Abstract

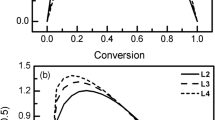

The non-isothermal decomposition behavior of grape marc (GM) residues from wine industry was investigated by using different thermal analysis techniques, including: (1) thermogravimetric analysis/differential thermogravimetry (TGA-DTG) to study the thermal decomposition kinetics; (2) thermogravimetry (TG-DTG) coupled with Fourier transform infrared spectroscopy (FTIR) to investigate the nature of the gas-phase products released during the pyrolytic breakdown; and (3) simultaneous thermogravimetry/differential scanning calorimetry (TGA–DSC) analysis to obtain information on the heat flows associated with the thermal decomposition of grape marc. Thermogravimetric measurements at five different heating rates (i.e., 2.5, 5, 10, 20, 40 K min−1) were performed for the kinetic computations, which were carried out by adopting a “model-free” approach based on the application of isoconversional methods. In more details, two different integral methods, i.e., the linear Ozawa–Flynn–Wall (OFW) method and the nonlinear Vyazovkin incremental method, were comparatively used in order to obtain a set of kinetic parameters useful for the conceptual design of thermochemical processes involving grape marc. The reliability of the obtained parameters was confirmed by the successful application of the same data to reproduce experimental TG curves not included in the kinetic computations. The effect of the heating rate on the nature of the gas-phase products arising from grape marc decomposition as well as on the heat flows associated with the pyrolytic process was also investigated. Finally, the study was complemented with an extensive investigation on chemical and physical properties of grape marc residues (i.e., ultimate analysis, proximate analysis, calorific values determination, FTIR analysis and cellulose, hemicellulose and lignin content determination), which provides useful input data for modeling grape march conversion processes.

Similar content being viewed by others

References

Hussain M, Cholette S, Castaldi RM. J Global Market. 2008;21:33–47.

Mattsson B, Sonesson U. Environmentally-friendly food processing. 1st ed. Cambridge: Woodhead Publishing; 2003.

Amico V, Napoli EM, Renda A, Ruberto G, Spatafora C, Tringali C. Food Chem. 2004;88:599–607.

Galanakis CM. Handbook of grape processing by-products: sustainable solutions. London: Academic Press; 2017.

Singh-Nee NP, Pandey A. Biotechnology for agro-industrial residues utilization. Dordrecht: Springer; 2009.

Baumgartel T, Kluth H, Epperlein K, Rodehutscord M. Small Rumin Res. 2007;67:302–6.

Schieber A, Stintzing FC, Carle R. Trends Food Sci Technol. 2001;12:401–13.

Hang YD, Lee CY, Woodams EE. Biotechnol Lett. 1986;8(53-5):6.

Hang YD, Woodams EE. Biotechnol Lett. 1985;7:253–4.

Negro C, Tommasi L, Miceli L. Bioresour Technol. 2003;87:41–4.

Llobera A, Cañellas J. Food Chem. 2007;101:659–66.

Basso D, Patuzzi F, Castello D, Baratieri M, Rada EC, Weiss-Hortala E, Fiori L. Waste Manage. 2016;47:114–21.

Petrović N, Perišić JD, Maksimović V, Maksimović M, Kragović M, Stojanović M, Lauševil M, Mihajlovi M. J Anal Appl Pyrol. 2016;118:267–77.

Lapuerta M, Hernández JJ, Pazo A, López J. Fuel Process Technol. 2008;89:828–37.

Miranda MT, Arranz JI, Román S, Rojas S, Montero I, López M, Cruz JA. Fuel Process Technol. 2011;92:278–83.

Miranda T, Román S, Montero I, Nogales-Delgado S, Arranz JI, Rojas CV, González JF. Fuel Process Technol. 2012;103:160–5.

Casazza AA, Aliakbarian B, Lagazzo A, Garbarino G, Carnasciali MM, Perego P, Busca G. Fuel Process Technol. 2016;153:121–8.

Botelhoa T, Costa M, Wilk M, Magdziarz A. Fuel. 2018;212:95–100.

Junges J, Carvalho Collazzo G, Perondi D, et al. Therm Anal Calorim. 2018;134:2329–38.

dos Reis Ferreira RA, da Silva Meireles C, Assunção RMN, et al. J Therm Anal Calorim. 2018;132:1535–44.

Brachi P, Miccio F, Miccio M, Ruoppolo G. Fuel Process Technol. 2015;130:147–54.

Brachi P, Miccio F, Miccio M, Ruoppolo G. Fuel Process Technol. 2016;154:243–50.

Adiletta G, Brachi P, Riianova E. et al. Waste Biomass Valor. (2019). In press. https://doi.org/10.1007/s12649-019-00582-4.

Vyazovkin S, Sbirrazzuoli N. Macromol Rapid Commun. 2006;27:1515–32.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. Thermochim Acta. 2011;520:1–19.

Ozawa T. B Chem Soc Jpn. 1965;38:1881–6.

Trache D, Abdelaziz A, Siouani B. J Therm Anal Calorim. 2017;128:335–48.

Zhao H, Yan H, Dong S, Zhang Y, Sun B, Zhang C, Qin S. J Therm Anal Calorim. 2013;111:1685–90.

Han Z, Zhuang D, Yan H, Zhao H, Sun B, Li D, Sun Y, Hu W, et al. J Therm Anal Calorim. 2017;127:1371–9.

Zhao H, Yan H, Zhang C, et al. J Therm Anal Calorim. 2012;110:611–7.

Lwin Y. Int J Eng Educ. 2000;16:335–9.

Viazovkyn S. Int J Chem Kinet. 1996;28:95–101.

Hyndmana RJ, Koehler AB. Int J Forecast. 2006;22:679–88.

Pouchert JC. The Aldrich Library of FT-IR. 1st ed. Milwaukee: Aldrich Chemical Company Inc; 1989.

Zapata B, Balmaseda J, Fregoso-Israel E, Torres-Garcia E. J Therm Anal Calorim. 2009;98:309–15.

Brachi P, Riianova E, Miccio M, Miccio F, Ruoppolo G, Chirone R. Energy Fuels. 2017;31:9595–604.

Bellamy LJ. The infrared spectra of complex molecules. London: Methuen & Co LTD; 1959.

Xiong F, Han Y, Wang S, Li G, Qin T, Chen Y, Chu F. ACS Sustain Chem Eng. 2017;5:2273–81.

Badot PM, Crini G. Sorption processes and pollution: conventional and non-conventional sorbents for pollutant removal from wastewaters. Besançon: Presses Universitaires de Franche-Comté; 2010.

Kacurakova M, Capek P, Sasinkova V, Wellner N, Ebringerova A. Carbohydr Polym. 2000;43:195–203.

Jin AX, Ren JL, Peng F, Xu F, Zhou GY, Sun RC, Kennedy JF. Carbohydr Polym. 2009;78:609–19.

Arenillas A, Pevida C, Rubiera F, Garcıa R, Pis J. J Anal Appl Pyrol. 2004;71:747–63.

Galano A, Aburto J, Sadhukhan J, Torres-García E. J Anal Appl Pyrol. 2017;128:208–16.

Lopez-Velazquez MA, Santes V, Balmaseda J, Torres-Garcia E. J Anal Appl Pyrol. 2013;99:170–7.

Tumuluru JS, Sokhansanj S, Hess JR, Wright CT, Boardman R. Ind Biotechnol. 2011;7:384–401.

Chen WH, Peng J, Bi XT. Renew Sustain Energy Rev. 2015;44:847–66.

Heydari M, Rahman M, Gupta R. Int J Chem Eng. 2015;2015:1–9.

Aburto J, Moran M, Galano A, Torres-García E. J Anal Appl Pyrol. 2015;11:94–104.

Miranda R, Bustos-Martinez D, Sosa Blanco C, Gutièrrez Villarreal MH, Rodrigues Cantù ME. J Anal Appl Pyrol. 2009;86:245–51.

Leng Y. Material characterization: introduction to microscopic and spectroscopic methods. Singapore: John Wiley & Sons (Asia) Pte Ltd; 2008.

Yang H, Yan R, Chen H, Ho Lee D, Zheng C. Fuel. 2007;86:1781–8.

Milosavljevic I, Oja V, Suuberg EM. Ind Eng Chem Res. 1996;35:653–62.

Mok WSL, Antal MJ Jr. Thermochim Acta. 1983;68:165–86.

Cho J, Davis JM, Huber GW. Chemsuschem. 2010;3:1162–5.

Nakamoto K. Infrared and Raman spectra of inorganic and coordination compounds. 5th ed. Hoboken: Wiley; 1997.

Yeo JY, Chin BLF, Tan JK, Loh YS. J Energy Inst. (2017) In press. https://doi.org/10.1016/j.joei.2017.12.003.

Mohan M, Gupta NK, Kumar M. Inorg Chim Acta. 1992;197:39–46.

Cervantes-Uc JM, Cauich-Rodríguez JV, Vázquez-Torres H, Garfias Mesías LF, Paul DR. Thermochim Acta. 2007;457:92–102.

Brachi P, Chirone R, Miccio F, Miccio M, Picarelli A, Ruoppolo G. Fuel. 2015;128:88–98.

Kalogiannis KG, Stefanidis SD, Michailof CM, Lappas AA, Sjöholm E. J Anal Appl Pyrol. 2015;115:410–8.

Kacurakova M, Capek P, Sasinkova V, Wellner N, Ebringerova A. Carbohydr Polym. 2000;43:195–203.

Grigiante M, Brighenti M, Antolini D. Renew Energy. 2016;99:1318–26.

Grigiante M, Brighenti M, Antolini D. J Therm Anal Calorim. 2017;129:553–65.

Dong Z, Cai J. J Energy Inst. 2018;91:513–8.

Chen T, Cai J, Liu R. Sour Recovery Util Environ Eff. 2015;37:2208–17.

Sharara M, Sadaka S. J Sustain Bioenergy Syst. 2014;4:75–86.

Slopiecka K, Bartocci P, Fantozzi F. Appl Energy. 2012;97:491–7.

Mamleev V, Bourbigot S, Le Bras M, Yvon J, Lefebvre J. Chem Eng Sci. 2006;61:1276–92.

Aboyade AO, Hugo TJ, Carrier M, Meyer EL, Stahl R, Knoetze JH, Görgens JF. Thermochim Acta. 2011;517:81–9.

Cai J, Xu D, Dong Z, Yu X, Yang Y, Banks SW, Bridgwater AW. Renew Sustain Energy Rev. 2017;82:2705–15.

Carrier M, Auret L, Bridgwater A, Knoetze JH. Energy Fuel. 2016;30:7834–41.

Hache F, Delichatsios M, Fateh T, Zhang J. J Fire Sci. 2015;33:232–46.

Šimon P. J Therm Anal Calorim. 2004;76:123–32.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Torres-Garcia, E., Brachi, P. Non-isothermal pyrolysis of grape marc. J Therm Anal Calorim 139, 1463–1478 (2020). https://doi.org/10.1007/s10973-019-08530-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08530-z