Abstract

This study involves isothermal kinetic simulation to evaluate the parameters of inhibition conditions for Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus) of high-risk pathogens. This is because the new type of the 2019 novel coronavirus (2019-nCoV) is continuously spreading and the importance of public health issues. Environmental disinfection and personal wearing of masks have become important epidemic prevention measures. Selection of concentration kinetics could be estimated best for E. coli and S. aureus of pathogens, 2.74 × 104 and 105 and 2.44 × 104 and 105 colony-forming units (CFU mL–1), by isothermal micro-calorimeter (TAM Air) tests, respectively. Comparisons were made of different doses of 0–70 ppm (in 20 mL test ampoule) hypochlorous acid treatment for conducting nth-order and autocatalytic reaction simulation to evaluate the inhibition reaction parameters, which determined the autocatalytic kinetic model that was beneficially applied on the E. coli and S. aureus. We developed the inhibition reaction parameters of the pathogens, which included the activation energy (Ea), the natural logarithm of pre-exponential factor (lnk0), the enthalpy of inhibition microbial growth reaction (∆H), inhibition microbial growth, and the inhibition growth analysis. Overall, we conducted isothermal kinetic simulation to understand the antimicrobial activity effects of electrolytically generated hypochlorous acid-treated pathogenic microorganisms, which will provide reference for public health and medical-related fields for SDG3, and can contribute to ensuring human health and hygiene.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Public health involves dealing primarily with protecting people’s health, including promoting healthcare quality and accessibility and the limitation of healthcare disparities [1]. The Centers for Disease Control and Prevention (CDC) has reported that there are 31 known foodborne pathogens or unspecified agents that cause infections in humans. Common high-risk foodborne pathogens include Staphylococcus aureus, Listeria monocytogenes, Escherichia coli, Salmonella typhimurium, and Enterococcus faecalis [2]. The 2019 novel coronavirus (2019-nCoV) has not yet been fully controlled, and the number of infections and deaths is still increasing. To prevent the novel coronavirus, in addition to the basic skills of washing hands and wearing a mask, disinfecting water with alcohol, bleach, and hypochlorous acid has become a highly inquired product, in the hope of reducing the risk of infection [3]. Considering healthcare quality, fostering safe environments, and developing sound health policies remain public health systems key responsibilities.

Chlorine is a potent, rapidly acting, short-term disinfectant. However, because it is a gas, chlorine has little practical use. Instead, many compounds that release chlorine find wide application, including hypochlorite and organic and inorganic chloramines [4]. Hypochlorous acid (also referred to as electrolyzed water) is an oxyacid of chlorine (with formula HClO) containing monovalent chlorine that acts as an oxidizing or reducing agent [5]. It has been demonstrated to have bactericidal effects. In vitro, when introduced to a variety of microorganisms, hypochlorous acid causes oxidation of nucleotides, inactivation of cell enzymes, disruption of cell membranes, and rapid cell lysis [6,7,8,9]. Its advantages include a broad dismicrobial spectrum, low cost, low risk for sensitization, and lack of bacterial resistance against the agent. HOCl is one of the only agents that is both nontoxic to the delicate cells that can heal wounds and lethal to almost all known dangerous bacteria and viruses that threaten health [10]. At an effective antimicrobial concentration range, HOCl is non-irritating and non-sensitizing because of its lower cytotoxicity to mammalian cells when compared with NaOCl and H2O2 [11].

Such a study may provide further insights into the basic understanding of microbial ecotoxicology to allow the development of this field to better understand and protect the physical environment from pollutants. Sterility tests are limited in their ability to detect microbial contamination in large production batches due to small sampling size. Microbial metabolic activity is an effective microbial index to assess the toxicity of chemicals. Different rapid microbial methods, such as isothermal microcalorimetry, are capable of detecting heat produced by biochemically active cells such as growing bacteria or fungi. Isothermal microcalorimetry is a technique which measures the heat flow of chemical, physical, and biological processes [12,13,14]. It has been used for the detection of infection and contamination of clinical products and samples, determination of effects of antimicrobial compounds, monitoring and quantification of soil microbial activity and contamination, viral infections and activities of antiviral compounds, and spoilage of food [15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30].

Microcalorimetry is a quantifiable and accurate measurement method for biological growth energy. It detects the effect of drugs on cell metabolism by continuously measuring the energy changes produced by biological growth [31, 32]. We have developed an approach using isothermal microcalorimetry to evaluate liquid-state microbial growth exothermic properties that include the enthalpy of growth [33, 34], biological growth curve differences (including lag, logarithmic, stationary, and decline phases), and isothermal liquid-state growth properties. The approach has been applied to the growth, storage, and culture conditions of Lactobacillus plantarum, Lactobacillus casei, and Saccharomyces cerevisiae that include increasing the exothermic properties of fermentation microorganisms, such as the kinetics of reaction, pre-exponential factor, reaction order, activation energy, enthalpy of endothermic reaction, time to maximum rate, and time to the conversion limit. We also used time to maximum rate to evaluate the bacterial isothermal condition to reach the maximum growth rate time and time to the conversion limit to determine the reliable growth and storage conditions of bacteria. Thus, we also used isothermal microcalorimetry to assess the effect of hypochlorous acid with different doses on the growth and metabolism of widespread pathogenic microorganisms Escherichia coli (E. coli) and Staphylococcus aureus (S. aureus) by applying reaction kinetic simulation. The approach can measure hypochlorous acid antibacterial activity, which can be used as a continuous measurement of non-destructive and interrupted methods to provide a method for evaluating antibacterial activity as a model for clinical application.

Materials and methods

Bacterial strains and culture conditions

The two species of pathogenic bacteria, including Gram-positive species Staphylococcus aureus (S. aureus) (BCRC 15,211) and Gram-negative species Escherichia coli (E. coli) (BCRC 10,675), were obtained from the Bioresource Collection and Research Center (BCRC), Food Industry Research and Development Institute, Hsinchu, Taiwan. Two species were inoculated in a 250-mL sterilized flask contacting 100 mL nutrient broth culture medium (NB, Merck KGaA, Darmstadt, Germany) and incubated in the shaker for 24 h at 37 °C. The rotation speed of the incubator shaker was 100 rpm prior to experimentation. The number of bacteria was determined by plating the bacteria on nutrient agar and incubating for 24 h at 37 °C; the average number of S. aureus and E. coli was 2.44 × 106 and 2.74 × 108 colony-forming units (CFU) mL–1, respectively. The inoculum needed for the experiments was prepared by diluting the bacteria in sterile physiological saline (0.85% NaCl) solution. These cells were prepared for microcalorimetry measurements.

Preparation of hypochlorous acid solutions

Electrolyzed water was generated using an ezbetter HW-900 generator (New Taipei, Taiwan) in our laboratory with normal tap water on the day of use. Hypochlorous acid solutions contained free chlorine at the rate of 800–1000 ppm. The quickest and simplest method for testing for chlorine residual is the OTD (o-tolidine) indicator test, using a comparator. A tablet of OTD is added to the water sample, colouring it yellow. The strength of colour is measured against standard colour on a chart to determine the chlorine concentration. On the day of the experiment, the hypochlorous acid solutions were dissolved in distilled water to prepare hypochlorous acid at the 10–70 ppm concentration for isothermal microcalorimetry measurements.

Isothermal microcalorimetry measurement

The thermal active monitor TAM Air isothermal calorimeter (TA Instruments, Newcastle, DE, USA) was used to monitor the metabolic activity of the living cells of E. coli and S. aureus. This microcalorimeter can record the heat flow dQ dt–1 in microwatt range directly, also called heat-flow power, P, which is different from classical calorimeters. The heat output Q value was obtained by integrating the metabolic power–time (P–t) curves using the TAM Assistant software (v2.0.175, date published 8 October 2020) (Newcastle, DE, USA) [35]. We used the TAM Air software to control the thermostat [33, 34]. All 20-mL glass ampoules were cleaned and sterilized in high-pressure steam (0.1 MPa) at 121 °C prior to use. The 20 mL ampoules contained 4 mL of NB culture medium added to these ampoules, 0.5 mL of various concentration of the hypochlorous acid (100–700 ppm), and 0.5 mL of test bacterial culture (103, 104, 105, and 106 colony-forming units mL–1). The TAM Air isothermal microcalorimeter results for all samples under various concentration are illustrated in Fig. 1. The positive control contained test microorganisms and NB without hypochlorous acid. TAM Air was used to investigate isothermal growth of bacteria at 35 °C. The loaded ampoules were allowed to equilibrate at this intermediated position for 30 min before being lowered into the measurement position. Data were analysed with origin 2019 (Microcal Software Inc.).

Isothermal kinetic parameter evaluation

In this study, isothermal microbial growth is a specific biological property that depends on the time, colony-forming units, and hypochlorous acid solutions concentration. This study was processed with the kinetics evaluated by applying software, including ARKS-TA (version 1.1.10, released 15 September 2020) and ARKS-FK (version 1.1.0, released 13 January, 2020) software developed by ChemInform Saint-Petersburg (CISP) Ltd [36]. The ARKS-TA is used for preliminary analysis of thermal analysis data. It can more precisely analyse the results of TAM Air to obtain the onset time, the total reaction time from the onset time to return the baseline, and the enthalpy of exothermic reaction. The ARKS-FK approach for the creation of a kinetic model and the algorithms that are employed is clearly described on the homepage [36]. Here, we compared the nth-order and the general autocatalytic kinetic equation and evaluated inhibition growth for traditional microbial growth of exothermic reaction under isothermal evaluations by ARKS-FK software. Simulations of isothermal kinetic models can be a single-stage reaction or complex multi-stage reactions, such as the generalized autocatalytic reaction, that may consist of several independent, parallel, and consecutive stages [34]:

Single stage of an nth-order reaction:

This model is the generalized autocatalytic reaction (multi-stage reaction):

where Ez is the difference between the activation energies of the initiation and autocatalytic stages, natural logarithm of the pre-exponential factor (lnk0), inhibition growth order (ni, i = 0, 1, and 2), z0 stands for the ratio of pre-exponents k01/k02 of considered E. coli and S. aureus inhibition growth under the autocatalytic model.

The above-mentioned method was used to obtain suitable kinetics and parameters and then treating with different doses of hypochlorous acid solutions. The best parameters were provided by better fitting of all the TAM Air tests [35]; these include the kinetics of inhibition, lnk0, reaction order (n), activation energy (Ea), and enthalpy of exothermic reaction (∆H), among others, along with the heat effect parameters that determine the antibacterial response of growth and the inhibition lifetime assessment. In addition, we used the calculation of the time to maximum rate (TMR) and time to the conversion limit (TCL) in the ARKS-FK software to evaluate the growth rate under the inhibition from low temperature − 10 to overheated 120 °C and isothermal lifetime assessment.

Results and discussion

Measurement and evaluation of energy released by inhibition reaction

Results of TAM Air analysis, from Fig. 2A to observe the growth energy changes of E. coli, belongs to a broad peak curve, and then, the growth reaction returns to the baseline. There was no subsequent exothermic reaction. Moreover, Fig. 2B S. aureus belongs to the steep peak curve; the growth curve returns to the baseline earlier, but there was a slight exothermic curve in the follow-up. From Tables 1 and 2 and Fig. 3, the results are consistent. When the hypochlorous acid concentration of E. coli is increased to 40 ppm and the hypochlorous acid concentration of S. aureus is up to 50 ppm, the results are shown under different colony count conditions, which are completely suppressed.

However, from Tables 1 and 2, the original inhibition effect of E. coli and S. aureus thermal analysis, raw data cannot distinguish the different colony count conditions and various hypochlorous acid concentrations for obtaining the start time, end time, and total growth time of the different results. Additionally, from Tables 3 and 4, applying ARKS-TA software to analyse again, we can more accurately evaluate the onset time, total growth time, and growth reaction enthalpy of different hypochlorous acid concentrations on the inhibition effects for E. coli and S. aureus. Therefore, it can be clearly known that E. coli and S. aureus are completely inhibited when the hypochlorous acid concentration is exceeding 40 and 50 ppm, respectively.

Evaluation of growth inhibition isothermal kinetic models

Confirming the original growth condition of E. coli and S. aureus, we used hypochlorous acid without any inhibitor added as a blank experiment. In addition, to ensure the accuracy of the isothermal kinetic evaluation, all blank experiments were also completed for the evaluation of colony counts of 103−106 to avoid errors caused by different colony counts. Comparisons of the results in Figs. 4 and 5 and Tables 5 and 6 clearly show the growth of E. coli and S. aureus simulated by isothermal autocatalytic kinetics; they could be more in line with actual growth conditions, along with the isothermal growth kinetic parameters of E. coli and S. aureus which were obtained with a good consistency.

The simulation of isothermal nth-order kinetics showed inconsistency and confusion in the calculation results of kinetic parameters. In addition, we can further know that the kinetic parameters obtained from the four groups of isothermal autocatalytic kinetic simulation calculation and analysis results are almost the same for different colony counts from 103 to 106. To ensure the reliability of the research results, the E. coli and S. aureus inhibition reaction kinetics were estimated with different concentrations of hypochlorous acid solutions, and the isothermal nth-order and autocatalytic reaction kinetics were still evaluated and analysed to create more certainty for the research.

From the results in Table 5 and 6, the hypochlorous acid solution of different concentrations was used to estimate the kinetics of the inhibition reaction of E. coli and S. aureus with various colony counts of 103−106, and the results are still consistent with the original two pathogens’ isothermal autocatalytic kinetic simulation results. Table 5 lists the calculation results of the inhibition kinetics of E. coli with different colony counts of 103−106 with different concentrations of hypochlorous acid solution, which exhibited the original zero-dose hypochlorous acid (0 ppm) of the pre-exponential factor of growth; the activation energy of inhibition was about 37 and 122 which reduced to 17 and 69 (at 30 ppm), respectively. Particularly, it is obvious that when the hypochlorous acid solution is added up to 30 ppm, the pre-exponential factor of growth is only close to half of the original 0 ppm value, which is very interesting. Because of the pre-exponential factor, which originally refers to the collision between molecules during a chemical reaction, we boldly estimated that this is related to the vitality and mobility of the bacteria. This is one of the interesting findings of this study.

Table 6 presents the simulation analysis results of the inhibition reaction kinetics of different concentrations of hypochlorous acid solutions on S. aureus that were treated with different colony counts of 103−106. From the results, without adding any hypochlorous acid to inhibit the growth reaction for determining the pre-exponential factor and activation energy, the original zero-dose hypochlorous acid (0 ppm) was ca. 42 and 131 which was reduced to 24 and 85 (at 40 ppm). Furthermore, when the concentration of S. aureus in the hypochlorous acid solution treatment reached 20 ppm, the pre-exponential factor and activation energy jumped up, even higher than the hypochlorous acid solution treatment concentration of 10 ppm. However, the energy release of the inhibition reaction is lower than 10 ppm, which is a very strange phenomenon. It is very significant that when the concentration of the hypochlorous acid solution is higher and higher, the energy release of the inhibition reaction is inversely proportional and has a tendency of lower and lower. However, whether the treatment of S. aureus concentration with this 20 ppm hypochlorous acid solution is a so-called biological adversity phenomenon is the second novel finding of this study.

Growth rate under inhibition reaction

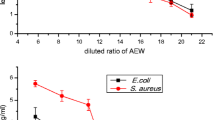

To determine the growth characteristics of E. coli and S. aureus at low-temperature conditions, we used general household refrigerator freezer (− 10 °C) or cold storage and overheating temperature (120 °C) conditions, which could be ascertained as the temperature and hypochlorous acid solution treatment for E. coli and S. aureus to evaluate the growth rate and lifetime of the inhibition reaction. This can also be used as a consideration for food hygiene and safety control factors. In addition, to avoid the errors of low- and high-concentration colony counts for further analysis, we used 104 and 105 colony counts and adopted a moderate balance to evaluate the results of this research. Table 7 shows that the original blank analysis of E. coli and S. aureus does not seem to cause the death of E. coli and S. aureus under low-temperature conditions, but slow growth occurs when the temperature is higher than 60 °C. However, at higher temperatures, these two pathogens even died.

Table 7 indicates that the treatment of E. coli and S. aureus by hypochlorous acid has an inhibitory effect on both pathogens. Among them, S. aureus was treated with 20 ppm hypochlorous acid solution; there was a growth rate jump, and the growth rate could approach the state without hypochlorous acid solution treatment. To determine this phenomenon, we reviewed the results in Table 5. E. coli was treated with 20 ppm hypochlorous acid solution, and the pre-exponential factor and activation energy of the inhibition reaction did not seem to be much different from the 10 ppm concentration. From Table 7, we found that the growth rate and isothermal lifetime performance of E. coli treated with 20 ppm hypochlorous acid solution are even better than those of 10 ppm inhibition treatment.

This seems to reveal that if the concentration of hypochlorous acid solution is insufficient, although it will affect the growth exothermic reaction, it will not have much effect on the growth of the bacteria. However, from Table 7, if the temperature is higher than 70 °C, E. coli and S. aureus almost do not grow regardless of whether it is the original or the hypochlorous acid inhibition treatment of hypochlorous acid solution. Therefore, if hypochlorous acid solution is used as the growth inhibition treatment of E. coli and S. aureus of pathogenic bacteria, as the concentration of the complete inhibitory treatment is not reached, the complete inhibition effect cannot be achieved, which may even be stimulated to live longer.

Evaluation of the lifetime of pathogenic bacteria under isothermal conditions

Consider the situation of low-temperature refrigeration, from Table 8, in the temperature range from 2.38 to 20.95 °C, the lifetime of the original and hypochlorous acid solution for the bacteriostatic growth treatment of E. coli and S. aureus, when at 20.95 °C, the 20 ppm hypochlorous acid solution treatment concentration, it seems to have no effect on the lifetime of E. coli and S. aureus (compared with 0 ppm). Interestingly, if the inhibition concentration of the hypochlorous acid solution is insufficient for treating E. coli and S. aureus, it will not have much impact on its lifetime. Table 8 also lists under low temperature for E. coli and S. aureus, which prolongs the lifetime, even after the hypochlorous acid solution has been used to inhibit growth. However, high-temperature treatment above 70 °C can be sterilizing for the immediate death of E. coli and S. aureus.

From the evaluation results of the isothermal lifetime in Table 8, it could be determined that without antibacterial treatment and after hypochlorous acid solution antibacterial treatment in summer (isothermal interval of 27.14 − 33.33 °C), it is almost the same lifetime under all conditions. Thus, the use of high-temperature sterilization is safe and reliable. According to food safety and eating habits, for some food ingredients, the risk is still very high for some ingredients to be eaten raw after being frozen. Furthermore, compared to the results of Tables 7 and 8, it could be confirmed that the concentration of 20 ppm hypochlorous acid solution for antibacterial treatment, for E. coli and S. aureus, not only stimulates growth, but also causes a special phenomenon of shelf life delay (only from the point of view of bacterial growth energy). This point is also a major discovery of this research.

Conclusions

Overall, we have established two types of E. coli and S. aureus pathogenic bacteria and evaluated the growth inhibition reaction by treating with hypochlorous acid solution and applying autocatalytic kinetic reaction simulations, which can obtain better and consistent results. We have also determined that when the concentration of hypochlorous acid solution reaches 20 ppm, it has a stimulating effect on the growth of E. coli and S. aureus, which is verified by inhibiting reaction pre-exponential factor and activation energy of growth rate and lifetime results. We have also confirmed that when the inhibition concentration of the hypochlorous acid solution does not reach the full inhibitory effect, the pathogen not only be completely killed but also live longer. Low temperature also does not inhibit pathogenic bacteria, but only prolongs the lifetime. The future research direction will continue to explore the application to food safety and hygiene, the efficacy of drug treatment and drug development.

Abbreviations

- CFU:

-

Colony-forming units/CFU mL−1

- E :

-

Activation energy of an endothermic reaction/kJ mol−1

- E a :

-

Activation energy of an exothermic reaction/kJ mol−1

- E z :

-

Activation energies of the difference between stages of an autocatalytic reaction/kJ mol−1

- k i :

-

Pre-exponential factor/m3 mol−1 s−1; i = 0, 01, 02

- n :

-

Reaction order, dimensionless

- NB:

-

Nutrient broth culture medium

- n i :

-

Reaction order of the ith stage, dimensionless; i = 1, 2, 11, 21, 22

- R :

-

Gas constant/8.31415 J K−1 mol−1

- r i :

-

Reaction rate of the ith stage/g sec−1; i = 1, 2, 3, 4

- T :

-

Absolute temperature/K

- TCL:

-

Time to conversion limit under isothermal conditions/day

- TMR:

-

Time to maximum rate under isothermal conditions/day

- T t :

-

Total time from start onset to back baseline of the exothermic reaction/min

- t :

-

Time/sec

- z :

-

Autocatalytic constant/dimensionless

- z 0 :

-

Stands for the ratio of pre-exponents k01/k02 of inhibition growth under the autocatalytic model/dimensionless

- α :

-

Degree of conversion/dimensionless

- ∆H :

-

Enthalpy of exothermic reaction/kJ kg−1

References

Feng L, Song B, Zang ZF, Sun NL, Wang JS, Liu F, Lei SW. Discussion on implementation of public health standards adopted in centers for disease control and prevention. Zhonghua Liu Xing Bing Xue Za Zhi. 2018;39(9):1287–90.

Bintsis T. Foodborne pathogens. AIMS Microbiol. 2017;3(3):529–63.

Chan JFW, Yuan SF, Kok KH, To KKW, Chu H, Yang J, Xing FF, Liu JL, Yip CCY, Poon RWS, Tsoi HW, Lo SKF, Chan KH, Poon VKM, Chan WM, Ip JD, Cai JP, Cheng VCC, Chen HL, Hui CKM, Yuen KY. A familial cluster of pneumonia associated with the 2019 novel coronavirus indicating person-to-person transmission: a study of a family cluster. The Lancet. 2020;395(10223):514–23.

Ramey DW, Kinde H. Commercial and homemade extremely dilute hypochlorous acid solutions are bactericidal against Staphylococcus aureus and Escherichia coli in vitro. J Equine Vet Sci. 2015;35(2):161–4.

Rahman SME, Khan I, Oh DH. Electrolyzed water as a novel sanitizer in the food industry: current trends and future perspectives. Compr Rev Food Sci Food Saf. 2016;15(3):471–90.

Anagnostopoulos AG, Rong A, Miller D, Tran AQ, Head T, Lee MC, Lee WW. 0.01% Hypochlorous acid as an alternative skin antiseptic: an in vitro comparison. Dermatol Surg. 2018;44(12):1489–93.

Jafry AT, Lee C, Kim D, Han G, Sung WK, Lee J. Development of high concentrated slightly acidic hypochlorous acid generator for food safety. J Mech Sci Technol. 2017;31(9):4541–7.

Kim C, Her Y, Kim Y, Jung C, Lim H, Suh K. Evaluating the effectiveness of HOCl application on odor reduction and earthworm population growth during vermicomposting of food waste employing Eisenia fetida. PLoS ONE. 2019;14(12):e0226229.

Liao XY, Xiang QS, Cullen PJ, Su Y, Chen SG, Yea XQ, Liu DH, Ding T. Plasma-activated water (PAW) and slightly acidic electrolyzed water (SAEW) as beef thawing media for enhancing microbiological safety. LWT-Food Sci Technol. 2020;117:108649.

Han Q, Song X, Zhang Z, Fu J, Wang X, Malakar PK, Liu H, Pan Y, Zhao Y. Removal of foodborne pathogen biofilms by acidic electrolyzed water. Front Microbiol. 2017;8:988.

Chen CJ, Chen CC, Ding SJ. Effectiveness of hypochlorous acid to reduce the biofilms on titanium alloy surfaces in vitro. Int J Mol Sci. 2016;17(7):1161.

Zhang X, Jiang X, Hao Z, Qu K. Advances in online methods for monitoring microbial growth. Biosens Bioelectron. 2019;126:433–47.

Braissant O, Wirz D, Göpfert B, Daniels AU. Use of isothermal microcalorimetry to monitor microbial activities. FEMS Microbio Lett. 2010;303:1–8.

Schumacher A, Vranken T, Malhotra A, Arts JJC, Habibovic P. In vitro antimicrobial susceptibility testing methods: agar dilution to 3D tissue-engineered models. Eur J Clin Microbiol Infect Dis. 2018;37(2):187–208.

Xu Z, Li H, Qin X, Wang T, Hao J, Zhao J, Wang J, Wang R, Wang D, Wei S, Cai H, Zhao Y. Antibacterial evaluation of plants extracts against ampicillin-resistant Escherichia coli (E. coli) by microcalorimetry and principal component analysis. AMB Express. 2019;9(1):101.

Pu SB, Ma ZJ, Wang Q. Anti-Staphylococcus aureus evaluation of gallic acid by isothermal microcalorimetry and principle component analysis. J Therm Anal Calorim. 2019;136(3):1425–32.

Fredua-Agyeman M, Gaisford S. Assessing inhibitory activity of probiotic culture supernatants against Pseudomonas aeruginosa: a comparative methodology between agar diffusion, broth culture and microcalorimetry. World J Microbiol Biotechnol. 2019;35(3):49.

Liu J, Ma L, Li Y, Zuo XB, Gao Y, Wang T, Zhang Y, et al. Biothermokinetic characterization and evaluation on the quality of Colla corii asini. J Therm Anal Calorim. 2020;139(2):1141–9.

Brueckner D, Roesti D, Zuber UG, Schmidt R, Kraehenbuehl S, Bonkat G, Braissant O. Comparison of tunable diode laser absorption spectroscopy and isothermal micro-calorimetry for non-invasive detection of microbial growth in media fills. Sci Rep. 2016;6:27894.

Zhang LX, Liu Y, Cia LH, Hu YJ, Yin J, Hu PZ. Inhibitory study of some novel Schiff base derivatives on Staphylococcus aureus by microcalorimetry. Thermochim Acta. 2006;440(1):51–6.

Morozova K, Armani M, Scampicchio M. Isothermal calorimetry for monitoring of grape juice fermentation with yeasts immobilized on nylon-6 nanofibrous membranes. J Therm Anal Calorim. 2020;139(1):375–82.

Nykyri J, Herrmann AM, Håkansson S. Isothermal microcalorimetry for thermal viable count of microorganisms in pure cultures and stabilized formulations. BMC Microbiol. 2019;19(1):65.

Hu X, Ma Y, Liu Z, Zhao M, Dong S, Yang H, Dai C. Microcalorimetric evaluation of the effects of three anthraquinone derivatives from Chinese Rhubarb and the synergistic effect of the mixture on Staphylococcus aureus. J Therm Anal Calorim. 2020;141:739–49.

Ma X, Xie Q, Wu M, Zhao Y, Wang J, Wen J, Dong T. Microcalorimetric study of the effect of l-borneol, d-borneol and synthetic borneol on the growth of P aeruginosa. J Therm Anal Calorim. 2018;131(2):1681–9.

Meng X, Zhou X, Wang T, Li F, Li H, Li J, Wang R, Wei S, Zhang Y, Cai H, Dai C, Zhao Y. Microcalorimetric study on the activation effects of Salviae miltiorrhizae combined with Radix puerariae on mice splenic lymphocytes. J Therm Anal Calorim. 2019;137(3):841–8.

Ma ZJ, Zhang CE, Wang RL, Zang QC, Yu XH, Wang JB, Sun CZ, Zhao KJ, Pu SB, Xiao XH. Microcalorimetry combined with chemometics for antibacterial evaluation of Sophora alopecuroides on Staphylococcus aureus. J Therm Anal Calorim. 2018;134:1883.

Morozova K, Bulbarello A, Schaefer C, Funda E, Porta F, Scampicchio M. Novel isothermal calorimetry approach to monitor micronutrients stability in powder forms. LWT-Food Sci Technol. 2020;117:108594.

Braissant O, Chavanne P, de Wild M, Pieles U, Stevanovic S, Schumacher R, Straumann L, Wirz D, Gruner P, Bachmann A, Bonkat G. Novel microcalorimetric assay for antibacterial activity of implant coatings: the cases of silver-doped hydroxyapatite and calcium hydroxide. J Biomed Mater Res B Appl Biomater. 2015;103:1161–7.

Fredua-Agyeman M, Gaisford S, Beezer AE. Observation with microcalorimetry: behaviour of P. aeruginosa in mixed cultures with S. aureus and E. coli. Thermochim Acta. 2018;663:93–8.

Aveledo R, Aveledo A, Vázquez C, Lago N, Mato MM, Legido JL. Study of bacterial sensitivity in zinc sulfate solutions by microcalorimetry. J Therm Anal Calorim. 2018;133:773–7.

Cabadaj M, Bashir S, Haskins D, Said J, McCoubrey L, Gaisford S, Beezer A. Kinetic analysis of microcalorimetric data derived from microbial growth: basic theoretical, practical and industrial considerations. J Microbiol Methods. 2021;187:106276.

Fricke C, Harms H, Maskow T. How to speed up the detection of aerobic microbial contaminations by using isothermal microcalorimetry. J Therm Anal Calorim. 2020;142:1933–49.

Tsai SY, Lin HY, Hsu YC, Lin CP. Prediction of the growth and storage conditions of Lactobacillus plantarum and Lactobacillus casei by isothermal kinetic simulation. Thermochim Acta. 2017;655:363–71.

Tsai SY, Hsu YC, Shu CM, Lin KH, Lin CP. Synchronization of isothermal calorimetry and liquid cultivation identifying the beneficial conditions for producing ethanol by yeast Saccharomyces cerevisiae fermentation. J Therm Anal Calorim. 2020;142:829–40.

TAM Air Assistant Software v2.0.175. TA Instruments Ltd. New Castle, DE. USA. 2021; http://www.tainstruments.com.

Thermal Safety Software (TSS). ChemInform Saint-Petersburg (CISP) Ltd., St. Petersburg, Russia. 2011; http://www.cisp.spb.ru.

Acknowledgements

We are indebted to the National Science and Technology Council (NSTC) under contract nos. MOST 108-2320-B-468 -001 -MY3 and MOST 109-2221-E-468-002-MY2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tsai, SY., Liu, YM., Lin, ZW. et al. Antimicrobial activity effects of electrolytically generated hypochlorous acid-treated pathogenic microorganisms by isothermal kinetic simulation. J Therm Anal Calorim 148, 1613–1627 (2023). https://doi.org/10.1007/s10973-022-11727-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11727-4