Abstract

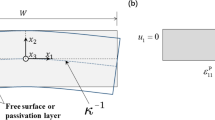

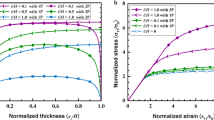

The continuum theory of dislocations is applied to formulate the problem of a double ended dislocation pileup under quadratic applied stress. Accordingly, a second order stress gradient plasticity model is presented to address the contribution of the first and the second stress gradients in the effect interpretation. The model is employed to predict the initial strengthening and subsequent hardening in curved and straight thin foils under pure bending within the continuum framework. It is shown that the so-called stress gradient plasticity model that ignores the second stress gradient may not give sound interpretations of the size effects. The plastic response of thin foils is affected by both the first and second stress gradients, yet their interaction strongly depends upon the length scale parameter. The larger the length scale parameter, the quadratic term contribution would be important and the predictions of the first and second order models deviate significantly from each other.

Similar content being viewed by others

Notes

The integral in Eq. (30) can also be evaluated by taking advantage of the complex variable and the Maclaurin series. The resulting expression is \( W = - \frac{{\tau_{0}^{2} }}{A}\left( {\frac{{L_{\text{obs}}^{2} }}{8} + \frac{{L_{\text{obs}}^{4} }}{{2^{7} }}\chi^{2} + \frac{{L_{\text{obs}}^{6} }}{{2^{9} }}\xi^{2} + \frac{{L_{\text{obs}}^{4} }}{{2^{5} }}\xi } \right) \) which is an approximate solution for the integral.

References

Acharya, A., Bassani, J.L.: Lattice incompatibility and a gradient theory of crystal plasticity. J. Mech. Phys. Solids 48, 1565–1595 (2000)

Akarapu, S., Hirth, J.P.: Dislocation pileups in stress gradients revisited. Acta Mater. 61, 3621–3629 (2013)

Akarapu, S., Zbib, H.M.: Dislocation interactions with tilt walls. Int. J. Mech. Mater. Des. 4, 399–406 (2008)

Armstrong, R.W.: Hall-Petch analysis of dislocation pileups in thin material layers and in nanopolycrystals. J. Mater. Res. 28, 1792–1798 (2013)

Belytschko, T., Liu, W.K., Moran, B.: Nonlinear finite elements for continua and structures. Wiley, Chichester (2000)

Bilby, B.A., Eshelby, J.D.: Dislocation and the theory of fracture. In: Liebowitz, H. (ed.) Fracture, vol. 1, pp. 99–182. Academic Press, New York (1968)

Chakravarthy, S.S., Curtin, W.A.: Effect of source and obstacle strengths on yield stress: a discrete dislocation study. J. Mech. Phys. Solids 58, 678–695 (2010)

Chakravarthy, S.S., Curtin, W.A.: Stress-gradient plasticity. Proc. Natl. Acad. Sci. USA 108, 15716–15720 (2011)

Demir, E., Raabe, D., Zaafarani, N., Zaefferer, S.: Investigation of the indentation size effect through the measurement of the geometrically necessary dislocations beneath small indents of different depths using EBSD tomography. Acta Mater. 57, 559–569 (2009)

Dunstan, D.J., Galle, J.U., Hou, X.D., P’ng, K.M.Y., Bushby, A.J., Yang, B., Kiener, D.: Yield and plastic flow of soft metals in small volumes loaded in tension and flexure. Philos. Mag. 92, 3199–3215 (2012a)

Dunstan, D.J., Thomas, A.J., de Lavau, I., Jardin, J.J., Bushby, A.J.: New experimental test of strain-gradient plasticity theory: metal foil sandwich structures in flexure. Philos. Mag. Lett. 92, 308–313 (2012b)

Ehrler, B., Hou, X.D., Zhu, T.T., P’ng, K.M.Y., Walker, C.J., Bushby, A.J., Dunstan, D.J.: Grain size and sample size interact to determine strength in a soft metal. Philos. Mag. 88, 3043–3050 (2008)

Fang, L., Friedman, L.H.: Strength of metallic multilayers at alllength scales from analytic theory ofdiscrete dislocation pileups. Phil. Mag. 85(28), 3321–3355 (2005)

Farokhi, H., Ghayesh, M.H.: Size-dependent behaviour of electrically actuated microcantilever-based MEMS. J. Mech. Mater. Des., Int (2015). doi:10.1007/s10999-015-9295-0

Fleck, N.A., Hutchinson, J.W.: A reformulation of strain gradient plasticity. J. Mech. Phys. Solids 49, 2245–2271 (2001)

Fleck, N.A., Muller, G.M., Ashby, M.F., Hutchinson, J.W.: Strain gradient plasticity: theory and experiment. Acta Metall. Mater. 42, 475–487 (1994)

Fleck, N.A., Willis, J.R.: A mathematical basis for strain-gradient plasticity theory. Part I: Scalar plastic multiplier. J. Mech. Phys. Solids 57, 161–177 (2009a)

Fleck, N.A., Willis, J.R.: A mathematical basis for strain-gradient plasticity theory. Part II: Tensorial plastic multiplier. J. Mech. Phys. Solids 57, 1045–1057 (2009b)

Friedman, L.H., Chrzan, D.C.: Continuum analysis of dislocation pile-ups: influence of sources. Phil. Mag. 77, 1185–1204 (1998)

Gao, H., Huang, Y., Nix, W.D., Hutchinson, J.W.: Mechanism-based strain gradient plasticity–I. Theory. J. Mech. Phys. Solids 47, 1239–1263 (1999)

Greer, J.R., De Hosson, JThM: Plasticity in small-sized metallic systems: intrinsic versus extrinsic size effect. Prog. Mater Sci. 56, 654–724 (2011)

Gurtin, M.E.: A gradient theory of single-crystal viscoplasticity that accounts for geometrically necessary dislocations. J. Mech. Phys. Solids 50, 5–32 (2002)

Hall, E.O.: The deformation and ageing of mild steel: III Discussion of results. Proc. Phys. Soc. B 64, 747–753 (1951)

Hirth, J.P., Lothe, J.: Theory of Dislocations, 2nd edn. Wiley, New York (1982)

Huang, Y., Qu, S., Hwang, K.C., Li, M., Gao, H.: A conventional theory of mechanism based strain gradient plasticity. Int. J. Plast 20, 753–782 (2004)

Johnson, W., Mellor, P.B.: Engineering Plasticity, 2nd edn. Wiley, New York (1983)

Khiabani, A.C., Sadrnejad, S.A.: Finite element evaluation of residual stresses in thick plates. Int. J. Mech. Mater. Des. 5(3), 253–261 (2009)

Kok, S., Beaudoin, A.J., Tortorelli, D.A.: A polycrystal plasticity model based on the mechanical threshold. Int. J. Plast 18(5–6), 715–741 (2002)

Li, J., Weng, G.J.: A micromechanical approach to the stress–strain relations, strain-rate sensitivity and activation volume of nanocrystalline materials. Int. J. Mech. Mater. Des. 9(2), 141–152 (2013)

Liu, D., He, Y., Zhang, B.: Towards a further understanding of dislocation pileup in the presence of stress gradients. Phil. Mag. 93(18), 2340–2362 (2013)

Liu, D., He, Y., Zhang, B., Shen, L.: A continuum theory of stress gradient plasticity based on the dislocation pile-up model. Acta Mater. 80, 350–364 (2014)

Muskhelishvili, N.I.: Singular Integral Equations: Boundary Problems of Function Theory and Their Application to Mathematical Physics, Noordhoff, P., Groningen, The Netherlands (1953)

Nix, W.D., Gao, H.: Indentation size effects in crystalline materials: a law for strain gradient plasticity. J. Mech. Phys. Solids 46, 411–425 (1998)

Petch, N.J.: The cleavage strength of polycrystals. J. Iron Steel Inst. 174, 25–28 (1953)

Shishvan, S.S., Asghari, A.H.: Particle size effect in metal matrix composites: a study by the continuum theory of stress gradient plasticity. J. Compos. Mater. (2015). doi:10.1177/0021998315595708

Soliman, R.M., El-Hadek, M.A., Abdu, S.I.: Stress analysis of multi-layer electronic and mechanical systems (MEMS) under fatigue and impact loading conditions. Int. J. Mech. Mater. Des. 6(4), 359–365 (2010)

Stolken, J.S., Evans, A.G.: A micobend test method for measuring the plasticity length scale. Acta Mater. 46, 5109–5115 (1998)

Suzuki, K., Matsuki, Y., Masaki, K., Sato, M., Kuroda, M.: Tensile and microbend tests of pure aluminum foils with different thicknesses. Mater. Sci. Eng., A 513–514, 77–82 (2009)

Taheri-Nassaj, N., Zbib, H.M.: On dislocation pileups and stress-gradient dependent plastic Flow. Int. J. Plast 74, 1–16 (2015)

Thompson, A.W., Baskes, M.I., Flanagan, W.F.: The dependence of polycrystal work hardening on grain size. Acta Metal. 21, 1017–1028 (1973)

Zamani, Z., Shishvan, S.S., Assempour, A.: Effect of source strength on dislocation pileups in the presence of stress gradients. Phil. Mag. 95, 2175–2197 (2015)

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Details for the evaluation of integral in Eq. (1)

The solution of Eq. (1) can be derived analytically by several approaches including the general theory of Hilbert transform (Liu et al. 2013), theory of functions of complex variables (Muskhelishvili 1953) and the real-variable proof through the trigonometric functions (Bilby and Eshelby 1968). It is found that all methods result in the same expression for the dislocation density function as

with

and

The applied stress is assumed as Eq. (2). For a pure dislocation pileup, the total number of dislocations in the pileup must be zero, i.e. \( N = \int_{{ - L_{\text{obs}} /2}}^{{L_{\text{obs}} /2}} {n(x)dx = 0} \); hence, we have E = 0. The integral in Eq. (16) can be performed by converting it to a contour integral in the complex plane, following the fundamental work of Friedman and Chrzan (1998). Integrating over \( \left( { - \frac{{L_{\text{obs}} }}{2} ,\frac{{L_{\text{obs}} }}{2}} \right) \) is equal to half the integral over C 1 as shown in Fig. 9. Since C 1 is a closed contour, it can be deformed into the contour C 2 which is an infinite circle as sketched in Fig. 9. Hence,

where

To evaluate the integral, we use the following Maclaurin series to simplify the integrand in Eq. (19),

Therefore, Eq. (20) becomes

Note that, the integral of h(z) over a closed contour equals the coefficient of 1/z in its expansion multiplied by \( ( - 2\pi {\text{i}}) \). Therefore, the integral in Eq. (19) becomes

Substitution of Eq. (23) into Eq. (16) yields

with

Appendix 2: Calculation of the force on the leading dislocation

As mentioned in Sect. 2, two methods can be applied with apparent success to calculate the force on the leading dislocation in the pileup configuration. A direct calculation through a limit formula derived by Bilby and Eshelby (1968) and a physically-based energy release method introduced in Hirth and Lothe (1982). For the cases of constant, \( \tau \left( x \right) = \tau_{0} , \) linear, \( \tau (x) = \tau_{0} \chi x, \) and quadratic, \( \tau \left( x \right) = \tau_{0} \xi x^{2} , \) stress distributions, we achieve the same expression for the force with both methods. However, for their combination i.e. \( \tau (x) = \tau_{0} \left( {1 + \chi x + \xi x^{2} } \right), \) the resulting expressions for the force calculated by two methods are found to be different.

Following Bilby and Eshelby (1968), the resulting expression for the forces at the left and the right tips are

The force at the right tip is obtained by substitution of Eq. (3) into Eq. (26) as

Alternatively, we can use an approach formulated in Hirth and Lothe (1982) to calculate this force. Thus, the energy released in forming the pileup is given by

Substituting Eq. (3) into Eq. (28) yields

To simplify the integral, we could change the integral variable as \( x = \frac{{L_{\text{obs}} }}{2}\cos\beta \). Equation (29) then becomes

which is evaluated asFootnote 1

Hence, the force per unit length on the leading dislocation is calculated as the rate of energy relaxation of the crystal during the advancing of pile up, i.e.

By comparing Eqs. (27) and (32), we conclude that the physically-based energy release method underestimates the interaction between the first and second stress gradient, i.e. \( \frac{{L_{\text{obs}}^{4} }}{{2^{7} }}\chi \xi \), and also the interaction between first stress gradient and constant stress, i.e. \( \frac{{L_{\text{obs}}^{2} }}{{2^{4} }}\chi \). It is thus emphasized that the resulting expression for the force on the leading dislocation in Eq. (27) cannot be obtained via a combination of this force for the constant, linear and quadratic stress cases.

For the force at the left tip, a similar procedure would apply which is not detailed here. However, the resulting expression is

Appendix 3: Numerical integration of governing equations in bending analysis

In this section, a numerical method based on the semi-implicit backward Euler integration scheme (Belytschko et al. 2000) is described to analyze the thin foil bending with the SσGP model. It is worth noting that the stress gradients are averaged over the length scale and attribution of these parameters into the fully implicit numerical method is quite complicated. Therefore, the stress gradients are assumed unchanged in each increment and the remaining parameters are obtained through the Newton–Raphson procedure.

The governing Eqs. (10) and (11) are reduced to solve the following non-linear algebraic equations

which can be linearized as (Belytschko et al. 2000)

where \( k \) denotes the iteration number, and

Hence, following set of equations can be solved for stress and plastic strain increments

Then, the effective plastic strain and stress are updated according to the incremental values as well as the solution at the last increment. This process is continued until the convergence is achieved to within a sufficient tolerance. It is noted that the governing Eqs. (14) and (15) for the straight foil can be solved in a similar manner by replacing \( \frac{ - \Delta \theta }{\theta } \) with \( \Delta \kappa \) and \( \frac{{x_{2} }}{{R - x_{2} }} \) with x 2 in above equations.

Rights and permissions

About this article

Cite this article

Assempour, A., Shishvan, S.S. & Zamani, Z. Second order stress gradient plasticity with an application to thin foil bending. Int J Mech Mater Des 13, 321–334 (2017). https://doi.org/10.1007/s10999-016-9336-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10999-016-9336-3