Abstract

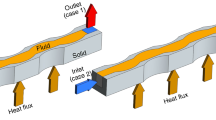

To find the sensitivity and dependence degree of the numerical simulation predictions on the property variations arising from the temperature gradients, a 3D conjugate heat transfer of Al2O3–water nanofluid convecting through rectangular microchannel heat sinks (MCHS) is considered in the present study. The Koo–Kleinstreuer–Li model is adopted to capture the temperature-dependent nature of thermophysical properties of the working nanofluid compared to the pure fluid (i.e., water). Both straight and width-tapered flow passages are studied using finite volume method within the laminar flow regime to see how sensitive are the predictions to the temperature dependency of the thermophysical properties for both the pure base fluid and nanofluid. Results show that the constant property assumption obtains unrealistic results up to 140% for the Reynolds number, which may mislead in predicting the flow regime (laminar/turbulent). The constant property approach predicts the convection heat transfer coefficient and the pumping power, respectively, 31% lower and 33% higher than those of the temperature-dependent property approach. In addition, the present study concludes that the MCHS should be simulated based on the temperature-dependent thermophysical property approach to be more realistic, especially for converging flow passages due to high-temperature gradients and for nanofluids for their induced temperature-dependent properties. The last two issues induced each other and increase the deviation of the predictions based on the constant property assumption. Finally, because of underestimating the heat transfer rate and overestimating the pumping power, the MCHS would be over-designed if one adopts the constant property assumption for conceptual design and the MCHS would perform under inefficient and off-design conditions.

Similar content being viewed by others

Abbreviations

- a 1–10 :

-

Coefficients

- C p :

-

Heat capacity (J kg−1 K−1)

- d p :

-

Diameter of nanoparticles (m)

- D h :

-

Hydraulic diameter (\(2WH/(W + H)\)) (m)

- g′:

-

A function (defined by Eq. 6)

- h :

-

Convection heat transfer coefficient (W m−2 K)

- H :

-

Height (m)

- k :

-

Conductivity (W m−1 K−1)

- Nu:

-

Nusselt number (\(hD_{\text{h}} /k\))

- L :

-

Length (m)

- P :

-

Pressure (Pa)

- Pr:

-

Prandtl number

- q :

-

Heat flux (W m−2)

- \(\dot{Q}\) :

-

Volumetric flow rate (m3 s−1)

- T :

-

Temperature (K)

- t :

-

Thickness (m)

- \(\vec{V}\) :

-

Velocity vector (m s−1)

- W :

-

Width (m)

- W i /W o :

-

Convergence factor

- z :

-

Axial location (m)

- ave:

-

Average

- b:

-

Bulk

- bf:

-

Base fluid

- eff:

-

Effective value

- i:

-

Inlet

- f:

-

Fluid

- h:

-

Hydraulic

- o:

-

Outlet

- p:

-

Nanoparticle

- s:

-

Solid

- W:

-

Wall

- * :

-

Dimensionless value

- \(\mu\) :

-

Viscosity (kg m−1 s−1)

- \(\rho\) :

-

Density (kg m−3)

- \(\phi\) :

-

Volume fraction (%)

References

Xu HJ, Zhao CY. Analytical considerations on optimization of cascaded heat transfer process for thermal storage system with principles of thermodynamics. Renew Energy. 2019;132:826–45.

Fuqiang W, Huijian J, Hao W, Ziming C, Jianyu T, Yuan Y, Yuhang S, Wenjie Z. Conductive and laminar convective coupled heat transfer analysis of molten salts based on finite element method. Appl Therm Eng. 2018;31:19–29.

Ma DD, Xia GD, Wang J, Yang YC, Jia YT, Zong LX. An experimental study on hydrothermal performance of microchannel heat sinks with 4-ports and offset zigzag channels. Energy Convers Manag. 2017;152:157–65.

Kandlikar S, Garimella S, Li D, Colin S, King MR. Heat transfer and fluid flow in minichannels and microchannels. Amsterdam: Elsevier; 2005.

Xu H, Zhao C, Vafai K. Analysis of double slip model for a partially filled porous microchannel—an exact solution. Eur J Mech B Fluids. 2018;68:1–9.

Dehghan M, Jamal-Abad MT, Rashidi S. Analytical interpretation of the local thermal non-equilibrium condition of porous media imbedded in tube heat exchangers. Energy Convers Manag. 2014;85:264–71.

Xu HJ, Xing ZB, Wang FQ, Cheng ZM. Review on heat conduction, heat convection, thermal radiation and phase change heat transfer of nanofluids in porous media: fundamentals and applications. Chem Eng Sci. 2018;195:462–83.

Dehghan M. Effects of heat generations on the thermal response of channels partially filled with non-Darcian porous materials. Transp Porous Media. 2015;110(3):461–82.

Akar S, Rashidi S, Esfahani JA, Karimi N. Targeting a channel coating by using magnetic field and magnetic nanofluids. J Therm Anal Calorim. 2019;137:1–8.

Rashidi S, Karimi N, Mahian O, Esfahani JA. A concise review on the role of nanoparticles upon the productivity of solar desalination systems. J Therm Anal Calorim. 2019;135(2):1145–59.

Hoseinpour B, Ashorynejad HR, Javaherdeh K. Entropy generation of nanofluid in a porous cavity by lattice Boltzmann method. J Thermophys Heat Transf. 2016;31(1):20–7.

Toh KC, Chen XY, Chai JC. Numerical computation of fluid flow and heat transfer in microchannels. Int J Heat Mass Transf. 2002;45(26):5133–41.

Herwig H, Mahulikar SP. Variable property effects in single-phase incompressible flows through microchannels. Int J Therm Sci. 2006;45(10):977–81.

Husain A, Kim KY. Optimization of a microchannel heat sink with temperature dependent fluid properties. Appl Therm Eng. 2008;28(8–9):1101–7.

Li Z, Huai X, Tao Y, Chen H. Effects of thermal property variations on the liquid flow and heat transfer in microchannel heat sinks. Appl Therm Eng. 2007;27(17–18):2803–14.

Liu JT, Peng XF, Wang BX. Variable-property effect on liquid flow and heat transfer in microchannels. Chem Eng J. 2008;141(1–3):346–53.

Liu JT, Peng XF, Yan WM. Numerical study of fluid flow and heat transfer in microchannel cooling passages. Int J Heat Mass Transf. 2007;50(9–10):1855–64.

Mirzaei M, Dehghan M. Investigation of flow and heat transfer of nanofluid in microchannel with variable property approach. Heat Mass Transf. 2013;49(12):1803–11.

Lee PS, Garimella SV, Liu D. Investigation of heat transfer in rectangular microchannels. Int J Heat Mass Transf. 2005;48(9):1688–704.

Koo J, Kleinstreuer C. A new thermal conductivity model for nanofluids. J Nanopart Res. 2004;6(6):577–88.

Li J. Computational analysis of nanofluid flow in microchannels with applications to micro-heat sinks and bio-MEMS. Ph.D. dissertation, MAE department, NCSU, Raleigh, NC, 2008.

Li J, Kleinstreuer C. Thermal performance of nanofluid flow in microchannels. Int J Heat Fluid Flow. 2008;29(4):1221–32.

Nield DA, Kuznetsov AV. Forced convection in cellular porous materials: effect of temperature-dependent conductivity arising from radiative transfer. Int J Heat Mass Transf. 2010;53(13–14):2680–4.

Dehghan M, Rahmani Y, Ganji DD, Saedodin S, Valipour MS, Rashidi S. Convection–radiation heat transfer in solar heat exchangers filled with a porous medium: homotopy perturbation method versus numerical analysis. Renew Energy. 2015;74:448–55.

Dehghan M, Mahmoudi Y, Valipour MS, Saedodin S. Combined conduction–convection–radiation heat transfer of slip flow inside a micro-channel filled with a porous material. Transp Porous Media. 2015;108(2):413–36.

Dehghan M, Valipour MS, Saedodin S. Temperature-dependent conductivity in forced convection of heat exchangers filled with porous media: a perturbation solution. Energy Convers Manag. 2015;91:259–66.

Hung TC, Sheu TS, Yan WM. Optimal thermal design of microchannel heat sinks with different geometric configurations. Int Commun Heat Mass Transf. 2012;39(10):1572–7.

Hung TC, Yan WM. Optimization of a microchannel heat sink with varying channel heights and widths. Numer Heat Transf Part A Appl. 2012;62(9):722–41.

Dehghan M, Daneshipour M, Valipour MS, Rafee R, Saedodin S. Enhancing heat transfer in microchannel heat sinks using converging flow passages. Energy Convers Manag. 2015;92:244–50.

Dehghan M, Daneshipour M, Valipour MS. Nanofluids and converging flow passages: a synergetic conjugate-heat-transfer enhancement of micro heat sinks. Int Commun Heat Mass Transf. 2018;97:72–7.

Akar S, Rashidi S, Esfahani JA. Second law of thermodynamic analysis for nanofluid turbulent flow around a rotating cylinder. J Therm Anal Calorim. 2018;132(2):1189–200.

Dehghan M, Tabrizi HB. On near-wall behavior of particles in a dilute turbulent gas–solid flow using kinetic theory of granular flows. Powder Technol. 2012;224:273–80.

Dehghan M, Basirat Tabrizi H. Turbulence effects on the granular model of particle motion in a boundary layer flow. Can J Chem Eng. 2014;92(1):189–95.

Dehghan M, Valipour MS, Keshmiri A, Saedodin S, Shokri N. On the thermally developing forced convection through a porous material under the local thermal non-equilibrium condition: an analytical study. Int J Heat Mass Transf. 2016;92:815–23.

Dehghan M, Valipour MS, Saedodin S, Mahmoudi Y. Investigation of forced convection through entrance region of a porous-filled microchannel: an analytical study based on the scale analysis. Appl Therm Eng. 2016;99:446–54.

Kakac S, Shah RK, Aung W. Handbook of single-phase convective heat transfer. New York: Wiley; 1987.

Bejan A. Convection heat transfer. Hoboken: Wiley; 2013.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dehghan, M., Vajedi, H., Daneshipour, M. et al. Pumping power and heat transfer rate of converging microchannel heat sinks: errors associated with the temperature dependency of nanofluids. J Therm Anal Calorim 140, 1267–1275 (2020). https://doi.org/10.1007/s10973-019-09020-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09020-y