Abstract

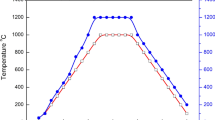

The present study has investigated the complex mechanisms in the aluminum–titanium system with different percentages of titanium through a combination of thermal and X-ray analyses. Thermogravimetry, derivative thermogravimetric, X-ray diffraction, scanning electron microscope and transition electron microscope were used for characterization of the samples. Initially, different Al–Ti powder mixtures were produced by high-energy ball milling and after 30 h of milling the phases generated at different percentages of Ti were analyzed. The XRD results revealed that the intermetallic Al3Ti powder is obtained after a certain duration of milling. In addition, L12 to D023 phase transformation is possible with increase of the Ti percent. Analyses of the powder annealed at different temperatures yielded interesting results, including the effect of stearic acid as the surface control agent on phase transformations of the aluminum–titanium system and also the formation of unexpected phases such as Al4C3 and TiC. Moreover, ductile to brittle transition during phase transformations of the intermetallic Al3Ti powder was quite conspicuous, which could result in more homogeneity of the powders and the occurrence of more reactions in the system. For example, formation of D023-Al3Ti powder which is more brittle compared to L12 resulted in the exit of Al from among its layers, leading to the increase of the chances for Al reaction with the system impurities.

Similar content being viewed by others

References

Karpets MV, Milman YV, Barabash OM, Korzhova NP, Senkov ON, Legkaya TN, Miracle DB, Voskoboyni IV. The influence of Zr alloying on the structure and properties of Al3Ti. Intermetallics. 2003;11:241–9.

Harada Y, Dunand DC. Microstructure of Al3Sc with ternary transition-metal additions. Mater Sci Eng A. 2002;329:686–95.

Dreizin E, Schoenitz M, Shoshin Y, Shtessel E. Proceedings of the eighth international workshop on combustion and propulsion Pozzuoli. In: DeLuca L, editor. Italy; 2002.

Schoenitz M, Zhu X, Dreizin EL. Mechanical alloys in the Al-rich part of the Al–Ti binary system. J Metastab Nanocryst Mater. 2004;20–21:455–61.

Zhu X, Schoenitz M, Dreizin EL. Oxidation of mechanically alloyed Al-rich Al–Ti powders. Oxid Met. 2006;65:357–76.

Schoenitz M, Zhu X, Dreizin EL. Carbide formation in Al–Ti mechanical alloys. Scripta Mater. 2005;53:1095–9.

Khorsand Zak A, Abd Majid WH, Abrishami ME, Yousefi R. X-ray analysis of ZnO nanoparticles by Williamsone Hall and size strain plot methods. Solid State Sci. 2001;13:251–6.

Zhang F, Lu L, Lai MO. Study of thermal stability of mechanically alloyed Ti–75% Al powders. J Alloy Compd. 2000;297:211–8.

Hong QZ, Lilienfeld DA, Mayer JW. Thermal and ion-induced, metastable-cubic Al3M phases in Al–Ti and Al–Hf thin films. J Appl Phys. 1988;64:4478.

Schwarz RB, Desch PB, Srinivasan S. In: Turchi PEA, Gonis A, editors. Static and dynamics of alloy phase transformation. New York: Plenum Press; 1994.

Klassen T, Oehring M, Bormann R. The early stages of phase formation during mechanical alloying of Ti–Al. J Mater Res. 1994;9:47–52.

Foley JC, Perepezko JH, Skinner DJ. Formation of metastable L12-Al3Y through rapid solidification processing. Mater Sci Eng A. 1994;179:205–9.

Abdellahi M, Heidari J, Sabouhi R. Influence of B source materials on the synthesis of TiB2–Al2O3 nanocomposite powders by mechanical alloying. Int J Miner Metall Mater. 2013;20:1214–21.

Baker I, Monroe PR. Improving intermetallic ductility and toughness. JOM. 1988;40:28–31.

Shoshin YL, Trunov MA, Zhu X, Schoenitz M, Dreizin EL. Ignition of aluminum-rich Al–Ti mechanical alloys in air. Combust Flame. 2006;144:688–97.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdellahi, M., Jabbarzare, S., Ghayour, H. et al. Thermal and X-ray analyses of aluminum–titanium nanocomposite powder. J Therm Anal Calorim 131, 853–863 (2018). https://doi.org/10.1007/s10973-017-6570-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6570-3