Abstract

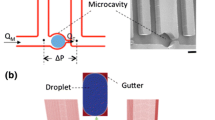

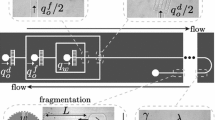

Drop deformation in constricted passages plays a vital role in porous media, microfluidic devices, lab-on-a-chip applications, etc. Depending on the viscosity ratio, Capillary number, drop volume and geometry of the constriction, drops may break-up by the snap-off mechanism. Different from the previous studies that consider symmetric single/periodic constrictions, we model a tube with a three-dimensional asymmetric constriction which is natural in porous media or can be used in microfluidic devices for the control of deformation and/or break-up mechanism. We model the motion of drops in Stokes regime and integrate the drop evolution using the axisymmetric boundary integral equations. Compared with the symmetric constrictions, the asymmetry of the constriction affects the snap-off time and thus the volume of the generated daughter droplet after snap-off. The volume is particularly affected by the smoothness of the upstream rather than the downstream of the constriction: more drop volume moves into to the constriction before the snap-off occurs. We show that in the case of a drop does not snap-off while passing through a particular constriction, an asymmetric design of this passage promotes snap-off. Pressure drop variation with time across the tube distinguishes the stages of snap-off from escape. Contrary to the use of two-dimensional models for flows in large aspect ratio microfluidic channels, we finally show that, because of the lack of out-of-plane curvature, planar models of tubular flows may be insufficient to observe certain physics such as jet formation and snap-off.

Similar content being viewed by others

References

Olbricht WL (1996) Pore-scale prototypes of multiphase flow in porous media. Annu Rev Fluid Mech 28:187–213

Stone HA, Stroock AD, Ajdari A (2004) Engineering flows in small devices: microfluidics toward a lab-on-a-chip. Annu Rev Fluid Mech 36:381–411

Jensen MJ, Stone HA, Bruus H (2006) A numerical study of two-phase stokes flow in an axisymmetric flow-focusing device. Phys Fluids 18:077103

Bremond N, Thiam AR, Bibette J (2008) Decompressing emulsion droplets favors coalescence. Phys Rev Lett 100:024501

Cubaud T (2009) Deformation and breakup of high-viscosity droplets with symmetric microfluidic cross flows. Phys Rev E 80:026307

Mandal A, Bera A (2015) Modeling of flow of oil-in-water emulsions through porous media. Petrol Sci 12:273–281

Anna SL (2016) Droplets and bubbles in microfluidic devices. Annu Rev Fluid Mech 48:285–309

Azarmanesh Milad, Farhadi Mousa (2016) The effect of weak-inertia on droplet formation phenomena in t-junction microchannel. Meccanica 51(4):819–834

Perazzo A, Tomaiuolo G, Preziosi V, Guido S (2018) Emulsions in porous media: from single droplet behavior to applications for oil recovery. Adv Colloid Interface Sci 256:305–325

Yousofvand R, Ghasemi K (2022) A novel microfluidic device for double emulsion formation: the effects of design parameters on droplet production performance. Colloids Surf A Physicochem Eng Asp 635

Fairbrother F, Stubbs AE (1935) 119. studies in electro-endosmosis. Part VI. The bubble-tube method of measurement. J Chem Soc (Resumed)

Taylor GI (1961) Deposition of a viscous fluid on the wall of a tube. J Fluid Mech 10:161–165

Bretherton FP (1961) The motion of long bubbles in tubes. J Fluid Mech 10:161–165

Goldsmith HL, Mason SG (1962) The movement of single large bubbles in closed vertical tubes. J Fluid Mech 14:42–58

Goldsmith HL, Mason SG (1963) The flow of suspensions through tubes. II. Single large bubbles. J Colloid Sci 18:237–261

Ho BP, Leal LG (1975) The creeping motion of liquid drops through a circular tube of comparable diameter. J Fluid Mech 71:361

Westborg H, Hassager O (1989) Creeping motion of long bubbles and drops in capillary tubes. J Colloid Interface Sci 133:135

Martinez MJ, Udell KS (1990) Axisymmetric creeping motion of drops through circular tubes. J Fluid Mech 210:565–591

Olbricht WL, Kung DM (1992) The deformation and breakup of liquid drops in low Reynolds number flow through a capillary. Phys Fluids A Fluid Dyn 4:1347–1354

Lac E, Sherwood JD (2009) Motion of a drop along the centreline of a capillary in a pressure-driven flow. J Fluid Mech 640:27–54

Tsai TM, Miksis MJ (1994) Dynamics of a drop in a constricted capillary tube. J Fluid Mech 274:197–217

Roof JG (1970) Snap-off of oil droplets in water-wet pores. Soc Petrol Eng J 10:85–90

Olbricht WL, Leal LG (1983) The creeping motion of immiscible drops through a converging/diverging tube. J Fluid Mech 134:329–355

Martinez MJ, Udell KS (1990) Axisymmetric creeping motion of drops through a periodically constricted tube. AIP Conf Proc 197:222–234

Peña TJ, Carvalho MS, Alvarado M (2009) Snap-off of a liquid drop immersed in another liquid flowing through a constricted capillary. AIChE J 55

Roman S, Abu-Al-Saud MO, Tokunaga T, Wan J, Kovscek AR, Tchelepi HA (2017) Measurements and simulation of liquid films during drainage displacements and snap-off in constricted capillary tubes. J Colloid Interface Sci 507:279–289

Zhang C, Yuan Z, Matsushita S, Xiao F, Suekane T (2021) Interpreting dynamics of snap-off in a constricted capillary from the energy dissipation principle. Phys Fluids 33:032112

Singla A, Ray B (2021) Effects of surface topography on low Reynolds number droplet/bubble flow through a constricted passage. Phys Fluids 33: 011301-1–17

Ransohoff TC, Gauglitz PA, Radke CJ (1987) Snap-off of gas bubbles in smoothly constricted noncircular capillaries. AIChE J 33:753–765

Kovscek AR, Radke CJ (1996) Gas bubble snap-off under pressure-driven flow in constricted noncircular capillaries. Colloids Surf A Physicochem Eng Asp 117:55–76

Kovscek AR, Radke CJ (2003) Pressure-driven capillary snap-off of gas bubbles at low wetting-liquid content. Colloids Surf A Physicochem Eng Asp 212:99–108

Kovscek AR, Tang GQ, Radke CJ (2007) Verification of roof snap off as a foam-generation mechanism in porous media at steady state. Colloids Surf A Physicochem Eng Asp 302:251–260

Deng W, Cardenas MB, Bennett PC (2014) Extended roof snap-off for a continuous nonwetting fluid and an example case for supercritical CO2. Adv Water Resources 64:34–46

Youngren GK, Acrivos A (1975) Stokes flow past a particle of arbitrary shape: a numerical method of solution. J Fluid Mech 69:377–403

Youngren GK, Acrivos A (1976) On the shape of a gas bubble in a viscous extensional flow. J Fluid Mech 76:433

Rallison JM, Acrivos A (1978) A numerical study of the deformation and burst of a viscous drop in an extensional flow. J Fluid Mech 89:191–200

Khayat RE, Luciani A, Utracki LA (1997) Boundary-element analysis of planar drop deformation in confined flow. Part 1. Newtonian fluids. Eng Anal Bound Elem 19:155–168

Janssen PJA, Anderson PD (2007) Boundary-integral method for drop deformation between parallel plates. Phys Fluids 19:043602

Janssen PJA, Anderson PD (2008) A boundary-integral model for drop deformation between two parallel plates with non-unit viscosity ratio drops. J Comput Phys 227:8807–8819

Wrobel LC, Soares D Jr, Das Bhaumik CL (2009) Drop deformation in stokes flow through converging channels. Eng Anal Bound Elem 33:993–1000

Pozrikidis C (2012) Passage of a liquid drop through a bifurcation. Eng Anal Bound Elem 36:93–103

Tao J, Song X, Liu J, Wang J (2013) Microfluidic rheology of the multiple-emulsion globule transiting in a contraction tube through a boundary element method. Chem Eng Sci 97:328–336

Cunha LHP, Siqueira IR, Albuquerque EL, Oliveira TF (2018) Flow of emulsion drops through a constricted microcapillary channel. Int J Multiphase Flow 103:141–150

Kadivar E (2018) Modeling droplet deformation through converging-diverging microchannels at low Reynolds number. Acta Mechanica 229:4239–4250

Telles JCF, Oliveira RF (1994) Third degree polynomial transformation for boundary element integrals: Further improvements. Eng Anal Bound Elem 13:457–466

Kaya B (2022) Axisymmetric deformation of drops through tubes with asymmetric constrictions. Master’s thesis, İzmir Katip Çelebi University

Brenner H (1970) Pressure drop due to the motion of neutrally buoyant particles in duct flows. J Fluid Mech 43:641–660

Gauglitz PA, Laurent CMSt, Radke CJ (1988) Experimental determination of gas-bubble breakup in a constricted cylindrical capillary. Ind Eng Chem Res 27:1282–1291

Gauglitz PA, Radke CJ (1990) The dynamics of liquid film breakup in constricted cylindrical capillaries. J Colloid Interface Sci 134:14–40

Cobos S, Carvalho MS, Alvarado V (2009) Flow of oil-water emulsions through a constricted capillary. Int J Multiphase Flow 35:507–515

Li Z, Gu Z, Li R, Wang C, Chen C, Yu C, Zhang Y, Shu Q, Su J (2021) Investigation on droplet dynamic snap-off process in a short, abrupt constriction. Chem Eng Sci 235:116496

Hammond PS (1983) Nonlinear adjustment of a thin annular film of viscous fluid surrounding a thread of another within a circular cylindrical pipe. J Fluid Mech 137:363–384

Shi Zhi, Lai Xiaochen, Sun Chengtao, Zhang Xingguo, Zhang Lei, Zhihua Pu, Wang Ridong, Haixia Yu, Li Dachao (2020) Step emulsification in microfluidic droplet generation: mechanisms and structures. Chem Commun 56(64):9056–9066

Wischke Christian (2020) Concepts for efficient preparation of particulate polymer carrier systems by droplet-based microfluidics. Int J Pharm 584:119401

Nagel Mathias, Gallaire François (2015) Boundary elements method for microfluidic two-phase flows in shallow channels. Comput Fluids 107:272–284

Abramowitz M, Stegun IA (1970) Handbook of mathematical functions: with formulas, graphs, and mathematical tables. National Bureau of Standards, Gaithersburg

Wang K (2002) BEM simulation for glass parisons. Technische Universiteit Eindhoven, Eindhoven

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

The analytical integration for the axisymmetric problem results with the following components of velocity and traction kernels with K(k) and E(k) being the elliptic integrals of the first and second kind [56]; R and r are the radial coordinates of source and field points, respectively [57].

with

The radial and axial components of normal vector and the interface curvature (\(\nabla \cdot {\varvec{n}}\)), which is the sum of axial (\(\kappa _z\)) and azimuthal curvatures (\(\kappa _r\)), are computed by

where s is the arc length along the generating curve. As the source point \({\varvec{x}}\) goes to zero (\(R=0\)), we use the limiting values of the kernel components:

Appendix 2

The fundamental solutions of planar Stokes flow, nondimensionalized with same scales as axisymmetric case but \(l_s=2R_0\), are

for velocity and stress, respectively. Unlike the axisymmetric problem, we directly place them into the linear system. The system is similar to the axisymmetric case (10) but in cartesian coordinates and given by

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaya, B., Ceyhan, U. Axisymmetric deformation of drops through tubes with symmetric and asymmetric constrictions. Meccanica 58, 1291–1306 (2023). https://doi.org/10.1007/s11012-023-01666-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-023-01666-1