Abstract

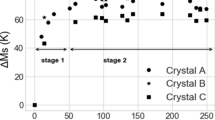

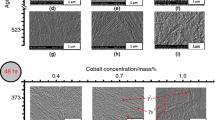

Isothermal treatments at 413 K were performed in Cu–Al–Mn shape memory alloy samples, to study their effects on the martensitic transformation. This procedure, within the miscibility gap, produces spinodal decomposition. After each aging thermal treatment, martensitic transformation was monitored using Differential Scanning Calorimetry (DSC). Spinodal decomposition significantly changes the characteristics of the martensitic transition, reducing the transformed volume and modifying the critical temperatures. Furthermore, transformation hysteresis loop narrows as the volume fraction of the spinodal precipitates increases. Effects of thermal cycling through the martensitic transformation were studied in aged alloy samples. It was found that cycling produces critical temperatures changes, an increase in the transformed volume fraction, and a wider hysteresis loop. The observed results were discussed considering the interaction between spinodal precipitates and martensitic plates.

Similar content being viewed by others

References

Ahlers M. Martensite and equilibrium phases in Cu-Zn and Cu-Zn-Al alloys. Prog Mater Sci. 1986;30:135–86.

Ortín J, Delaey L. Hysteresis in shape-memory alloys. Int J Non Linear Mech. 2002;37:1275–81.

Mallik US, Sampath V. Effect of alloying on microstructure and shape memory characteristics of Cu–Al–Mn shape memory alloys. Mater Sci Eng, A. 2008;481–482:680–3.

Prado MO, Decorte PM, Lovey FC. Martensitic transformation in Cu-Mn-Al Alloys. Scr Metall Mater Mater. 1995;33:877–83.

Obradó E, Mañosa L, Planes A. Stability of the bcc phase of Cu-Al-Mn shape-memory alloys. Phys Rev B. 1997;56:20–3.

Kainuma R, Satoh N, Liu XJ, Ohnuma I, Ishida K. Phase equilibria and Heusler phase stability in the Cu-rich portion of the Cu–Al–Mn system. J Alloys Compd. 1998;266:191–200.

Bouchard M, Livak RJ, Thomas G. Interphase interfaces in spinodal alloys. Surf Sci. 1972;31:275–95.

Bouchard M, Thomas G. Phase Transitions and Modulated Structures in Ordered (Cu-Mn)3Al Alloys. Acta Metall. 1975;23:1485–500.

Marcos J, Mañosa L, Planes A, Romero R, Castro ML. Kinetics of the phase separation in Cu–Al–Mn alloys and the influence on martensitic transformations. Philos Mag. 2004;84:45–68.

Kokorin VV, Kozlova LE, Titenko AN. Temperature hysteresis of martensite transformation in aging Cu-Mn-Al alloy. Scr Mater. 2002;47:499–502.

Aslani H, Cabrera C, Rahnama M. Potential of Cu-Al-Mn alloys bars for seismic applications. Earthq Eng Struct Dyn. 2012;41:1549–68.

O’Brien B, Bruzzi M. Shape Memory Alloys for use in medicine. Compr. Biomater. Vol. 1. Elsevier Ltd.; 2011.

Oliveira JP, Panton B, Zeng Z, Omori T, Zhou Y, Miranda RM, et al. Laser welded superelastic Cu-Al-Mn shape memory alloy wires. Mater Des. 2016;90:122–8.

Pishchur DP, Drebushchak VA. Recommendations on DSC calibration. J Therm Anal Calorim. 2016;124:951–8.

Kato H, Sasaki K. Avoiding error of determining the martensite finish temperature due to thermal inertia in differential scanning calorimetry : model and experiment of Ni–Ti and Cu–Al–Ni shape memory alloys. J Mater Sci. 2012;47:1399–410.

Pelegrina JL, Torra V. Comment on “Effects of heat-flux features on the differential scanning calorimetry curve of a thermoelastic martensitic transformation” by Benke et al. [Mater Sci Eng A 481-482 (2008) 522]. Mater Sci Eng A 2010;527:2437–40.

Lohan NM, Pricop B, Burlacu L, Bujoreanu L-G. Using DSC for the detection of diffusion-controlled phenomena in Cu-based shape memory alloys. J Therm Anal Calorim. 2016. doi:10.1007/s10973-016-5926-4.

Pelegrina JL, Romero R. Calorimetry in Cu–Zn–Al alloys under different structural and microstructural conditions. Mater Sci Eng, A. 2000;282:16–22.

Salzbrenner RJ, Cohen M. On the thermodinamics of thermoelastic martensitic transformations. Acta Metall. 1979;27:739–48.

Planes A, Romero R, Ahlers M. Thermal properties of the martensitic transformation of Cu-Zn and Cu-Zn-Al shape memory alloys. Scr Metall. 1989;23:989–94.

Bachaga T, Rekik H, Krifa M, Suñol JJ, Khitouni M. Investigation of the enthalpy/entropy variation and structure of Ni–Mn–Sn (Co, In) melt-spun alloys. J Therm Anal Calorim. 2016. doi:10.1007/s10973-016-5716-z.

de Castro Bubani F, Lovey FC, Sade ML. A short review on the interaction of precipitates and martensitic transitions in CuZnAl shape memory alloys. Funct Mater Lett. 2017;10:1740006.

Zárubová N, Gemperle A, Novak V. Initial stages of y2 precipitation in an aged Cu-Al-Ni shape memory alloy. Mater Sci Eng, A. 1997;222:166–74.

Araujo VEA, Gastien R, Zelaya E, Beiroa JI, Corro I, Sade M, et al. Effects on the martensitic transformations and the microstructure of CuAlNi single crystals after ageing at 473 K. J Alloys Compd. 2015;641:155–61.

Cuniberti A, Montecinos S, Lovey FC. Effect of γ2-phase precipitates on the martensitic transformation of a β-CuAlBe shape memory alloy. Intermetallics. 2009;17:435–40.

Pons J, Portier R. Accommodation of γ-phase precipitates in Cu-Zn-Al shape memory alloys studied by high resolution electron microscopy. Acta Mater. 1997;45:2109–20.

Pons J, Cesari E. Precipitates in β Cu-Zn-Al: Iinfluence on Martensitic Transformations. Thermochim Acta. 1989;145:237–43.

Lovey FC, Torra V, Isalgué A, Roqueta D, Sade M. Interaction of single variant martensitic transformation with small γ type precipitates in CuZnAl. Acta Metall Mater. 1994;42:453–60.

Lovey FC, Torra V. Shape memory in Cu-based alloys: phenomenological behavior at the mesoscale level and interaction of martensitic transformation with structural defects in Cu-Zn-Al. Prog Mater Sci. 1999;44:189–289.

Auguet C, Cesari E, Rapacioli R, Mañosa L. Effect of γ precipitates on the martensitic transformation of β CuZnAl studied by calorimetry. Scr Metall. 1989;23:579–83.

Pons J, Cesari E. Martensitic Transformation Cycling in a β Cu-Zn-Al Alloy Containing γ-Precipitates. Acta Met Mater. 1993;41:2547–55.

Liu Y, McCormick PG. Thermodynamic analysis of the martensitic transformation in NiTi-I. Effect of heat treatment on transformation behaviour. Acta Metall Mater. 1994;42:2401–6.

Cuniberti A, Romero R, Ahlers M. The plastic deformation of long range ordered 18R martensitic single crystals of Cu-Zn-Al alloys. Scr Metall Mater. 1992;26:495–500.

Umakoshi Y, Yamaguchi M, Yamane T. Deformation and fracture behaviour of the alloy Cu2MnAl single crystals. Acta Metall. 1984;32:649–54.

Cuniberti A, Romero R. Differential scanning calorimetry study of deformed Cu-Zn-Al martensite. Scr Mater. 2004;51:315–20.

Yawny A, Lovey FC, Torra V. Entropy production in single-crystal single-interface martensite transformation. Scr Metall Mater. 1995;32:439–44.

Wollants P, Roos JR, Delaey L. Thermally and stress-induced thermoelastic martensitic transformations in the reference frame of equilibrium thermodynamics. Prog Mater Sci. 1993;37:227–88.

Lashley JC, Drymiotis FR, Safarik DJ, Smith JL, Romero R, Fisher RA, et al. Contribution of low-frequency modes to the specific heat of Cu-Zn-Al shape-memory alloys. Phys Rev B. 2007;75:64304.

Tuncer N, Qiao L, Radovitzky R, Schuh CA. Thermally induced martensitic transformations in Cu-based shape memory alloy microwires. J Mater Sci. 2015;50:7473–87.

Acknowledgements

This work has been carried out with the financial support of the CONICET, ANPCYT, SECAT-UNCPBA and CICPBA, Argentina. We are grateful for our fruitful discussions with our colleague Dra. A. Cuniberti and her critical reading of this paper’s manuscript. The authors acknowledge O. Toscano and E. Portalez for their contributions to the experimental work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Velazquez, D., Romero, R. Spinodal decomposition and martensitic transformation in Cu–Al–Mn shape memory alloy. J Therm Anal Calorim 130, 2007–2013 (2017). https://doi.org/10.1007/s10973-017-6584-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6584-x