Abstract

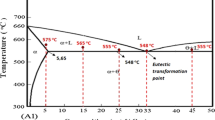

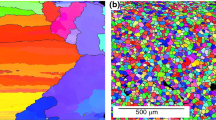

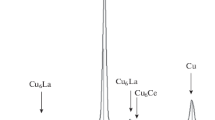

The present work investigates the influence of different Cu–Cr ratios on the solidification path and microstructure formation in as-cast hypoeutectic Al–(2.5, 3.5, 4.5)Cu alloys with additions of 0.25 and 0.50Cr (mass%). The alloys were prepared by melting pure aluminum, electrolytic copper, and pure chromium. Thermal analyses based on cooling curves were carried out to determine the solidification intervals and transformation temperatures of each alloy with low and moderate cooling conditions. Comparisons with data obtained from both differential thermal analyses (DTA) and simulations using the Thermo-Calc thermodynamics software were done. Samples were taken from the solidified ingots, and subjected to metallographic investigations (optical—OM and scanning electron—SEM microscopies), X-ray diffraction (XRD) analyses and Vickers microhardness (HV) measurements. Thermal analyses showed that the Liquidus and Solidus temperatures were practically unaffected by the range of cooling rates investigated in this work. Microstructural analyses revealed that Cr additions refined the microstructure when compared to the binary Al–Cu alloys. SEM with semi-quantitative EDS (energy-dispersive X-ray spectroscopy) analyses permitted to identify the presence of the CuAl2 intermetallic compound, AlCuCrFe precipitates, and some dispersed needle-like Al–Fe particles in all samples. The XRD analyses confirmed peaks of the α-Al (cubic, matrix) and CuAl2 (tetragonal, interdendritic) phases. Additional peaks were undetected due to the small contents of the investigated alloys. As the alloy Cu and Cr contents increased, microhardness values increased.

Similar content being viewed by others

References

Hatch JE. Aluminum properties and physical metallurgy. Ohio: ASM International; 1984.

Davis JR. Alloying: understanding the basics. Ohio: ASM International; 2001.

Školáková A, Novák P, Mejzlíková L, Průša F, Salvetr P, Vojtěch D. Structure and mechanical properties of Al–Cu–Fe–X alloys with excellent thermal stability. Materials. 2017;10(11):1269. https://doi.org/10.3390/ma10111269.

Kaufman JG, Rooy EL. Aluminum alloy castings: properties, processes, and applications. Ohio: ASM International; 2004.

Metals Handbook Desk Edition. 2nd ed. Ohio: ASM International; 1998.

Ribeiro TM, Catellan E, Garcia A, Santos CA. The effects of Cr addition on microstructure, hardness and tensile properties of as-cast Al–3.8 wt%Cu–(Cr) alloys. J Mater Res Technol. 2020;9(3):6620–31. https://doi.org/10.1016/j.jmrt.2020.04.054.

Ravikumar A, Sellamuthu R, Saravanan R. Effect of Cr addition on mechanical properties and wear rate of cast Al–Cu alloy. Indian J Sci Technol. 2016;9(34):1–7. https://doi.org/10.17485/ijst/2016/v9i34/100952.

Sugiyama K, Saito H, Hiraga K. On the crystal structures of the Al–Cu–Cr alloy system. J Alloys Compd. 2002;342(1–2):148–52. https://doi.org/10.1016/S0925-8388(02)00161-5.

Djurdjevic MB, Manasijevic S, Odanovic Z, Radisa R. Influence of different contents of Si and Cu on the solidification pathways of cast hypoeutectic Al–(5–9)Si–(1–4)Cu (wt%) alloys. Int J Mater Res. 2013;104(9):865–73. https://doi.org/10.3139/146.110940.

Costa AM, Costa CE, Vecchia FD, Ricka C, Scherer M, Santos CA, Dedavid BA. Study of the influence of copper and magnesium additions on the microstructure formation of Zn–Al hypoeutectic alloys. J Alloys Compd. 2009;448(1):89–99. https://doi.org/10.1016/j.jallcom.2009.08.125.

Jigajini SM, Venkateswarlu K, Kori SA. Computer aided cooling curve analysis for Al–5Si and Al–11Si alloys. Int J Eng Sci Technol. 2012;3(6):257–73. https://doi.org/10.4314/ijest.v3i6.21.

Farahany S, Ourdjini A, Idris MH, Shabestari SG. Computer-aided cooling curve thermal analysis of near eutectic Al–Si–Cu–Fe alloy. J Therm Anal Calorim. 2013;114(2):705–17. https://doi.org/10.1007/s10973-013-3005-7.

Ferreira IL, Garcia A. The application of numerical and analytical approaches for the determination of thermophysical properties of Al–Si–Cu–Mg alloys. Contin Mech Thermodyn. 2020;32:1231–44. https://doi.org/10.1007/s00161-019-00836-5.

Jung I-H, Van Ende M-A. Computational thermodynamic calculations: FactSage from CALPHAD thermodynamic database to virtual process simulation. Metall Mater Trans B. 2020;51:1851–74. https://doi.org/10.1007/s11663-020-01908-7.

Porás BR, França RP, Spim JA, Garcia A, Costa EM, Santos CA. The effects of dendritic arm spacings (as-cast) and aging time (solution heat-treated) of Al–Cu alloy on hardness. J Alloys Compd. 2013;549:324–35. https://doi.org/10.1016/j.jallcom.2012.09.041.

ASTM E 3-11. Standard guide for preparation of metallographic specimens. West Conshohocken: ASTM International; 2017.

ASTM E 407-07. Standard practice for microetching metals and alloys. West Conshohocken: ASTM International; 2015.

ASTM E 10-18. Standard test methods for Brinell hardness of metallic materials. West Conshohocken: ASTM International; 2018.

Zimmermann M, Carrard M, Kurz W. Rapid solidification of Al–Cu eutectic alloy by laser remelting. Acta Metall. 1989;37:3305–13. https://doi.org/10.1016/0001-6160(89)90203-4.

ASM Handbook. V. 3—alloy phase diagrams. 1st ed. Ohio: ASM International; 1992. p. 1741.

Ache CT, Lopes MM, Porás BR, Garcia A, Santos CA. Dendritic spacing/columnar grain diameter of Al–2Mg–Zn alloys affecting hardness, tensile properties, and dry sliding wear in the as-cast/heat-treated conditions. Adv Eng Mater. 2020;1901145:1–11. https://doi.org/10.1002/adem.201901145.

Grushko B, Przepiórzynski B, Pavlyuchkov D, Mi S, Kowalska-Strzęciwilk E, Surowiec M. Complex intermetallics in Al–Cu–Cr system. J Alloys Compd. 2007;442:114–6. https://doi.org/10.1016/j.jallcom.2006.12.154.

Grushko B. A contribution to the Al–Cu–Cr phase diagram. J Alloys Compd. 2017;729:426–37. https://doi.org/10.1016/j.jallcom.2017.09.116.

Liu B, Yuan XG, Huang HJ, Guo Z. The effect of alloying elements on the microstructure of Al–5Fe Alloys. JOM. 2012;64(2):316–22. https://doi.org/10.1007/s11837-012-0244-1.

Quaresma JMV, Santos CA, Garcia A. Correlation between unsteady-state solidification conditions, dendrite spacings, and mechanical properties of Al–Cu alloys. Metall Mater Trans A. 2000;31:3167–78. https://doi.org/10.1007/s11661-000-0096-0.

Talamantes-Silva MA, Rodríguez A, Talamantes-Silva J, Valtierra S, Colás R. Characterization of an Al–Cu cast alloy. Mater Charact. 2008;59:1434–9. https://doi.org/10.1016/j.matchar.2008.01.005.

Jaradeh M, Carlberg T. Differential thermal analysis and differential scanning calorimetry studies of aluminum 3003 alloys with Zn and Cu additions. Metall Mater Trans A. 2007;38A:2138–47. https://doi.org/10.1007/s11661-007-9251-1.

Aranda VA, Figueroa IA, González G, García-Hinolosa JA, Lara-Rodríguez GA. Effect of small additions of Cr, Ti, and Mn on the microstructure and hardness of Al–Si–Fe–X alloys. Metals. 2019;9(136):3–14. https://doi.org/10.3390/met9020136.

D’Elia F, Ravindran C, Sediako D, Donaberger R. Solidification analysis of Al–5 wt%Cu alloy using in situ neutron diffraction. Can Metall Q. 2014;54:9–15. https://doi.org/10.1179/1879139514Y.0000000158.

Mingqi Z, Yuan X, Zhihong J, Qing L, Xiaozhi W. Effects of heating rate on the hardness and microstructure of Al–Cu and Al–Cu–Zr–Ti–V alloys. J Alloys Compd. 2016;686:312–7. https://doi.org/10.1016/j.jallcom.2016.06.063.

Mandal PK, Robi PS. Influence of micro-alloying with silver on microstructure and mechanical properties of Al–Cu alloy. Mater Sci Eng A. 2018;722:99–111. https://doi.org/10.1016/j.msea.2018.03.012.

Webmineral [Internet]. David Barthelmy; Khatyrkite mineral data. http://webmineral.com/data/Khatyrkite.shtml (2014).

Acknowledgements

The authors acknowledge the support provided by National Council for Scientific and Technological Development (CNPq—Brazil): Grant No.: 403303/2016-8, Financiadora de Estudos e Projetos (FINEP—Brazil): Grant No.: 0082/16, Fundação de Amparo à Pesquisa do Rio Grande do Sul (FAPERGS—Brazil), and Pontifícia Universidade Católica do Rio Grande do Sul (PUCRS—Brazil). This study was also financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES—Brazil)—Finance Code 001.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design, material preparation, data collection and analysis. The first draft of the manuscript was written by DSGE and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Elesbão, D.S.G., Kakitani, R., Cheung, N. et al. Influence of Cu and Cr contents on the solidification path and microstructure formation of hypoeutectic as-cast Al–Cu–Cr alloys. J Therm Anal Calorim 148, 9403–9421 (2023). https://doi.org/10.1007/s10973-023-12346-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12346-3