing mechanical properties of glass fabric composite with surfactant treated zirconia nanoparticles,” Compos. Part A Appl. Sci. Manuf., 118, 131-141 (2019).

Y. Zhou, P. X. Wu, Z. Y. Cheng, J. Ingram, and S. Jeelani, “Improvement in electrical, thermal and mechanical properties of epoxy by filling carbon nanotube,” Express Polym. Lett., 2, No. 1, 40-48 (2008).

P. Subba Rao, K. Renji, M. R. Bhat, D. R. Mahapatra, and G. N. Naik, “Mechanical properties of CNT-Bisphenol e cyanate ester-based CFRP nano-composite developed through VARTM process,” J. Reinf. Plast. Compos., 34, No. 12, 1000-1014 (2015).

S. Amir Ahmadi, A. R. Ghasemi, and M. Mohammadi, “Evaluation of thermal residual stresses of thin-walled laminated composite pipes to characterize the effects of mandrel materials and addition MWCNTs,” Mech. Mater., 136, 103083 (2019).

K. Bilisik, N. S. Karaduman, and E. Sapanci, “Tensile properties of nanoprepreg/nanostitched 3D carbon/epoxy MWCNTs composites”, Mech. Mater., 128, 11-23 (2019).

I. A. Kazakov, A. N. Krasnovskii, and P. S. Kishuk, “The influence of randomly oriented CNTs on the elastic properties of unidirectionally aligned composites,” Mech. Mater., 134, 54-60 (2019).

A. N. Krasnovskii, I. A. Kazakov, and P. S. Kishchuk, “Mechanical properties of glass fiber reinforced plastics modified with carbon nanotubes,” Glass Ceram., 76, 167-170 (2019).

M. J. Mahmoodi, Y. Rajabi, and B. Khodaiepour, “Electro-thermo-mechanical responses of laminated smart nanocomposite moderately thick plates containing carbon nanotube-A multi-scale modeling,” Mech. Mater., 141, No. 7, 103247 (2020).

A. F. M. Nor, M. T. H. Sultan, A. U. M. Shah, A. M. R. Azmi, and K. I. Ismail, “Carbon nanotubes (CNTs) as nanofillers in bamboo/glass hybrid composites and their effect on tensile, flexural and impact properties,” AIP Conference Proceedings, 2030, 020171 (2018).

M. Sarafrazi, M. Hamadanian, and A. R. Ghasemi, “Optimize epoxy matrix with RSM/CCD method and influence of multi-wall carbon nanotube on mechanical properties of epoxy/polyurethane,” Mech. Mater., 138, 103154 (2019).

H. Wang, L. Yang, H. Guo, Y. Zhao, and J. Zhao, “Mechanical and thermodynamic properties of unidirectional flax fiber reinforced cnt modified epoxy composites,” Fibers Polym., 20, 1266-1276 (2019).

A. Haghbin, G. Liaghat, H. Hadavinia, A. M. Arabi, and M. H. Pol, “Enhancement of the electrical conductivity and interlaminar shear strength of CNT/GFRP hierarchical composite using an electrophoretic deposition technique,” Mater., 10, No. 10, 1120 (2017).

N. Li, G. dong Wang, S. K. Melly, T. Peng, Y. C. Li, Q. D. Zhao, and S. de Ji, “Interlaminar properties of GFRP laminates toughened by CNTs buckypaper interlayer,” Compos. Struct., 208, No. 36, 13-22 (2019).

P. S. Shin, D. J. Kwon, J. H. Kim, S. I. Lee, K. L. DeVries, and J. M. Park, “Interfacial properties and water resistance of epoxy and CNT-epoxy adhesives on GFRP composites,” Compos. Sci. Technol., 142, 98-106 (2017).

J. B. Bai and A. Allaoui, “Effect of the length and the aggregate size of MWNTs on the improved efficiency of the mechanical and electrical properties of nanocomposites-Experimental investigation,” Compos. Part A Appl. Sci. Manuf., 34, No. 8, 689-694 (2003).

J. H. Du, J. Bai and H. M. Cheng, “The present status and key problems of carbon nanotube-based polymer composites,” Express Polym. Lett., 1, No. 5, 253-273 (2007).

P. C. Ma, S. Y. Mo, B. Z. Tang, and J. K. Kim, “Dispersion, interfacial interaction and re-agglomeration of functionalized carbon nanotubes in epoxy composites,” Carbon, 48, No. 6, 1824-1834 (2010).

A. H. Esbati and S. Irani, “Effect of functionalized process and CNTs aggregation on fracture mechanism and mechanical properties of polymer nano-composite,” Mech. Mater., 118, 106-119 (2018).

F. L. Jin and S. J. Park, “Recent advances in carbon-nanotube-based epoxy composites,” Carbon Lett., 14, No. 1, 1-13 (2013).

Y. Pan, G. J. Weng, S. A. Meguid, W. S. Bao, Z. H. Zhu, and A. M. S. Hamouda, “Interface effects on the viscoelastic characteristics of carbon nanotube-polymer matrix composites,” Mech. Mater., 58, 1-11 (2013).

K. Yang, M. Gu, Y. Guo, X. Pan, and G. Mu, “Effects of carbon nanotube functionalization on the mechanical and thermal properties of epoxy composites,” Carbon, 47, No. 7, 1723-1737 (2009).

C. M. Wang, Y. Y. Zhang, Y. Xiang, and J. N. Reddy, “Recent studies on buckling of carbon nanotubes,” Appl. Mech. Rev., 63, No. 3, 030804 (2010).

B. Raju, S. R. Hiremath, and D. R. Mahapatra, “A review of micromechanics based models for effective elastic properties of reinforced polymer matrix composites,” Compos. Struct., 204, 607-619 (2018).

A. R. Ghasemi, M. M. Mohammadi, and M. Mohandes, “The role of carbon nanofibers on thermo-mechanical properties of polymer matrix composites and their effect on reduction of residual stresses,” Compos. B. Eng., 77, 519-527 (2015).

A. R. Ghasemi and M. M. Fesharaki, “Effect of carbon nanotube on the cured shape of cross-ply polymer matrix nanocomposite laminates: analytical and experimental study,” Iran. Polym. J., 27, No. 12, 965-977 (2018).

A. R. Ghasemi, M. M. Fesharaki, and M. Mohandes, “Three-phase micromechanical analysis of residual stresses in reinforced fiber by carbon nanotubes,” J. Compos. Mater., 51, No.12, 1783-1794 (2017).

O. V. Kharissova, B. I. Kharisov, and E. G. de C. Ortiz, “Dispersion of carbon nanotubes in water and non-aqueous solvents,” RSC Adv., 3, 24812-24852 (2013).

H. M. Tajammul, P. S. S. Gouda, I. G. Siddhalingeshwar and K. G. Kodancha, “Effect of alcoholic treated MWCNT on tensile behavior of epoxy composite,” Int. J. Eng. Sci. Technol., 8, No. 1, 57-63 (2016).

N. Laws and G. J. Dvorak, “Progressive transverse cracking in composite laminates,” J. Compos. Mater., 22, No. 10, 900-916 (1988).

A. S. D. Wang, “Fracture mechanics of sub laminate cracks in composite laminates,” Compos. Technol. Rev., 6, 45-62 (1984).

Acknowledgment

Authors thankfully acknowledge funding support under the ACECOST Phase-III program of Aeronautics Research & Development Board (AR&DB), DRDO, India, to carry out this research at the ACECOST Centre at Department of Aerospace Engineering, IISc. We also thank MNCF CeNSE, IISc for the SEM facility.

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 58, No. 4, pp. 835-856, July-August, 2022. Russian DOI: https://doi.org/10.22364/mkm.58.4.10.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gupta, N., Hiremath, S.R. & Mahapatra, D.R. Micro-Crack Bridging Effects on the Tensile and Compressive Strengths of CNT-Epoxy Composites. Mech Compos Mater 58, 585–598 (2022). https://doi.org/10.1007/s11029-022-10051-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-022-10051-0