Abstract

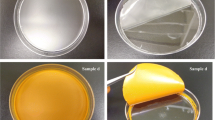

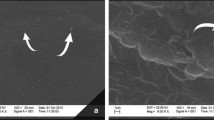

Loquat (Eriobotrya japonica Lindl) seed starch (KS)-based films obtained via casting were developed using glycerol and sorbitol as plasticizers. Higher purity starch was achieved using the alkaline steeping method. The starch characterization involved proximal composition, thermal, structural, morphological and antioxidant analyses in order to assess its impact on the film properties. Film performance was evaluated in water vapor permeability (WVP), microstructure, physical properties, antioxidant activity, opacity and solubility. KS exhibited a high yield (24%), amylose (33.61%) and phenolics compared to non-conventional starches, indicating appreciable antioxidant capacity. Film solubility and WVP were affected by the plasticizers. Alkaline starch film (KSF) plasticized with sorbitol was strong and rigid, little soluble and less permeable compared to KSF plasticized with glycerol. Therefore, while all KSF films appear as a potential material for active food packaging, and due to their antioxidant properties, KS presents itself as a highly promising starch source for application in films.

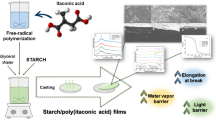

Graphical abstract

Similar content being viewed by others

References

Geyer R, Jambeck JR, Law KL. Production, use, and fate of all plastics ever made - Supplementary Information. Sci Adv. 2017;3(7):19–24. https://doi.org/10.1126/sciadv.1700782.

ASTM Standard D6954–18 (2018). Standard Guide for Exposing and Testing Plastics that Degrade in the Environment by a Combination of Oxidation and Biodegradation. Annual book of ASTM Standards. ASTM International, West Conshohocken, PA, 2018.

Alcázar-alay SC, Angela M, Meireles A. Physicochemical properties, modifications and application of starches from different botanical sources. Food Sci Technol. 2015;35(2):215–36. https://doi.org/10.1590/1678-457X.6749.

Galus S, Kibar EAA, Gniewosz M, Kraśniewska K. Novel materials in the preparation of edible films and coatings - a review. Coatings. 2020;10(7):1–14. https://doi.org/10.3390/coatings10070674.

Han JH. Edible Films and Coatings: A Review. In Innovations in Food Packaging: Second Edition. 2020; Elsevier Ltd. https://doi.org/10.1016/B978-0-12-394601-0.00009-6

Maniglia BC, Tessaro L, Ramos AP, Tapia-Blácido DR. Which plasticizer is suitable for films based on babassu starch isolated by different methods? Food Hydrocoll. 2018;2019(89):143–52. https://doi.org/10.1016/j.foodhyd.2018.10.038.

Costa BP, Carpiné D, Alves FESB, Barbi RT, Ikeda M, Melo AM, Ribani RH. Thermal, structural, morphological and bioactive characterization of acid and neutral modified loquat (Eriobotrya japonica Lindl.) seed starch and its by-products. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-021-10965-2.

Juliano BO. (2015). Relation of Starch Composition , Protein Content , and Gelatinization Temperature to Cooking and Eating Qualities of Milled Rice. January 1965.

Hoover R. The impact of heat-moisture treatment on molecular structures and properties of starches isolated from different botanical sources. Crit Rev Food Sci Nutr. 2010;50(9):835–47. https://doi.org/10.1080/10408390903001735.

Abbas KA, Khalil KS, Hussin MAS. Modified starches and their usages in selected food products: a review Study. J Agric Sci. 2014. https://doi.org/10.5539/jas.v2n2p90.

Haq F, Yu H, Wang L, Teng L, Haroon M, Khan RU, Mehmood S, Bilal-Ul-Amin, Ullah RS, Khan A, Nazir A. Advances in chemical modifications of starches and their applications. Carbohydr Res. 2019;476:12–35. https://doi.org/10.1016/j.carres.2019.02.007.

Buffo RA, Han JH. Edible films and coatings from plant origin proteins. Innov Food Packag. 2015. https://doi.org/10.1016/B978-012311632-1/50049-8.

Dangaran K, Tomasula PM, Qi P. Edible films and coatings for food applications. In Edible Films and Coatings for Food Applications. 2009; https://doi.org/10.1007/978-0-387-92824-1

Gheribi R, Puchot L, Verge P, Jaoued-Grayaa N, Mezni M, Habibi Y, Khwaldia K. Development of plasticized edible films from Opuntia ficus-indica mucilage: a comparative study of various polyol plasticizers. Carbohydr Polym. 2018;190:204–11. https://doi.org/10.1016/j.carbpol.2018.02.085.

Guo K, Lin L, Fan X, Zhang L, Wei C. Comparison of structural and functional properties of starches from five fruit kernels. Food Chem. 2018;257:75–82. https://doi.org/10.1016/j.foodchem.2018.03.004.

Lopes MMA, Sanches AG, de Souza KO, Silva EO. Loquat/Nispero Eriobotrya japonica Lindl. Exot Fruits. 2018. https://doi.org/10.1016/b978-0-12-803138-4.00037-x.

Barbi TR, Teixeira GL, Hornung PS, Ávila S, Ribani RH. Eriobotrya japonica seed as a new source of starch: assessment of phenolic compounds, antioxidant activity, thermal, rheological and morphological properties. Food Hydrocoll. 2018;77:646–58. https://doi.org/10.1016/j.foodhyd.2017.11.006.

AOAC. American association of official analytical chemists. Official methods of analysis of the American association of official analytical chemists. 17th ed. USA: Gaithersburg; 2000.

Martínez C, Cuevas F. Evaluación de la calidad culinaria y molinera del arroz. Centro Int Agric Trop (CIAT). 1989. https://doi.org/10.1017/CBO9781107415324.004.

Hunterlab. (1997). The color management company. Universal software. Version 3.2. Reston.

Cai YZ, Corke H. Production and properties of 2,3-butanediol. J Sens Nutr Qual food. 2000;65(3600):1248–52.

Cano-Chauca M, Stringheta PC, Ramos AM, Cal-Vidal. Effect of the carriers on the microstructure of mango powder obtained by spray drying and its functional characterization. Innov Food Sci Emerg Technol. 2005;6:420–8.

Fuchs M, Turchiuli C, Bohin M, Cuvelier ME, Ordonnaud C, Peyrat-Maillard MN. Encapsulation of oil in powder using spray drying and fluidized bed agglomeration. J Food Eng. 2006;75(1):27–35.

Ikeda M, de Melo AM, Costa BP, Barbi RT, Ribani RH. Nutritional and bioactive composition of achachairu (Garcinia humilis) seed flour: A potential ingredient at three stages of ripening, LWT; 2021; (152), 112251, ISSN 0023–6438, https://doi.org/10.1016/j.lwt.2021.112251.

ASTM Standard D2457–13 (2013). Standard test method for specular gloss of plastic films and solid plastics. Annual book of ASTM Standards. ASTM International, West Conshohocken, PA, 2013.

ASTM Standard D6988–13 (2013). Standard guide for determination of thickness os plastic film test specimens. Annual book of ASTM Standards. ASTM International, West Conshohocken, PA, 2013.

Zahedi Y, Ghanbarzadeh B, Sedaghat N. Physical properties of edible emulsified films based on pistachio globulin protein and fatty acids. J Food Eng. 2010;100(1):102–8. https://doi.org/10.1016/j.jfoodeng.2010.03.033.

ASTM Standard D543–20 (2020). Standard Practices for Evaluating the Resistance of Plastics to Chemical Reagents. Annual book of ASTM Standards. ASTM International, West Conshohocken, PA, 2020.

ASTM Standard E96/E96M (2013). Standard test methods for water vapor transmission of materials. Annual book of ASTM Standards. ASTM International, West Conshohocken, PA, 2013.

Laureanti EJG, Paiva TS, Tasso IS, Dallabona ID, Helm CV, Jorge LMM, Jorge RMM. Development of active cassava starch films reinforced with waste from industrial wine production and enriched with pink pepper extract. J Appl Polym Sci. 2021. https://doi.org/10.1002/app/50922.

Benzie I, Strain J. the ferric reducing ability of plasma(FRAP)as a measure of “Antioxidan power”:the FRAP assay analytical biochemistry. Anal Biochem. 1996;239:70–6.

Brand-Williams W, Cuvelier ME, Berset C. Respostas perceptivas E. LWT Food Sci Technol. 1995;28(1):25–30. https://doi.org/10.1016/S0023-6438(95)80008-5.

Re R, Pellegrini N, Protegente A, Pannala A, Yang M, Rice-Evans C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radical Biol Med. 1999;26:1231–7.

Singleton VL, Orthofer R, Lamuela-Raventós RM. Analysis of total phenols and other oxidation substrates and antioxidants by means of folin-ciocalteu reagent. Methods Enzymol. 1998;299:152–78. https://doi.org/10.1016/S0076-6879(99)99017-1.

Brazil. Agência Nacional de Vigilância Sanitária – RDC 263 de 22 de setembro de 2005. Regulamento Técnico Para Produtos de Cereais, Amidos, Farinhas e Farelos.

Nogueira GF, Fakhouri FM, Oliveira RA. Extraction and characterization of arrowroot (Maranta arundinaceae L) starch and its application in edible films. Carbohydr Polym. 2018;186:64–72. https://doi.org/10.1016/j.carbpol.2018.01.024.

Galindez A, Daza LD, Homez-Jara A, Eim VS, Váquiro HA. Characterization of ulluco starch and its potential for use in edible films prepared at low drying temperature. Carbohydr Polym. 2019;215:143–50. https://doi.org/10.1016/j.carbpol.2019.03.074.

Ojo MO, Ariahu CC, Chinma EC. Proximate, functional and pasting properties of cassava starch and mushroom (Pleurotus Pulmonarius) flour blends. Am J Food Sci Technol. 2016;5(1):11–8. https://doi.org/10.12691/AJFST-5-1-3.

Tian SJ, Rickard JE, Blanshard JMV. Physicochemical properties of sweet potato starch. J Sci Food Agric. 1991;57(4):459–91. https://doi.org/10.1002/jsfa.2740570402.

Gordillo SCA, Valencia AG, Zapata VRA, Henao AAC. Physicochemical characterization of arrowroot starch (Maranta arundinacea Linn) and glycerol/arrowroot starch membranes. Int J Food Eng. 2014;10(4):727–35. https://doi.org/10.1515/ijfe-2014-0122.

de Castro DS, Moreira SI, Silva MLM, Lima JP, da Silva WP, Gomes JP, de Figueirêdo RMF. Isolation and characterization of starch from pitomba endocarp. Food Res Int. 2018. https://doi.org/10.1016/j.foodres.2018.06.032.

Correia PR, Beirão-Da-Costa ML. Chestnut and acorn starch properties affected by isolation methods. Starch/Staerke. 2010;62(8):421–8. https://doi.org/10.1002/star.201000003.

Gonçalves PM, Noreña CPZ, Silveira NP, Brandelli A. Characterization of starch nanoparticles obtained from Araucaria angustifolia seeds by acid hydrolysis and ultrasound. LWT. 2014;58(1):21–7. https://doi.org/10.1016/j.lwt.2014.03.015.

Denardin CC, Silva LP. Estrutura dos grânulos de amido e sua relação com propriedades físico-químicas. Ciência Rural. 2009;39(3):945–54. https://doi.org/10.1590/s0103-84782009005000003.

Hoover R. Composition, molecular structure, and physicochemical properties of tuber and root starches: a review. CarbohydR Polym. 2001;45(3):253–67. https://doi.org/10.1016/S0144-8617(00)00260-5.

Maniglia BC, Tapia-Blácido DR. Isolation and characterization of starch from babassu mesocarp. Food Hydrocoll. 2016. https://doi.org/10.1016/j.foodhyd.2015.11.001.

Silveira Hornung P, Ávila S, Apea-Bah FB. Sustainable use of Ilex paraguariensis waste in improving biodegradable corn starch films’ mechanical, thermal and bioactive properties. J Polym Environ. 2020;28:1696–709. https://doi.org/10.1007/s10924-020-01723-w.

Corradini A, Elisângela I. Composição química, propriedades mecânicas e térmicas da fibra de frutos de cultivares de coco verde. Rev Bras Frutic [online]. 2009;31(3):837–46. https://doi.org/10.1590/S0100-29452009000300030.

Micić DM, Ostojić SB, Simonović MB, Pezo BL, Simonović BR. Thermal behavior of raspberry and blackberry seed flours and oils. Thermochim Acta. 2015;617:21–7. https://doi.org/10.1016/j.tca.2015.08.017.

Zhu F, Wang S. Physicochemical properties, molecular structure, and uses of sweetpotato starch. Trends Food Sci Technol. 2014;36(2):68–78. https://doi.org/10.1016/j.tifs.2014.01.008.

Thomaz L, Ito VC, Malucelli LC, da Silva MACF, Demiate IM, Bet CD, Lacerda LG. Effects of dual modification on thermal, structural and pasting properties of taro (Colocasia esculenta L) starch. J Therm Anal Calorim. 2019;139:3123–32.

Bisinella RZB, Beninca C, Bet CD, Oliveira CS, Demiate IM, Schnitzler E. Thermal, structural, and morphological characterization of organic rice starch after physical treatment. J Therm Anal Calorim. 2021;1:1–9.

Iturriaga L, Lopez B, Añon M. Thermal and physicochemical characterization of seven argentine rice flours and starches. Food Res Int. 2004;37–5:439–47. https://doi.org/10.1016/j.foodres.2003.12.005.

Kong X, Bao J, Corke H. Physical properties of Amaranthus starch. Food Chem. 2009;113:371–6.

Villarreal ME, Ribotta PD, Iturriaga LB. Comparing methods for extracting Amaranthus starch and the properties of the isolated starches. LWT Food Sci Technol. 2013;51:441–7.

Hong J, Li L, Li C, Liu C, Zheng X, Bian K. Effect of heat-moisture treatment on physicochemical, thermal, morphological, and structural properties of mechanically activated large a- and small B-wheat starch granules. J Food Sci. 2019;84(10):2795–804. https://doi.org/10.1111/1750-3841.14745.

Nogueira GF, Soares CT, Cavasini R, Fakhouri FM, de Oliveira RA. Bioactive films of arrowroot starch and blackberry pulp: physical, mechanical and barrier properties and stability to pH and sterilization. Food Chem. 2019;275(2019):417–25. https://doi.org/10.1016/j.foodchem.2018.09.054.

Miller K, Silcher C, Lindner M, Schmid M. Effects of glycerol and sorbitol on optical, mechanical, and gas barrier properties of potato peel-based films. Packag Technol Sci. 2020;34(1):11–23. https://doi.org/10.1002/pts.2536.

Ma S, Zheng Y, Zhou R, Ma M. Characterization of chitosan films incorporated with different substances of konjac glucomannan, cassava starch, maltodextrin and gelatin, and application in mongolian cheese packaging. Coatings. 2021;11(1):84. https://doi.org/10.3390/coatings11010084.

Sanyang ML, Sapuan SM, Jawaid M, Ishak MR., Sahari J. Effect of glycerol and sorbitol plasticizers on physical and thermal properties of sugar palm starch based films. Recent Advances in Environment, Ecosystems and Development Effect. 13Th International Conference on Environment, Ecosystems, and Development (EED ’15), Kuala Lumpur, Malaysia; 2015. p. 157–162.

Lusiana SW, Putri D, Nurazizah IZ, Bahruddin. Bioplastic properties of Sago-PVA starch with glycerol and sorbitol plasticizers. J Phys Conf Ser. 2019. https://doi.org/10.1088/1742-6596/1351/1/012102.

Sothornvit R, Krochta JM. Plasticizers in edible films and coatings. Innov Food Packag. 2005. https://doi.org/10.1016/B978-012311632-1/50055-3.

Sogut E, Cakmak H. Utilization of carrot (Daucus carota L.) fiber as filler for chitosan based filmes Food Hydrocolloids, 2020; 106, 105861

de Carvalho GR, Marques GS, Jorge MLM, Jorge RMM. Journal of Applied Polymers Science, 2019; 136, 1

Remor Lopes A, Dragunski DC, Júnior LFB, Francisco CB. Caetano J. Revista Brasileira de Agropecuária Sustentável 2018, 8.

Basiak E, Lenart A, Debeaufort F. Effects of carbohydrate/protein ratio on the microstructure and the barrier and sorption properties of wheat starch–whey protein blend edible films. J Sci Food Agric. 2017;97(3):858–67. https://doi.org/10.1002/jsfa.7807.

Beigzadeh Ghelejlu S, Esmaiili M, Almasi H. Chracterization of chitosan-nanoclay bionanocomposity active filmes containing milk thistly. Int J Biol Macromol. 2016;86:613.

Qin Y, Liu Y, Yuan L, Yong H, Liu J. Preparation and characterization of antioxidant, antimicrobial and pH-sensitive films based on chitosan, silver nanoparticles and purple corn extract. Food Hydrocoll. 2019. https://doi.org/10.1016/j.foodhyd.2019.05.017.

Treenate P, Monvisade P, Yamaguchi M. The effect of glycerol/water and sorbitol/water on the plasticization of hydroxyethylacryl chitosan/sodium alginate films. MATEC Web of Conf. 2015. https://doi.org/10.1051/matecconf/20153002006.

Jangchud A, Chinnan MS. Properties of peanut protein film: sorption isotherm and plasticizer effect. LWT Food Sci Technol. 1999;32(2):89–94. https://doi.org/10.1006/fstl.1998.0498.

Guilbert S, Cuq B, Gontard N. Recent innovation in edible and/or biodegradable packaging materials. Food Addit Contam. 1997;14:741.

ASTM Standard D6400–21 (2021). Standard Guide for Exposing and Testing Plastics that Degrade in the Environment by a Combination of Oxidation and Biodegradation. Annual book of ASTM Standards. ASTM International, West Conshohocken, PA, 2018.

Brown WE. Plastics in Food Packaging: Properties, Design and Fabrication; Marcel Dekker Inc, Ed.; New York, 1992.

Piñeros-Hernandez D, Medina-Jaramillo C, López-Córdoba A, Goyanes S. Edible cassava starch filmes carrying rosemary antioxidant extracts for potential use as active food packaging. Food Hydrocoll. 2017;63:488.

Alqahtani N, Alnemr T, Ali S. Development of low-cost biodegradable films from corn starch and date palm pits (Phoenix dactylifera). Food Biosci. 2021;42: 101199. https://doi.org/10.1016/j.fbio.2021.101199.

Waterschoot J, Goman SV, Fierens E, Delcour JA. Production, structure, physicochemical and functional properties of maize, cassava, wheat, potato and rice starches. Starch/Staerke. 2015;67(1–2):14–29. https://doi.org/10.1002/star.201300238.

García MA, Martino MN, Zaritzky NE. Edible starch films and coatings characterization: scanning electron microscopy, water vapour, and gas permeabilities. Scanning. 1999;21(5):348–53. https://doi.org/10.1002/sca.4950210508.

Palacios-Fonseca AJ, Castro-Rosas J, Gómez-Aldapa CA, Tovar-Benítez T, Millán-Malo BM, del Real A, Rodríguez-García ME. Effect of the alkaline and acid treatment on the physicochemical properties of corn starch. CyTA-J Food. 2013;11(1):67–74. https://doi.org/10.1080/19476337.2012.761651.

Zainuddin SYZ, Ahmad I, Kargarzadeh H. Cassava starch biocomposites reinforced with cellulose nanocrystals from kenaf fibers. Composit Interfaces. 2013;20(3):189–99. https://doi.org/10.1080/15685543.2013.766122.

Debandi MV, Bernal C, Francois NJ. Development of biodegradable films based on chitosan/glycerol blends suitable for biomedical applications. J Tissue Sci & Eng. 2017. https://doi.org/10.4172/2157-7552.1000187.

Silveira Hornung P, Ávila S, Apea-Bah FB, Liu J, Teixeira GL, Ribani RH, Beta T. Sustainable use of ilex paraguariensis waste in improving biodegradable corn starch films’ mechanical, thermal and bioactive properties. J Polym Environ. 2020;28(6):1696–709. https://doi.org/10.1007/s10924-020-01723-w.

Chang-Bravo L, López-Córdoba A, Martino M. Biopolymeric matrices made of carrageenan and corn starch for the antioxidant extracts delivery of Cuban red propolis and yerba mate. React Funct Polym. 2014;85:11–9. https://doi.org/10.1016/j.reactfunctpolym.2014.09.025.

Jaramillo CM, Seligra PG, Goyanes S, Bernal C, Famá L. Biofilms based on cassava starch containing extract of yerba mate as antioxidant and plasticizer. Starch/Staerke. 2015;67(9–10):780–9. https://doi.org/10.1002/star.201500033.

Acknowledgements

The authors would like to thank the support of the Center of Electronic Microscopy of UFPR for the scanning electron microscopy analysis and the Federal University of Paraná.

Funding

Financial support from CAPES (Coordination for the Improvement of Higher Education Personnel) granted to B. P. Costa (grant number 88882.3816556/2019–01). Financial support from National Council for Scientific and Technological Development CNPq (grant number 432361/2018–9) granted for R. H. Ribani.

Author information

Authors and Affiliations

Contributions

BPC: Conceptualization, Software, Validation, Formal Analysis, Investigation, Resources, Data Curation, Writing—Original Draft; DC: Conceptualization, Validation, Data Curation, Writing—Original Draft; MI: Formal Analysis, Investigation, Writing—Review & Editing; AMM: Formal Analysis, Investigation, Writing—Review & Editing; FESBA: Writing—Review & Editing; RHR: Conceptualization, Writing—Original Draft, Writing—Review & Editing, Supervision, Project Administration, Funding acquisition.

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Practical Application: A bioactive and non-conventional starch can be an alternative to the food industry since they meet the new process requirements of solubility, thermal resistance being capable to maintain the phenolic compounds and antioxidants. Also, meeting the growing interest to develop active, biodegradable food packaging.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Costa, B.P., Carpiné, D., Ikeda, M. et al. Developing a bioactive and biodegradable film from modified loquat (Eriobotrya japonica Lindl) seed starch. J Therm Anal Calorim 147, 14297–14313 (2022). https://doi.org/10.1007/s10973-022-11780-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11780-z