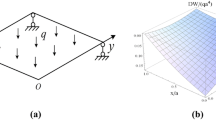

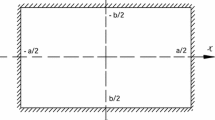

The analytical solution of the bending problem for a clamped rectangular plate with a variable in-plane stiffness is found by using the method of superposition. The flexural rigidity of the plate varies across its width according to an exponential function. First, the analytical solution for a simply supported rectangular plate with a variable in-plane stiffness is obtained, and then the bending problem for the plate clamped at its four edges is solved analytically by the superposition of one simply supported plate under the transverse load and two simply supported plates under pure bending. The influence of the variable in-plane stiffness, aspect ratio, and different boundary conditions on the deflection and bending moment is studied by numerical examples. The analytical solution presented here may be helpful for the design of rectangular plates with a variable in-plane stiffness.

Similar content being viewed by others

References

R. Li, Y. Zhong, B. Tian, and Y. M. Liu, “On the finite integral transform method for exact bending solutions of fully clamped orthotropic rectangular thin plates,” Appl. Math. Lett., 22, 1821-1827 (2009).

Z. Zhong and E. T. Shang, “Closed-form solutions of three-dimensional functionally graded plates,” Mech. Adv. Mater. Struc., 15, 355-363 (2008).

H. Nguyen-Xuan, Loc V. Tran, Chien H. Thai, S. Kulasegaram, and S. P. A. Bordas, “Isogeometric analysis of functionally graded plates using a refined plate theory,” Compos. Part B., 64, 222-234 (2014).

G. J. Nie and Z. Zhong, “Dynamic analysis of multi-directional functionally graded annular plates,” Appl. Math. Model., 34, 608-616 (2010).

K. Li, D. Wu, and W. Gao, “Spectral stochastic isogeometric analysis for static response of FGM plate with material uncertainty,” Thin. Wall. Struct., 132, 504-521 (2018).

H. Beik Mohammadlou, and H. Ekhteraei Toussi, “Parametric studies on elastoplastic buckling of rectangular FGM thin plates,” Aerosp. Sci. Technol., 69, 513-525 (2017).

B. Yang, H. J. Ding, and W. Q. Chen, “Elasticity solutions for functionally graded rectangular plates with two opposite edges simply supported,” Appl. Math. Model., 36, 488-503 (2012).

M. Mehrkash, M. Azhari, and H. R. Mirdamadi, “Reliability assessment of different plate theories for elastic wave propagation analysis in functionally graded plates,” Ultrasonics, 54, 106-120 (2014).

L. Sator, V. Sladek, and J. Sladek, “Coupling effects in transient analysis of FGM plates bending in non-classical thermo elasticity,” Compos. Part B., 165, 233-246 (2019).

D. G. Zhang and H. M. Zhou, “Nonlinear bending analysis of FGM circular plates based on physical neutral surface and higher-order shear deformation theory,” Aerosp. Sci. Technol., 41, 90-98 (2015).

Y. X. Hao, W. Zhang, and Z. Yang, “Nonlinear dynamics of a FGM plate with two clamped opposite edges and two free edges,” Acta. Mech. Solida. Sin., 27, No.4, 394-406 (2014).

A. Alibeigloo and M. Alizadeh, “Static and free vibration analyses of functionally graded sandwich plates using state space differential quadrature method,” Euro. J. Mech. A/Solid., 54, 252-266 (2015).

S. Dastjerdia and B. Akgözb, “New static and dynamic analyses of macro and nano FGM plates using exact threedimensional elasticity in thermal environment,” Compos. Struct., 192, 626-641 (2018).

Z. Vafakhah and Z. B. Neya, “An exact three dimensional solution for bending of thick rectangular FGM plate,” Compos. Part B., 156, 72-87 (2019).

P. F. Tan, N. T. Nhon, T. Rabczuk, and C. J. Yang, “Static, dynamic and buckling analyses of 3D FGM plates and shells via an isogeometric-meshfree coupling approach,” Compos. Struct., 198, 35-50 (2018).

V. N. Van and C. H. Lee, “Nonlinear analyses of FGM plates in bending by using a modified radial point interpolation mesh-free method,” Appl. Math. Model., 57, 1-20 (2018).

H. Salehipoura, A. Shahsavarb, and O. Civalekc, “Free vibration and static deflection analysis of functionally graded and porous micro nanoshells with clamped and simply supported edges,” Compos. Struct., 221, 110842 (2019).

T. C. Yu, G. J. Nie, Z. Zhong, and F. Y. Chu, “Analytical solution of a rectangular plate with in-plane material inhomogeneity, ” Appl. Math. Mech.-Engl., 34, No.4, 395-404 (2013).

P. Lyu, J. T. Du, Z. G. Liu, and P. Zhang, “Free in-plane vibration analysis of elastically restrained annular panels made of functionally graded material,” Compos. Struct., 178, 246-259 (2017).

G. J. Nie, Z. Zhong, and R. C. Batra, “Material tailoring for reducing stress concentration factor at a circular hole in a functionally graded material (FGM) panel,” Compos. Struct., 205, 49-57 (2018).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 11,802,145 and 11,772,232).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian translation published in Mekhanika Kompozitnykh Materialov, Vol. 57, No. 1, pp. 161-174, January-February, 2021.

Appendix A

Appendix A

The expressions of Φi (y), i = 1,2,3,4 .

1) r1, r2, r3, and r4 are real;

2) P(r) = (r − r1)(r − r2)(r2 + 2α1r + α0); r1, and r2 are real and \( {\alpha}_1^2-{\alpha}_0<0: \)

where

3) \( P(r)=\left({r}^2+2{\alpha}_1r+{\alpha}_0\right)\left({r}^2+2{\beta}_1r+{\beta}_0\right),\kern0.5em {\alpha}_1^2-{\alpha}_0<0, \) and \( {\beta}_1^2-{\beta}_0<0,\kern0.5em {\left({\alpha}_1-{\beta}_1\right)}^2+{\left({\alpha}_0-{\beta}_0\right)}^2\ne 0, \)

where \( \mu =\sqrt{\alpha_0-{\alpha}_1^2}, \) and \( \lambda =\sqrt{\beta_0-{\beta}_1^2}. \)

Rights and permissions

About this article

Cite this article

Yu, T.C., Nie, G.J., Zhong, Z. et al. Analytical Solution of the Bending Problem for Rectangular Orthotropic Plates with a Variable in-Plane Stiffness. Mech Compos Mater 57, 115–124 (2021). https://doi.org/10.1007/s11029-021-09938-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-021-09938-1