Abstract

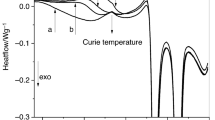

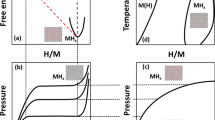

The search for any correlation between the iso-kinetic relationship (IKR) and the Meyer–Neldel rule (also known as the compensation effect) is a key problem in the area of physics, chemistry, and physical chemistry. The iso-kinetic relationship (IKR) and the Meyer–Neldel compensation rule (MNCR) seem to be valid for a diversified range of materials, but the true understanding of what is the exact connection between IKR and MNCR is still an unresolved puzzle. Various researchers believed that both effects be two sides of the same coin. The iso-conversion study of solid-state reactions using non-isothermal calorimetric measurements is famous over the globe in the scientific community. It is a standard noteworthy tool to attain qualitative and quantitative analysis of the consequences of the different kinds of solid-state reactions. This endeavor aims to explore some novel insights in MNCR and its connection with IKR by considering thermally activated crystallization. For this, we have started our analysis by using JMA theory and scrutinized the relationship between Arrhenius parameters (crystallization activation energy and rate of crystal growth) for the different situations using the iso-conversional thermal analysis. Further, our results confirm the analogy between MNCR and IKR by comparing the Meyer–Neldel and iso-kinetic temperatures for thermally controlled crystallization that follows an Arrhenius temperature dependence.

Similar content being viewed by others

References

Yan QL, Zeman S, Zhang JG, Qi XF, Li T, Musil T. Multistep thermolysis mechanisms of azido-s-triazine derivatives and kinetic compensation effects for the rate-limiting processes. J Phys Chem C. 2015;119:14861–72.

Kim BJ, Yu H, Oh JH, Kang MS, Cho JH. Electrical transport through single nanowires of dialkyl perylene diimide. J Phys Chem C. 2013;117:10743–9.

Naffakh M, Marco C, Gomez MA, Jimenez I. Unique nucleation activity of inorganic fullerene-like WS2 nanoparticles in polyphenylene sulfide nanocomposites: isokinetic and isoconversional study of dynamic crystallization kinetics. J Phys Chem B. 2009;113:7107–15.

Freed KF. Entropy−enthalpy compensation in chemical reactions and adsorption: an exactly solvable model. J Phys Chem B. 2011;115:1689–92.

Morishita T, Nakamura T, Shinoda W, Ito AM. Isokinetic approach in logarithmic mean-force dynamics for on-the-fly free energy reconstruction. Chem Phys Lett. 2018;706:633–40.

Vyazovkin S, Linert W. The application of isoconversional methods for analyzing isokinetic relationships occurring at thermal decomposition of solids. J Solid State Chem. 1995;114:392–8.

Belskii VE. Isokinetic relationships for nucleophilic substitution reactions at the saturated carbon atom Reactions in aqueous solutions. Russ Chem Bull. 2000;49:806–11.

Rego F, Dias APS, Casquilho M, Rosa FC, Rodrigues A. Pyrolysis kinetics of short rotation coppice poplar biomass. Energy. 2020;207:118191.

Lyon RE. Isokinetic analysis of reaction onsets. Thermochim Acta. 2022;708:179117.

Lyon RE. Isokinetics. J Phys Chem A. 2019;123:2462–9.

Starikov EB. “Meyer–Neldel Rule”: true history of its development and its intimate connection to classical thermodynamics. J App Sol Chem Mod. 2014;3:15–31.

Sedivy L, Belas E, Grill R, Musiienko A, Vasylchenko I. Extension of Meyer–Neldel rule using chemical diffusion experiments in CdTe. J Alloys Comp. 2019;788:897–904.

Shcherbak L, Kopach O, Fochuk P, Bolotnikov AE, James RB. Empirical correlations between the Arrhenius parameters of impurities diffusion coefficients in CdTe crystals. J Phase Equilibria Diffusion. 2015;36:99–109.

Kotomin E, Kuzovkov V, Popov AI, Maier J, Vila R. Anomalous kinetics of diffusion-controlled defect annealing in irradiated ionic solids. J Phys Chem A. 2018;122:28–32.

Fishchuk II, Bassler H, Kohler A, Genoe J, Kadashchuk A. Unraveling the role of multiphonon excitations and disorder concerning the Meyer–Neldel type compensation effect in organic semiconductors. Phys Rev Appl. 2018;10:054063.

He Q, Xu X, Gu Y, Cheng X, Xu J, Jiang Y. Single-walled carbon nanotube-controlled Meyer−Neldel rules in vanadium oxide films for applications as thermistor materials in sensors and detectors. ACS Appl Nano Mater. 2018;1:6959–66.

Krongauz VV. Compensation effect: sublimation, diffusion in polymers, polymer degradation. J Therm Anal Calorim. 2019;138:3425–44.

Sapunov VN, Saveljev EA, Voronov MS, Valtiner M, Linert W. The basic theorem of temperature-dependent processes. Thermo. 2021;1:45–60.

Ullah M, Pivrikas A, Fishchuk II, Kadashchuk A, Stadler P, Simbrunner C, Sariciftci NS, Sittera H. Electric field and grain size dependence of Meyer–Neldel energy in C60 films. Synth Met. 2011;161:1987–90.

Jones AG. Compensation of the Meyer–Neldel compensation law for H diffusion in minerals. Geochem Geophys Geosys. 2014;15:2616–31.

Polfus JM, Peters T, Bredesena R, Lovvik OM. Vacancy diffusion in palladium hydrides. Phys Chem Chem Phys. 2021;23:13680–6.

Seguini G, Zanenga F, Cannetti G, Perego M. Thermodynamics and ordering kinetics in asymmetric PS-b-PMMA block copolymer thin films. Soft Matter. 2020;16:5525–33.

Mianowski A, Radko T, Siudyga T. Kinetic compensation effect of isoconversional methods. Reac Kinet Mech Cat. 2021;132:37–58.

Taskesen T, Pareek D, Neerken J, Schoneberg J, Hirwa H, Nowak D, Parisi J, Gutay L. The effect of excess selenium on the opto-electronic properties of Cu2ZnSnSe4 prepared from Cu–Sn alloy precursors. RSC Adv. 2019;9:20857–64.

He H, Liu Y, Yin J, Wang X, Lin X, Zhang S. Introducing effective temperature into Arrhenius equation with Meyer–Neldel rule for describing both Arrhenius and non-Arrhenius dependent drain current of amorphous InGaZnO TFTs. Solid-State Elect. 2021;181:108011.

Muy S, Bachman J, Chang HH, Giordano L, Maglia F, Lupart S, Lamp P, Zeier WG, Shao-horn Y. Lithium conductivity and Meyer–Neldel Rule in Li3PO4-Li3VO4-Li4GeO4 lithium superionic conductors. Chem Mater. 2018;30:5573–82.

Han Z, Wang M. Analysis of the Meyer–Neldel rule based on a temperature-dependent model for thin-film transistors. IEEE Trans Electron Devices. 2017;64:145–52.

Stallinga P, Gomes HL. Trap states as an explanation for the Meyer Neldel rule in semiconductors. Org Elect. 2005;6:137141.

Wang J, Yellezuome D, Zhang Z, Liu S, Lu J, Zhang P, Zhang S, Wen P, Rahman MM, Li C, Cai J. Understanding pyrolysis mechanisms of pinewood sawdust and sugarcane bagasse from kinetics and thermodynamics. Ind Crops Prod. 2022;177:114378.

Hudson EA, Campos de Paula HM, Coelho Y, Glanzmann N, da Silva AD, da Silva LHM, Cla A. The kinetics of formation of resveratrol-β-cyclodextrin-NH2 and resveratrol analog-β-cyclodextrin-NH2 supramolecular complexes. Food Chem. 2022;366:130612.

Liu L, Guo QX. Isokinetic relationship, isoequilibrium relationship, and enthalpy-entropy compensation. Chem Rev. 2001;101:673–95.

Du P, Li P, Ling X, Fan Z, Braun A, Yang W, Chen Q, Yelon A. Optimizing the proton conductivity with the isokinetic temperature in perovskite-type proton conductors according to Meyer–Neldel rule. Adv Energy Mater. 2022;12:2102939.

Gao Y, Li N, Wu Y, Yang W. Rethinking the design of ionic conductors using Meyer-Neldel-conductivity plot. Adv Energy Mater. 2021;11:2100325.

Borisenko KB, Shanmugam J, Williams BAO, Ewart P, Gholipour B, Hewak DW, Hussain R, Javorfi T, Siligardi G, Kirkland AI. Photo-induced optical activity in phase-change memory materials. Sci Rep. 2015;5:8770.

Hamann H, O’Boyle M, Martin YC, Rooks M, Wickramasinghe HK. Ultra-high density phase-change storage and memory. Nature Mater. 2006;5:383–7.

Hegedus J, Elliot SR. Microscopic origin of the fast crystallization ability of Ge-Sb-Te phase-change memory materials. Nature Mater. 2008;7:399–405.

Wuttig M, Yamada N. Phase-change materials for rewriteable data storage. Nature Mat. 2007;6:824–32.

Zhang W, Mazzarello R, Wuttig M, Ma E. Designing crystallization in phase-change materials for universal memory and neuro-inspired computing. Nat Rev Mater. 2019;4:150–68.

Orava J, Greer A, Gholipour B, Hewak DW, Smith CE. Characterization of supercooled liquid Ge2Sb2Te5 and its crystallization by ultrafast-heating calorimetry. Nature Mater. 2012;11:279–83.

Perez-Maqueda LA, Criado JM, Malek J. Combined kinetic analysis for crystallization kinetics of non-crystalline solids. J Non-Cryst Solids. 2003;320:84–91.

Bennett T, Yue Y, Li P, Qiao A, Tao H, Greaves NG, Richards T, Lampronti GI, Redfern SAT, Blanc F, Farha O, Hupp J, Cheetham A, Keen D. Melt-quenched glasses of metal-organic frameworks. J Am Chem Soc. 2016;138:3484–92.

Qiao C, Guo YR, Dong F, Wang J, Shen H, Wang S, Xu M, Miao X, Zheng Y, Zhang R, Chen L, Wang C, Ho K. Evolution of short and medium-range order in the melt-quenching amorphization of Ge2Sb2Te5. J Mater Chem C. 2018;6:5001–11.

Brand MC, Greenwell F, Clowes R, Egleston BD, Kai A, Cooper A, Bennett T, Greenaway RL. Melt-quenched porous organic cage glasses. J Mater Chem A. 2021;9:19807–16.

Mehta N. Characterization techniques for the study of thermally activated phase Transitions and determination of thermo-physical/kinetic properties. In: Pekar Libor, editor. Advanced analytic and control techniques for thermal systems with heat exchangers. Elsevier; 2020.

Greer A. New horizons for glass formation and stability. Nature Mater. 2015;14:542–6.

Rios C, Stegmaier M, Hosseini P, Wang D, Scherer T, Wright CD, Bhaskaran H, Pernice WHP. Integrated all-photonic non-volatile multi-level memory. Nature Photon. 2015;9:725–2.

Ding K, Chen B, Chen Y, Wang J, Shen X, Rao F. Recipe for ultrafast and persistent phase-change memory materials. NPG Asia Mater. 2020;12:63.

Simon AA, Badamchi B, Subbaraman H, Sakaguchi Y, Jones L, Kunold H, Rooyen IJV, Mitkova M. Introduction of chalcogenide glasses to additive manufacturing: Nanoparticle ink formulation, inkjet printing, and phase change devices fabrication. Sci Rep. 2021;11:14311.

Dohare C, Mehta N. Iso-conversional approach for study of glass transition and crystallization kinetics of ternary glassy Se98−xAg2Inx (x = 0, 2, 4, 6) system. J Alloys Compd. 2014;587:565–72.

Kumar M, Shukla SK, Upadhyaya SN, Mishra PK. Analysis of thermal degradation of banana (Musa balbisiana) trunk biomass waste using iso-conversional models. Bioresour Technol. 2020;310:123393.

Wang Z, Zhang J, Zhao B, Fu H, Pang J. Effect of pore characteristics on hydrogen reduction kinetics based on a novel analysis approach combined model-fitting and iso-conversion. Int J Hydrog Energy. 2021;46:23164–73.

Arrhenius S. About the rate of reaction in the inversion of cane sugar by acids. Z Phys Chem. 1889;4:226–48.

Arrhenius SA. About the dissociation of water dissolved substances. Z Physik Chem. 1887;1:631–48.

Petrou A, Roulia M, Tampouris K. The use of the Arrhenius equation in the study of deterioration and of cooking of foods: some scientific and pedagogic aspects. Chem Educ Res Pract. 2002;3:87–97.

Samsudin H, Auras R, Burgess G, Dolan K, Soto-Valdez H. Migration of antioxidants from polylactic acid films, a parameter estimation approach: reparameterization of the Arrhenius equation. Food Control. 2020;113:107208.

Yan G, Crivoi A, Sun Y, Maharjan N, Song X, Li F, Tan M. An Arrhenius equation-based model to predict the residual stress relief of post weld heat treatment of Ti-6Al-4V plate. J Manufact Proc. 2018;32:763–72.

Jung D, Kruse A. Evaluation of Arrhenius-type overall kinetic equations for hydrothermal carbonization. J Anal Appl Pyroly. 2017;127:286–91.

Abdel-Hay M, Ragab MAA, Ahmed H, Mohyeldin SM. The use of Arrhenius kinetics to evaluate different hydrolytic stability of amiloride hydrochloride and cyclopenthiazide using chromatographic methods. Microchem J. 2019;147:682–90.

Meijer E, Rep DBA, Leeuw DM, Matters M, Herwig P, Klapwijk T. The isokinetic temperature in disordered organic semiconductors. Synth Met. 2001;121:1351–2.

Rooney JJ. Isokinetic temperature and the compensation effect in catalysis. J Mol Cataly A: Chem. 1998;133:303–5.

Czochara R, Kusio J, Litwinienko G. Fullerene C60 conjugated with phenols as new hybrid antioxidants to improve the oxidative stability of polymers at elevated temperatures. RSC Adv. 2017;7:44021–5.

Mianowski A, Radko T. Analysis of isokinetic effect by means of temperature criterion in coal pyrolysis. Pol J Appl Chem. 1994;38:395–405.

Lai VMF, Lii C, Huang WL, Lu TJ. Kinetic compensation effect in depolymerisation of food polysaccharides. Food Chem. 2000;68:319–25.

Zhang Z, Duan H, Zhang Y, Guo X, Yu X, Zhang X, Rahman MM, Cai J. Investigation of kinetic compensation effect in lignocellulosic biomass torrefaction: Kinetic and thermodynamic analyses. Energy. 2020;207:118290.

Drusedau T, Bindemann R. The Meyer- Neldel rule and the fundamental pre-exponential factor in the conductivity of a-Si:H. Phys Stat Sol B. 1986;136:61–4.

Wang JC, Chen YF. The Meyer–Neldel rule in fullerenes. Appl Phys Lett. 1998;73:948–50.

Pal RK, Agnihotri AK, Dwivedi PK, Kumar A. Further Meyer–Neldel rule in a-Se70Te30-xZnx thin films. J Ovon Res. 2009;5:135–44.

Anjali W, Patial BS, Thakur N. On the study of “further Meyer-Neldel Rule” in thermally activated high field conduction of Se-Te-Pb glassy alloys. J Elect Mater. 2022;51:1089–96.

Acknowledgements

Neeraj Mehta is thankful to his university for providing an incentive under IoE scheme (Dev. Scheme No. 6031) of UGC, New Delhi, India.

Author information

Authors and Affiliations

Contributions

SKP was involved in synthesis bulk samples; DSC measurements. NM helped in writing—original draft, writing—review & editing.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pal, S.K., Mehta, N. Some novel perspectives of iso-conversional analysis in the study of Meyer–Neldel energy for thermally governed crystallization by using Johnson–Mehl–Avrami (JMA) theory. J Therm Anal Calorim 148, 883–895 (2023). https://doi.org/10.1007/s10973-022-11836-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11836-0