Abstract

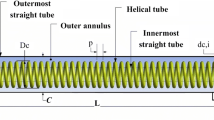

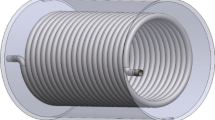

In this work, a three-dimensional study of shell and helically corrugated coiled tube heat exchanger with considering exergy loss is investigated. Various design parameters and operating conditions such as corrugation depth (e), corrugation pitch (p) or the number of rounds, inlet fluid flow rate on the coil and shell sides are numerically investigated to examine the heat exchanger hydrothermal performance. Taguchi analysis is used to analyze the hydrothermal parameters by considering the interaction effects of them. The obtained results showed that increasing the inlet fluid flow rate on the coil side, corrugation depth and the number of rounds increases both heat transfer and pressure drop. It is also found that the most effective parameter on the thermal performance of the heat exchanger is the fluid flow rate on the coil side, followed by the corrugation depth and the most effective parameter on the hydrodynamic performance of the heat exchanger is fluid flow rate on the coil side, followed by corrugation pitch and corrugation depth. Based on the exergy analysis in the heat exchanger, using a helically corrugated coiled tube instead of the helically plain coiled tube in the heat exchanger for the cases of low Reynolds numbers has higher effectiveness.

Similar content being viewed by others

Abbreviations

- c p :

-

Specific heat capacity (J kg−1 K−1)

- \(C_{\upmu}\) :

-

Coefficient of turbulent viscosity

- d :

-

Tube diameter (m)

- D s :

-

Shell diameter (m)

- D c :

-

Coil diameter (m)

- Ex:

-

Exergy (W)

- e :

-

Corrugation depth (m)

- h :

-

Enthalpy (J)

- k :

-

Turbulent kinetic energy (J)

- L :

-

Length (m)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- n :

-

Number of rounds

- Nu:

-

Nusselt number

- P :

-

Pressure (Pa)

- p :

-

Corrugation pitch (m)

- p c :

-

Coil pitch (m)

- Q :

-

Heat transfer rate (W)

- q1:

-

Flow rate (cold side) (kg s−1)

- q2:

-

Flow rate (shell side) (kg s−1)

- S :

-

Entropy (W)

- S ij :

-

Strain rate tensor

- Re:

-

Reynolds number

- SN:

-

Signal to noise ratio

- T :

-

Temperature (K)

- u :

-

Velocity (m s−1)

- x i, x j :

-

Cartesian coordinates

- \(\varepsilon\) :

-

Turbulent dissipation rate (m2 s−3)

- \(\mu\) :

-

Dynamic viscosity (kg m−1 s−1)

- \(\nu\) :

-

Kinematics viscosity (m2 s−1)

- \(\rho\) :

-

Density (kg m−3)

- \(\sigma_{\text{k}}\) :

-

Turbulent Prandtl number for k

- \(\sigma_{\upvarepsilon}\) :

-

Turbulent Prandtl number for \(\varepsilon\)

- e:

-

Environment

- c:

-

Cold

- h:

-

Hot

- i:

-

Inlet

- o:

-

Outlet

- s:

-

Shell

- ci:

-

Fluid inlet-cold side

- co:

-

Fluid outlet-cold side

- hi:

-

Fluid inlet-hot side

- ho:

-

Fluid outlet-hot side

References

Darzi AAR, Farhadi M, Sedighi K. Experimental investigation of convective heat transfer and friction factor of Al2O3/water nanofluid in helically corrugated tube. Exp Therm Fluid Sci. 2014;57:188–99.

Vicente PG, Garcıa A, Viedma A. Mixed convection heat transfer and isothermal pressure drop in corrugated tubes for laminar and transition flow. Int Commun Heat Mass Transf. 2004;31(5):651–62.

Vicente PG, Garcıa A, Viedma A. Experimental investigation on heat transfer and frictional characteristics of spirally corrugated tubes in turbulent flow at different Prandtl numbers. Int J Heat Mass Transf. 2004;47(4):671–81.

Naphon P, Nuchjapo M, Kurujareon J. Tube side heat transfer coefficient and friction factor characteristics of horizontal tubes with helical rib. Energy Convers Manag. 2006;47(18–19):3031–44.

Hasanpour A, Farhadi M, Sedighi K. Experimental heat transfer and pressure drop study on typical, perforated, V-cut and U-cut twisted tapes in a helically corrugated heat exchanger. Int Commun Heat Mass Transf. 2016;71:126–36.

Han H, Li B, Shao W. Effect of flow direction for flow and heat transfer characteristics in outward convex asymmetrical corrugated tubes. Int J Heat Mass Transf. 2016;92:1236–51.

Liu JJ, Liu ZC, Liu W. 3D numerical study on shell side heat transfer and flow characteristics of rod-baffle heat exchangers with spirally corrugated tubes. Int J Therm Sci. 2015;89:34–42.

Han HZ, Li BX, Wu H, Shao W. Multi-objective shape optimization of double pipe heat exchanger with inner corrugated tube using RSM method. Int J Therm Sci. 2015;90:173–86.

Dizaji HS, Jafarmadar S, Mobadersani F. Experimental studies on heat transfer and pressure drop characteristics for new arrangements of corrugated tubes in a double pipe heat exchanger. Int J Therm Sci. 2015;96:211–20.

Salimpour MR, Golmohammadi K, Sedaghat A, Campo A. Experimental study of the turbulent convective heat transfer of titanium oxide nanofluid flowing inside helically corrugated tubes. J Mech Sci Technol. 2015;29(9):4011–6.

Kareem ZS, Abdullah S, Lazim TM, Jaafar MNM, Wahid AFA. Heat transfer enhancement in three-start spirally corrugated tube: experimental and numerical study. Chem Eng Sci. 2015;134:746–57.

Han HZ, Li BX, Li FC, He YR. RST model for turbulent flow and heat transfer mechanism in an outward convex corrugated tube. Comput Fluids. 2014;91:107–29.

Panahi D, Zamzamian K. Heat transfer enhancement of shell-and-coiled tube heat exchanger utilizing helical wire turbulator. Appl Therm Eng. 2017;115:607–15.

Etghani MM, Baboli SAH. Numerical investigation and optimization of heat transfer and exergy loss in shell and helical tube heat exchanger. Appl Therm Eng. 2017;121:294–301.

Mirgolbabaei H. Numerical investigation of vertical helically coiled tube heat exchangers thermal performance. Appl Therm Eng. 2018;136:252–9.

Mashoofi N, Pesteei SM, Moosavi A, Dizaji HS. Fabrication method and thermal-frictional behavior of a tube-in-tube helically coiled heat exchanger which contains turbulator. Appl Therm Eng. 2017;111:1008–15.

Alimoradi A, Olfati M, Maghareh M. Numerical investigation of heat transfer intensification in shell and helically coiled finned tube heat exchangers and design optimization. Chem Eng Process Process Intensif. 2017;121:125–43.

Milani Shirvan K, Mamourian M, Abolfazli Esfahani J. Experimental study on thermal analysis of a novel shell and tube heat exchanger with corrugated tubes. J Therm Anal Calorim. 2019;138(2):1583–606.

Hosseinnezhad R, Akbari OA, Afrouzi HH, Biglarian M, Koveiti A, Toghraie D. Numerical study of turbulent nanofluid heat transfer in a tubular heat exchanger with twin twisted-tape inserts. J Therm Anal Calorim. 2018;132(1):741–59.

Asadollahi A, Esfahani JA, Ellahi R. Evacuating liquid coatings from a diffusive oblique fin in micro-/mini-channels: an application of condensation cooling process. J Therm Anal Calorim. 2019;138(1):255–63.

Milani Shirvan K, Mamourian M, Mirzakhanlari S, Ellahi R. Numerical investigation of heat exchanger effectiveness in a double pipe heat exchanger filled with nanofluid: a sensitivity analysis by response surface methodology. Powder Technol. 2017;313:99–111.

Zadkhast M, Toghraie D, Karimipour A. Developing a new correlation to estimate the thermal conductivity of MWCNT-CuO/water hybrid nanofluid via an experimental investigation. J Therm Anal Calorim. 2017;129(2):859–67.

Arabpour A, Karimipour A, Toghraie D. The study of heat transfer and laminar flow of kerosene/multi-walled carbon nanotubes (mwcnts) nanofluid in the microchannel heat sink with slip boundary condition. J Therm Anal Calorim. 2018;131(2):1553–66.

Arabpour A, Karimipour A, Toghraie D. Investigation into the effects of slip boundary condition on nanofluid flow in a double-layer microchannel. J Therm Anal Calorim. 2018;131(3):2975–91.

Balootaki AA, Karimipour A, Toghraie D. Nano scale lattice Boltzmann method to simulate the mixed convection heat transfer of air in a lid-driven cavity with an endothermic obstacle inside. Phys A Stat Mech Appl. 2018;508:681–701.

Khodadadi H, Toghraie D, Karimipour A. Effects of nanoparticles to present a statistical model for the viscosity of MgO-water nanofluid. Powder Technol. 2019;342:166–80.

Toghraie D, Karami A, Afrand M, Karimipour A. Effects of geometric parameters on the performance of solar chimney power plants. Energy. 2018;162:1052–61.

Akbari OA, Toghraie D, Karimipour A, Safaei MR, Goodarzi M, Alipour H, Dahari M. Investigation of rib’s height effect on heat transfer and flow parameters of laminar water Al2O3 nanofluid in a rib-microchannel. Appl Math Comput. 2016;290:135–53.

Afrand M, Toghraie D, Karimipour A, Wongwises S. A numerical study of natural convection in a vertical annulus filled with gallium in the presence of magnetic field. J Magn Magn Mater. 2017;430:22–8.

Akbari OA, Toghraie D, Karimipour A. Impact of ribs on flow parameters and laminar heat transfer of water-aluminum oxide nanofluid with different nanoparticle volume fractions in a three-dimensional rectangular microchannel. Adv Mech Eng. 2015;7(11):1–11.

Alimoradi A, Veysi F. Prediction of heat transfer coefficients of shell and coiled tube heat exchangers using numerical method and experimental validation. Int J Therm Sci. 2016;107:196–208.

Alimoradi A. Study of thermal effectiveness and its relation with NTU in shell and helically coiled tube heat exchangers. Case Stud Therm Eng. 2017;9:100–7.

Alimoradi A. Investigation of exergy efficiency in shell and helically coiled tube heat exchangers. Case Stud Therm Eng. 2017;10:1–8.

Milani Shirvan K, Ellahi R, Mirzakhanlari S, Mamourian M. Enhancement of heat transfer and heat exchanger effectiveness in a double pipe heat exchanger filled with porous media: numerical simulation and sensitivity analysis of turbulent fluid flow. Appl Therm Eng. 2016;109:761–74.

Mamourian M, Milani Shirvan K, Ellahib R, Rahimi AB. Optimization of mixed convection heat transfer with entropy generation in a wavy surface square lid-driven cavity by means of Taguchi approach. Int J Heat Mass Transf. 2016;102:544–54.

Arasteh H, Mashayekhi R, Toghraie D, Karimipour A, Bahiraei M, Rahbari A. Optimal arrangements of a heat sink partially filled with multilayered porous media employing hybrid nanofluid. J Therm Anal Calorim. 2019;137:1–14.

Miansari M, Valipour MA, Arasteh H, Toghraie D. Energy and exergy analysis and optimization of helically grooved shell and tube heat exchangers by using Taguchi experimental design. J Therm Anal Calorim. 2020;139:3151–64.

Tian Z, Arasteh H, Parsian A, Karimipour A, Safaei MR, Nguyen TK. Estimate the shear rate and apparent viscosity of multi-phased non-Newtonian hybrid nanofluids via new developed Support Vector Machine method coupled with sensitivity analysis. Phys A Stat Mech Appl. 2019;535:122456.

Arasteh H, Mashayekhi R, Goodarzi M, Motaharpour SH, Dahari M, Toghraie D. Heat and fluid flow analysis of metal foam embedded in a double-layered sinusoidal heat sink under local thermal non-equilibrium condition using nanofluid. J Therm Anal Calorim. 2019;138:1461–76.

Arasteh H, Salimpour MR, Tavakoli MR. Optimal distribution of metal foam inserts in a double-pipe heat exchanger. Int J Numer Method. 2019;29:1322–42.

Toghraie D, Mashayekhi R, Arasteh H, Sheykhi S, Niknejadi M, Chamkha AJ. Two-phase investigation of water-Al2O3 nanofluid in a micro concentric annulus under non-uniform heat flux boundary conditions. Int J Numer Method. 2019. https://doi.org/10.1108/hff-11-2018-0628.

Jamshidi N, Farhadi M, Ganji DD, Sedighi K. Experimental analysis of heat transfer enhancement in shell and helical tube heat exchangers. Appl Therm Eng. 2013;51(1–2):644–52.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Heydari, O., Miansari, M., Arasteh, H. et al. Optimizing the hydrothermal performance of helically corrugated coiled tube heat exchangers using Taguchi’s empirical method: energy and exergy analysis. J Therm Anal Calorim 145, 2741–2752 (2021). https://doi.org/10.1007/s10973-020-09808-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09808-3