Abstract

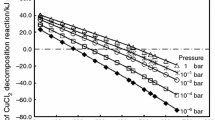

Recently, we reported detailed investigations on a hydrolysis step of Cu–Cl thermochemical cycle (Singh et al. in Int J Energy Res 44:2845–2863, 2020) where we demonstrated CuCl2 hydrolysis using a fixed-bed reactor under optimized conditions. Thermolysis of CuCl2 and oxide formation are associated hindrances in achieving 100% phase-pure hydrolysis product, Cu2OCl2. With an objective to understand the thermolysis and hydrolysis processes at molecular level, both these reactions were investigated independently in the present study using in situ XAS as a probe. The progress of both the reactions was recorded from RT to 400 °C by monitoring temperature-dependent evolution of Cu species using Cu K-edge XAS measurements at BL-09, Indus-2 SRS, RRCAT, Indore, India. XAS results are also corroborated with ex situ analysis by XRD and TG of samples containing various compositions of CuCl2 mixed with boron nitride (pellets employed for XAS). Besides LCF, hydrolysis product Cu2OCl2 yield was further supported by chemical titrations. EXAFS revealed that with increasing temperature, coordination of Cu atoms in reactant CuCl2 progressively decreased during thermolysis. For hydrolysis process, coordination of Cu atoms in Cu–Cu, Cu–O and Cu–Cl linkages approached towards that of Cu2OCl2 and CuO. CuCl2 diminished and transformed into CuCl (88 mass%) at 350 °C during thermolysis and ~ 60 mass% of Cu2OCl2 and 40 mass% of CuO during hydrolysis reaction. Based on in situ investigations in the present study, the most probable reactions taking place during CuCl2 hydrolysis at different temperatures are proposed for S/Cu of 14.6.

Similar content being viewed by others

References

Polverino P, D’Aniello F, Arsie I, Pianese C. Study of the energetic needs for the on-board production of Oxy-Hydrogen as fuel additive in internal combustion engines. Energ Convers Manag. 2019;179:114–31.

El-Emam RS, Ozcan H. Comprehensive review on the techno-economics of sustainable large-scale clean hydrogen production. J Clean Prod. 2019;220:593–609.

Safari F, Dincer I. A review and comparative evaluation of thermochemical water splitting cycles for hydrogen production. Energ Convers Manag. 2020;205:112182.

Oruc O, Dincer I. Assessing the potential of thermochemical water splitting cycles: A bridge towards for clean and sustainable hydrogen generation. Fuel. 2021;286:119325.

Liu H, Kantor I, Elkamel A, Fowler M. Optimal synthesis of heat exchanger network for thermochemical S-I cycle. J Therm Anal Calorim. 2009;96:27–33.

Mehrpooya M, Tabatabaei SH, Pourfayaz F, Ghorbani B. High temperature hydrogen production by solar thermochemical reactors, metal interfaces, and nanofluid cooling. J Therm Anal Calorim. 2020;1–23. https://doi.org/10.1007/s10973-020-09797-3.

Ying Z, Wang Y, Zheng X, Geng Z, Dou B, Cui G. Experimental study and development of an improved sulfur-iodine cycle integrated with HI electrolysis for hydrogen production. Int J Hydrogen Energy. 2020;45:131176–88.

Nadar A, Banerjee AM, Pai MR, Meena SS, Pai RV, Tewari R, Yusuf SM, Tripathi AK, Bharadwaj SR. Nanostructured Fe2O3 dispersed on SiO2 as catalyst for high temperature sulfuric acid decomposition—structural and morphological modifications on catalytic use and relevance of Fe2O3–SiO2 interactions. Appl Catal B. 2017;217:154–68.

Nadar A, Banerjee AM, Pai MR, Pai RV, Meena SS, Tewari R, Tripathi AK. Catalytic properties of dispersed iron oxides Fe2O3/MO2 (M = Zr, Ce, Ti and Si) for sulfuric acid decomposition reaction: Role of support. Int J Hydrogen Energy. 2018;43:37–52.

Banerjee AM, Pai MR, Tewari R, Raje N, Tripathi AK, Bharadwaj SR, Das D. A comprehensive study on Pt/Al2O3 granular catalyst used for sulfuric acid decomposition step in sulfur–iodine thermochemical cycle: Changes in catalyst structure, morphology and metal-support interaction. Appl Catal B. 2015;162:327–37.

Razi F, Dincer I, Gabriel K. Energy and exergy analyses of a new integrated thermochemical copper-chlorine cycle for hydrogen production. Energy. 2020;205:117985.

Naterer GF, Suppiah S, Rosen MA, Gabriel K, Dincer I, Jianu OA, Wang Z, Easton EB, Ikeda BM, Rizvi G, Pioro I, Pope K, Mostaghimi J, Lvov SN. Advances in unit operations and materials for the Cu-Cl cycle of hydrogen production. Int J Hydrogen Energy. 2017;42:15708–23.

El-Emam RS, Dincer I, Zamfirescu C. Enhanced CANDU reactor with heat upgrade for combined power and hydrogen production. Int J Hydrog Energy. 2019;44:23580–8.

Dulera IV, Sinha RK, Rama Rao A, Patel RJ. High temperature reactor technology development in India. Prog Nucl Energy. 2017;101:82–99.

Balta MT, Dincer I, Hepbasli A. Comparative assessment of various chlorine family thermochemical cycles for hydrogen production. Int J Hydrogen Energy. 2016;41(19):7802–13.

Al-Zareer M, Dincer I, Rosen MA. Analysis and assessment of the integrated generation IV gas-cooled fast nuclear reactor and copper-chlorine cycle for hydrogen and electricity production. Energ Convers Manag. 2020;205:112387.

Farsi A, Dincer I, Naterer GF. Second law analysis of CuCl2 hydrolysis reaction in the Cu–Cl thermochemical cycle of hydrogen production. Energy. 2020;202:117721.

Farsi A, Zamfirescu C, Dincer I, Naterer GF. Thermodynamic assessment of lab-scale experimental copper-chlorine cycle for sustainable hydrogen production. Int J Hydrogen Energy. 2019;44:17595–610.

Razi F, Dincer I, Gabriel K. Thermal management of a new integrated copper-chlorine cycle for hydrogen production. Energ Convers Manag. 2020;212:112629.

Wang ZL, Naterer GF, Gabriel KS, Gravelsins R, Daggupati VN. Comparison of different copper-chlorine thermochemical cycles for hydrogen production. Int J Hydrog Energy. 2009;34:3267–76.

Ferrandon MS, Lewis MA, Alvarez F, Shafirovich E. Hydrolysis of CuCl2 in Cu-Cl thermochemical cycle for hydrogen production: Experimental studies using a spray reactor with an ultrasonic atomizer. Int J Hydrogen Energy. 2010;35:1895–904.

Daggupati VN, Naterer GF, Gabriel KS, Gravelsins RJ, Wang ZL. Solid particle decomposition and hydrolysis reaction kinetics in Cu–Cl thermochemical hydrogen production. Int J Hydrog Energy. 2010;35:4877–82.

Pope K, Naterer GF, Wang ZL. Nitrogen carrier gas flow for reduced steam requirements of water splitting in a packed bed hydrolysis reactor. Exp Therm Fluid Sci. 2013;44:815–24.

Lewis MA, Ferrandon MS, Tatterson DF, Mathias P. Evaluation of alternative thermochemical cycles—part III further development of the Cu–Cl cycle. Int J Hydrogen Energy. 2009;34:4136–45.

Singh RV, Pai MR, Banerjee AM, Patkare GR, Pai RV, Kumar A, Yadav AK, Phaphale S, Tripathi AK. Investigations on the hydrolysis step of copper-chlorine thermochemical cycle for hydrogen production. Int J Energy Res. 2020;44:2845–63.

Ferrandon MS, Lewis MA, Tatterson DF, Gross A, Doizi D, Croizé L, Dauvois V, Roujou JL, Zanella Y, Carles P. Hydrogen production by the Cu–Cl thermochemical cycle: Investigation of the key step of hydrolysing CuCl2 to Cu2OCl2 and HCl using a spray reactor. Int J Hydrogen Energy. 2010;35:992–1000.

Thomas D, Baveja NA, Shenoy KT, Joshi JB. Experimental study on the mechanism and kinetics of CuCl2 hydrolysis reaction of Cu–Cl thermochemical cycle in a fluidized bed reactor. Ind Eng Chem Res. 2020;59:12028–37.

Daggupati VN, Naterer GF, Gabriel KS. Diffusion of gaseous products through a particle surface layer in a fluidized bed reactor. Int J Heat Mass Transf. 2010;53:2449–58.

Nixon A, Ferrandon M, Kaye MH, Trevani L. Thermochemical production of hydrogen, Synthesis, characterization, and decomposition of copper oxychloride. J Therm Anal Calorim. 2012;110:1095–105.

Gaur A, Shrivastava BD, Khalid S. Study of XAFS spectroscopic methods of speciation using mixtures of Cu(I) and Cu(II) chlorides. J Phys Conf Ser. 2013;430:012045.

Poswal AK, Agrawal A, Yadav AK, Nayak C, Basu S, Kane SR, Garg CK, Bhattachryya D, Jha SN, Sahoo NK. Commissioning and first results of scanning type EXAFS beamline (BL-09) at INDUS-2 synchrotron source. AIP Conf Proc. 2014;1591:649.

Basu S, Nayak C, Yadav AK, Agrawal A, Poswal AK, Bhattacharyya D, Jha SN, Sahoo NK. A comparative facility for EXAFS measurements at INDUS-2 synchrotron source at RRCAT, Indore, India. . J Phys Conf Ser. 2014;493:012032.

Konigsberger DC, Prins R. X ray Absorption: Principles, Applications, Techniques of EXAFS. New York: SEXAFS and XANES. Wiley; 1988.

Bunker G. Introduction to XAFS: A practical guide to X ray Absorption Fine Structure Spectroscopy. Cambridge University Press; 2010.

Newville M, Ravel B, Haskel D, Rehr JJ, Stern EA, Yacoby Y. Analysis of Multiple Scattering XAFS Data using Theoretical Standards. Physica B Condens Matter. 1995;154:208–9.

Dobkin DM, Zuraw MK. Principles of Chemical Vapor Deposition. What’s going on inside the reactor. 1st ed. Springer Netherlands;2003.

Sarode P, Sankar G, Rao CNR. XANES and EXAFS of copper compounds: studies of copper carboxylates with metal-metal bonds and of the complex formed by Pseudomonas aeruginosa. J Chem Sci. 1983;92:527–42.

Shulman GR, Yafet Y, Eisenberger P, Blumberg WE. Observations and interpretation of X-ray absorption edges in iron compounds and proteins. Proc Natl Acad Sci USA. 1976;73:1384–8.

Ferrandon M, Daggupati V, Wang Z, Naterer G, Trevani L. Using XANES to obtain mechanistic information for the hydrolysis of CuCl2 and the decomposition of Cu2OCl2 in the thermochemical Cu-Cl cycle for H2 production. J Therm Anal Calorim. 2015;119:975–82.

Muddada NB, Olsbye U, Leofanti G, Gianolio D, Bonino F, Bordiga S, Fuglerud T, Vidotto S, Marsella A, Lamberti C. Quantification of copper phases, their reducibility and dispersion in doped CuCl2/Al2O3 catalysts for ethylene oxychlorination. Dalton Trans. 2010;39:8437–49.

Burns PC, Hawthorne FC. Tolbachite, CuCl2, the first example of Cu2+ octahedrally coordinated by Cl-. Am Mineral. 1993;78:187–9.

Hull S, Keen DA. High-pressure polymorphism of the copper(I) halides: A neutron-diffraction study to ∼10 GPa. Phys Rev B Condens Matter. 1994;50:5868–85.

Ahmad A, Elvati P, Violi A. Size and phase-dependent structure of copper (II) oxide nanoparticles. RSC Adv. 2015;5:35033–41.

Krivovichev SV, Filatov SK. The cuprite-like framework of OCu4 tetrahedra in the crystal structure of synthetic melanothallite, Cu2OCl2, and its negative thermal expansion. Can Mineral. 2002;40:1185–90.

Kawashima K, Okabe H, Suzuki K, Kuroiwa S, Akimitsu J, Sato KH, Koda A, Kadono R. Antiferromagnetic ordering in Cu2OCl2 studied by the muon spin rotation/relaxation technique. J Phys: Condens Matter. 2007;19:145275.

Acknowledgements

We thank Dr. A. K. Tyagi, Head, Chemistry Division, Associate Director, Chemistry Group, BARC, for keen support and encouragement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Singh, R.V., Pai, M.R., Banerjee, A.M. et al. Cu–Cl Thermochemical Water Splitting Cycle: Probing Temperature-Dependent CuCl2 Hydrolysis and Thermolysis Reaction Using In Situ XAS. J Therm Anal Calorim 147, 7063–7076 (2022). https://doi.org/10.1007/s10973-021-10969-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10969-y