Abstract

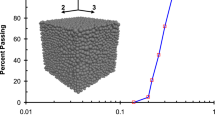

In this work, the approach for thermo-mechanical analysis of particulate composites having uniform, clustered and interpenetrating phase distribution of particles has been proposed. This study investigates the effects of convection cooling rate on the generated thermal residual stresses in metal matrix composites using a sequential coupled transient heat conduction analysis. FE simulations are conducted on 3D RVEs, and the predicted elastic modulus has been compared with the reported experimental values and also with the Mori–Tanaka and Double-inclusion models. In addition to the effective mechanical properties of composites, the thermal residual stresses are also computed by simulating the processing conditions of composites. We observed that for composites having high volume fraction of reinforcement and a high particle to matrix stiffness ratio (Ep/Em > 8), the Mori–Tanaka predictions are off the mark, while the double inclusion model shows good agreement with FE predictions. The interpenetration phase composites having 25% or more volume fraction result in enhanced effective properties. Our study reveals that the thermal residual stresses increase sharply as the molten metal changes its phase during transient cooling process. A high convection coefficient during composite cooling process results in substantially high thermal residual stresses.

Similar content being viewed by others

References

Aboudi J. Mechanics of composite materials, A unified micromechanical approach. Amsterdam: Elsevier; 1991.

Hori M, Nemat-Nasser S. On two micromechanics theories for determining micro–macro relations in heterogeneous solids. Mech Mater. 1999;31:667–82.

Sharma NK. Finite element modelling and simulations on effective thermal conductivity of particulate composites. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-021-10756-9.

Sharma NK, Misra RK, Sharma S. Finite element modeling of effective thermomechanical properties of Al–B4C metal matrix composites. J Mater Sci. 2017;52:1416–31.

Hashin Z, Shtrikman S. A variational approach to the theory of elastic behavior of multiphase materials. J Mech Phys Solids. 1963;11:127–40.

Benveniste Y. A new approach to the application of Mori–Tanaka’s theory in composite materials. Mech Mater. 1987;6(2):147–57.

Mori T, Tanaka K. Average stress in matrix and average elastic energy of materials with misfitting inclusions. Acta Metall. 1973;21(5):571–4.

Ashton JE, Halpin JC, Petit PH. Primer on composite materials: analysis. Stamford (Conn): Technomic Pub. Co.; 1969.

Halpin JC. Stiffness and expansion estimates for oriented short fiber composites. J Compos Mater. 1969;3(4):732–4.

Fornes TD, Paul DR. Modeling properties of nylon 6/clay nanocomposites using composite theories. Polymer. 2003;44(17):4993–5013.

Li X, Gao H, Scrivens WA, Fei D, Xu X, Sutton MA, et al. Reinforcing mechanisms of single-walled carbon nanotube-reinforced polymer composites. J Nano Sci Nano Technol. 2007;7(7):2309–17.

Luo J-J, Daniel IM. Characterization and modeling of mechanical behavior of polymer/clay nanocomposites. Compos Sci Technol. 2003;63(11):1607–16.

Sheng N, Boyce MC, Parks DM, Rutledge GC, Abes JI, Cohen RE. Multiscale micromechanical modeling of polymer/clay nanocomposites and the effective clay particle. Polymer. 2004;45(2):487–506.

Zeng QH, Yu AB, Lu GQ. Multiscale modeling and simulation of polymer nanocomposites. Prog Polym Sci. 2008;33(2):191–269.

Mortazavi B, Baniassadi M, Bardon J, Ahzi S. Modeling of two-phase random composite materials by finite element, Mori-Tanaka and strong contrast methods. Comp B. 2013;45:1117–25.

Sharma NK, Misra RK, Sharma S. Modeling of thermal expansion behavior of densely packed Al/SiC composites. Int J Sol Struc. 2016;102–103:77–88.

Sharma NK, Misra RK. Sharma Satpal, thermal expansion behavior of Ni–Al2O3 composites with particulate and interpenetrating phase structures: an analysis using finite element method. Comp Mater Sci. 2014;90:130–6.

Gudlur P, Muliana A, Radovic M. Effective thermo-mechanical properties of aluminum–alumina composites using numerical approach. Compos Part B. 2013;58:534–43.

Reid ACE, Lua RC, Garcia RE, Coffman VR, Langer SA. Modeling microstructures with OOF2. Int J Mater and Prod Tech. 2009;35:361–73.

Peng Z, Fuguo L. Effects of particle clustering on the flow behavior of SiC particle reinforced Al metal matrix composites. Rare Metal Mater Eng. 2010;39(9):1525–31.

Abedini A, Butcher C, Chen ZT. Numerical simulation of the influence of particle clustering on tensile behavior of particle-reinforced composites. Comput Mater Sci. 2013;73:15–23.

Yishi Su, Ouyang Q, Zhang W, Li Z, Guo Q, Fan G, Zhang Di. Composite structure modeling and mechanical behavior of particle reinforced metal matrix composites. Mater Sci Eng A. 2014;597:359–69.

Cheng F, Kim SM, Reddy JN, Rashid K, Al-Rub A. Modeling of elastoplastic behavior of stainless-steel/bronze interpenetrating phase composites with damage evolution. Int J Plast. 2014;61:94–111.

Bruck HA, Rabin BH. Evaluation of rule-of-mixtures predictions of thermal expansion in powder-processed Ni–Al2O3 composites. J Am Ceram Soc. 1999;82(10):2927–30.

Huber T, Degischer HP, Lefranc G, Schmitt T. Thermal expansion studies of aluminum-matrix composites with different reinforced architecture of SiC particles. Comp Sci Technol. 2006;66:2206–17.

Ma YE, Staron P, Fischer T, Irving PE. Size effects on residual stress and fatigue crack growth in friction stir welded 2195–T8 aluminium – Part I: experiments. Int J Fatigue. 2011;33(11):1417–25.

Schöbel M, Baumgartner G, Gerth S, Bernardi J, Hofmann M. Microstresses and crack formation in AlSi7MgCu and AlSi17Cu4 alloys for engine components. Acta Mater. 2014;81:401–8.

Zhang XX, Xiao BL, Andrä H, Ma ZY. Multiscale modeling of macroscopic and microscopic residual stresses in metal matrix composites using 3D realistic digital microstructure models. Compos Struct. 2016;137:18–32.

Moosbrugger C. Atlas of stress–strain curves. 2nd ed. Almere: ASM International; 2002.

Shen H, Lissenden CJ. 3D finite element analysis of particle-reinforced aluminium. Mater Sci Eng. 2002;338(1):271–81.

Khan KA, Barello R, Muliana HA, Lévesque M. Coupled heat conduction and thermal stress analyses in particulate composites. Mech Mater. 2011;43:608–25.

Zhao B, Ren Yi, Gao D, Lizhi Xu. Performance ratio prediction of photovoltaic pumping system based on grey clustering and second curvelet neural network. Energy. 2019;171:360–71.

Zhao B, Ren Yi, Gao D, Lizhi Xu, Zhang Y. Energy utilization efficiency evaluation model of refining unit based on contourlet neural network optimized by improved grey optimization algorithm. Energy. 2019;185:1032–44.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sharma, N.K. Thermo-mechanical analysis of uniform, clustered and interpenetrating phase particulate composites using finite element method. J Therm Anal Calorim 148, 5967–5984 (2023). https://doi.org/10.1007/s10973-023-12157-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-023-12157-6