Abstract

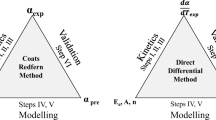

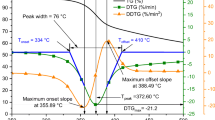

In this work, the thermo-gravimetric and differential thermo-gravimetric curves of rice husk at different heating rates (20, 40, 60, 80 and 100 °C min−1) were obtained using a thermo-gravimetric analyzer under nitrogen atmosphere. The pyrolysis characteristics of rice husk were analyzed. The fitted Gaussian function peaks showed that the pyrolysis mass loss of rice husk can be characterized by three independent reactions. The devolatilization index D was calculated, and the effect of different experimental statuses on the pyrolysis of rice husk was discussed. The kinetic parameters of rice husk were calculated using iso-conversional models and distributed activation energy models (DAEMs). The kinetic parameters obtained by differential Friedman method and integral Ozawa method were found to be 224.85 kJ mol−1 and 220.06 kJ mol−1, respectively. The apparent activation energies for pyrolysis were not fixed value and continuously fluctuated with the increase in conversion rate. The kinetic parameters, obtained using the Kissinger method, were relatively simple and could not represent the variation trends of variables. Six different probability density functions for DAEMs were used to compute the pyrolysis kinetic parameters. The energy compensation effect existed between the activation energy and the frequency factors. It can be concluded from a comprehensive F test and the amount criterion test (Akaike information criterion test) that the Weibull model is more appropriate to study the pyrolysis of rice husk. Finally, the apparent activation energy, calculated using the Weibull model, was calculated to be 131.97 kJ mol−1, whereas the reaction order was 3.2.

Similar content being viewed by others

References

Liu CF. The development of biomass energy and its energy application. Shanxi J Agric Sci. 2015;61(08):74–6.

Chen D, Jiang X, Lv S, et al. Thermal treatment of Indonesian lignite washery tailing. Part 2. Kinetic analysis. J Therm Anal Calorim. 2016;123:1735–42.

Shi YY, Li SY, Hu HQ, et al. Studies on pyrolysis characteristic of lignite and properties of its pyrolysates. J Anal Appl Pyrol. 2012;95:75–8.

Magdziarz A, Malgorzata W. Thermal characteristics of the combustion process of biomass and sewage sludge. J Therm Anal Calorim. 2013;114:519–29.

Xiang L, Meiqian C, Yuanghang W. Kinetics based on two-stage for co-combustion of herbaceous biomass and bituminous coal. Fuel. 2015;143:577–83.

Han XX, Jiang XM, Cui ZG. Study of the combustion mechanism of shale semicoke in a thermgravimetric analyzer. J Therm Anal Calorim. 2008;92(2):595–600.

Williams PT, Home PA. The role of metal salts in the pyrolysis of biomass. Trans Chin Soc Agric Eng. 1994;4(1):1–13.

Wang X, Hu M, Hu WY, et al. Thermo-gravimetric kinetic study of agricultural residue biomass pyrolysis based on combined kinetics. Bioresour Technol. 2016;219:510–20.

Cheng SQ, Shang LL, Zhang HQ. The pyrolysis characteristics of biomass and its kinetic law. J coal. 2006;31(4):501–6.

Cai JM, Yi WM, He F, et al. Kinetic analysis of slow pyrolysis of nut shell biomass. Trans Chin Soc Agric Eng. 2006;22(1):119–22.

Wang MF, Jiang EC, Zhang Q, et al. Trans Chin Soc Agric Eng. 2011;27(S2):114–8.

Che DY, Jiang WQ. Experiments on the pyrolysis of rice husk based on TG-FTIR analysis. J Chin Agric Mech. 2016;37(05):241–7.

Wang YP, Liu YH, Ruan RS, et al. Comparison and analysis of physicochemical properties of rice hull pyrolysis kinetics. J Agric Mech Res. 2015;37(03):254–7.

Hou J, Hou SL, Zhao LX, et al. Typical biomass particle fuel combustion characteristics test. J Agric Eng. 2010;26(5):220–6.

Tian H, Liao ZZ. Pyrolysis characteristics of biomass and oil shale mixture. Clean Coal Technol. 2015;21(03):93–7.

Chen XP, Gu LF, Han XQ, et al. Pyrolysis characteristics and ash fusion property of sludge and blended fuel of sludge and coal. J Southeast Univ (Nat Sci Ed). 2008;38(06):1038–43.

Vyazovkin S, Burnham AK, Criado JM, et al. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520(1):1–19.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38(11):1881–6.

Roduit B, Dermaut W, Lunghi A, et al. Advanced kinetics-based simulation of time to maximum rate under adiabatic conditions. J Therm Anal Calorim. 2008;93(1):163–73.

ASTM E-698-05. Standard test method for arrhenius kinetic constants for thermally unstable materials. ASTM International, West Conshohocken, PA, ASTM Standard E 698; 1999. http://www.astm.org.

Braun BL, Burnham AK. Analysis of chemical reaction kinetics using a distribution of activation energies and simpler models. Energy Fuels. 1987;1:153–61.

Soriaverdugo A, Garcíahernando N, Garciagutierrez LM, et al. Analysis of biomass and sewage sludge devolatilization using the distributed activation energy model. Energy Convers Manag. 2013;65(65):239–44.

Cai J, Wu W, Liu R. An overview of distributed activation energy model and its application in the pyrolysis of lignocellulosic biomass. Renew Sustain Energy Rev. 2014;36:236–46.

Yao X, Xu K, Yan F, et al. Comparative study on pyrolysis characteristics and dynamics characteristics of different agriculture. J Northeast Univ (Nat Sci). 2016;37(11):1593–7.

Min FF, Zhang MX, Chen QR, et al. Study on catalytic pyrolysis of fresh biomass. Chem Ind For Prod. 2008;28(3):28–34.

Fu XF, Zhong ZP, Xiao G, et al. Comparative study on pyrolysis characteristics and dynamics of grass biomass. Trans Chin Soc Agric Eng. 2009;25(01):199–202.

Xu TT, Xu F, Hu ZQ, et al. Non-isothermal kinetics of biomass-pyrolysis-derived-tar (BPDT) thermal decomposition via thermogravimetric analysis. Energy Convers Manag. 2017;138:452–60.

Yishui Tian R, Wang R. Thermokinetics analysis of biomass based on model-free different heating rate method. Trans Chin Soc Agric Eng. 2016;32(3):234–40.

Haensel T, Comouth A, Lorenz P, et al. Pyrolysis of cellulose and lignin. Appl Surf Sci. 2009;255(18):8183–9.

Templeton DW, Quinn M, Van WS, et al. Separation and quantification of microalgal carbohydrates. J Chromatogr. 2012;1270(24):225–34.

Roduit B, Folly P, Berger B, et al. Evaluating sadt by advanced kinetics-based simulation approach. J Therm Anal Calorim. 2008;93(1):153–61.

Hu RZ, Shi QZ. Thermal analysis kinetics. Beijing: Science Press; 2001. p. 151–9.

Wang ZX, Chen MQ, Wang J, et al. Study on characteristics and kinetics of pyrolysis process of rice husk. J Anhui Univ Sci Technol (Nat Sci). 2009;29(01):43–6.

Burnham K, Anderson D. Multi-model inference understanding AIC and BIC in model selection. Soc Methods Res. 2004;32:261–304.

Cai J, Liu R. Weibull mixture model for modeling non-isothermal kinetics of thermally stimulated solid-state reactions: application to simulated and real kinetic conversion data. Phys Chem B. 2007;111:10681–6.

Acknowledgements

This research was supported by the Natural Science Foundation of China (No. 51676032), The China Scholarship Council (CSC) and The Development of Education of Jilin Province (JJKH20190702KJ).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jia, C., Chen, J., Liang, J. et al. Pyrolysis characteristics and kinetic analysis of rice husk. J Therm Anal Calorim 139, 577–587 (2020). https://doi.org/10.1007/s10973-019-08366-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08366-7