Abstract

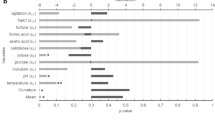

This study focused on the Saccharomyces cerevisiae (S. cerevisiae) fermentation process using various sugar concentrations for ethanol fermentation; the isothermal calorimeter (TAM Air) and liquid state fermentation were compared to determine the effects of adjusting the sugar concentration, culture temperature, and culture time for S. cerevisiae cultivation. We compared the effects of different culture temperatures, 25, 31, and 37 °C, various glucose and fructose concentrations, 2, 4, and 8%, and suitable culture times, up to 96 h, for S. cerevisiae growth and metabolism under synchronous conditions. Comparisons of the calorimetric measurement and liquid state fermentation results were made to determine the beneficial culture conditions at 25 °C. In addition, based on the heat power-time curves of the TAM Air tests, we obtained an accessible kinetics model by autocatalytic reaction simulation, which further determined an accurate culture time of 85.22 h, a high ethanol production of 34.80 μL mL−1 in medium with 8% fructose; the time to reach the maximum growth rate under an isothermal temperature of 26.59 °C for all media was 24 h, and a longer growth lifetime of 134. 03 days was achieved in 8% fructose at 4 °C. Overall, the results of this research can be widely used in beverages, bioenergy, and food processing.

Similar content being viewed by others

References

Walker GM, Stewart GG. Saccharomyces cerevisiae in the production of fermented beverages. Beverages. 2016;2(4):30.

Zainab B, Fakhra A. Production of ethanol by fermentation process by using yeast Saccharomyces cerevisae. Int Res J Environ Sci. 2014;3(7):24–32.

Ingledew WM. Alcohol production by Saccharomyces cerevisiae: a yeast primer. In: Lyons TP, Kelsall DR, editors. The alcohol textbook. 3rd ed. Nottingham: Nottingham University Press; 1999. p. 49–87.

Zainab B, Fakhra A. Production of ethanol by fermentation process by using yeast Saccharomyces cerevisae. Int Res J Environ Sci. 2014;3:24–32.

Pietrzak W, Kawa-Rygielska J. Ethanol fermentation of waste bread using granular starch hydrolyzing enzyme: effect of raw material pretreatment. Fuel. 2014;134:250–6.

Antoce AO, Nămoloşanu IC. A rapid method for testing yeast resistance to ethanol for the selection of strains suitable for winemaking. Rom Biotechnol Lett. 2011;16(1):5953.

Armani M, Morozova K, Scampicchio M. Immobilization of Saccharomyces cerevisiae on nylon-6 nanofibrous membranes for grape juice fermentation. LWT. 2019;110:360–4.

Hittinger CT, Steele JL, Ryder DS. Diverse yeasts for diverse fermented beverages and foods. Curr Opin Biotechnol. 2018;49:199–206.

Anagnostopoulos VA, Vlachou A, Symeopoulos BD. Immobilization of Saccharomyces cerevisiae on low-cost lignocellulosic substrate for the removal of Cd2+ from aquatic systems. J Environ Biotechnol Res. 2015;1:23–9.

Zeren F, Akkuş HT. The relationship between renewable energy consumption and trade openness: new evidence from emerging economies. Renew Energy. 2020;147(1):322–9.

Talukder AA, Adnan N, Siddiqa A, Miah R, Tuli JF, Khan ST, Dey SK, Lertwattanasakul N, Yamada M. Fuel ethanol production using xylose assimilating and high ethanol producing thermosensitive Saccharomyces cerevisiae isolated from date palm juice in Bangladesh. Biocatal Agric Biotechnol. 2019;18:101029.

Duy VN, Duc KN, Cong DN, Xa HN, Le Anh T. Experimental study on improving performance and emission characteristics of used motorcycle fueled with ethanol by exhaust gas heating transfer system. Energy Sustain Dev. 2019;51:56–62.

Braissant O, Wirz D, Gopfert B, Daniels AU. Use of isothermal microcalorimetry to monitor microbial activities. FEMS Microbiol Lett. 2010;303:1–8.

Braissant O, Bachmann A, Bonkat G. Microcalorimetric assays for measuring cell growth and metabolic activity: methodology and applications. Methods. 2015;76:27–34.

Zhang X, Jiang X, Hao Z, Qu K. Advances in online methods for monitoring microbial growth. Biosens Bioelectron. 2019;126:433–47.

Cuenca M, Romen B, Gatti G, Mason M, Scampicchio M. Microcalorimetry as a tool for monitoring food fermentations. Chem Eng Trans. 2017;57:1957–62.

Khalef N, Campanella O, Bakri A. Isothermal calorimetry: methods and applications in food and pharmaceutical fields. Curr Opin Food Sci. 2016;9:70–6.

Chen XJ, Feng WS, Yu YH. Studies on the nongrowth metabolism of the different strains of Tetrahymena cells by isothermal microcalorimetry. J Thermal Anal. 2014;115(3):2145–9.

Hussain M, Lin Y, Wang L. Effect of temperature on longevity of Diaphorina citri (Hemiptera: Liviidae) studied by microcalorimeter. J Thermal Anal. 2017;127(2):1245–52.

Garcia AH, Herrmann AM, Håkansson S. Isothermal microcalorimetry for rapid viability assessment of freeze-dried Lactobacillus reuteri. Process Biochem. 2017;55:49–54.

Kabanova N, Stulova I, Vilu R. Microcalorimetric study of growth of Lactococcus lactis IL1403 at low glucose concentration in liquids and solid agar gels. Thermochim Acta. 2013;559:69–75.

Wernli L, Bonkat G, Gasser TC, Bachmann A, Braissant O. Use of isothermal microcalorimetry to quantify the influence of glucose and antifungals on the growth of Candida albicans in urine. J Appl Microbiol. 2013;115(5):1186–93.

Morozova K, Andreotti C, Armani M, Cavani L, Cesco S, Cortese L, Gerbi V, Mimmo T, Spena PR, Scampicchio M. Indirect effect of glyphosate on wine fermentation studied by microcalorimetry. J Therm Anal Calorim. 2017;127(2):1351–60.

Brueckner D, Krähenbühl S, Zuber U, Bonkat G, Braissant O. An alternative sterility assessment for parenteral drug products using isothermal microcalorimetry. J Appl Microbiol. 2017;123(3):773–9.

Fredua-Agyeman M, Gaisford S, Beezer AE. Observation with microcalorimetry: behaviour of P. aeruginosa in mixed cultures with S. aureus and E. coli. Thermochim Acta. 2018;663:93–8.

Ma X, Xie Q, Wu M, Zhao Y, Wang J, Wen J, et al. Microcalorimetric study of the effect of l-borneol, d-borneol and synthetic borneol on the growth of P. aeruginosa. J Therm Anal Calorim. 2018;131(2):1681–9.

Pu SB, Ma ZJ, Wang Q. Anti-Staphylococcus aureus evaluation of gallic acid by isothermal microcalorimetry and principle component analysis. J Therm Anal Calorim. 2019;136(3):1425–32.

Tsai SY, Lin HY, Hsu YC, Lin CP. Prediction of the growth and storage conditions of Lactobacillus plantarum and Lactobacillus casei by isothermal kinetic simulation. Thermochim Acta. 2017;655:363–71.

Tsai SY, Hsu YC, Lin HY, Huang FK, Lin CP. Comparison of the effect of Pleurotus citrinopileatus extract and vitamin E on the stabilization properties of camellia oil. J Therm Anal Calorim. 2017;130(3):1281–92.

Acknowledgements

Authors are indebted to the Ministry of Science and Technology (MOST), Taiwan, ROC, under the contract No. MOST 107-2221-E-468-007-MY2 and MOST 105-2221-E-468-001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tsai, SY., Hsu, YC., Shu, CM. et al. Synchronization of isothermal calorimetry and liquid cultivation identifying the beneficial conditions for producing ethanol by yeast Saccharomyces cerevisiae fermentation. J Therm Anal Calorim 142, 829–840 (2020). https://doi.org/10.1007/s10973-020-09629-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09629-4