Abstract

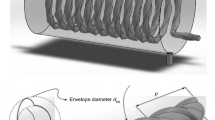

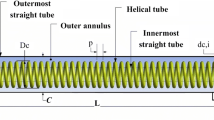

In this research, the thermo-hydraulic performance of a multi-fluid heat exchanger is experimentally investigated in regard to variations in control parameters, namely flow rate, flow configuration, and inlet temperature. A brazed helix tube (BHT), constructed from a helical coil tube with precision brazing between successive coil turns, is novel and integrated inside the present novel multi-fluid heat exchanger (NMFHE). The NMFHE presented here is part of a residential heating system where concurrent heating of cold water (HF2) and cold air (HF3) takes place with effective heat transfer from hot water (HF1) flowing inside the BHT. The JF factor and entropy generation number (Ns) are considered the key performance parameters of the study and experimentally predicted with respect to variations in control factors. The HF1 flow rate, HF2 flow rate, and flow configuration are identified as the most effective parameters for the JF factor (HF1, HF2, and HF3) with a contribution of 58.67%, 65.88%, and 34.85%, respectively. The HF1 inlet temperature and flow configuration are identified as the most effective parameters for the Ns (HF1, HF2, and HF3) with a contribution of 31.51%, 84.95%, and 98.44%, respectively. Afterward, the thermo-hydraulic performance of the NMFHE is optimized using the Taguchi–Grey technique for maximum JF factor and minimum Ns. The optimized performance of the NMFHE is predicted in counter-flow (cold water reversal) configuration with HF1 and HF2 flow rate of 150 LPH, and HF1 inlet temperature of 353 K and confirmed with significant improvement in Grey relational grade of 8.36%.

Similar content being viewed by others

Data availability

All data generated or analysed during this study are available from the corresponding author on reasonable request.

Abbreviations

- CF1:

-

Counter flow (hot water reverse)

- CF2:

-

Counter flow (cold water reverse)

- CF3:

-

Counter flow (cold air reverse)

- HF1 :

-

Hot water

- HF2 :

-

Cold water

- HF3 :

-

Cold air

- LPH:

-

Litre per hour

- NTU:

-

Numbers of transfer unit

- PF:

-

Parallel flow

- S/N:

-

Signal-to-noise

- TFHE:

-

Three-fluid heat exchanger

- TTHE:

-

Triple tube heat exchanger

- D c :

-

Coil diameter, m

- d c,i :

-

Helical tube diameter, m

- f :

-

Friction factor

- k :

-

Thermal conductivity, W m−1 K−1

- ṁ :

-

Mass flow rate, kg s−1

- Ns:

-

Entropy generation number

- Pr:

-

Prandtl number

- q′:

-

Heat transfer per unit length, W m−1

- Re:

-

Reynolds number

- T :

-

Temperature, K

- µh :

-

Dynamic viscosity, kg m−1 s−1

- ρ :

-

Density, Kg m−3

References

Sekulić DP, Shah RK. Thermal design theory of three-fluid heat exchangers. Adv Heat Transf. 1995;26:219–328.

García-Valladares O. Numerical simulation of triple concentric-tube heat exchangers. Int J Therm Sci. 2004;43:979–91.

Sekulić DP. A compact solution of the parallel flow three-fluid heat exchanger problem. Int J Heat Mass Transf. 1994;37:2183–7.

Aulds DD, Barron RF. Three-fluid heat exchanger effectiveness. Int J Heat Mass Transf. 1967;10:1457–62.

Sekulic DP, Kmecko I. Three-fluid heat exchanger effectiveness—revisited. J Heat Transf. 1995;117:226–9. https://doi.org/10.1115/1.2822309.

Saeid NH, Seetharamu KN. Finite element analysis for co-current and counter-current parallel flow three-fluid heat exchanger. Int J Numer Methods Heat Fluid Flow. 2006;16:324–37.

Ünal A. Effectiveness-NTU relations for triple concentric-tube heat exchanges. Int Commun Heat Mass Transf. 2003;30:261–72.

Ünal A. Theoretical analysis of triple concentric-tube heat exchangers part 2: case studies. Int Commun Heat Mass Transf. 2001;28:243–56.

Ünal A. Theoretical analysis of triple concentric-tube heat exchangers part 1: mathematical modelling. Int Commun Heat Mass Transf. 1998;25:949–58.

Nema PK, Datta AK. Improved milk fouling simulation in a helical triple tube heat exchanger. Int J Heat Mass Transf. 2006;49:3360–70.

Sahoo PK, Ansari IA, Datta AK. Milk fouling simulation in helical triple tube heat exchanger. J Food Eng. 2005;69:235–44.

Ghosh I, Sarangi SK, Das PK. Synthesis of multistream heat exchangers by thermally linked two-stream modules. Int J Heat Mass Transf. 2010;53:1070–8.

Quadir GA, Badruddin IA, Salman Ahmed NJ. Numerical investigation of the performance of a triple concentric pipe heat exchanger. Int J Heat Mass Transf. 2014;75:165–72.

Hashemi Karouei SH, Ajarostaghi SSM, Gorji-Bandpy M, Hosseini Fard SR. Laminar heat transfer and fluid flow of two various hybrid nanofluids in a helical double-pipe heat exchanger equipped with an innovative curved conical turbulator. J Therm Anal Calorim. 2021;143:1455–66. https://doi.org/10.1007/s10973-020-09425-0.

Rout A, Singh S, Mohapatra T, Sahoo SS, Solanki CS. Energy, exergy, and economic analysis of an off-grid solar polygeneration system. Energy Convers Manag. 2021;238:114177.

Quadir GA, Jarallah SS, Ahmed NJS, Badruddin IA. Experimental investigation of the performance of a triple concentric pipe heat exchanger. Int J Heat Mass Transf. 2013;62:562–6.

Radulescu S, Negoita I, (Buchar) IO-RC, 2012 undefined. Heat transfer coefficient solver for a triple concentric-tube heat exchanger in transition regime. Res Radulescu, Negoita, I OnutuRev Chim (Buchar), 2012 esearchgate.net [Internet]. 2016 [cited 2023 Aug 26]; Available from: https://www.researchgate.net/profile/Sinziana-Radulescu/publication/289224033_Heat_Transfer_Coefficient_Solver_for_a_Triple_Concentric-tube_Heat_Exchanger_in_Transition_Regime/links/56be8e6e08ae44da37f8ac36/Heat-Transfer-Coefficient-Solver-for-a-Triple-Co

Peigné P, Inard C, Druette L. Experimental study of a triple concentric tube heat exchanger integrated into a wood-based air-heating system for energy-efficient dwellings. Energies. 2013; Available from: https://www.mdpi.com/45316

Singh S, Mishra M, Jha PK. Experimental investigations on thermo-hydraulic behaviour of triple concentric-tube heat exchanger. Proc Inst Mech Eng Part E J Process Mech Eng. 1989;229:299–308. https://doi.org/10.1177/0954408914531118.

Gomaa A, Halim MA, Elsaid AM. Experimental and numerical investigations of a triple concentric-tube heat exchanger. Appl Therm Eng. 2016;99:1303–15.

Gomaa A, Halim MA, Elsaid AM. Enhancement of cooling characteristics and optimization of a triple concentric-tube heat exchanger with inserted ribs. Int J Therm Sci. 2017;120:106–20.

Mohapatra T, Padhi BN, Sahoo SS. Experimental investigation of convective heat transfer in an inserted coiled tube type three fluid heat exchanger. Appl Therm Eng. 2017;117:297–307.

Touatit A, Bougriou C. Optimal diameters of triple concentric-tube heat exchangers. Int J Heat Technol. 2018;36:367–75.

Liang C, Wang Y, Li X. Energy-efficient air conditioning system using a three-fluid heat exchanger for simultaneous temperature and humidity control. Energy Conv Manag; 2022. Available from: https://www.sciencedirect.com/science/article/pii/S0196890422010135

Afzal A, Islam MT, Kaladgi AR, Manokar AM, Samuel OD, Mujtaba MA, et al. Experimental investigation on the thermal performance of inserted helical tube three-fluid heat exchanger using graphene/water nanofluid. J Therm Anal Calorim. 2022;147:5087–100.

Mohapatra T, Sahoo SS, Mishra SS, Mishra P, Biswal DK. Performance Investigation of a three fluid heat exchanger used in domestic heating applications. Int J Automot Mech Eng. 2022;19:9693–708.

Liang C, Wang Y, Li X. Energy-efficient air conditioning system using a three-fluid heat exchanger for simultaneous temperature and humidity control. Energy Convers Manag. 2022;270:116236.

Alghamdi KI, Bach CK, Spitler JD, Istiaque F. Modeling, Simulating, and validating a novel three-fluid heat exchanger (TricoilTM) for a residential heating and air-conditioning system integrating water-based thermal energy storage. [cited 2023 Aug 16]; Available from: https://papers.ssrn.com/abstract=4466045

Ruan DF, Yuan XF, Li YR, Wu SY. Entropy generation analysis of parallel and counter-flow three-fluid heat exchangers with three thermal communications. J Non-Equilib Thermodyn. 2011;36:141–54.

Panda RC, Sahoo SS, Barik AK, Sahu D, Mohapatra T, Rout A. Performance of solar collector coupled with three fluid heat exchanger and heat storage system for simultaneous water and space heating. Lect Notes Mech Eng. 2023. https://doi.org/10.1007/978-981-19-4388-1_30.

Mohapatra T, Ray S, Sahoo SS, Padhi BN. Numerical study on heat transfer and pressure drop characteristics of fluid flow in an inserted coiled tube type three fluid heat exchanger. Heat Transf Res. 2019;48:1440–65. https://doi.org/10.1002/htj.21440.

Rogers GFC, Mayhew YR. Heat transfer and pressure loss in helically coiled tubes with turbulent flow. Int J Heat Mass Transf. 1964;7:1207–16.

Heat Transfer To Moving Fluids (Journal Article)|OSTI.GOV [Internet]. [cited 2022 Jul 26]. Available from: https://www.osti.gov/biblio/4222485

Vicente PG, García A, Viedma A. Experimental investigation on heat transfer and frictional characteristics of spirally corrugated tubes in turbulent flow at different Prandtl numbers. Int J Heat Mass Transf. 2004;47:671–81.

Rout A, Sahoo SS, Singh S, Pattnaik S, Barik AK, Awad MM. Benefit-cost analysis and parametric optimization using Taguchi method for a solar water heater. In: Design and performance optimization of renewable energy systems, 2021. p. 101–16.

Sahin B, Yakut K, Kotcioglu I, Celik C. Optimum design parameters of a heat exchanger. Appl Energy. 2005;82:90–106.

Pandey N, Murugesan K, Thomas HR. Optimization of ground heat exchangers for space heating and cooling applications using Taguchi method and utility concept. Appl Energy. 2017;190:421–38.

Miansari M, Valipour MA, Arasteh H, Toghraie D. Energy and exergy analysis and optimization of helically grooved shell and tube heat exchangers by using Taguchi experimental design. J Therm Anal Calorim. 2020;139:3151–64.

Mohapatra T, Padhi BN, Sahoo SS. Analytical investigation and performance optimization of a three fluid heat exchanger with helical coil insertion for simultaneous space heating and water heating. Heat Mass Transf Stoffuebertragung. 2019;55:1723–40. https://doi.org/10.1007/s00231-018-02545-2.

Chamoli S, Yu P, Kumar A. Multi-response optimization of geometric and flow parameters in a heat exchanger tube with perforated disk inserts by Taguchi grey relational analysis. Appl Therm Eng. 2016;103:1339–50.

Celik N, Pusat G, Turgut E. Application of Taguchi method and grey relational analysis on a turbulated heat exchanger. Int J Therm Sci. 2018;124:85–97.

Kumar V, Sahoo RR. Parametric and design optimization investigation of a wavy fin and tube air heat exchanger using the T-G technique. Heat Transf. 2022;51:4641–66. https://doi.org/10.1002/htj.22516.

Acknowledgements

This study has not been supported or funded by any organization or institution.

Author information

Authors and Affiliations

Contributions

BA experimented on the test setup, collected and analysed the data, and wrote the initial draft of the manuscript. TM contributed to the design and fabrication of the test setup and conducted overall performance optimization analysis. SSM provided expertise in critical revisions to the manuscript and assisted with data interpretation. All authors reviewed and approved the final version of the manuscript. This statement shows the roles and responsibilities of each author in the research process. It lists the specific contributions that each author made to the study and manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Almasri, B., Mohapatra, T. & Mishra, S.S. Experimental investigation and performance optimization of thermo-hydraulic and exergetic characteristics of a novel multi-fluid heat exchanger. J Therm Anal Calorim 148, 14051–14068 (2023). https://doi.org/10.1007/s10973-023-12594-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12594-3